High-strength flame-retarding conveying rubber belt

A tape, high-strength technology, applied in conveyors, transportation and packaging, etc., to achieve the effect of improving structural stability, reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

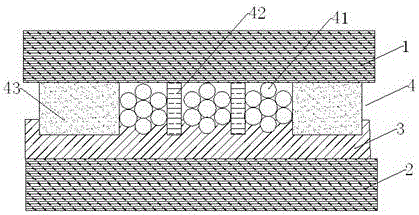

[0015] A high-strength flame-retardant conveyor belt, comprising an upper cover rubber 1 with a thickness of 8-10 mm, a lower cover rubber 2 with a thickness of 8-10 mm, a core rubber 3 with a thickness of 14-16 mm, and a reinforcement layer 4; the reinforcement layer 4 The lower 1 / 4 to 1 / 3 of the core rubber 3 is embedded in the core rubber 3 to play the role of restricting the positioning reinforcement layer. The reinforcing layer 4 covers the upper cover rubber 1 , and the core rubber 3 covers the lower cover rubber 2 .

[0016] The reinforcement layer 4 is composed of a steel wire rope group 41, a filling rubber 42, an edge glue 43 and a braided rope belt (not shown), wherein the steel wire rope group is formed by spirally weaving 5 to 9 steel wires with a diameter of 5 to 10 mm, and the steel wire rope group The gaps are filled with filling glue 42, and the side glue 43 is attached to the outside of the steel wire rope group 41 at both ends of the reinforcement layer 4 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com