Rotary peanut shelling device for processing agricultural products

An agricultural product processing and rotary technology, applied in the field of rotary peanut shelling devices for agricultural product processing, can solve the problems of inability to dry peanuts, difficult shelling, low shelling efficiency, etc. Guaranteed dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

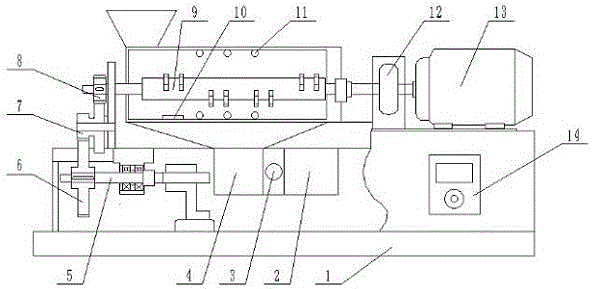

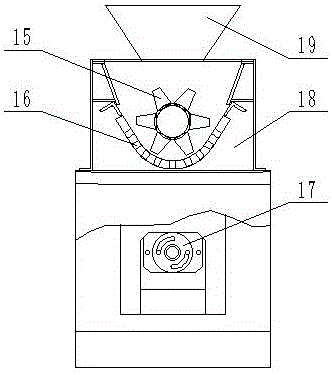

[0017] Such as figure 1 , figure 2 As shown, a rotary peanut shelling device for agricultural product processing includes a body 1, a controller 14, a heater 11, and a travel switch 17. A controller 14 is installed on the front side of the body 1, and the controller 14 controls the entire device. Core, a motor 13 is installed at one end of the fuselage 1, a reducer 12 is installed at one end of the motor 13, a casing 18 is installed at the upper end of the fuselage 1, a discharge hopper 4 is installed at the lower end of the casing 18, and a vacuum cleaner 3 is installed at one side of the discharge hopper 4, The vacuum cleaner 3 can absorb the broken shells and dust generated. A dust collection box 2 is installed on one side of the vacuum cleaner 3. A feed hopper 19 is installed on the upper end of the box body 18. A main shaft 9 is installed inside the box body 18. A bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com