Feeding platform and freeze-drying-line mobile feeding and discharging system

A material feeding platform, feeding and discharging technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of reduced conveying efficiency and conveying stability, increased manufacturing costs and operating costs, and large floor space, etc., to achieve The effect of improving conveying efficiency and conveying stability, reducing manufacturing cost and operating cost, and reducing design area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific embodiment and accompanying drawing, it should be pointed out that protection scope of the present invention is not only limited to following embodiment, for those of ordinary skill in the art, without departing from the principle premise of the present invention The following improvements and modifications should also be considered as protection scope of the present invention.

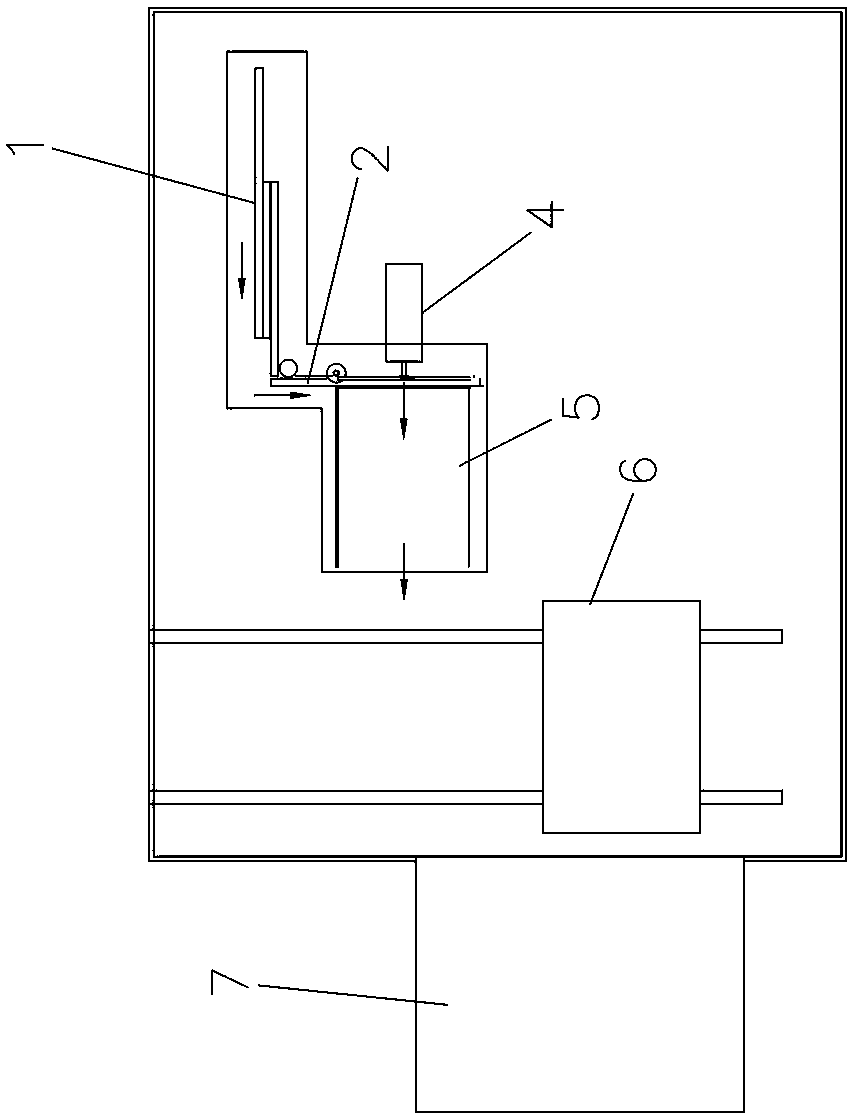

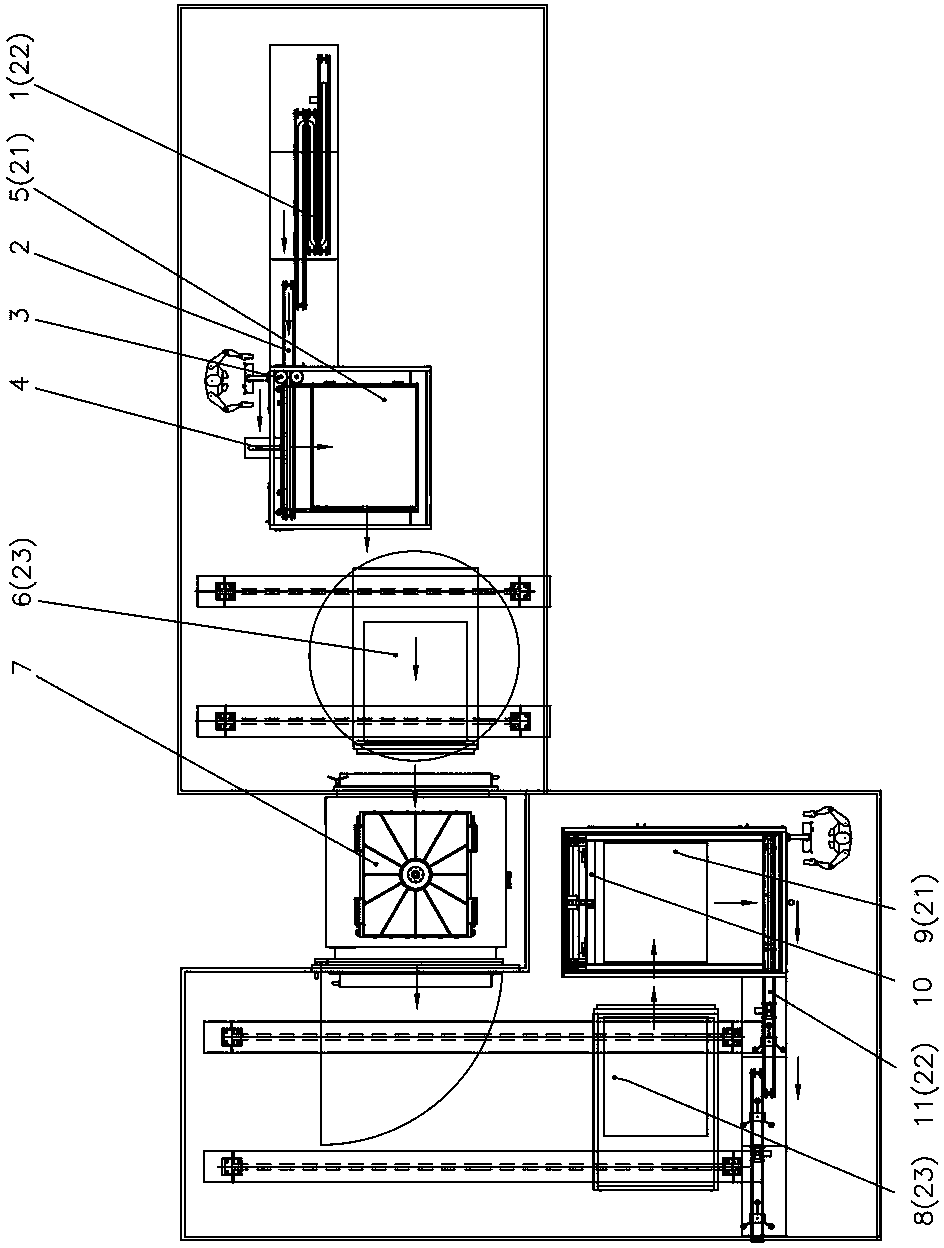

[0021] Such as figure 2 As shown, the feeding platform for the mobile feeding and discharging system of the freeze-drying line in this embodiment, according to the material delivery sequence, the feeding platform 21 is located between the feeding mesh belt 22 of the freeze-drying line and the mobile feeding car 23, and the feeding platform 21 The feeding direction is perpendicular to the discharging direction, and the direction in which the material is sent from the feeding platform 21 to the feeding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com