Preparation method of titanium/tilox black/lead composite substrate

A titanium oxide, composite substrate technology, applied in lead-acid batteries, electrode carriers/current collectors, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

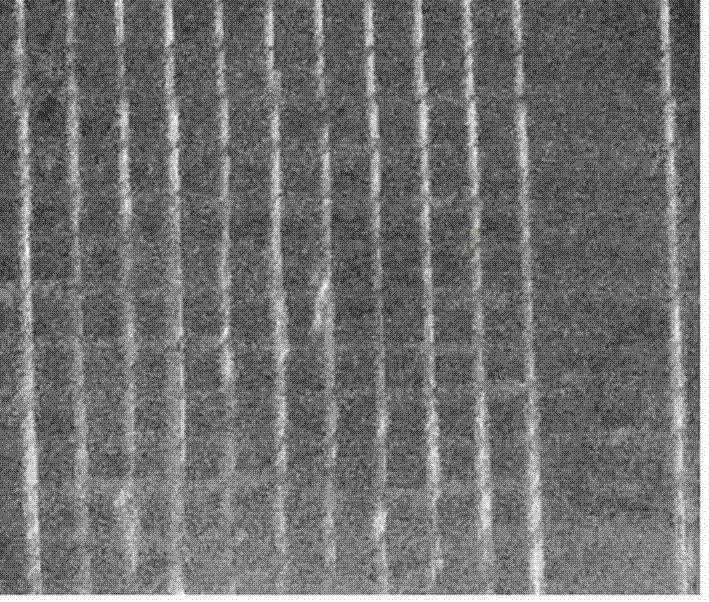

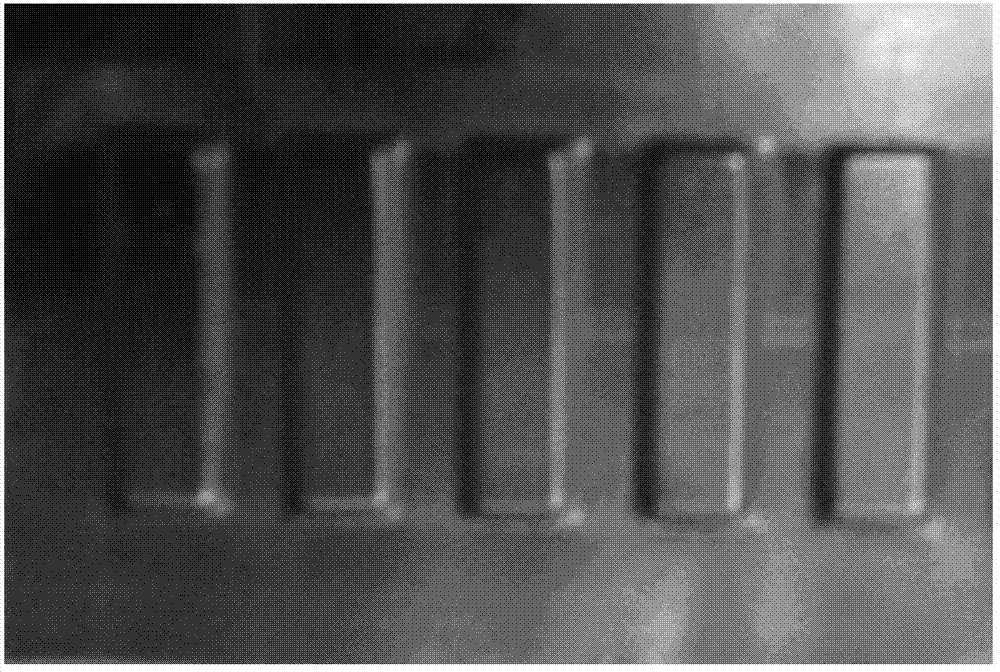

[0025] The preparation method of the titanium / titanium oxide / lead composite substrate of the present invention comprises the following steps:

