Water jet pulse type magnetic abrasive material feeding device for micro abrasive materials and control method of water jet pulse type magnetic abrasive material feeding device

An abrasive water jet and magnetic abrasive technology, which is applied to abrasive feeding devices, abrasives, manufacturing tools, etc., can solve problems such as poor controllability and unstable feeding, so as to improve processing quality, eliminate blockages, and improve conveying efficiency. and precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

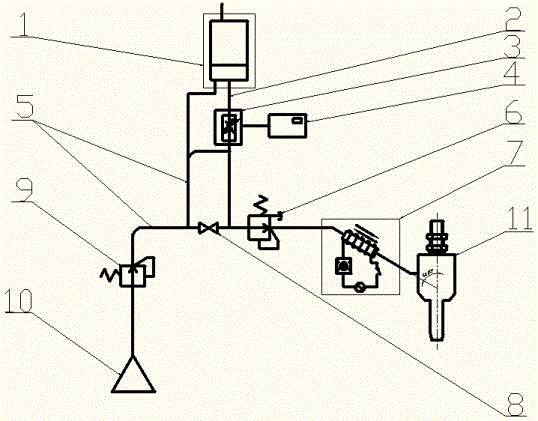

[0023] Describe the implementation process of the present invention in detail in conjunction with accompanying drawing, as figure 1 Shown:

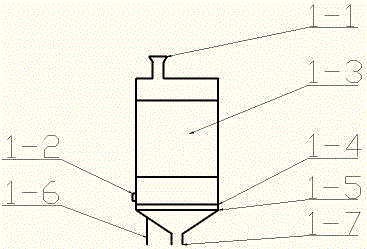

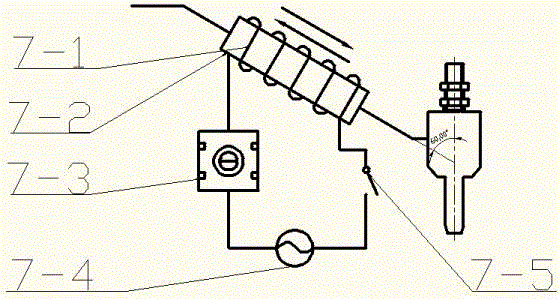

[0024] The fine abrasive water jet pulse type precision magnetic abrasive supply device is mainly composed of silo 1, feed pipe 2, flow valve 3, pulse transmitter 4, air supply pipe 5, pressure stabilizing valve 6, electromagnetic control circuit 7, stop valve 8, regulator Pressure valve 9, gas source 10 etc. are formed. The air inlet of the pressure regulating valve 9 is connected to the gas source 10 through the pipeline, the gas outlet of the pressure regulating valve 9 is connected to the shut-off valve 8 through the pipeline, the silo 1 is connected to the flow valve 3 through the pipeline, and the flow valve 3 is connected to the pulse The transmitter is connected, and the pressure stabilizing valve 6 is connected with the electromagnetic control circuit 7 through a pipeline. During application, the outlet of the feed pipe is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com