A kind of aluminum-air battery electrolyte composite additive and preparation method thereof

An empty battery and electrolyte technology, which is applied in the field of aluminum-empty battery electrolyte compound additive and its preparation, and electrolyte additive field, can solve the problems of unsatisfactory environmental protection, complex composition, environmental pollution, etc., and achieves simple structure and good development. Promising, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The aluminum-air battery electrolyte composite additive in this embodiment, wherein the mother solution of the electrolyte is a 4mol / L sodium hydroxide solution, and the additive is sodium carboxymethylcellulose (CMC) with a concentration of 10-10000mg / L . The preparation method of the electrolyte is as follows: configure a sodium hydroxide solution with a concentration of 4 mol / L, cool to room temperature, add CMC, and stir to dissolve.

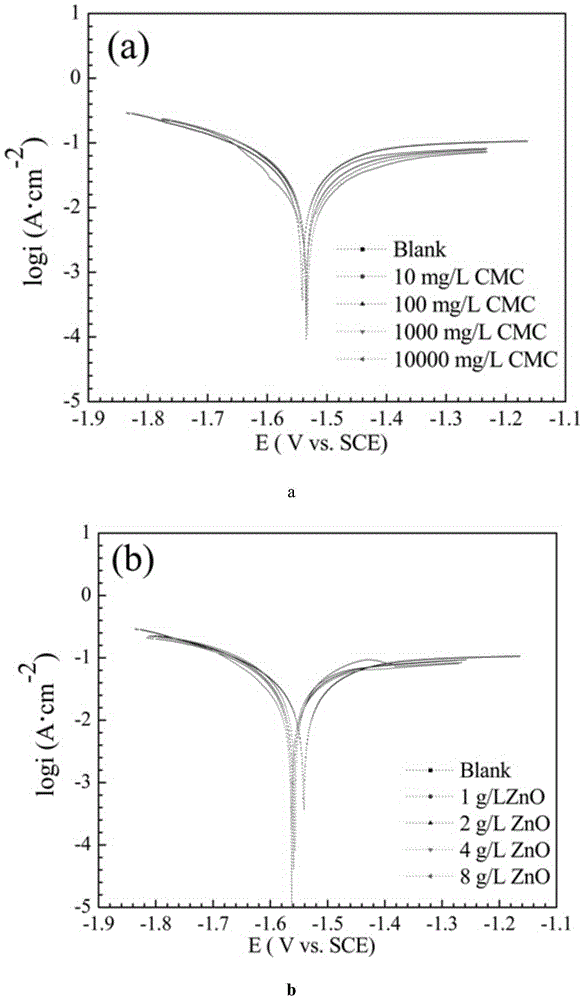

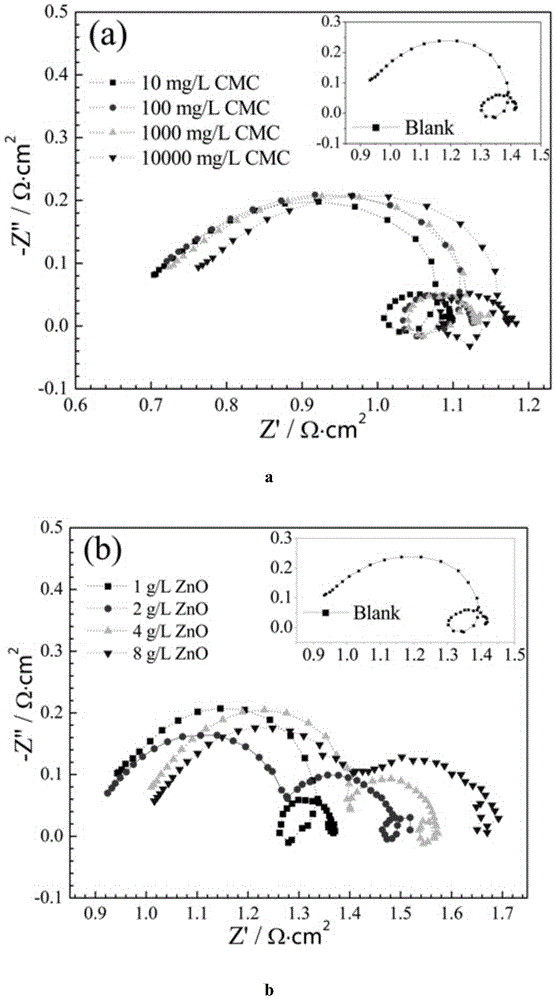

[0026] The hydrogen evolution corrosion rate of the AA5052 aluminum alloy anode in the electrolyte prepared in this example was tested by the collected gas method, and the test time was 30 minutes. The results are shown in Table 1. The polarization curve and AC impedance of the AA5052 aluminum alloy anode in the above electrolyte were tested by electrochemical testing, and the results are shown in figure 1 (a), figure 2 (a) and Table 2, the temperature is controlled at 25°C.

