Optical fiber connector assembly machine

A fiber optic connector and assembly machine technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve problems such as poor assembly efficiency and yield, difficulty in ensuring feeding accuracy, and easy blockage of springs, etc., to improve assembly Accuracy, processing efficiency and yield are high, and the effect of reducing machine failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

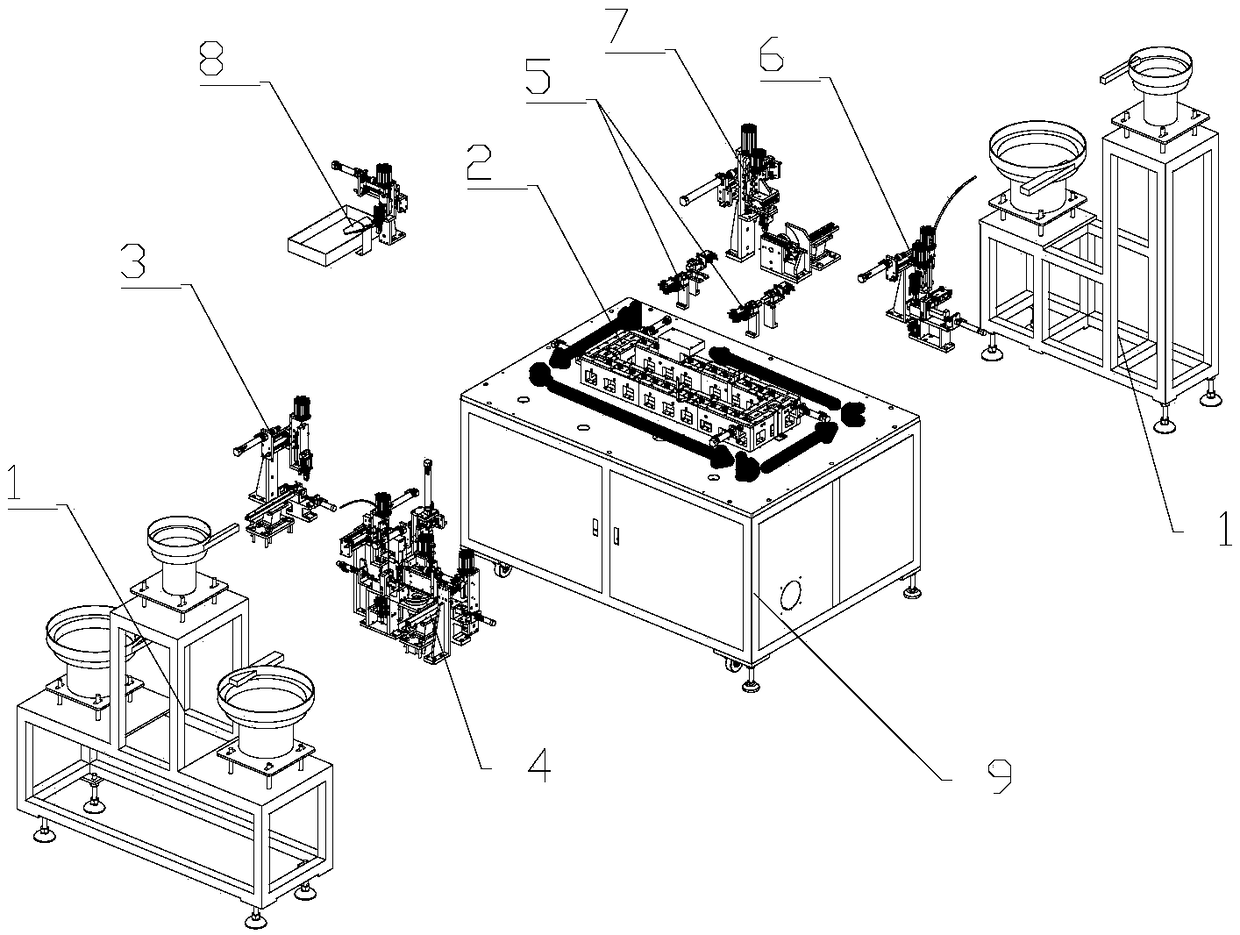

[0036] Combine below Figure 1-Figure 22 The present invention is further described.

