Automatic terminal riveting mechanism

A technology of riveting mechanism and terminal crimping, which is applied in the direction of connection, electrical components, circuits, etc., can solve the problems of complex structure of the main part, inconvenient maintenance, and low work efficiency, so as to improve the precision, safety and maintenance of terminal crimping And the effect of convenient troubleshooting, simple structure and scientific

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

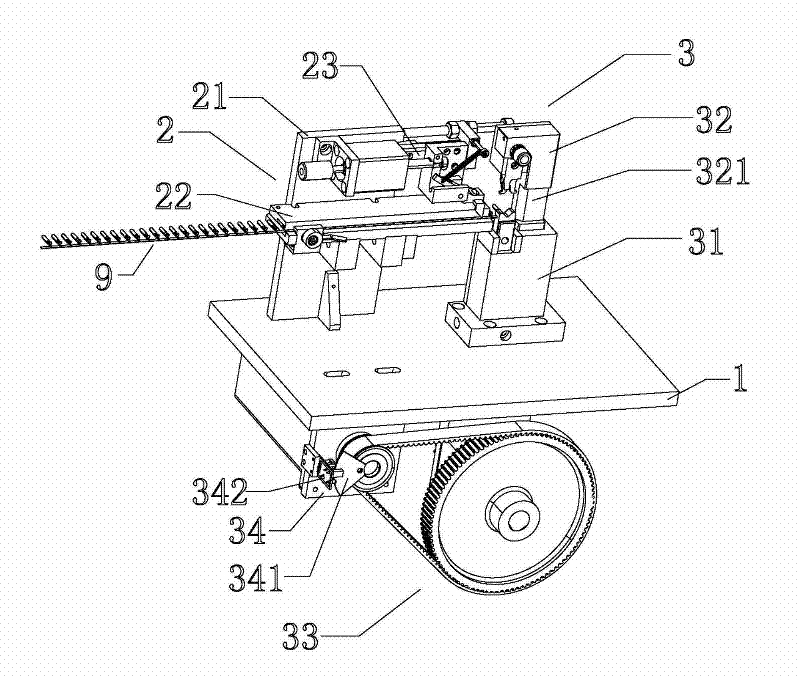

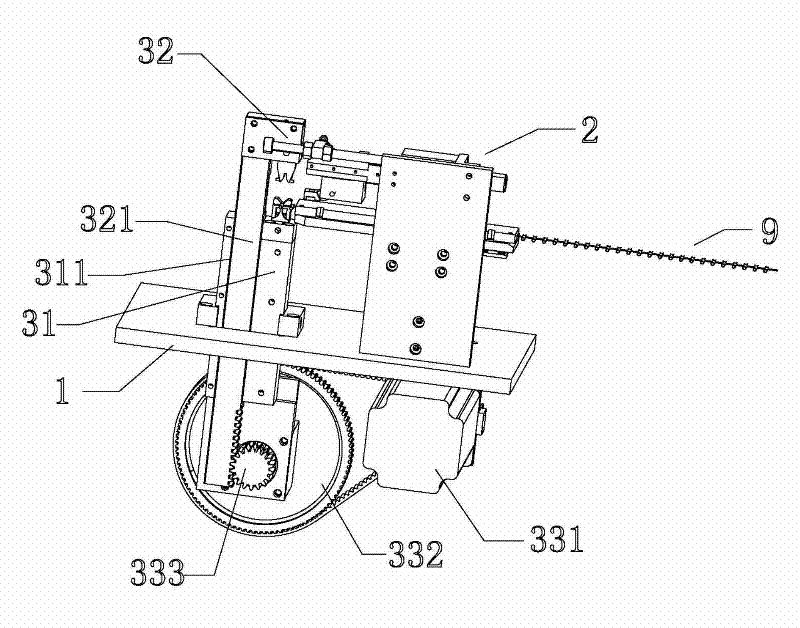

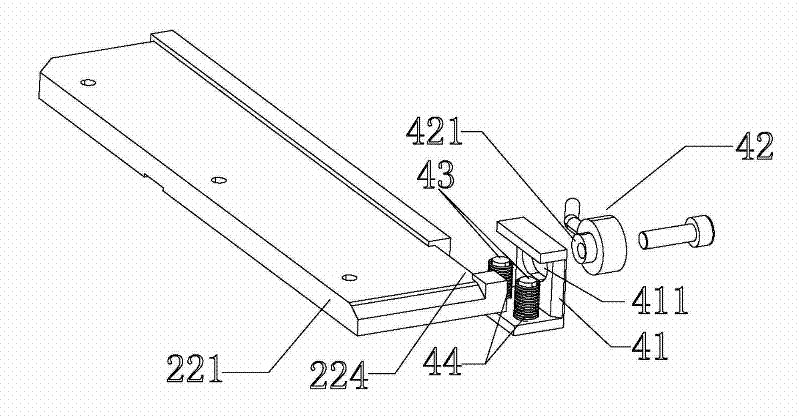

[0022] refer to Figure 1 to Figure 5 , Figure 1 to Figure 5 It is a schematic structural diagram of the present invention. As shown in the figure, an automatic terminal riveting mechanism includes a base 1, a terminal conveying mechanism 2 installed on the base 1, and a terminal crimping mechanism 3. The terminal crimping mechanism 3 is installed on On the base 1, and located in the terminal output direction of the terminal delivery mechanism 2, the terminal crimping mechanism 3 includes a lower mold assembly 31 fixed on the base 1, an upper mold assembly 32 arranged on the upper side of the lower mold assembly 31, And the die drive assembly 33 arranged on the lower side of the base 1, the die drive assembly 33 includes a motor 331 and an output gear 333 arranged on the base 1, and the motor 331 is connected with the output gear 333 through a speed change device. In this embodiment Among them, the transmission device is a large gear 332 arranged on the base 1 through a conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com