A kind of preparation method of fused silica ceramic shell

A fused silica and ceramic type technology, applied in casting molding equipment, cores, molds, etc., can solve the problems of heat dissipation, cooling, easy formation of thermal joints, difficult molding technology, etc. Difficulty, fast heat dissipation, and the effect of reducing wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

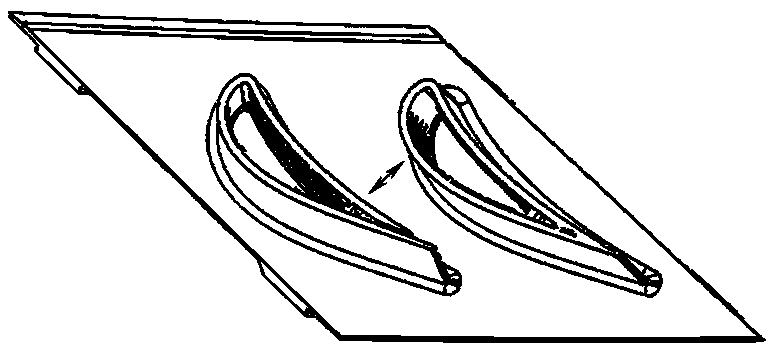

Image

Examples

Embodiment 1

[0037] The present invention comprises the following steps:

[0038] Step 1. According to the design requirements, the shell is made of fused silica material on the wax pattern. The fused silica shell made on the wax pattern has five layers, until the last layer is completed, that is, the fifth layer of shell; the paraffin water emulsion is used for sealant;

[0039] Specifically, the preparation and sealing process of the five-layer fused silica shell on the wax model is achieved according to the following detailed steps:

[0040] Step ①. Mix 300 mesh white corundum powder and silica sol (SiO 2 content of 30%) according to the mass ratio of 3.3:1 formula mix evenly to prepare 1# slurry;

[0041] 180 mesh fused silica powder and silica sol (SiO 2 content of 30%) according to the mass ratio of 2.3:1 formula mix evenly to prepare 2# slurry;

[0042] Step ②. Dip the wax model into 1# slurry, and evenly coat a layer of 1# slurry on the surface of the wax model;

[0043] When ...

Embodiment 2

[0063] The present invention comprises the following steps:

[0064] Step 1. According to the design requirements, the shell is made of fused silica material on the wax pattern. The fused silica shell made on the wax pattern has five layers, until the last layer is completed, that is, the fifth layer of shell; the paraffin water emulsion is used for sealant;

[0065] Specifically, the preparation and sealing process of the five-layer fused silica shell on the wax model is achieved according to the following detailed steps:

[0066] Step ①. Mix 280 mesh white corundum powder and silica sol (SiO 2 The content is 25%) according to the mass ratio of 3.6: 1 and mixed evenly to prepare 1# slurry;

[0067] 200 mesh fused silica powder and silica sol (SiO 2 The content is 25%) according to the mass ratio of 2.6:1 and mix evenly to prepare 2# slurry;

[0068] Step ②. Dip the wax model into 1# slurry, and evenly coat a layer of 1# slurry on the surface of the wax model;

[0069] Wh...

Embodiment 3

[0089] The present invention comprises the following steps:

[0090] Step 1. According to the design requirements, the shell is made of fused silica material on the wax pattern. The fused silica shell made on the wax pattern has five layers, until the last layer is completed, that is, the fifth layer of shell; the paraffin water emulsion is used for sealant;

[0091] Specifically, the preparation and sealing process of the five-layer fused silica shell on the wax model is achieved according to the following detailed steps:

[0092] Step ①. Mix 320 mesh white corundum powder and silica sol (SiO 2 content of 30%) according to the mass ratio of 3.5:1 formula mix evenly to prepare 1# slurry;

[0093] 200 mesh fused silica powder and silica sol (SiO 2 The content is 25%) according to the mass ratio of 2.5: 1 and mixed evenly to prepare 2# slurry;

[0094] Step ②. Dip the wax model into 1# slurry, and evenly coat a layer of 1# slurry on the surface of the wax model;

[0095] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com