Lithium metal electrode prepared through 3D printing technology and preparation method thereof

A lithium metal electrode, 3D printing technology, applied in the direction of electrode manufacturing, negative electrode, battery electrode, etc., can solve the problems that lithium-ion batteries are difficult to meet the application, and achieve excellent deep charge and deep discharge performance, high Coulombic efficiency, good rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a kind of printing paste, and its composition is made of titanium carbide (Ti carbide) in the transition metal carbide 3 C 2 T x ) and water, where Ti 3 C 2 T x The preparation process includes steps 1) to 3):

[0050] Step 1): Put 2g Ti 3 AlC 2 Add the powder into a mixture of 4g lithium fluoride (LiF) and 40mL 12mol / mL hydrochloric acid (HCl), and stir for 40h in a water bath at 30°C;

[0051] Step 2): The suspension obtained in step 1) was suction filtered, washed repeatedly with deionized water, and ultrasonically treated for 30 minutes to obtain Ti 3 C 2 T x A suspension in which nanosheets are uniformly dispersed;

[0052] Step 3): The suspension obtained in step 2) was further concentrated to obtain a 300 mg / ml slurry, which was the printing paste of the present invention.

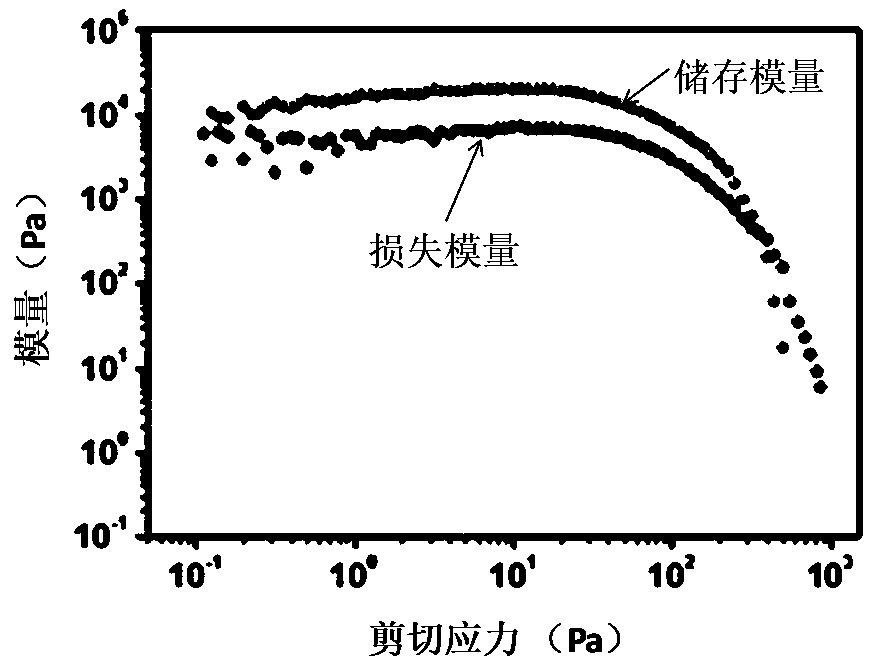

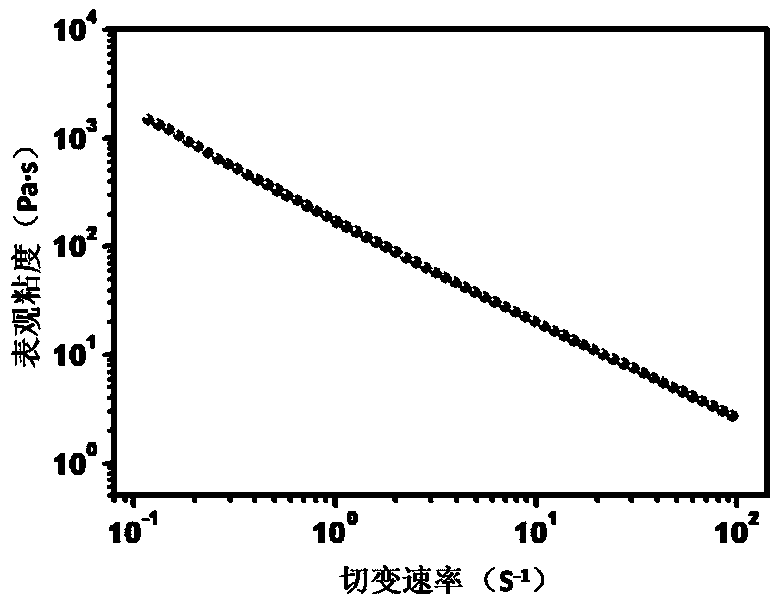

[0053] The rheological properties of the printing paste are measured by a DHR-2 rotational rheometer (TA Instruments, USA), and the fixture is a 20mm steel...

Embodiment 2

[0056] This embodiment provides a printing paste whose components are composed of graphene and water.

[0057] The preparation steps include: concentrating the graphene solution prepared by the liquid phase exfoliation method (available from the market) through a rotary evaporator to obtain a high-concentration viscous slurry with a concentration of 80 mg / ml, which is the printing slurry of the present invention.

[0058] Measured by a rotational rheometer at a shear rate of 1 s -1 The apparent viscosity of the printing paste was 300 Pa·s.

[0059] Graphene is a two-dimensional conductive material with a sheet structure.

Embodiment 3

[0061] This embodiment provides a printing paste whose components are composed of fluorinated graphite and water. The preparation steps include: dispersing the fluorinated graphite powder in water to prepare a uniform and stable viscous slurry with a concentration of 100 mg / ml.

[0062] measured by a rotational rheometer at a shear rate of 1 s -1 The apparent viscosity of the printing paste was 200 Pa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Surface capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com