A kind of organic composite corrosion inhibitor for pulp layer paper and its slurry

A composite corrosion inhibitor, pulp layer paper technology, applied in paper coating, coating, papermaking and other directions, can solve the problems of narrow corrosion inhibition range, difficult to control, insoluble in water, etc., to reduce self-corrosion rate, slow down Self-corroding, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

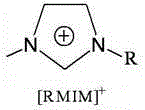

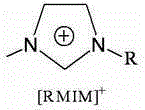

[0033] Preparation of organic composite high-efficiency corrosion inhibitor for pulp paper, wherein the selected ionic liquid is [C 4 mim] BF 4 0.0580g, the organic nonionic surfactant is a mixture of lauryl polyoxyethylene ether 0.0090g, PEG4000.1200g, Tween 800.0726g and coconut oil polyoxyethylene ether 0.0624g, wherein the water-soluble ionic liquid and organic nonionic surface The mass ratio of the active agent is 1:4.55.

[0034] Prepare the slurry for pulp layer paper according to the following method:

[0035] Accurately weigh 1.6g of PVA and add it to a beaker containing 35g of deionized water at 98°C, stir to dissolve it; when the temperature of the PVA aqueous solution drops to 50°C, add 20g of PAM and 1.6g of CMC in turn, and stir evenly; use 2mol / L HCl solution and ZnO Adjust the pH of the solution at 3.5; then add 7.3g of modified starch and the above-prepared organic compound high-efficiency corrosion inhibitor, the modified starch is a mixture of cross-linked...

Embodiment 2

[0038] Preparation of organic composite high-efficiency corrosion inhibitor for pulp paper, wherein the selected ionic liquid is [C 5 Bmim] BF 4 0.1025g, and the organic nonionic surfactant is a mixture of 0.1407g of polyoxyethylene lauryl ether and TX-100.0824g, wherein the mass ratio of the water-soluble ionic liquid to the organic nonionic surfactant is 1:2.18.

[0039] Prepare the slurry for pulp layer paper according to the following method:

[0040] Accurately weigh 1.8g of PVA and add it to a beaker containing 45g of deionized water at 98°C, stir to dissolve it; when the temperature of the PVA aqueous solution drops to 55°C, add 22g of PAM and 1.3g of CMC in turn, and stir evenly; use 2mol / L HCl solution and ZnO Adjust the pH of the solution to 3.8; then add 7.8g of modified starch and the organic composite high-efficiency corrosion inhibitor prepared above, the modified starch is cross-linked starch, stir well and adjust the viscosity to obtain the slurry, and the cor...

Embodiment 3

[0043] Preparation of organic composite high-efficiency corrosion inhibitor for pulp paper, wherein the selected ionic liquid is [C 2 mim]HSO 4 0.0830g, the organic nonionic surfactant is a mixture of 0.1524g lauryl polyoxyethylene ether, PEG4000.2368g, and OP-100.1050g, wherein the mass ratio of water-soluble ionic liquid to organic nonionic surfactant is 1:5.95 .

[0044] Prepare the slurry for pulp layer paper according to the following method:

[0045] Accurately weigh 1.3g of PVA and add it to a beaker containing 43g of 100°C deionized water, stir to dissolve it; when the temperature of the PVA aqueous solution drops to 58°C, add 18.5g of PAM and 1.4g of CMC in turn, and stir evenly; use 2mol / L HCl solution and ZnO adjusts the pH of the solution at 3.6; then add 7.1g of modified starch and the above-prepared organic composite high-efficiency corrosion inhibitor, the modified starch is etherified starch, stir thoroughly and adjust the viscosity to obtain the slurry, slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com