Vacuum sealed type 3D printing device

A 3D printing and vacuum sealing technology, applied in the direction of additive processing, etc., can solve problems such as affecting the strength and quality of molded products, inability to flatten more, and limited flattening effect, and achieve good tiling effect, stable speed, and product quality. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

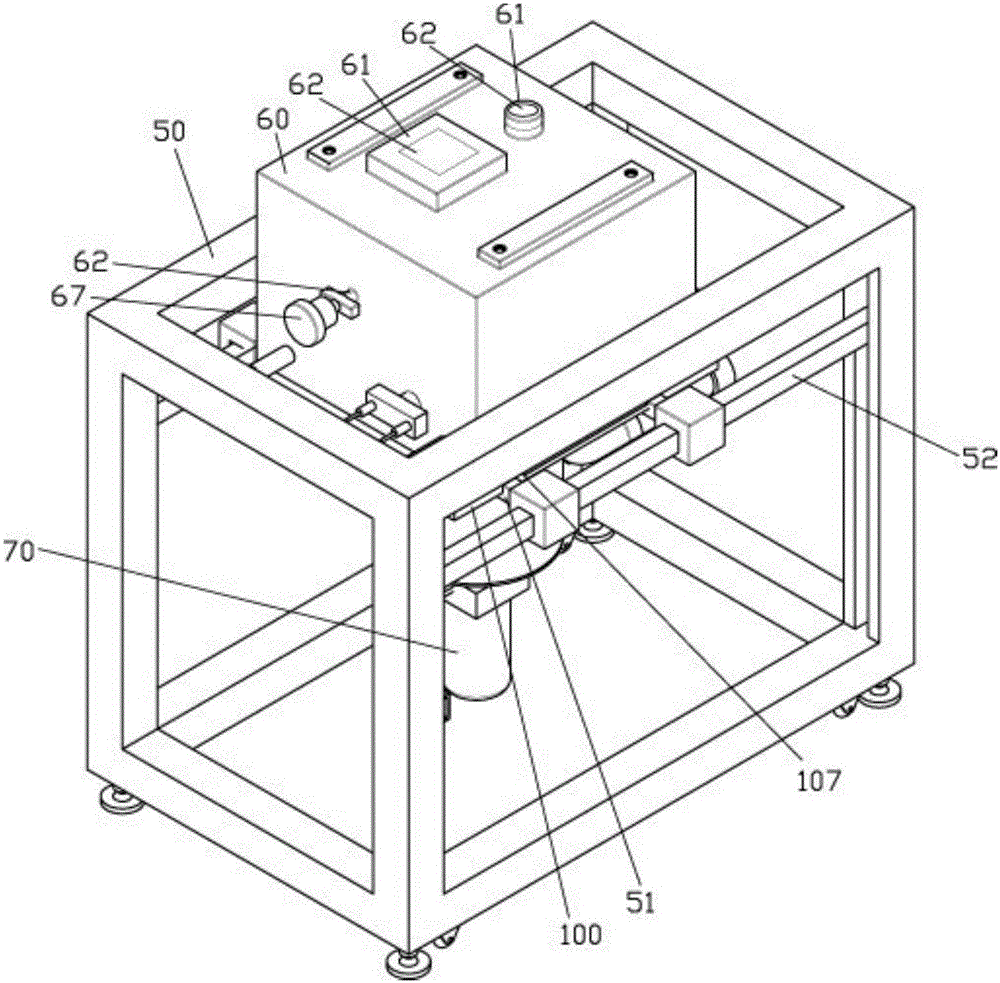

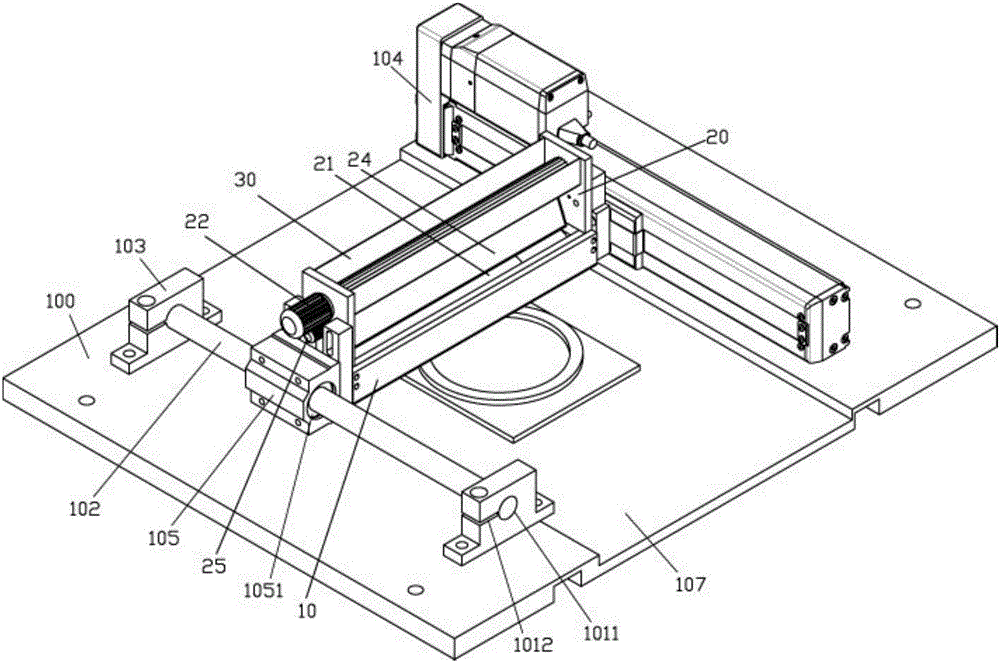

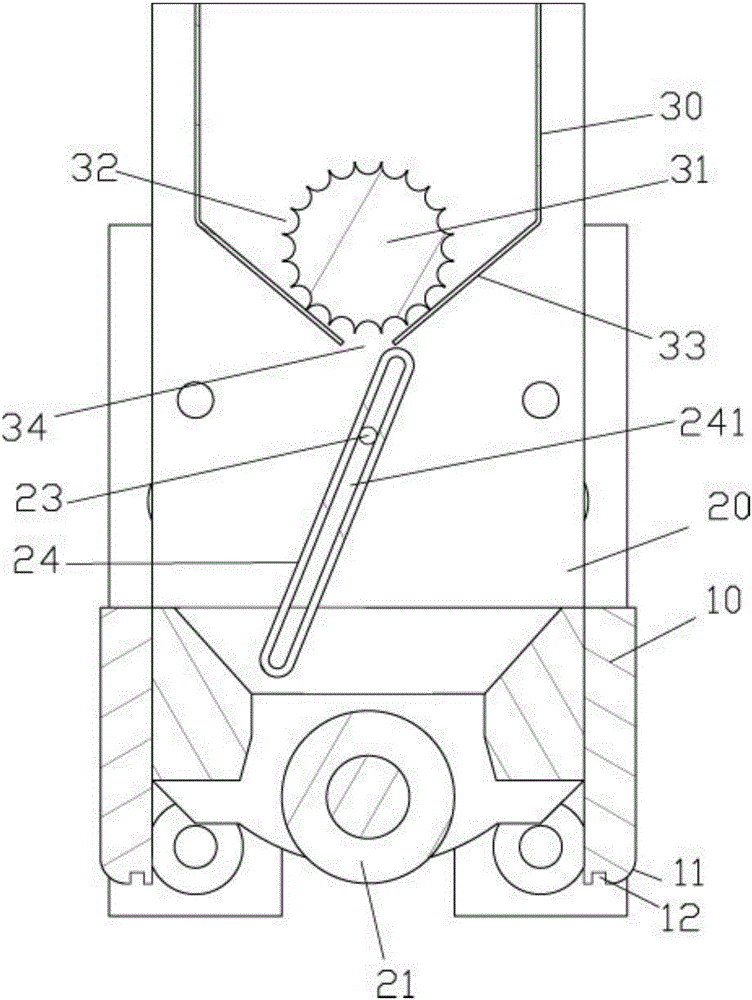

[0029] Examples, see e.g. Figures 1 to 6 As shown, a vacuum-sealed 3D printing device includes a frame-shaped frame body 50 and a laying powder feeding device. The middle part of the frame-shaped frame body 50 is fixed with a transverse beam 51, and the transverse beam 51 is fixed with a powder-spreading bottom plate 100. A box body 60 is fixed on the powder floor 100, the top surface of the box body 60 has an observation hole 61, the top surface of the box body 60 is fixed with a quartz glass block 62, the quartz glass block 62 covers the observation hole 61, and the side wall of the box body 60 The upper connection is connected with an air intake pipe 63, and the air intake pipe 63 communicates with the side wall through hole 64 provided on the side wall of the casing 60. The bottom surface of the edge of the powder floor 100 is connected with an exhaust pipe 65, and the edge of the powder floor 100 The bottom has a bottom through hole 66, and the bottom through hole 66 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com