A kind of high-activity aluminum alloy anode material containing sc for new energy battery power and preparation method thereof

An anode material and new energy technology, which is applied in the field of high-activity aluminum alloy anode material and its preparation, can solve the problems of unsatisfactory aluminum anode activity, high self-corrosion rate, low self-corrosion rate, etc., so as to reduce hydrogen evolution and self-corrosion. speed, improve use efficiency, and achieve a reasonable balance of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

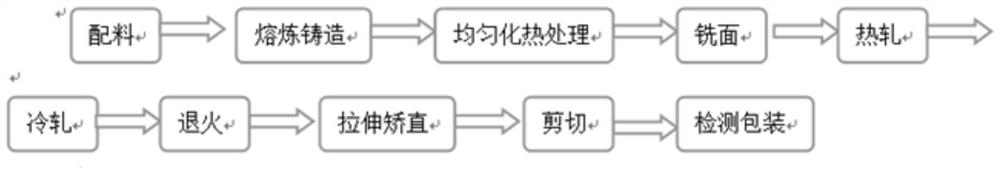

[0043] The present invention provides a method for preparing a high-activity aluminum alloy anode material containing Sc for new energy battery power as described in the above technical solution, comprising:

[0044] Batching, smelting and casting, homogenizing heat treatment, milling, hot rolling, cold rolling, annealing and stretch straightening are performed in sequence.

[0045] The process flow diagram of the preparation method of the high-activity aluminum alloy anode material containing Sc for the power of the new energy battery provided by the embodiment of the present invention is as follows: figure 1 shown.

[0046] The present invention does not have special restrictions on the method of the batching, and the alloy raw materials well-known to those skilled in the art are used for proportioning according to the composition of the high-activity aluminum alloy anode material containing Sc for new energy battery power as described in the above technical scheme. , the c...

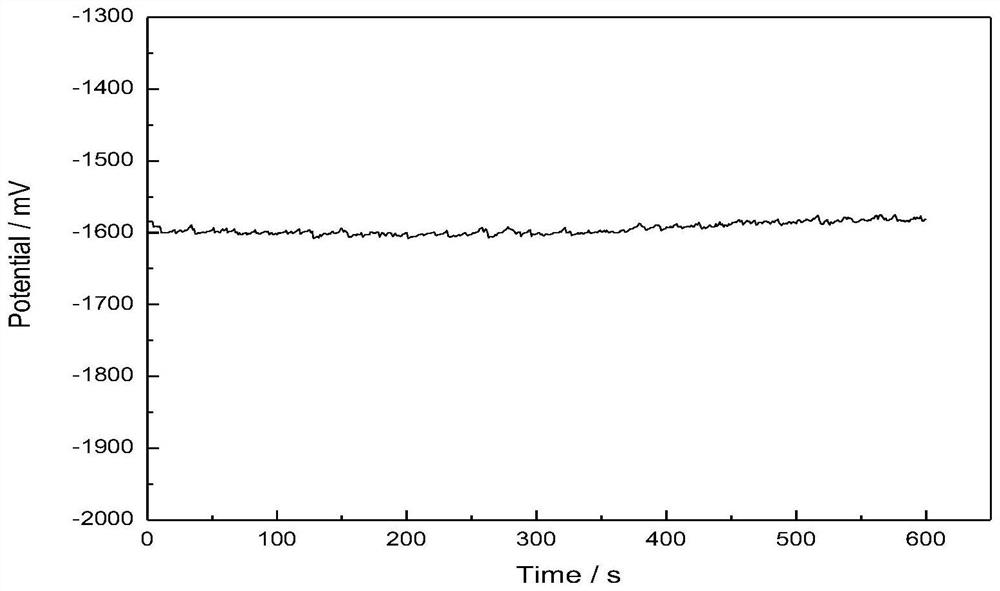

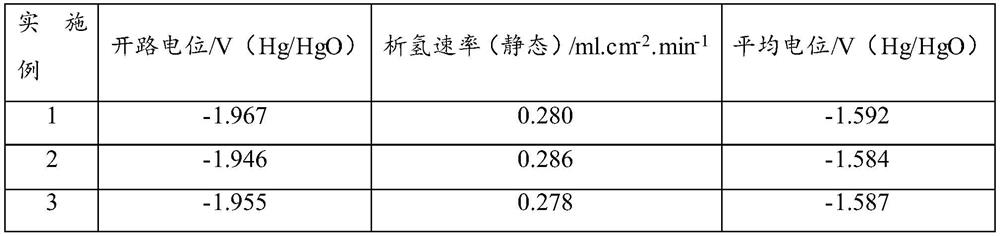

Embodiment 1

[0071] The Al with a purity of 99.995% is melted in the furnace, and the charge is flattened and covered with flux powder; when the melt temperature is 720 ℃ ~ 740 ℃, slag is removed, and alloying elements are added; the weighed Ga, In, Sn and Pb The pure metal is dispersed and evenly put into the aluminum melt in the furnace; the weighed pure Mg ingot is pressed into the aluminum melt to melt; the weighed Al-2%Sc master alloy is added to the aluminum melt to melt, Then stir thoroughly; after stirring, take the sample of the furnace to analyze the alloy composition.

[0072] After the components in front of the furnace are qualified, when the melt temperature is 730 ℃ ~ 740 ℃, use a "T" type refining tube and high-purity argon gas for refining in the furnace for 8 minutes, then slag slag, and cast after standing for 15 minutes.

[0073] The size of the ingot is 400×1320mm, the casting process parameters are: the casting temperature is 720~740℃, the casting speed is 45mm / min, a...

Embodiment 2

[0080] The Al with a purity of 99.995% is melted in the furnace, and the charge is flattened and covered with flux powder; when the melt temperature is 720 ℃ ~ 740 ℃, slag is removed, and alloying elements are added; the weighed Ga, In, Sn and Pb The pure metal is dispersed and evenly put into the aluminum melt in the furnace; the weighed pure Mg ingot is pressed into the aluminum melt to melt; the weighed Al-2%Sc master alloy is added to the aluminum melt to melt; Then stir thoroughly. After stirring, take the sample before the furnace to analyze the alloy composition.

[0081] After the components in front of the furnace are qualified, when the melt temperature is 730 ℃ ~ 740 ℃, use a "T" type refining tube and high-purity argon gas for refining in the furnace for 8 minutes, then slag slag, and cast after standing for 15 minutes.

[0082] The size of the ingot is 400×1320mm, the casting process parameters are: the casting temperature is 720~740℃, the casting speed is 47mm / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com