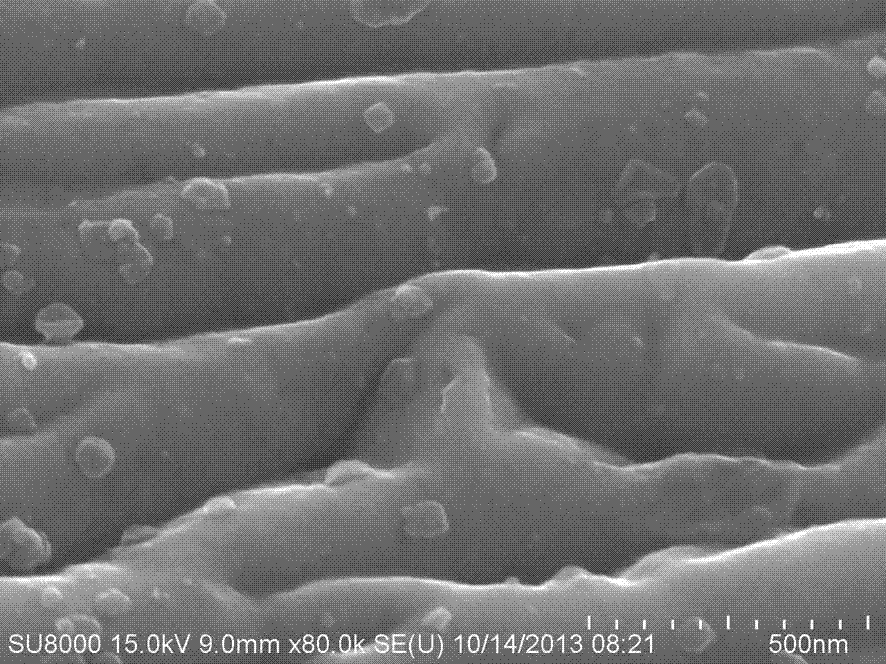

[0026] Step 1, pretreat the titanium plate, ultrasonically oscillate the titanium plate in acetone for 1-3 min to remove the oil on the surface of the titanium plate; clean the titanium plate cleaned with acetone in distilled water, and clean the cleaned titanium plate Immerse in the mixed solution of hydrofluoric acid, nitric acid and hydrogen peroxide for 1 to 3 minutes to remove the oxide layer on the surface of the titanium plate; wash the titanium plate with the surface oxide layer removed with distilled water, and then engrave it with oxalic acid solution at 85 to 95 °C etched for 2 to 3 hours, and dried in vacuum to obtain a titanium plate with a roughened surface, which can enhance the bonding force with the sintered titanium oxide layer; wherein, the thickness of the titanium plate is 0.05-1 mm; the concentration of hydrofluori...

Embodiment 1

[0032] The preparation method of the titanium / titanium oxide / lead composite substrate of the present invention comprises the following steps:

[0033] Step 1, after degreasing and washing the titanium plate, immerse it in 40ml / L of 42% HF and 65% HNO 3 50ml / L and 30% H by mass 2 o 2Etch in 100 ml / L mixed solution for 2 minutes to remove the oxide layer on the surface of the titanium plate; after washing with distilled water, etch with 15% oxalic acid solution at 95°C for 2 hours to obtain a uniform pitted surface.

[0034] Step 2, measure tetrabutyl titanate, absolute ethanol I, and hydrochloric acid solution with a mass percentage of 36% according to the volume ratio of 17:68:2, and fully mix them to obtain the first solution; add a certain amount of glucose to the In the water ethanol II, obtain the second solution, the addition molar quantity of glucose is equal to the addition molar quantity of tetrabutyl titanate; While stirring, the second solution is added in the fir...

Embodiment 2

[0038] The preparation method of the titanium / titanium oxide / lead composite substrate of the present invention comprises the following steps:

[0039] Step 1, after degreasing and washing the titanium plate, immerse it in 60ml / L of HF with a mass percentage of 42% and HNO with a mass percentage of 65% 3 80ml / L and 30% H by mass 2 O 2 The 150 ml / L mixed solution was etched for 3 minutes to strongly remove the oxide layer on the surface of the titanium plate; after washing with distilled water, it was etched with 15% oxalic acid solution at 85°C for 2 hours to obtain a uniform pitted surface.

[0040] Step 2, measure tetrabutyl titanate, absolute ethanol I, and hydrochloric acid solution with a mass percentage of 36% according to the volume ratio of 17:68:3, and fully mix them to obtain the first solution; add a certain amount of citric acid In absolute ethanol II, the second solution is obtained, wherein the molar amount of citric acid is equal to the molar amount of tetrab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com