Water chestnut de-hulling device

A water chestnut and shell breaking technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of laborious, manual shelling costs, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

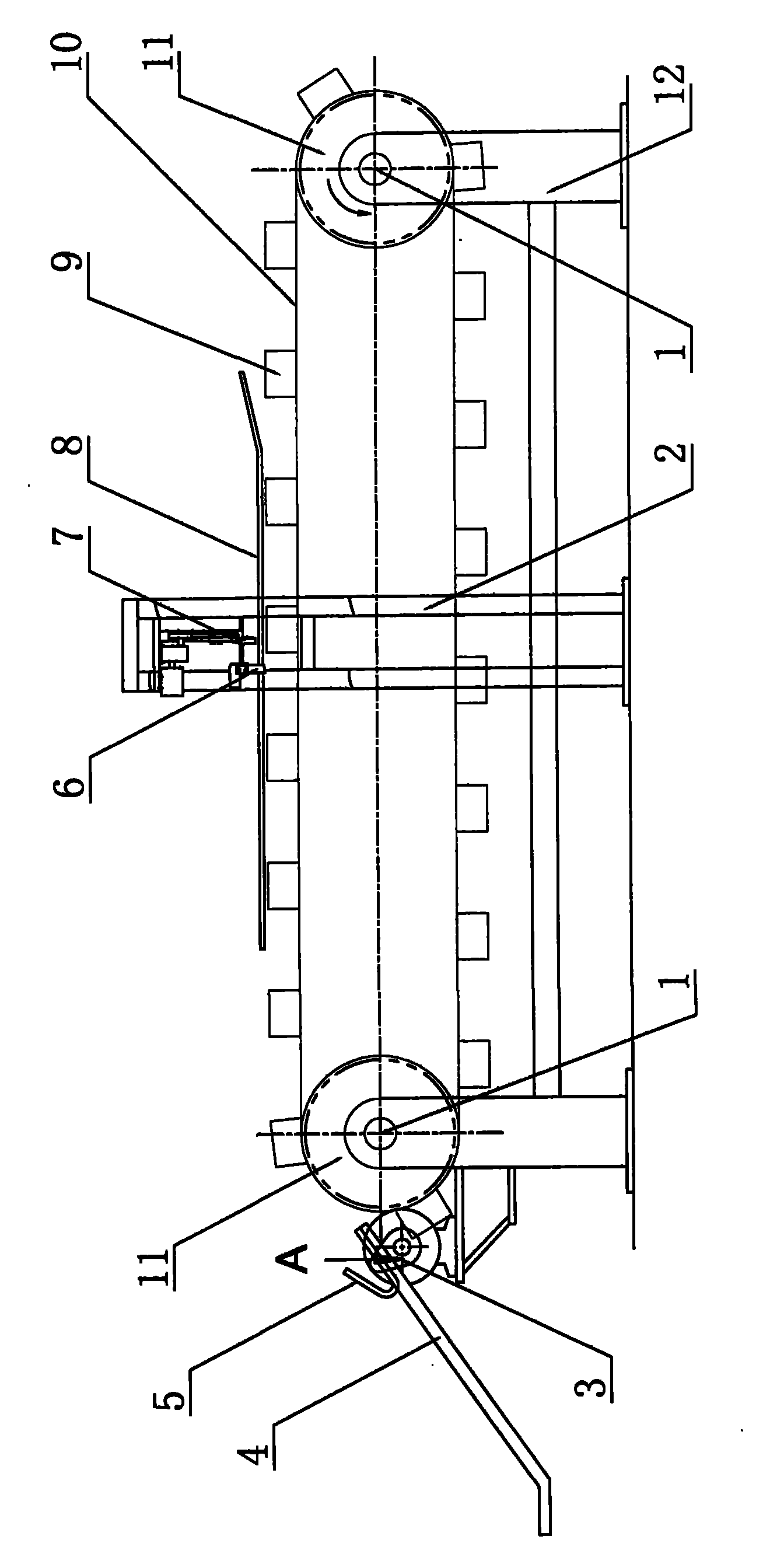

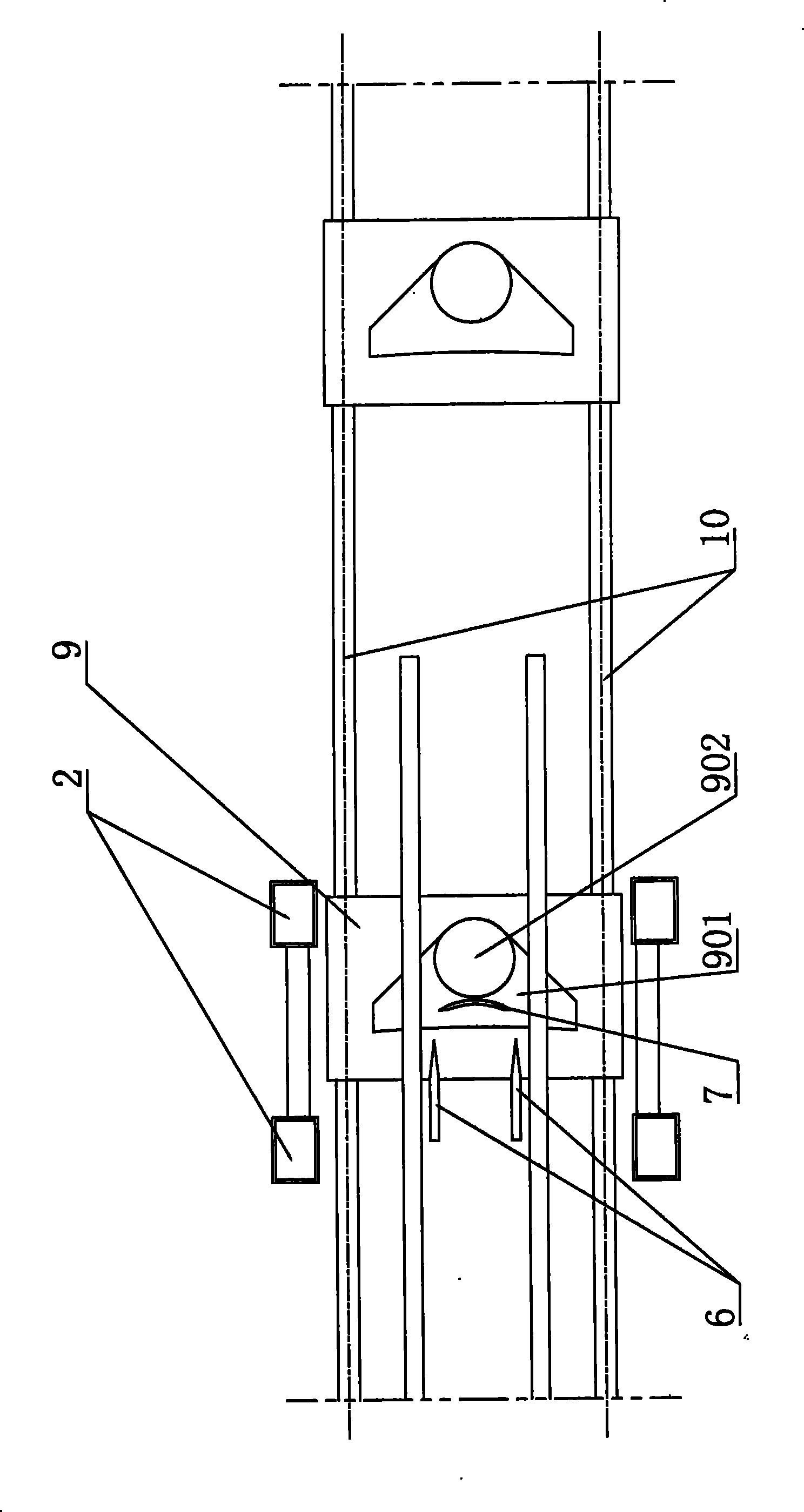

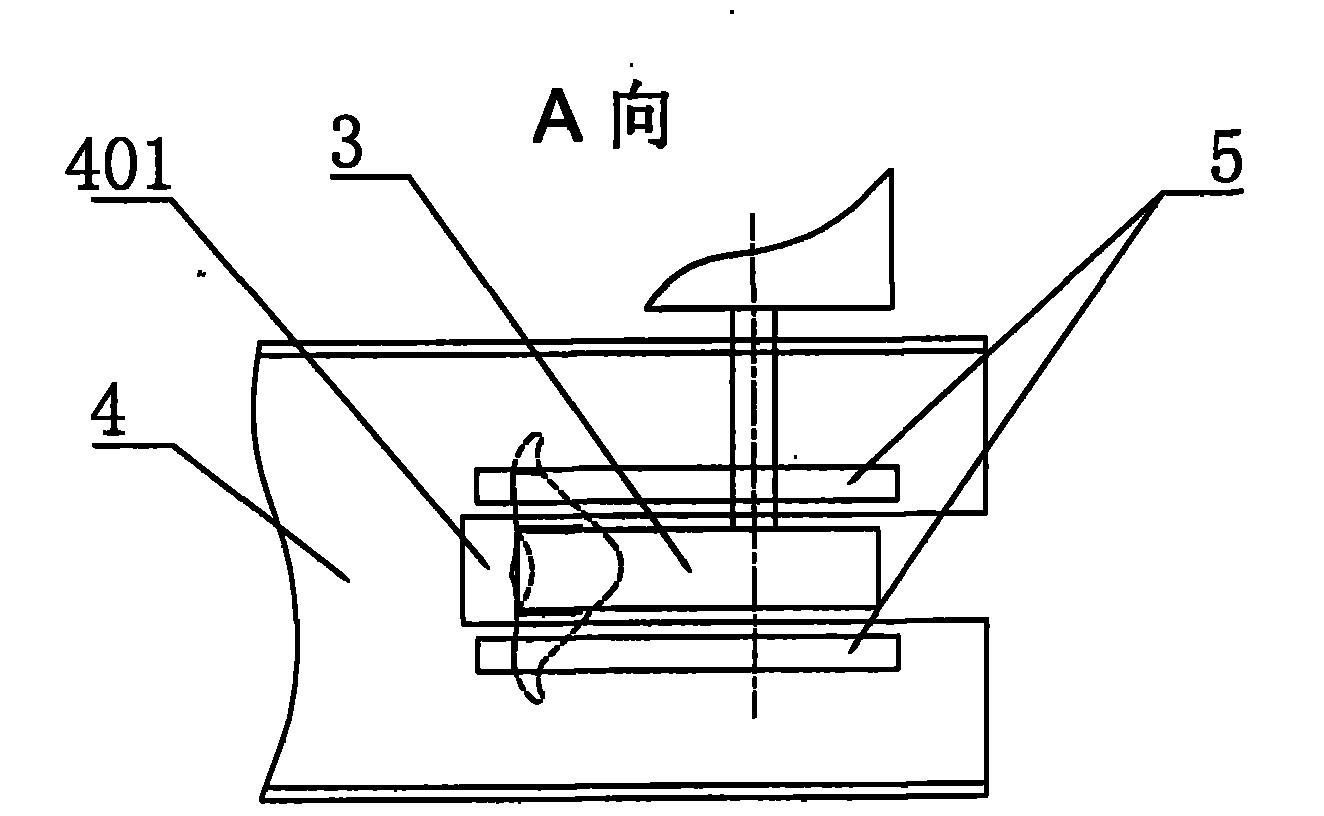

[0015] Such as Figure 1-3 Shown, be a kind of water chestnut shelling device, comprise frame 12, be provided with two rotating shafts 1 in parallel on the frame 12, all be fixed with two gears 11 on each rotating shaft, on the corresponding gear 11 between two rotating shafts 1 Two parallel chains 10 are installed around, and some feeding molds 9 are fixed at intervals between the two chains 10. The feeding mold 9 is provided with a groove 901 that can just place water chestnuts, and the bottom of the groove 901 is provided with a middle part for a square water chestnut. The hole 902 that the pointed corner is inserted, so that the square water chestnut can also be put into the groove 901 smoothly, the upper both sides of the groove 901 are respectively provided with two elastic bead 8 that are used to press down the both sides of the water chestnut; The outer side of the chain is provided with a column 2, and the column 2 is provided with a navel cutting knife 7 that can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com