Electrolyte corrosion inhibitor for aluminum-air battery, electrolyte and preparation method

An air battery and electrolyte technology, which is applied to fuel cell type half cells and primary cell type half cells, etc., can solve the problems of complex corrosion inhibitor components, waste of materials and resources, and non-compliance with environmental protection requirements. , to reduce the self-corrosion rate of hydrogen evolution, reduce the polarization of aluminum anode, and improve the discharge performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The aluminum-air battery electrolyte mother solution in this embodiment is 4 mol / L sodium hydroxide solution, the corrosion inhibitor is sodium thiosulfate, and the concentration in the electrolyte is 0.005 mol / L. The preparation method of the electrolytic solution is as follows: prepare a sodium hydroxide solution with a concentration of 4 mol / L, cool to room temperature, add accurately weighed sodium thiosulfate, stir and dissolve completely.

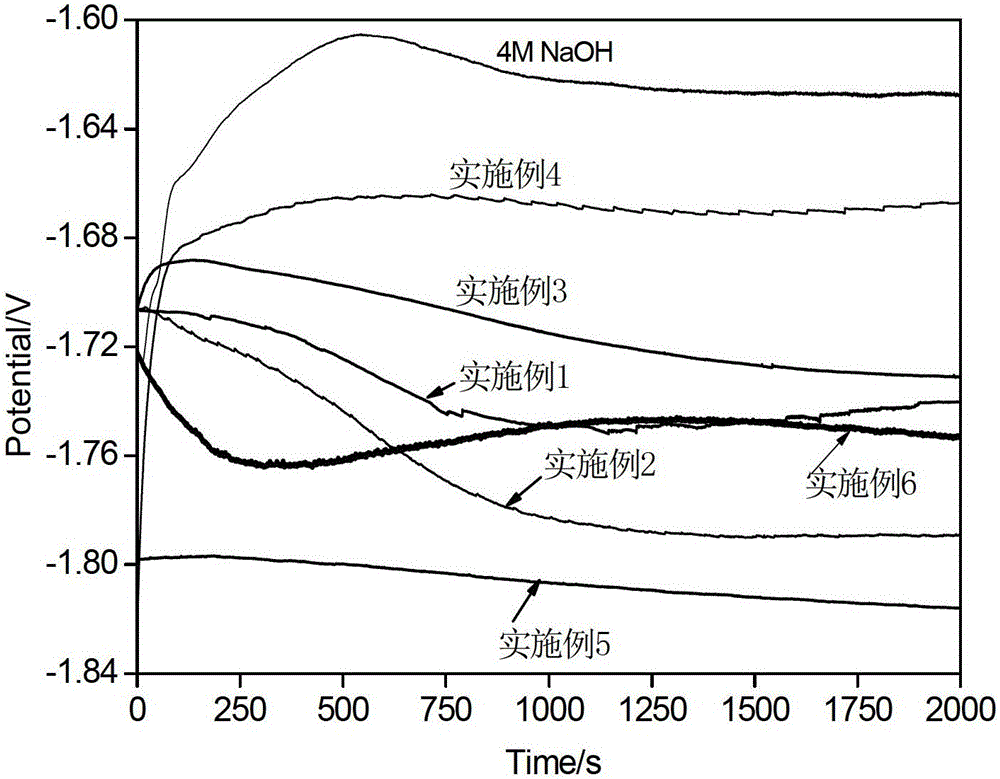

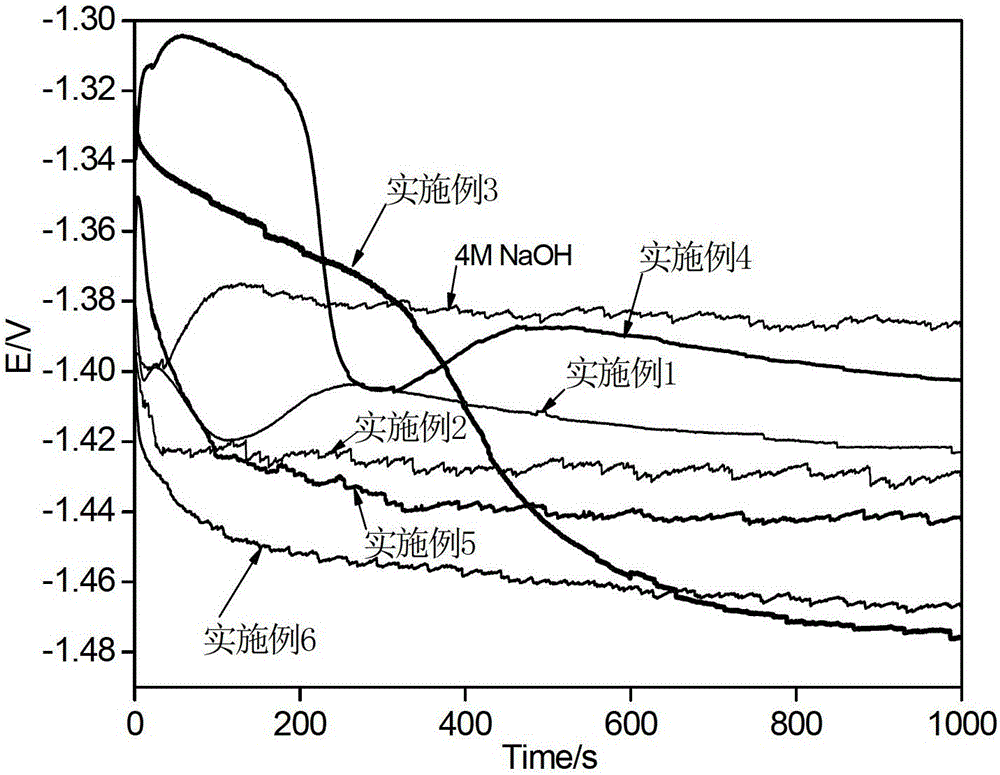

[0036] The static self-corrosion rate of the Al-0.1Sn-0.1Ga aluminum anode alloy in the electrolyte prepared in this embodiment was tested by the gas collection method, and the test time was 30 minutes. The results are shown in Table 1 below. Using a three-electrode system to test the open circuit potential of the Al-0.1Sn-0.1Ga aluminum anode alloy in the above electrolyte and at 25°C, 100mA / cm 2 The working potential curve under the current density, the results are detailed in figure 1 , figure 2 . The self-corrosion rat...

Embodiment 2

