Multi-element alloy for making lead acid accumulator plate grid

A lead-acid battery, multi-component alloy technology, applied in the direction of electrode carrier/current collector, etc., can solve problems such as unsatisfactory results, and achieve the effects of low cost, good corrosion resistance, and improved corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

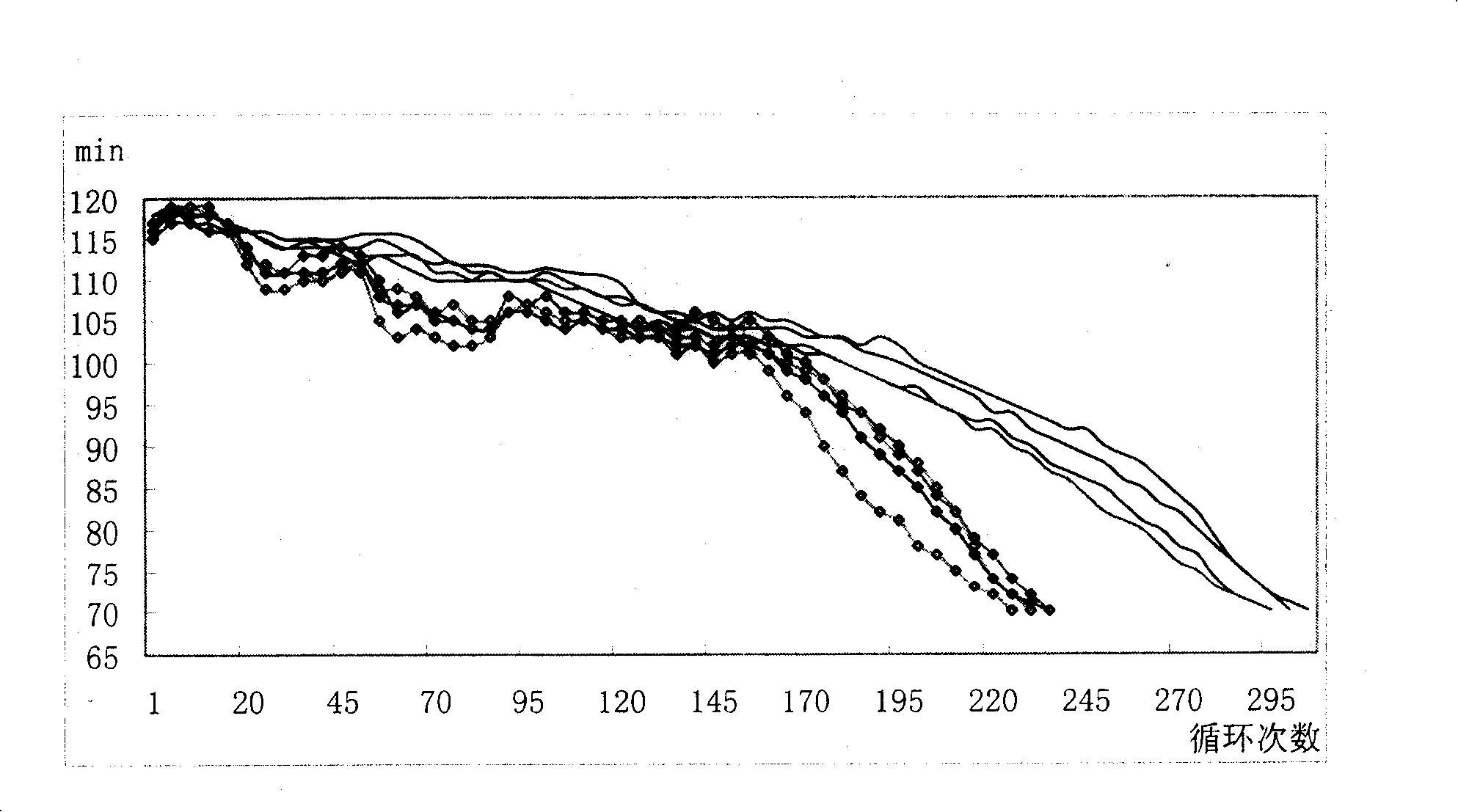

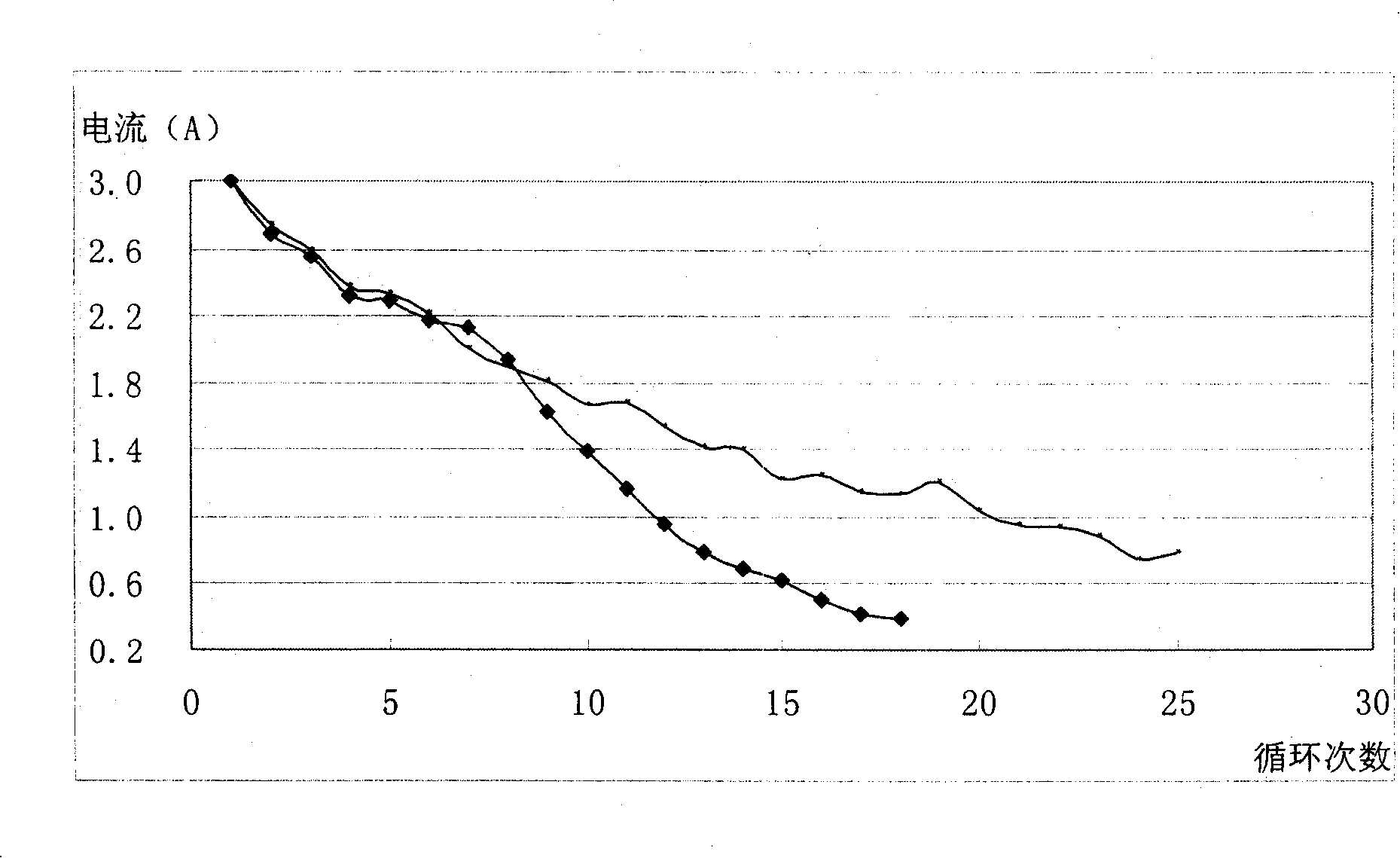

Embodiment 1

[0016] 1. Battery preparation

[0017] The Pb-Ca-Sn-Al quaternary master alloy is quantitatively put into the molten Zhuye No. 1 electrolytic lead to prepare a Pb-Ca-Sn-Al quaternary application alloy. The mass percentages of each component of the alloy are as follows: Ca 0.064%; Sn 1.224%; Al 0.018%, the rest is No. 1 electrolytic lead. A grid A is cast from this alloy.

[0018] On the basis of the above alloys, pure bismuth grains were put into quantitative analysis to prepare a Pb-Ca-Sn-Al-Bi five-element alloy. The mass percentages of the alloy components were: Ca 0.064%; Sn 1.224%; Al 0.018% , Bi 0.094%; the rest is No. 1 electrolytic lead. The bismuth-containing grid B is cast from the alloy.

