Trace-amount and balanced light-emitting diode (LED) fluorescent powder feeding device and operation method thereof

A technology of feeding device and phosphor powder, which is applied in the field of precision instruments, can solve the problems of clogging of the feeding pipe, uneven output of the discharge port of the hopper, and large error in the proportioning ratio of phosphor powder, so as to save costs and improve the proportioning accuracy. , The effect of high conveying precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

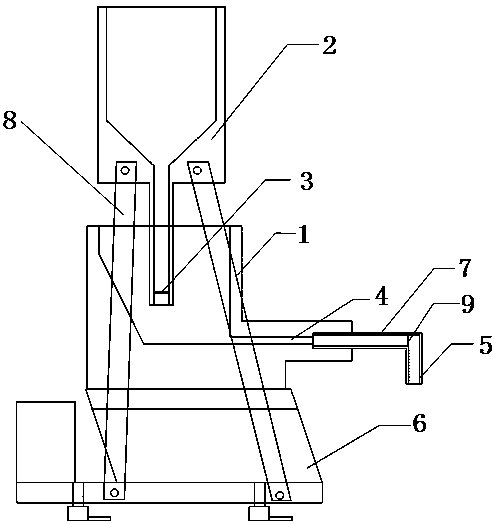

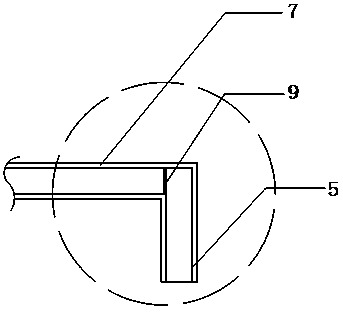

Method used

Image

Examples

Embodiment

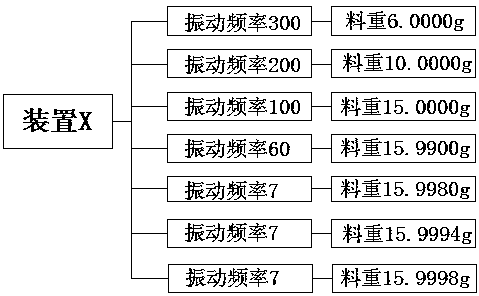

[0048] Example: Prepare 20g of a kind of RG fluorescent powder, first analyze the distribution ratio of each component of the RG fluorescent powder, the ratio of fluorescent powder R red and G blue is 4:1, that is, the required weight of R powder and G powder They are 16g and 4g respectively, and an error of 0.3mg is allowed.

[0049]1) Take 30g and 15g of the prepared fluorescent powder R red and G blue respectively and put them into the two feeding devices of the present invention, and dispose of them at the outlet of the feeding elbow 5 of the two feeding devices A receiving container, the receiving container is placed on a precision weighing device;

[0050] 2) The device of the present invention is connected to a controller, which is operated by a touch screen and has an operating software inside, through which the operating steps of the device can be set, various parameters can be set and started;

[0051] 3. Assuming that the two devices are device X and device Y respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com