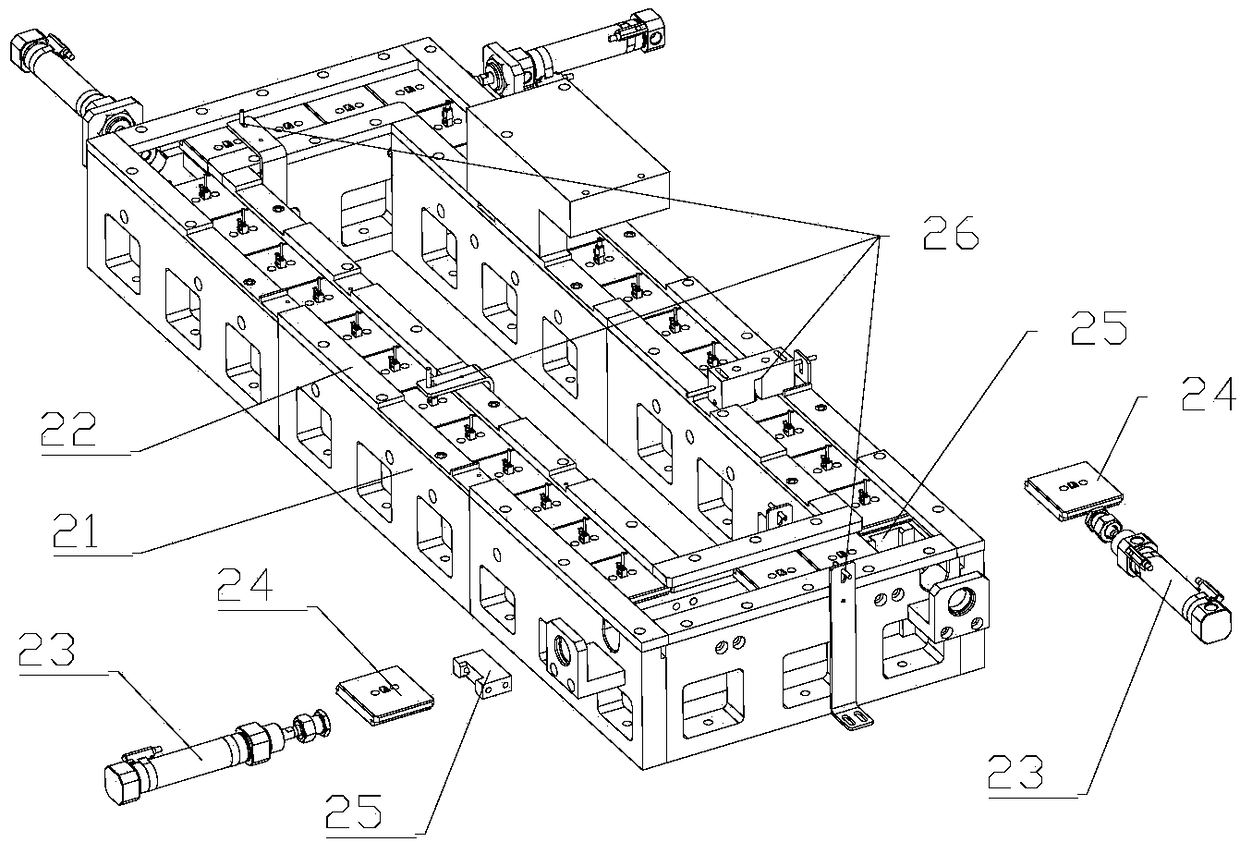

[0037] Such as Figure 1-Figure 22 The optical fiber connector assembly machine shown includes a frame 9 and a vibrating feeding assembly 1 on it, a carrier rectangular circulation device 2, a front shell feeding device 3, a rubber hose and an optical fiber core assembly feeding device 4, and a guiding mechanism 5. Spring loading device 6, back shell feeding device 7 and finished product handling device 8.

[0038] The optical fiber connector is assembled by the front shell e, the optical fiber core f, the rubber tube g, the spring h and the rear shell i.

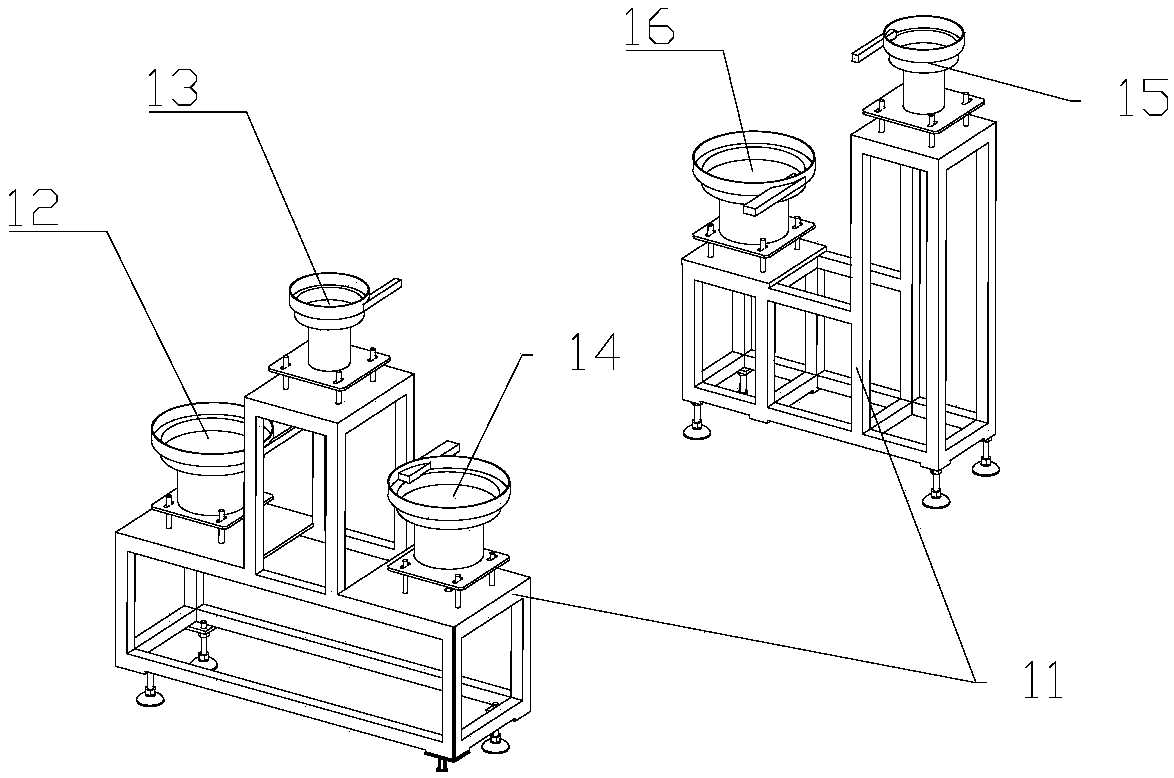

[0039] The vibrating feeding assembly 1 includes a fixed chassis 11 and a front shell vibrating feeding tray 12 on it, a rubber hose vibrating feeding tray 13, an optical fiber core vibrating feeding tray 14, a spring vibrating feeding tray 15 and a rear shell vibrating feeding tray 16. The front shell vibrating feeding tray 12 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com