Numerical control vane wheel intelligent forming machine and using method thereof

A forming machine and intelligent technology, applied to the wheels, abrasives, metal processing equipment and other directions of the working part with flexibility, can solve the problems of unsightly appearance of the finished product, increase the production cost of the enterprise, and low efficiency, and achieve stable product quality Reliable, ingenious and reasonable design, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

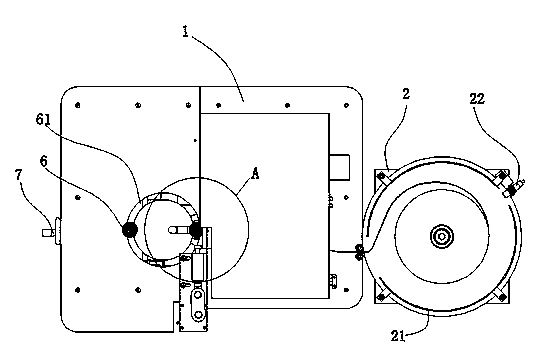

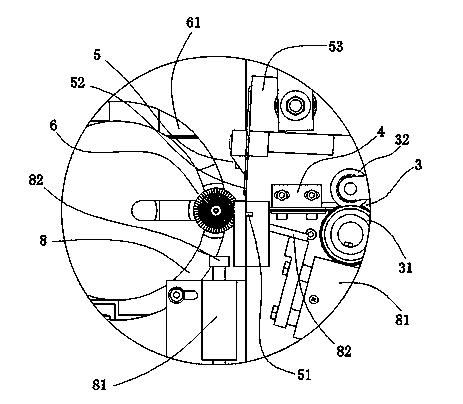

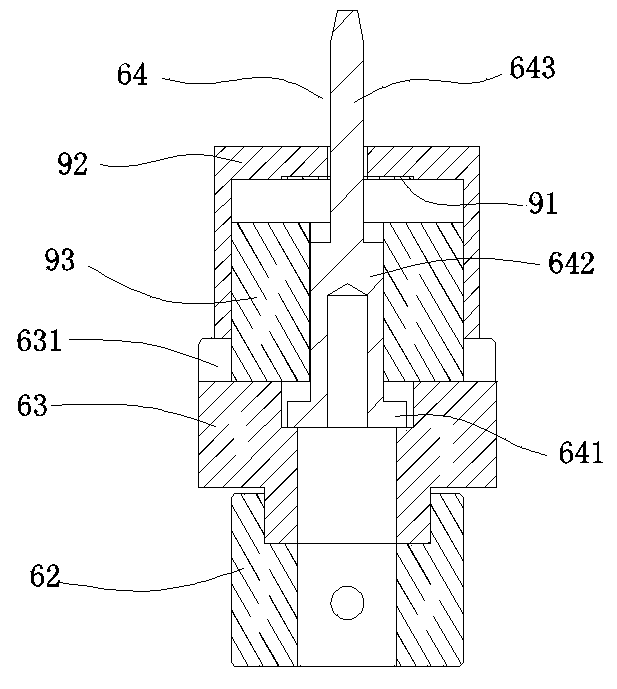

[0030] Example: such as Figure 1 to Figure 3 As shown, the present invention is a numerical control page wheel intelligent forming machine, which includes an intelligent forming main body 1 and an emery cloth receiving turntable 2, and the intelligent forming main body 1 includes a servo feeding mechanism 3 and an emery cloth positioning groove arranged in sequence according to the feeding direction of the emery cloth 4. The emery cloth blanking mechanism 5 and the automatic typesetting assembly of the emery cloth page wheel, the automatic typesetting assembly of the emery cloth page wheel includes a turntable 61, the turntable 61 is fixed on a turntable servo motor, and the turntable 61 is placed on the turntable 61 according to the interval distance At least two emery cloth page wheel indexing automatic typesetting devices 6 are provided. When the turntable servo motor is in the initial position, one of the emery cloth page wheel indexing automatic typesetting devices 6 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com