Magnesium alloy anode material and preparation method and application thereof

A kind of anode material, alloy anode technology, applied in the direction of primary battery electrode, battery electrode, fuel cell type half cell and primary cell type half cell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

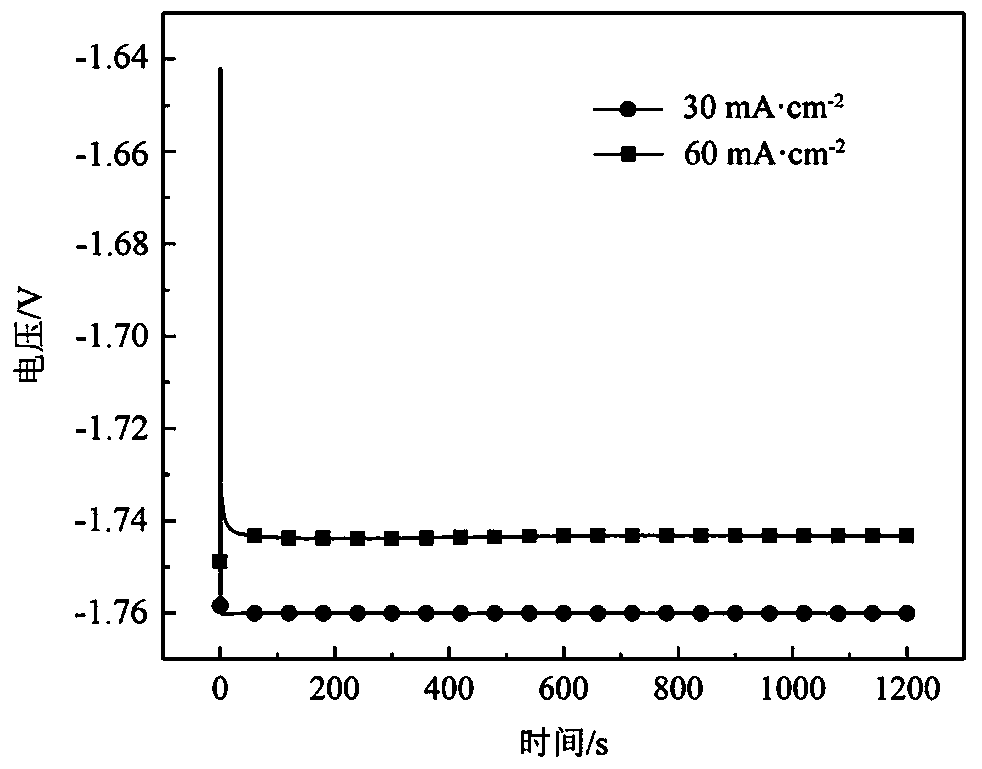

Embodiment 1

[0031] A magnesium alloy anode material, the chemical composition of the magnesium alloy is (mass percentage): 6% Al, 1% Ge, and the balance is magnesium.

[0032] The preparation method of the magnesium alloy anode material preparation method comprises the following steps:

[0033] (1) Pretreat the magnesium ingots and aluminum ingots respectively: cut the magnesium ingots and aluminum ingots into small pieces of 100mm×30mm×20mm respectively, and remove the oxides and oil stains on the surface according to the conventional method, and then wash them with absolute ethanol After cleaning, dry at a temperature of 90°C to constant weight to obtain pretreated magnesium ingots and aluminum ingots;

[0034] (2) Pretreatment of germanium grains: remove oxides and oil stains on the surface of germanium grains according to conventional methods, then clean them with absolute ethanol, and dry them at a temperature of 90°C to constant weight to obtain the pretreated germanium grains. Tre...

Embodiment 2

[0040]A magnesium alloy anode material, the alloy product is composed of the following components in weight percentage (g / g): 6% Al, 3% Ge, and the balance is magnesium.

[0041] The preparation steps are as in Example 1.

Embodiment 3

[0043] A magnesium alloy anode material, the alloy product is composed of the following components in weight percentage (g / g): 6% Al, 5% Ge, and the balance is magnesium.

[0044] The preparation steps are as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com