[0039] The electrolyte mother solution for the aluminum-air battery in this embodiment is 4 mol / L sodium hydroxide solution, the corrosion inhibitor is sodium thiosulfate, and the concentration in the electrolyte is 0.01 mol / L. The preparation method of the electrolytic solution is as follows: prepare a sodium hydroxide solution with a concentration of 4 mol / L, cool to room temperature, add accurately weighed sodium thiosulfate, stir and dissolve completely.

[0040] The static self-corrosion rate of the Al-0.1Sn-0.1Ga aluminum anode alloy in the electrolyte prepared in this embodiment was tested by the gas collection method, and the test time was 30 minutes. The results are shown in Table 1 below. Using a three-electrode system to test the open circuit potential of the Al-0.1Sn-0.1Ga aluminum anode alloy in the above electrolyte and at 25°C, 100mA / cm 2 The working potential curve under the current density, the results are detailed in figure 1 , figure 2 . The self-corros...

Embodiment 3

[0043] The electrolyte mother solution for the aluminum-air battery in this embodiment is 4 mol / L sodium hydroxide solution, the corrosion inhibitor is sodium thiosulfate, and the concentration in the electrolyte is 0.05 mol / L. The preparation method of the electrolytic solution is as follows: prepare a sodium hydroxide solution with a concentration of 4 mol / L, cool to room temperature, add accurately weighed sodium thiosulfate, stir and dissolve completely.

[0044] The static self-corrosion rate of the Al-0.1Sn-0.1Ga aluminum anode alloy in the electrolyte prepared in this embodiment was tested by the gas collection method, and the test time was 30 minutes. The results are shown in Table 1 below. Using a three-electrode system to test the open circuit potential of the Al-0.1Sn-0.1Ga aluminum anode alloy in the above electrolyte and at 25°C, 100mA / cm 2 The working potential curve under the current density, the results are detailed in figure 1 , figure 2 . The self-corros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com