Cathode material for polymer batteries and method of preparing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

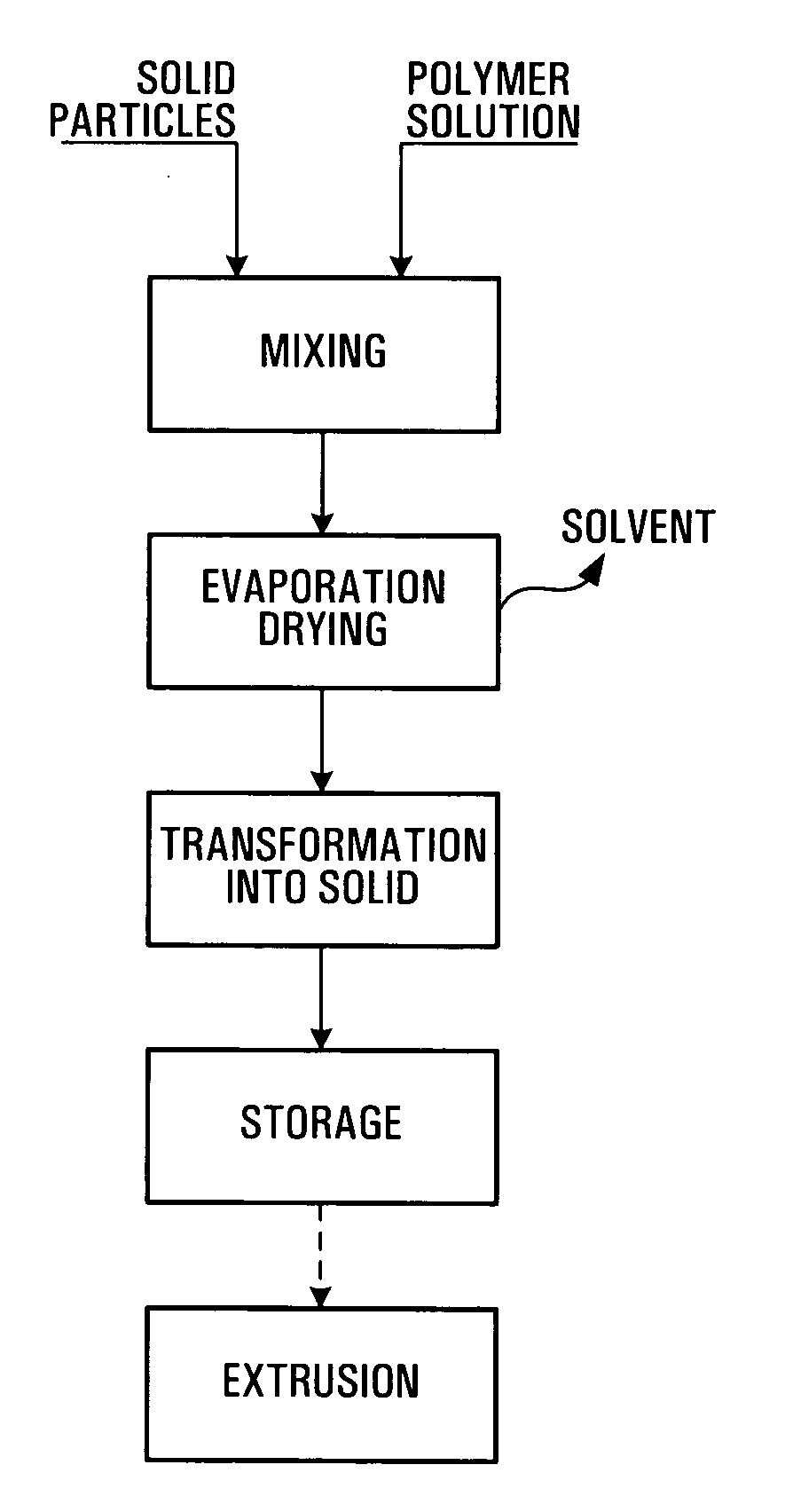

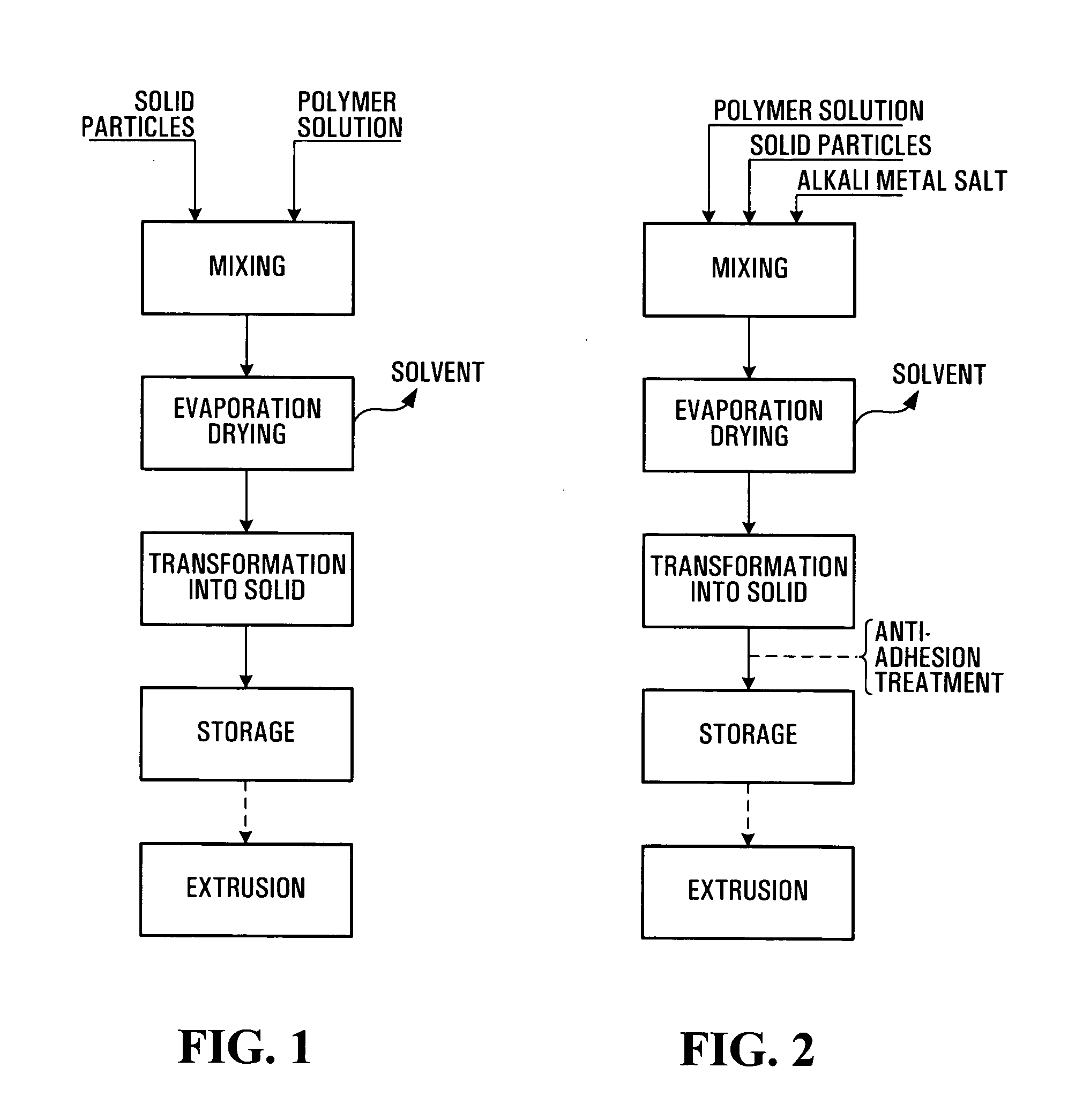

[0044] With reference to FIG. 1, a solution of polymer in solvent or mixture of solvents is mixed with solid particles of active cathode material and electronic conductive additives. The polymer solution could be obtained by the dissolution of a polymer in a solvent(s) or directly at the outlet of a polymerization reactor if the polymer is already in solution. In a preferred embodiment the active cathode material and electronic conductive additives have been blended together prior to introduction into the polymer solution. However, the active cathode material and the electronic conductive additives may be introduced separately into the polymer solution. The polymer solution and the solid particles are mixed in any type of mixing device(s) capable of proper dispersion for a sufficient time to obtain a good dispersion of the solid particles in the polymer solution and / or in any equipment that homogenize the mixture in order to achieve the same dispersion. The mixing process may be don...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com