Mask machine production line

A production line and mask technology, applied to clothing, tools for sewing clothes, clothing, etc., can solve the problems of different masks, poor air tightness, poor fit, etc., to simplify process steps, improve tightness, and improve transportation. The effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0036] Embodiments of the invention are:

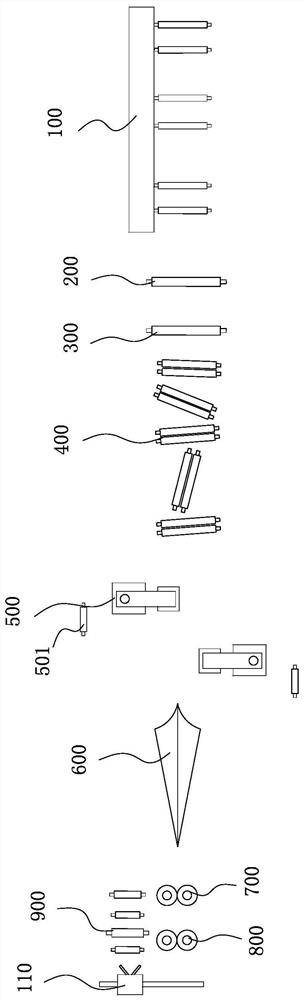

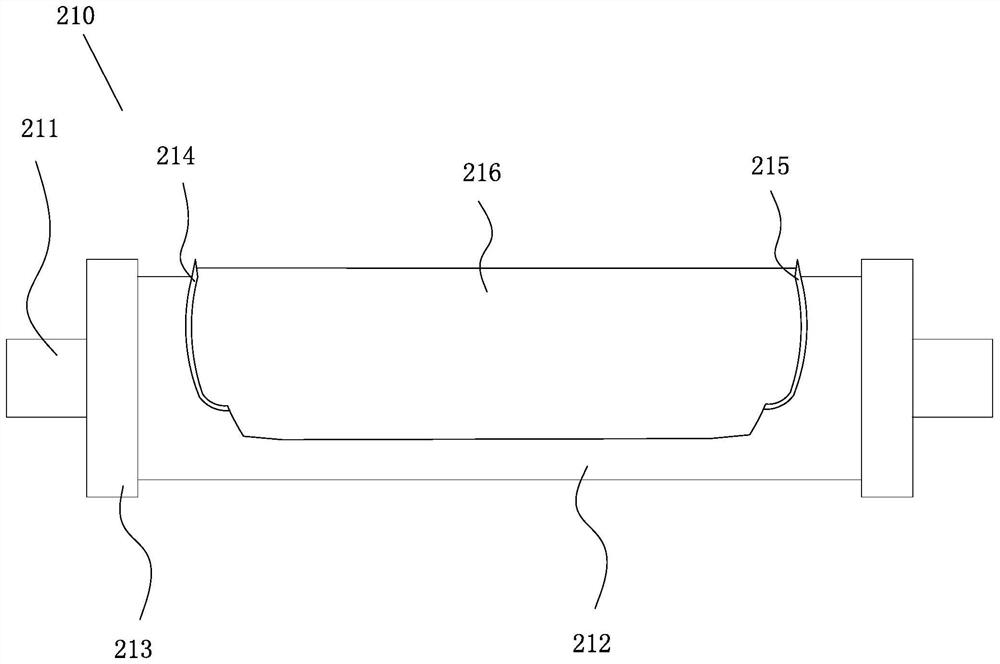

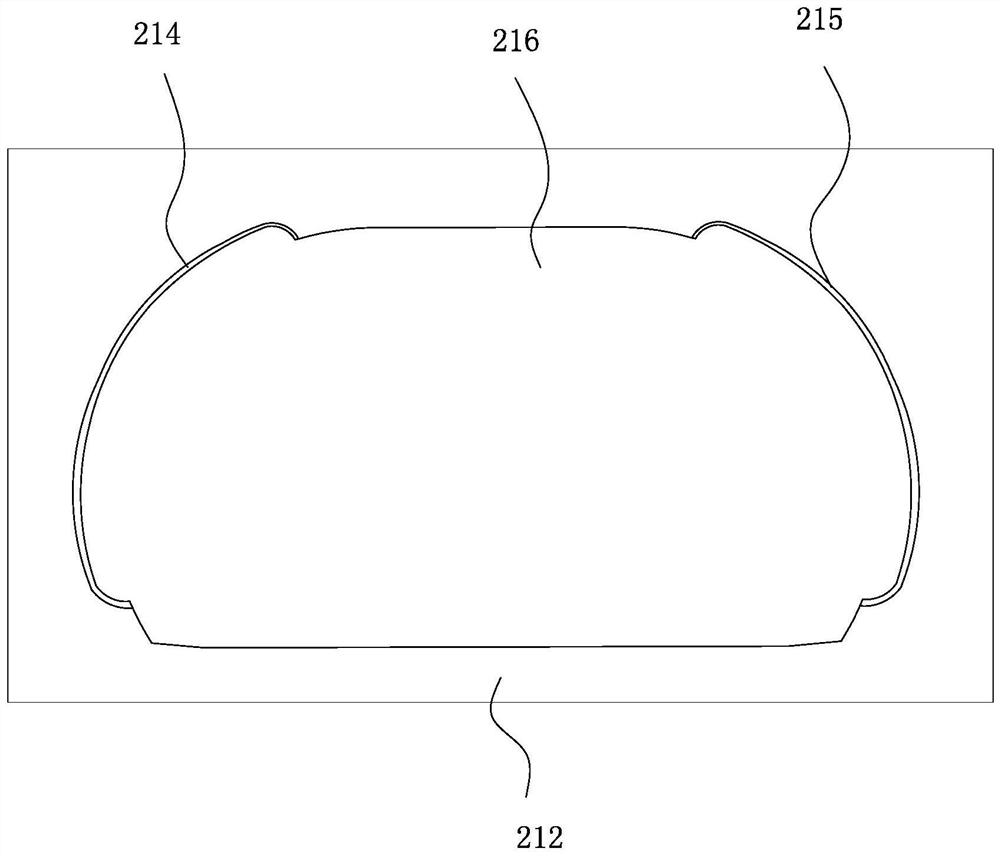

[0037] refer to figure 1 As shown, a mask machine production line includes a frame, a control device arranged on the frame, and an unwinding device 100 arranged on the frame according to the assembly line, a pre-pressing trimming device 200, a pad forming device 300, an overturning Device 400, earband feeding spot welding device 500, folding device 600, inclined sealing device 700, cutting device 800, nose bridge strip feeding and cutting device 900 and nose bridge strip welding and blanking device 110, the unwinding device 100, Pre-press trimming device 200, pad forming device 300, turning device 400, ear strap feeding and spot welding device 500, folding device 600, inclined sealing device 700, cutting device 800, nose bridge strip feeding and cutting device 900 and nose bridge The strip welding and unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com