Method for preparing rare-earth aluminum alloy electrode material

An aluminum alloy electrode and rare earth technology, which is applied in the field of preparation of aluminum alloy electrode materials for high-performance batteries, can solve the problems of few researches on rare earth doped aluminum alloy anodes and unsatisfactory results, and achieve large output current and high specific energy , The effect of negative open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

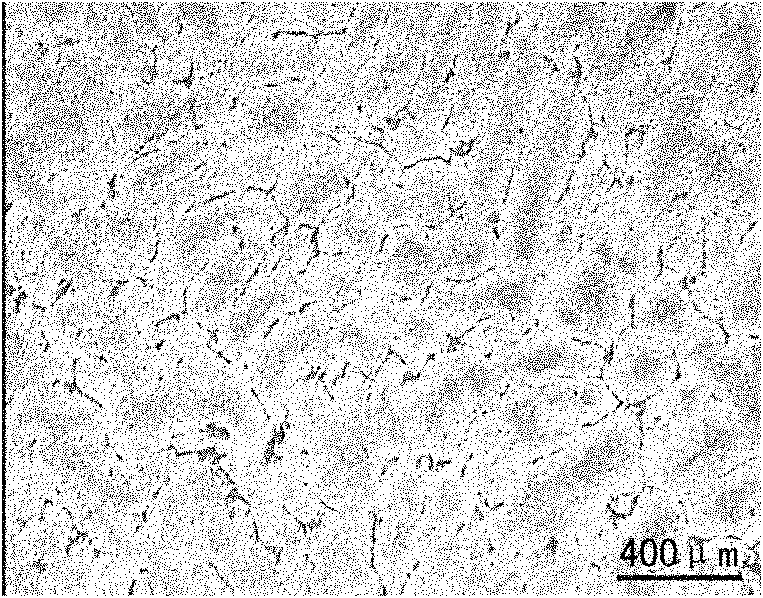

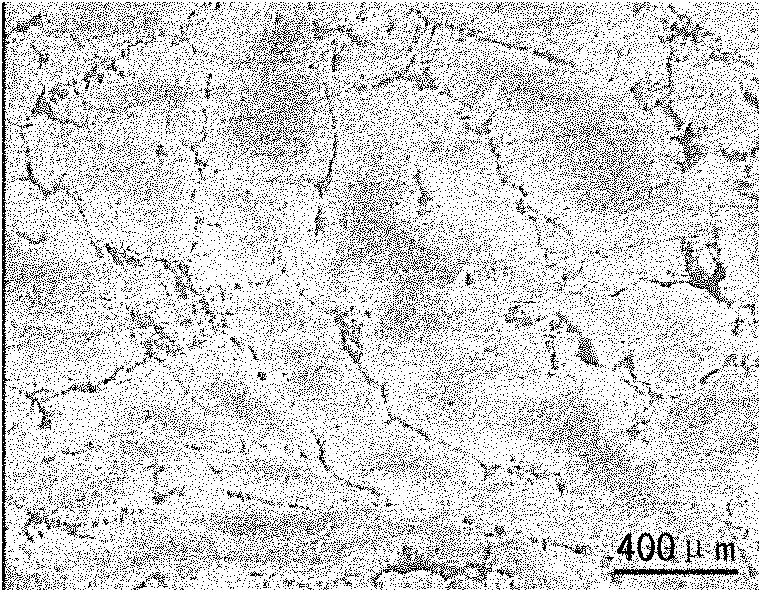

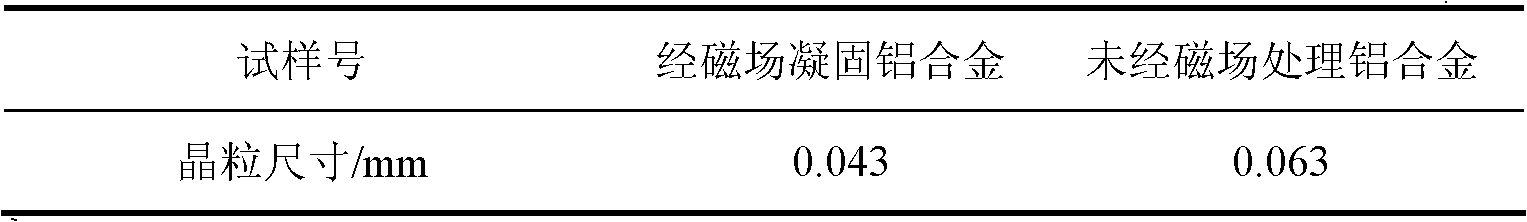

Embodiment 1

[0017] Using chemically pure Al (99.9%) as the raw material, the composition ratio of the selected aluminum alloy anode is: aluminum: 90%, zinc: 9.40%, Ga: 0.10%; In: 0.05%; Pb: 0.09%; Sn: 0.05%; Mn: 0.10%; Re: 0.20%, put the measured aluminum in a corundum crucible, in an argon protective atmosphere, melt it with a resistance furnace, remove slag and gas, wrap the rest of the alloy elements in aluminum foil and put them in order, completely After melting, remove the slag, stir, keep the temperature for 2 hours, pour it into a graphite mold to cast an ingot, and apply a 0.2T AC magnetic field to solidify. Press the aluminum ingot into thin slices of about 1 mm for use. The rare earth aluminum alloy sheet is made into a working area of 1cm 2 square with a copper wire attached to the end. The non-working area is sealed with AB glue. After curing, use 400#, 600#, 800#, 1000# metallographic sandpaper to polish the smooth working surface, then rinse with distilled water, degre...

Embodiment 2

[0022] According to the method and steps of Example 1, aluminum: 90%, zinc: 9.20%, the ratio of rare earth elements used is: Ga: 0.15%; In: 0.09%; Pb: 0.10%; Mn: 0.15%; Re: 0.30% .

[0023] The electrochemical capacity test data of the material prepared in embodiment 2:

[0024] sample

Embodiment 3

[0026] According to the method and steps of Example 1, but the external magnetic field used is a DC magnetic field.

[0027] The electrochemical capacity test data of the material prepared in embodiment 3:

[0028] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com