Automatic workpiece feeding mechanism

A technology of feeding mechanism and feeding mechanism, which is applied in the field of parts processing, can solve problems such as difficult control and maintenance, decreased work efficiency, and difficult stable feeding, and achieves good market prospects, low cost, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

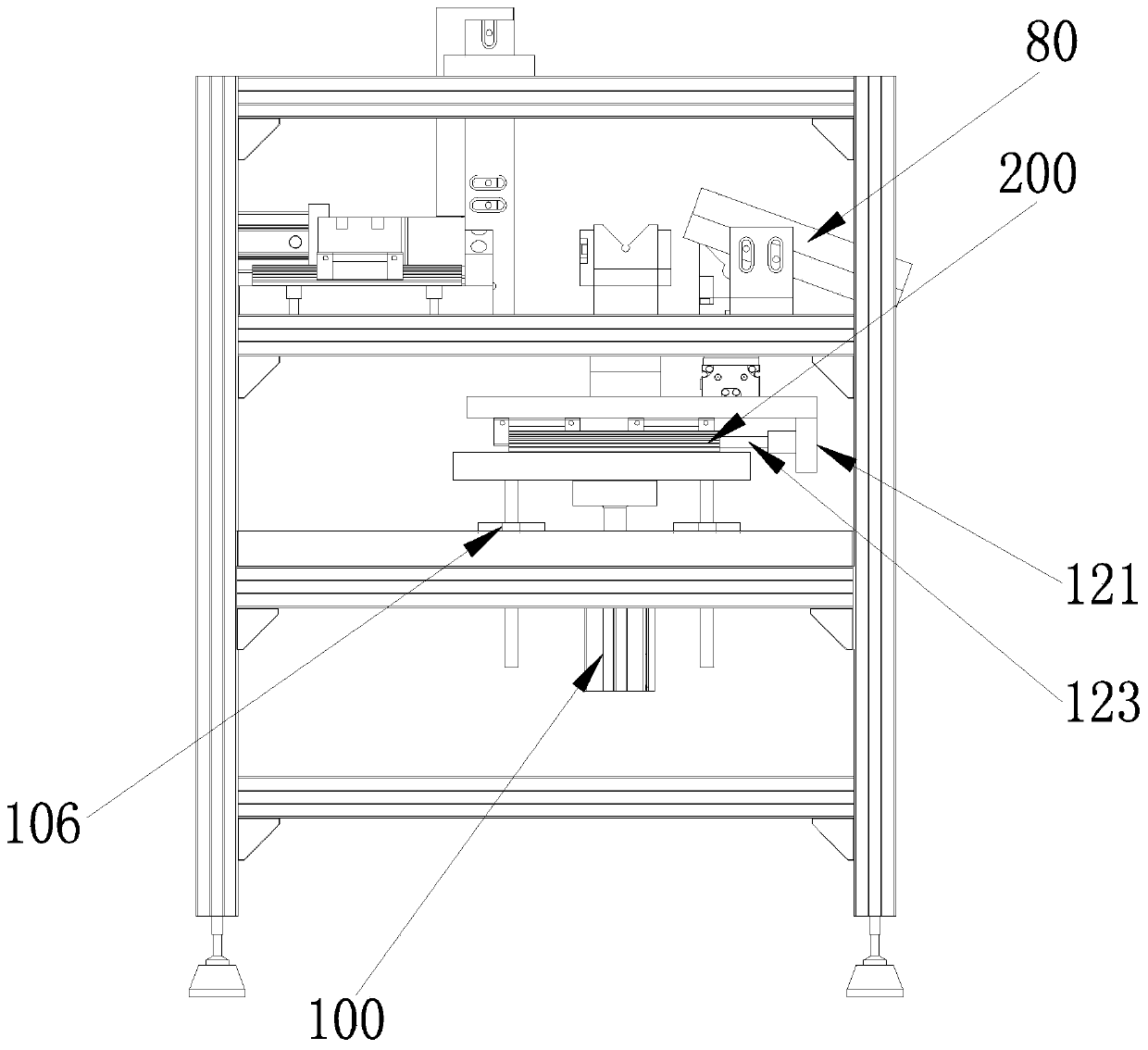

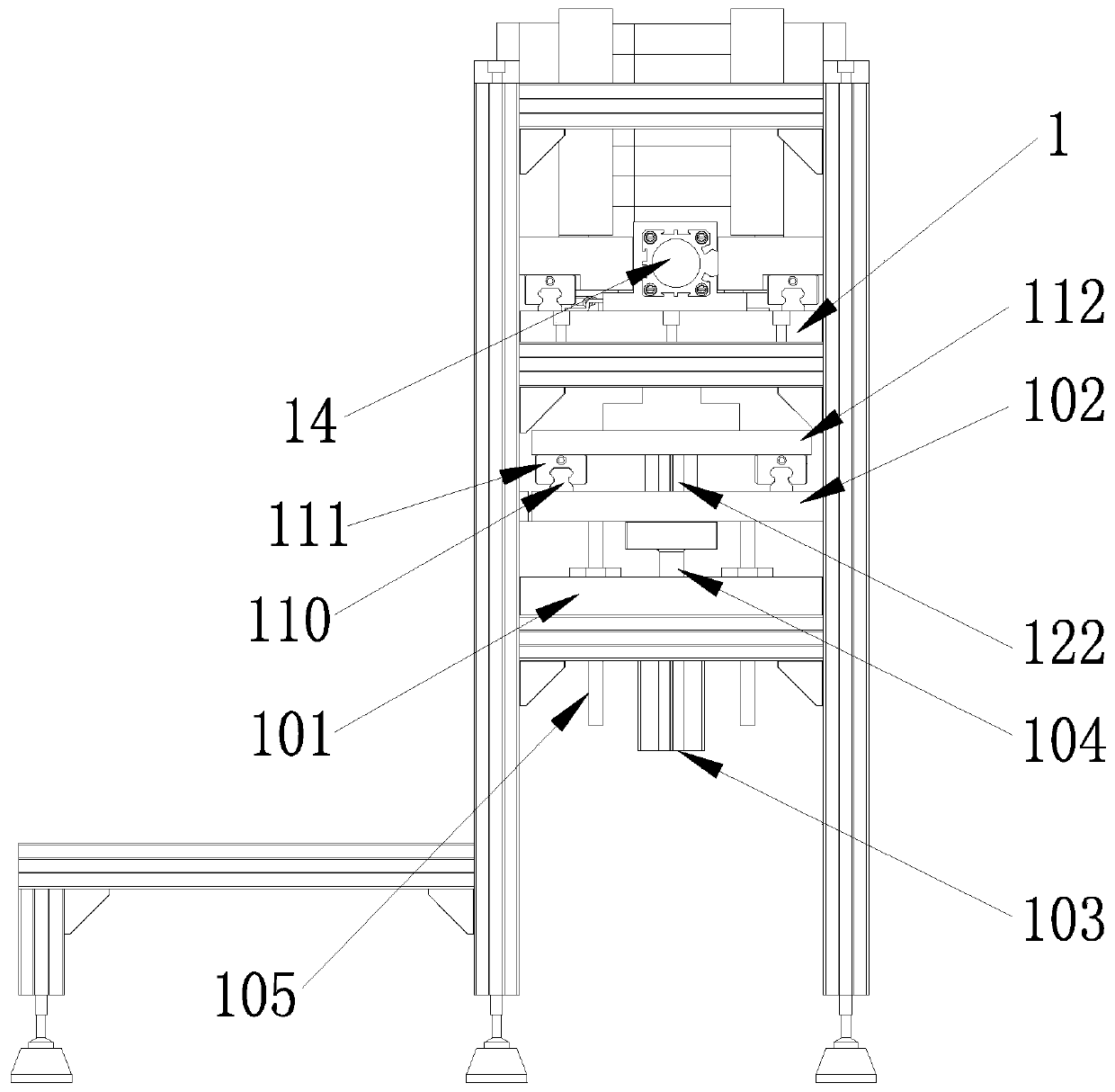

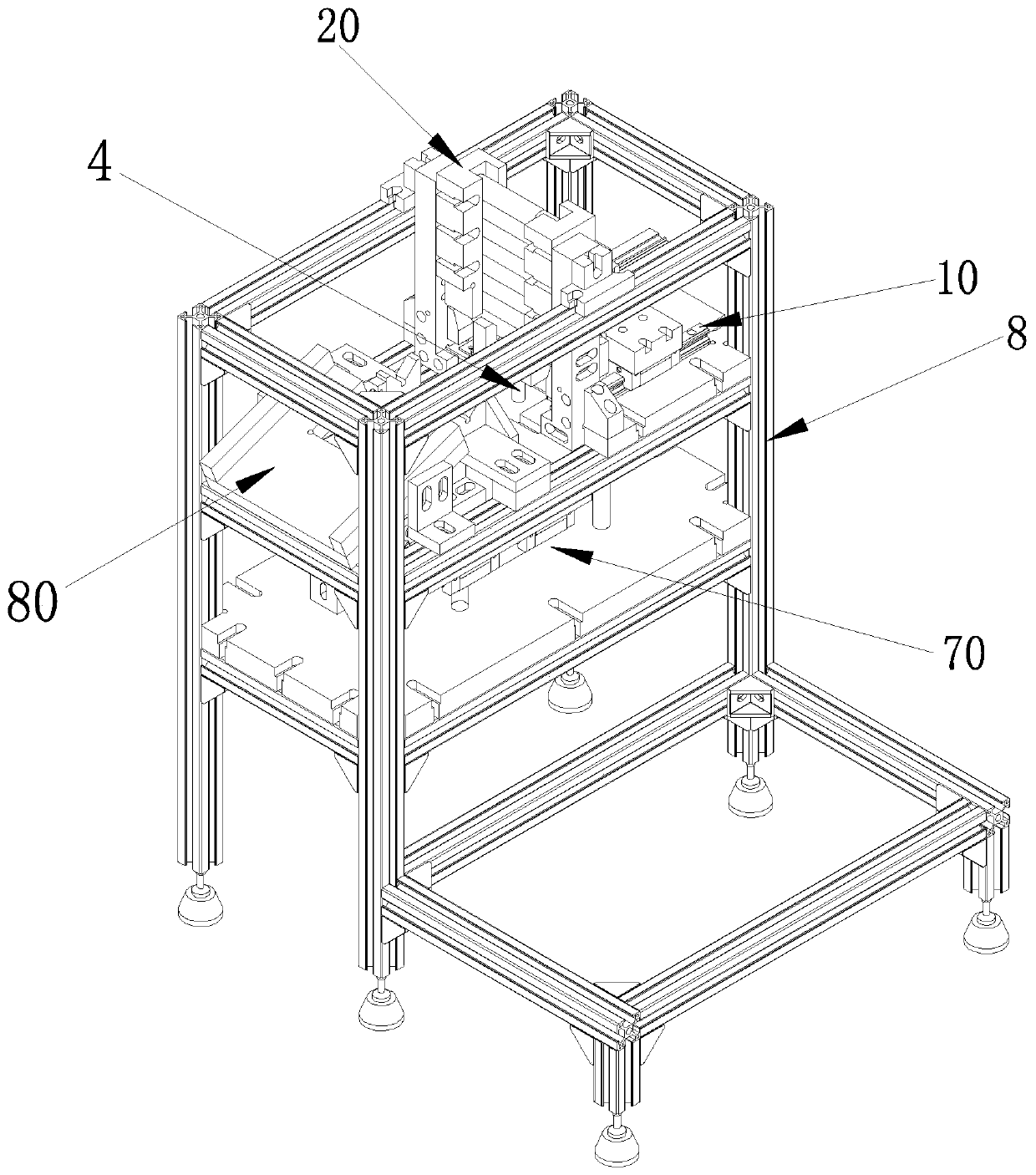

[0048] Such as Figure 1-8 As shown, a kind of automatic workpiece feeding mechanism provided by the present embodiment includes a frame 8, a feeding mechanism 20, a feeding device 40, a material receiving mobile device 70 and a material discharging mechanism 80; the feeding mechanism 20, the feeding device 40, the receiving device The material moving device 70 and the discharging mechanism 80 are assembled on the frame 8; the feeding mechanism 20 is located on the feeding device 40; On the frame 8; the pushing device 10 includes a conveying slide rail 11 fixed on the base plate 1 and arranged symmetrically along the length direction of the base plate 1, a slide block 12 is slidably mounted on the transport slide rail 11, and a slide block 12 is fixed on the slide block 12. There is a product fixture 30 for placing workpieces. The rear end of the product fixture 30 is connected with a drive mechanism 14. The drive mechanism 14 is fixed on the bottom plate 1. The drive mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com