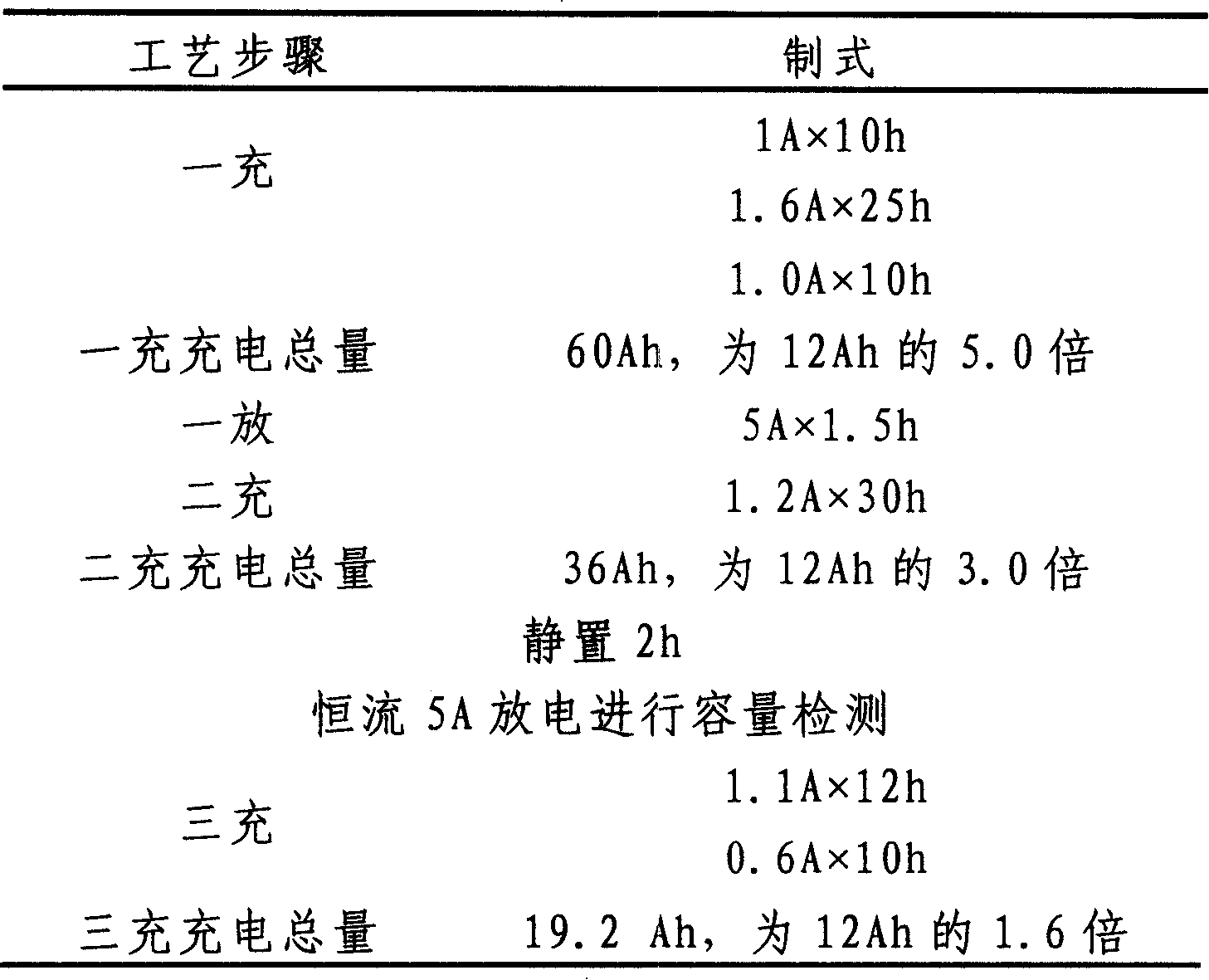

[0019] The above-mentioned alloy composition is the average value of the actual analysis results of three consecutive samples of the prepared alloy on the ARL4460-433 atomic direct-reading emission spectrometer produced by Swiss ARL Company. After the grid is cast, it is age h...

Embodiment 2

[0041] Change the mass percentage content of each component of grid A to Ca 0.096%; Sn 0.084%; Al 0.032%; the rest is No. 1 electrolytic lead, and the mass percentage content of each component of grid B is changed to Ca 0.096%; Sn 0.084%; Al 0.032%; Bi 0.085%; the rest is No. 1 electrolytic lead, and the battery preparation and test effect comparison are consistent with Example 1.

Embodiment 3

[0043] Change the mass percentage content of each component of grid A to Ca 0.11%; Sn 1.4%; Al 0.022%; the rest is No. 1 electrolytic lead, and the mass percentage content of each component of grid B is changed to Ca 0.11%; Sn 1.4%; Al 0.022%; Bi 0.12%; the rest is No. 1 electrolytic lead, and the preparation and test effect comparison of the battery are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com