Method for processing dried mussels by aid of strong brine

A technology of concentrated salt water and dried mussels, which is applied in the field of processing dried mussels with concentrated salt water, can solve the problems of poor shelling effect, inability to remove sediment, and high sediment content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

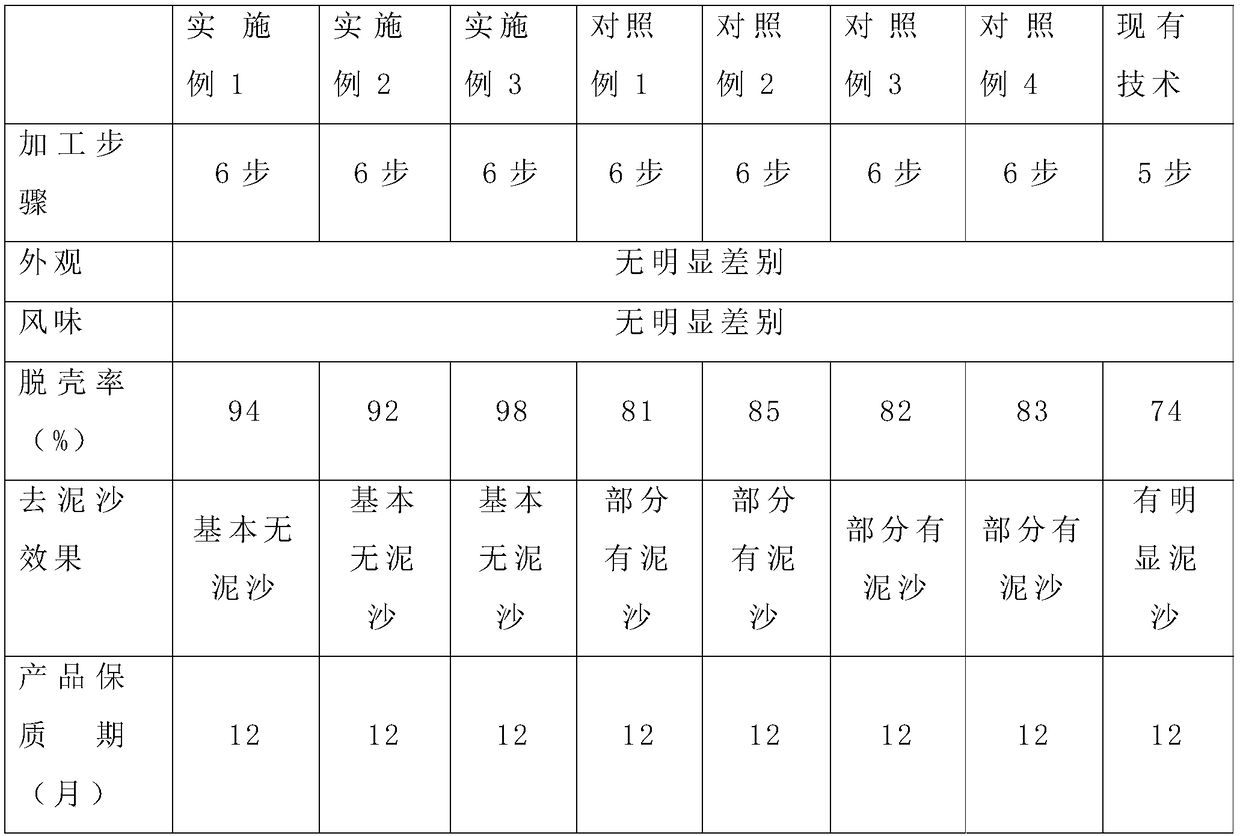

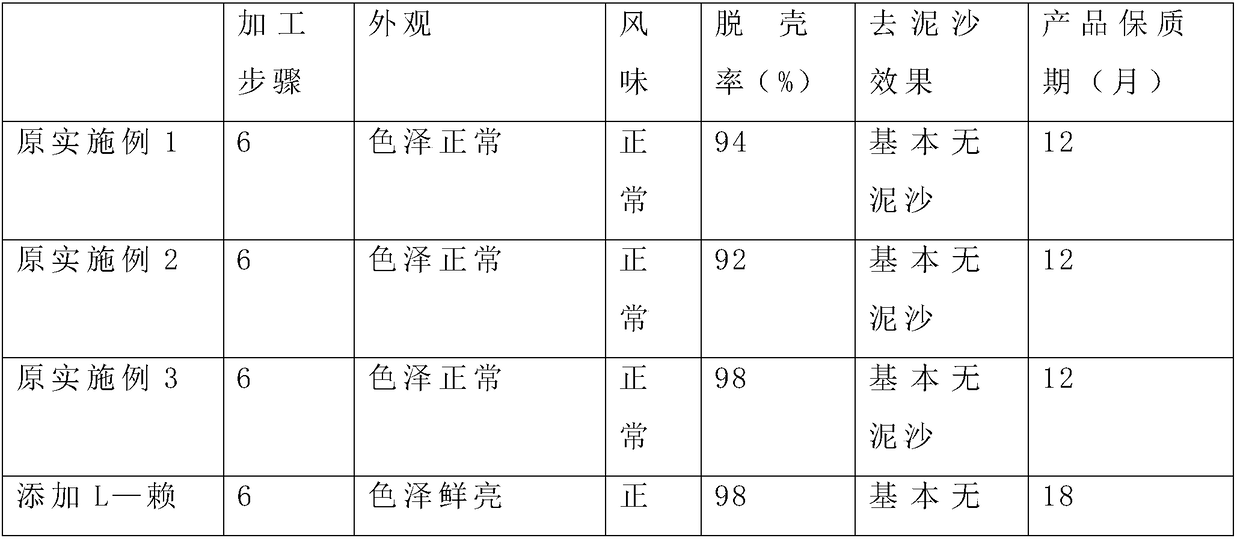

Examples

Embodiment 1

[0045] This implementation case shows a method of processing dried mussels using concentrated brine according to the following steps:

[0046] 1. Harvesting: the mussels are harvested, washed with seawater to remove the sediment on the surface;

[0047] 2. Temporary cultivation: transfer the cleaned mussels to concentrated brine at 15°C for temporary cultivation for 10 hours. The volume of the concentrated brine is 1.5 times the volume of the mussels; the salt content of the concentrated brine is generally 1.5 times that of the feed seawater. ;

[0048] 3. Cooking: Take out the temporarily raised mussels, boil them in the boiler, and cook them for 5 minutes;

[0049] 4. Separation of shell and meat: use a vibrating sieve type shell and meat separator to remove the shell and take the meat;

[0050] 5. Drying: use a dryer to dry the mussel meat at 70°C until the water content is lower than 20%.

[0051] 6. Packaging and finished products.

Embodiment 2

[0053] This implementation case shows a method of processing dried mussels using concentrated brine according to the following steps:

[0054] 1. Harvesting: the mussels are harvested, washed with seawater to remove the sediment on the surface;

