Belting feed mechanism capable of automatically eliminating cumulative errors

A technology of accumulating errors and feeding, applied in the field of belt feeding mechanism, can solve the problems of poor feeding accuracy, etc., and achieve the effects of simple structure, high conveying accuracy, and eliminating cumulative errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In the following, the present invention will be further described through embodiments with reference to the drawings.

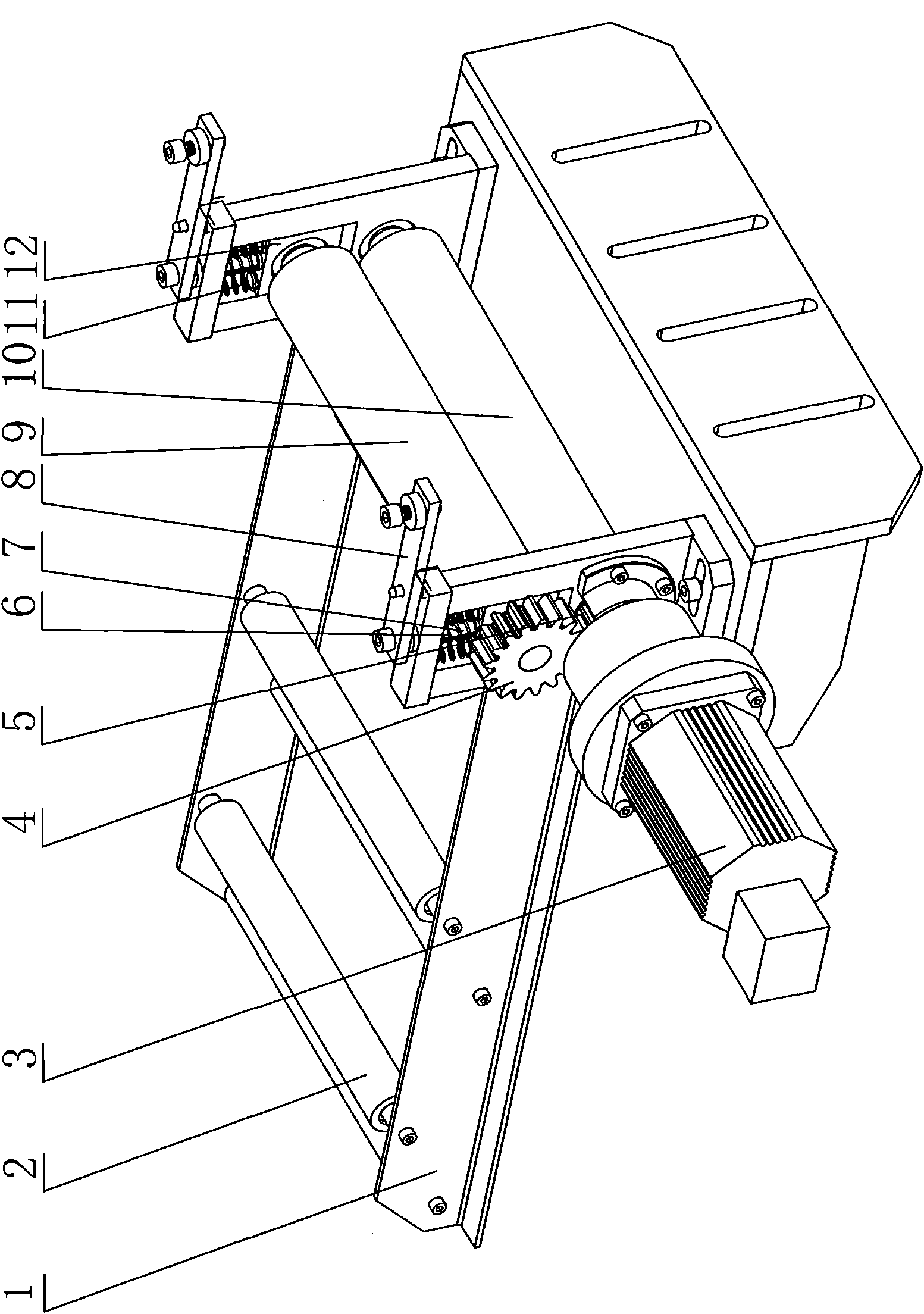

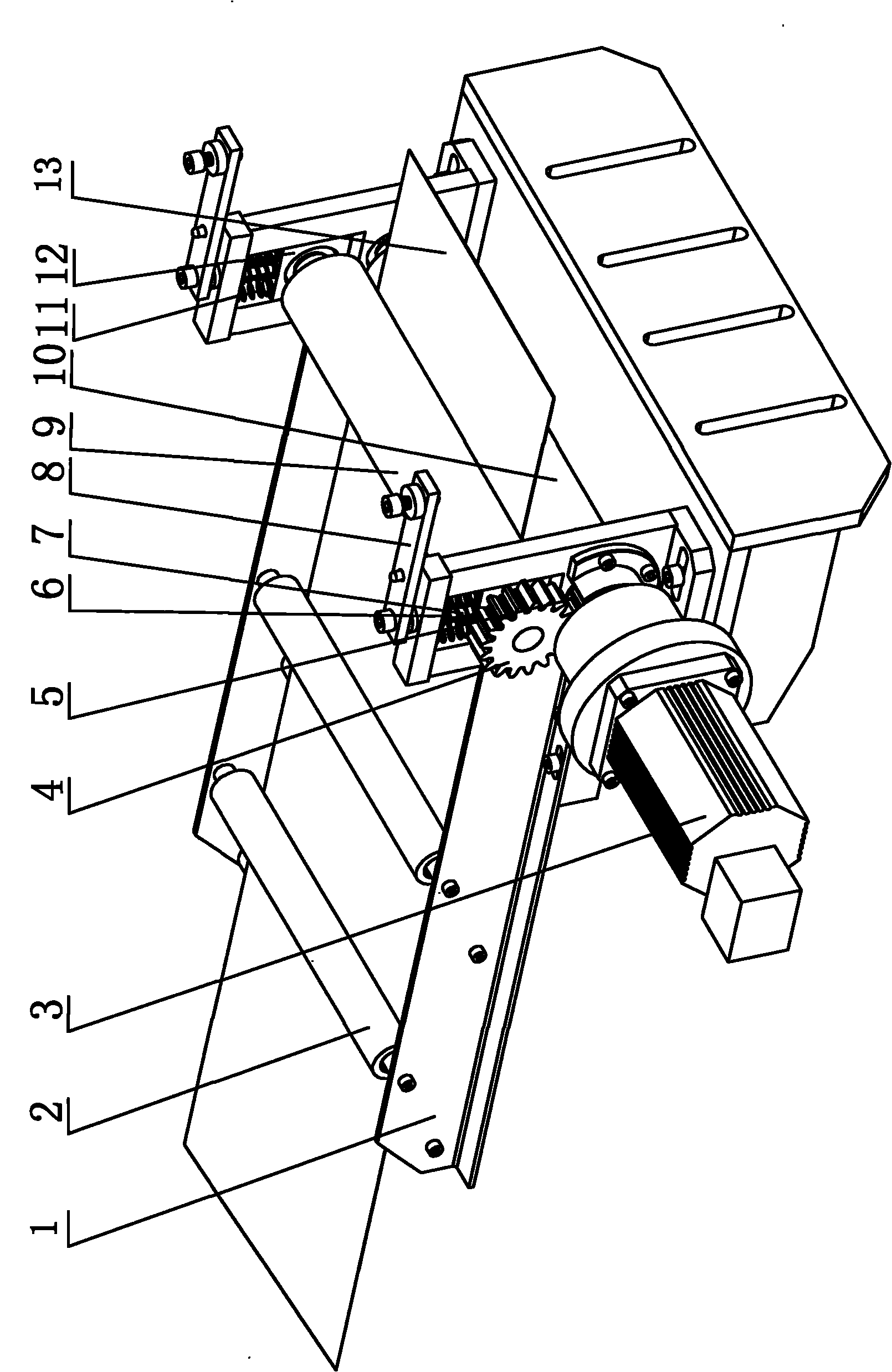

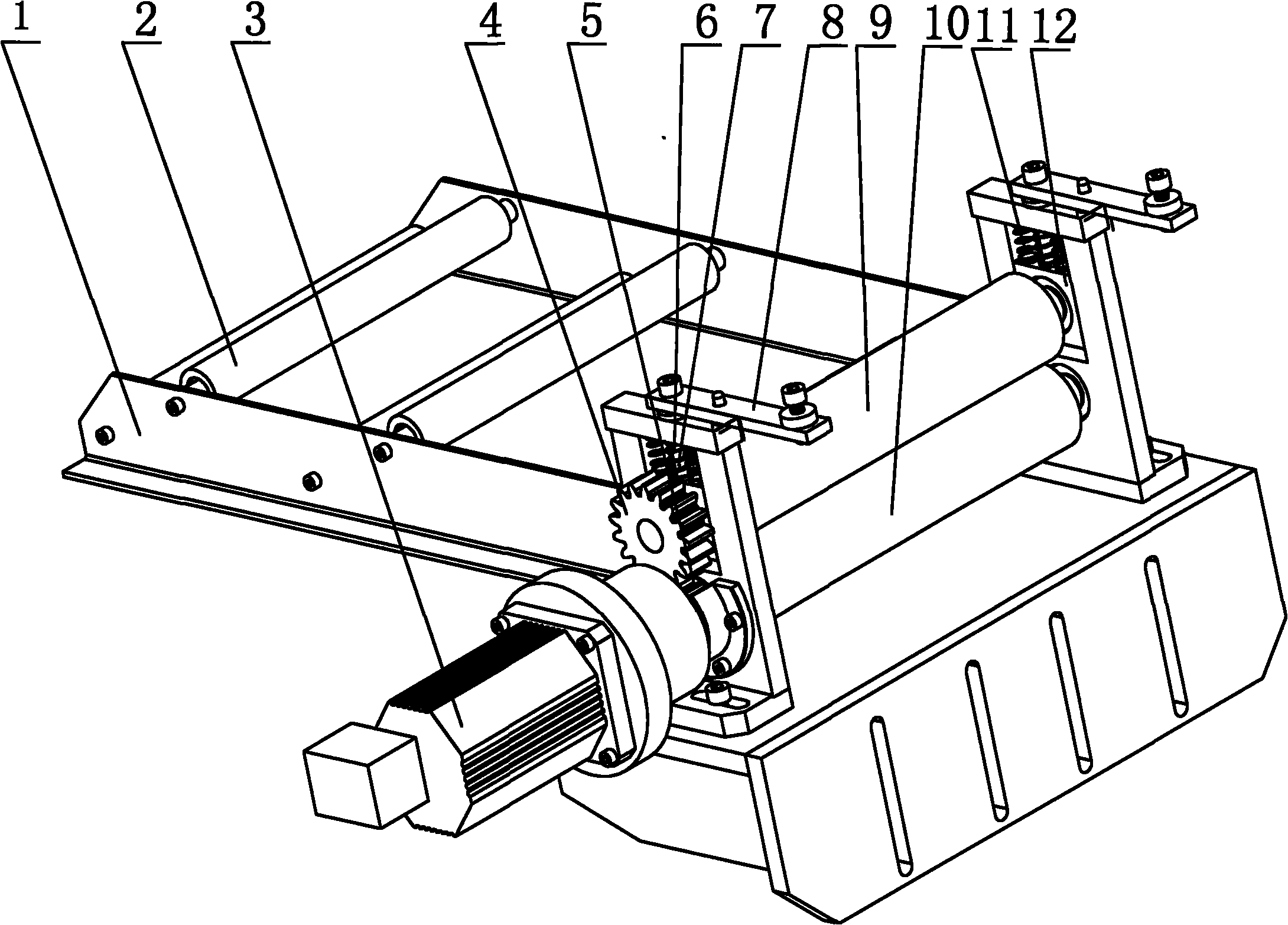

[0009] Such as figure 1 with figure 2 As shown, the tape feeding mechanism of the present invention that automatically eliminates accumulated errors includes a frame 1. The frame 1 is provided with a conveying roller 2 and an active roller 10, and the active roller 10 is driven by a motor 3 to actively grind A driving gear 5 is also pierced on the roller 10, which is characterized in that a slider 12 is provided on the frame 1, a passive roller 9 is provided on the slider 12, and a passive gear 4 is provided on the passive roller 9. An anti-backlash spring 11 is provided. The slider 12 is connected to a pull rod 7, and a return spring 6 is inserted on the pull rod 7. The pull rod 7 is also connected to a pressure rod 8. The strip 13 can be placed between the active roller 10 and the passive roller 9 Transport without gaps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com