Electrolyte additive for inhibiting hydrogen evolution of negative plate for lead-acid storage battery

A technology for electrolyte additives and lead-acid batteries, applied in lead-acid batteries, secondary batteries, circuits, etc., can solve the problems of limited solubility, negative electrode hydrogen evolution inhibition is not obvious, unstable, etc., to reduce water loss, improve Hydrogen evolution overpotential, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

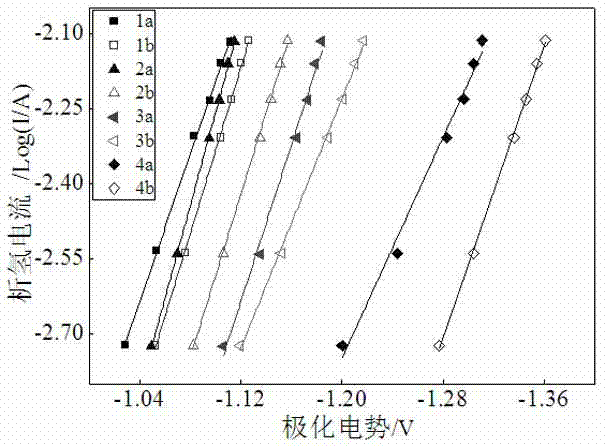

[0031] Prepare a negative plate containing 0.5% activated carbon, put it into 1.28g / cm 3 Soak in sulfuric acid solution for 24 hours. Then take the negative plate as the working electrode, take the positive plate produced by the factory as the counter electrode, Hg / Hg 2 SO 4 The electrode is a reference electrode, 1.28g / cm 3 The sulfuric acid solution is used as the electrolyte to form a three-electrode system. The working electrode was polarized with a cathodic current of 10mA for 16h by the constant current polarization method, so that the active material in the negative plate was completely converted into lead, and the gas dissolved in the solution around the negative plate was removed by overcharging. , 7mA, 6mA, 5mA, 3mA, 2mA current constant current polarization for 2h, after the polarization potential φ is stable, use a foam flowmeter to measure the amount of gas evolution, calculate the hydrogen evolution current I, take the average value of multiple measurements,...

Embodiment 2

[0034]Prepare negative plates containing different carbon materials first, and put them into 1.28g / cm 3 Soak in sulfuric acid solution for 24 hours. Then take the negative plate as the working electrode, take the positive plate produced by the factory as the counter electrode, Hg / Hg 2 SO 4 The electrode is a reference electrode, 1.28g / cm 3 The sulfuric acid solution is used as the electrolyte to form a three-electrode system. The working electrode was polarized with a cathodic current of 10mA for 16h by the constant current polarization method, so that the active material in the negative plate was completely converted into lead, and the gas dissolved in the solution around the negative plate was removed by overcharging. , 7mA, 6mA, 5mA, 3mA, and 2mA current constant current polarization for 2h each, after the polarization potential φ is stable, use a foam flowmeter to measure the amount of gas evolution, calculate the hydrogen evolution current I, take the average value o...

Embodiment 3

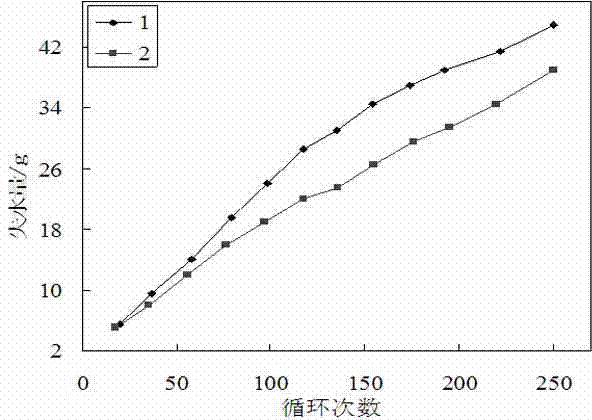

[0037] Additive of the present invention is applied to actual battery and carries out the impact of life cycle on water consumption: at first get two unformed 12V12Ah valve-regulated lead-acid batteries (the carbon material added in the negative plate is acetylene black), respectively marked as No. 1 ( Blank control battery), No. 2 (experimental battery). Add conventional lead-acid battery electrolyte to No. 1 battery, and add 0.025% Dy to the No. 2 battery electrolyte on the basis of No. 1 battery electrolyte 2 o 3 and 0.025% PTFE, the electrolyte is ultrasonically dispersed and added to the battery. Then the two batteries are internalized according to the same procedure. After the formation is completed, weigh and record the original weight of the battery, and then perform the water loss test in a cycle according to the same procedure. Weigh the battery and calculate the water loss at regular intervals, such as figure 2 As shown, the experiment shows that the water loss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com