[0027] From Table 1, Table 2, figure 1 (a) and figu...

Embodiment 2

[0029] The aluminum-air battery electrolyte composite additive in this embodiment, wherein the mother liquid of the electrolyte is 4mol / L sodium hydroxide solution, and zinc oxide (ZnO) is used as the additive with a concentration of 1-8g / L. The preparation method of the electrolyte is as follows: prepare a sodium hydroxide solution with a concentration of 4 mol / L, cool to room temperature, add ZnO, and stir to dissolve.

[0030] The hydrogen evolution corrosion rate of the AA5052 aluminum alloy anode in the electrolyte prepared in this example was tested by the collected gas method, and the test time was 30 minutes. The results are shown in Table 1. The polarization curve and AC impedance of the AA5052 aluminum alloy anode in the above-mentioned electrolyte are tested by electrochemical testing, and the results are shown in Table 2, figure 1 (b) and figure 2 (b), the temperature is controlled at 25°C.

[0031] From Table 1, Table 2, figure 1 (b) and figure 2 (b) It can ...

Embodiment 3

[0033] The aluminum-air battery electrolyte compound additive in this embodiment, wherein the mother liquid of the electrolyte is 4mol / L sodium hydroxide solution, the additive adopts zinc oxide (ZnO), the concentration is 8g / L, compound and add CMC The solubility is 10-10000mg / L. The preparation method of the electrolyte is as follows: configure a sodium hydroxide solution with a concentration of 4mol / L, cool to room temperature, add 8g / LZnO, after completely dissolving, add CMC, and stir to dissolve.

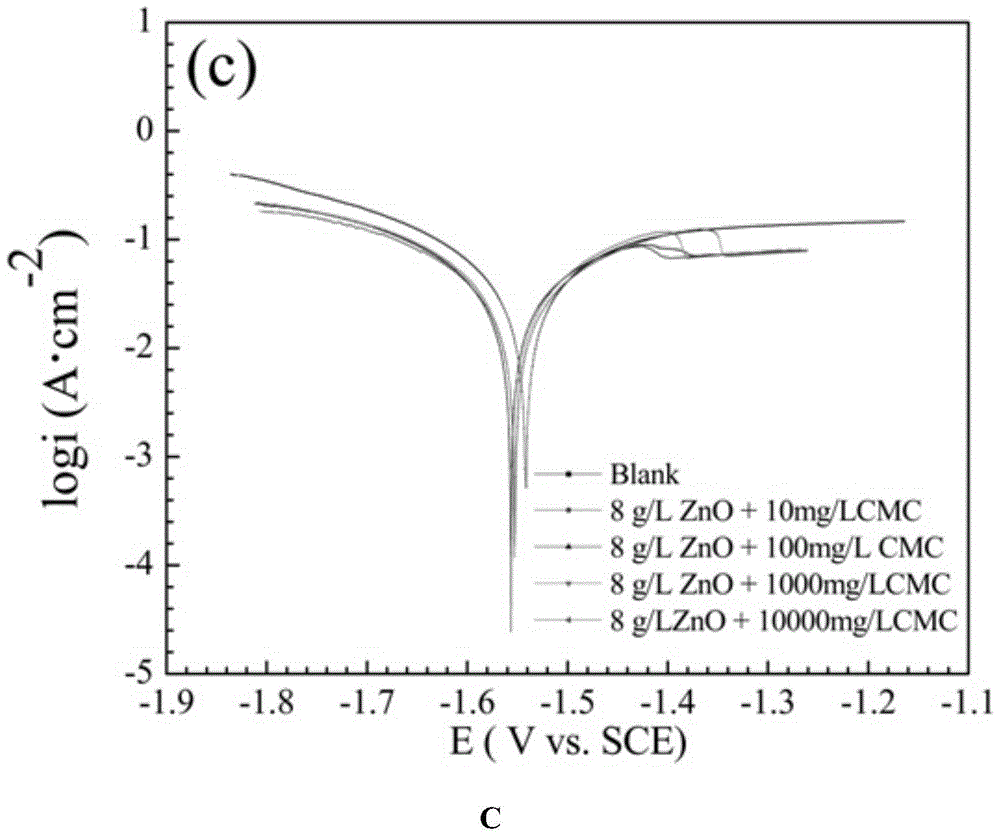

[0034]The hydrogen evolution corrosion rate of the AA5052 aluminum alloy anode in the electrolyte prepared in this example was tested by the collected gas method, and the test time was 30 minutes. The results are shown in Table 1. The polarization curve and AC impedance of the AA5052 aluminum alloy anode in the above-mentioned electrolyte were tested by electrochemical testing, and the results are shown in Table 2, figure 1 (c) and figure 2 (c), the temperature is controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com