[0055] 2. Temporary cultivation: transfer the cleaned mussels to concentrated brine at 20°C for temporary cultivation for 11 hours. The volume of the concentrated brine is twice the volume of the mussels; the salt content of the concentrated brine is generally 1.8 times that of the feed seawater. ;

[0056] 3. Cooking: take out the temporarily raised mussels, boil them in the boiler, and cook them for 8 minutes;

[0057] 4. Separation of shell and meat: use a vibrating sieve type shell and meat separator to remove the shell and take the meat;

[0058] 5. Drying: use a dryer to dry the mussel meat at 70°C until the water content is lower than 20%.

[0059] 6. Packaging and finished products.

Embodiment 3

[0061] This implementation case shows a method of processing dried mussels using concentrated brine according to the following steps:

[0062] 1. Harvesting: the mussels are harvested, washed with seawater to remove the sediment on the surface;

[0063] 2. Temporary cultivation: Put the cleaned mussels into concentrated brine at 25°C for temporary cultivation for 12 hours. The volume of the concentrated brine is 2.5 times the volume of the mussels; the salt content of the concentrated brine is generally 2 times that of the feed seawater. ;

[0064] 3. Cooking: Take out the temporarily raised mussels, boil them in the boiler, and cook them for 10 minutes;

[0065] 4. Separation of shell and meat: use a vibrating sieve type shell and meat separator to remove the shell and take the meat;

[0066] 5. Drying: use a dryer to dry the mussel meat at 70°C until the water content is lower than 20%.

[0067] 6. Packaging and finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com