Double-sided polishing processing automatic production line for flaky parts

A technology for automated production lines and sheet parts, used in metal processing equipment, grinding/polishing equipment, grinding/polishing safety devices, etc. Machine tool utilization rate and workpiece production efficiency, etc., to achieve the effect of improving utilization rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

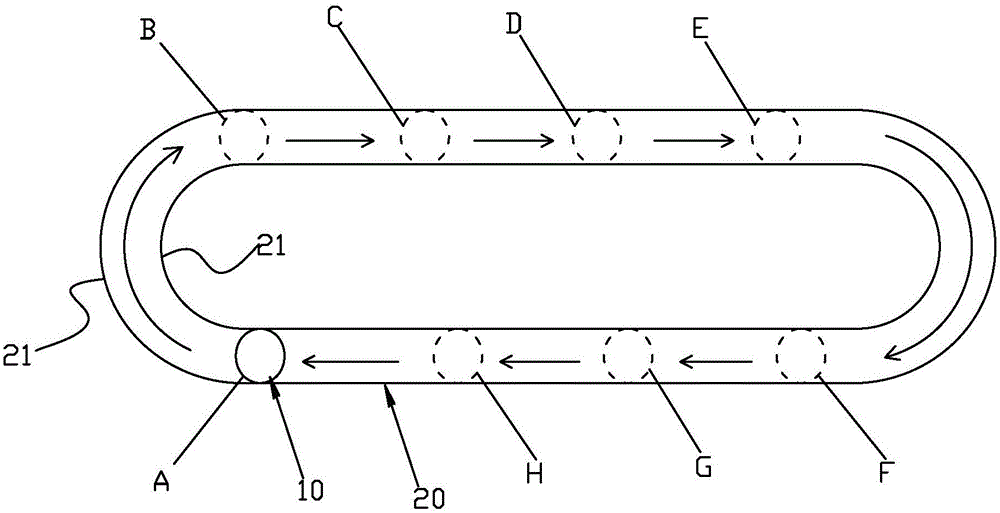

[0023] Please check figure 1 with figure 2 , an automatic production line for double-sided grinding and polishing of sheet parts, including a frame on which a first grinding mechanism, a first cleaning mechanism, a second grinding mechanism, a second cleaning mechanism, a detection mechanism, a conveying Mechanism 20, carrier tray 10, slave drive, first master drive and second master drive. The first grinding mechanism is divided into a rough grinding mechanism and a fine grinding mechanism.

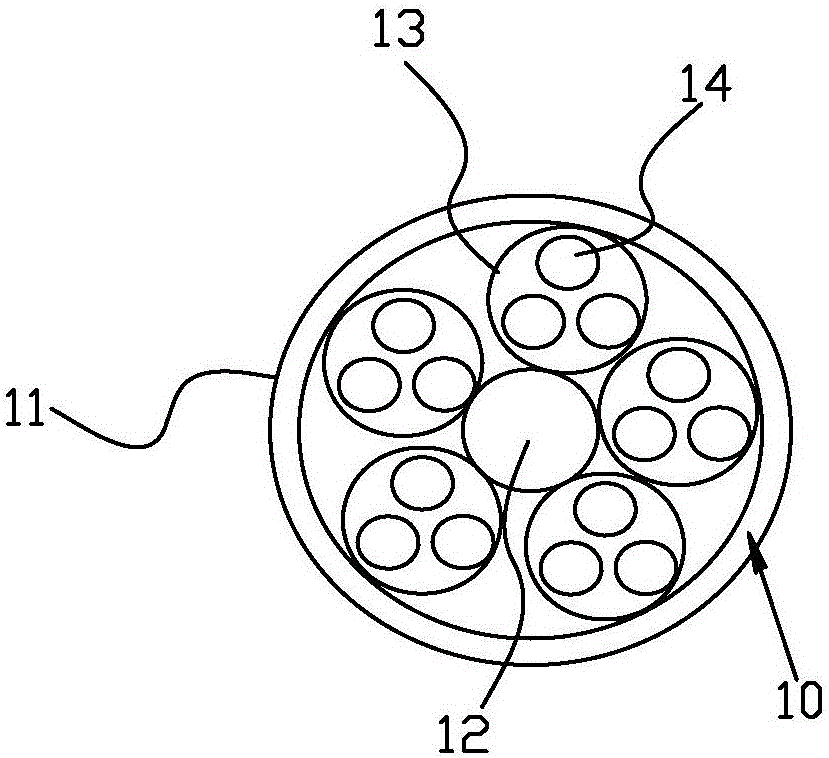

[0024] The loading tray 10 includes an outer ring 11, a sun gear 12 and a plurality of planetary gears 13, the sun gear 12 is located in the outer ring 11 and the planetary gears 13 are engaged between the sun gear 12 and the outer ring 11, the planetary gears The mounting hole 14 for installing the workpiece is set at 13 places, and the outer ring 11 is provided with outer gear teeth, such as the outer peripheral edge of the outer ring is provided with outer gear teeth at annular int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com