Electrolyte for super lead acid battery

A super lead-acid battery and electrolyte technology, applied in the direction of lead-acid batteries, etc., can solve the problems of increasing battery cost and complicated process, and achieve the effects of greatly suppressing hydrogen evolution, increasing hydrogen evolution overpotential, and increasing hydrogen evolution impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 100ppmPb(NO 3 ) 2 and 0.1g / L citric acid to make electrolyte.

[0029] Prepare activated carbon, conductive agent, and adhesive (PVDF) according to the ratio of 8:1:1. After fully grinding in the mortar for 30 minutes, add the solvent NMP to continue grinding for a period of time, and then apply the mixed slurry on the current collector. pressed into a pole plate, and dried to obtain an activated carbon negative electrode.

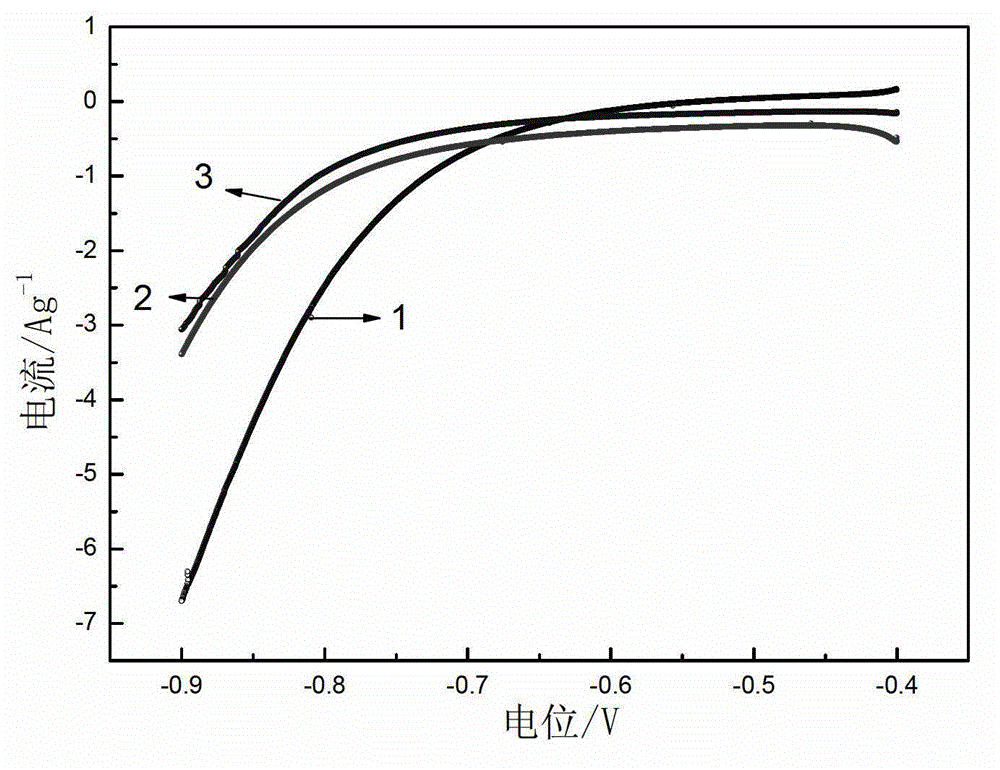

[0030] Assemble a super lead-acid battery, use the carbon electrode as the working electrode, and the saturated calomel electrode as the reference electrode, and investigate the hydrogen evolution characteristics of the activated carbon electrode in the range of -0.9~-0.4V at a scanning speed of 10mV / s. Compared with ordinary electrolyte super batteries, the hydrogen evolution of the carbon negative electrode of the new electrolyte super lead-acid battery is reduced by 10%-20%.

Embodiment 2

[0032] Add 100ppmPb(NO 3 ) 2 , 20g / LZnSO 4 And 5g / L citric acid to make electrolyte.

[0033] Prepare activated carbon, conductive agent, and adhesive (PVDF) according to the ratio of 8:1:1. After fully grinding in the mortar for 30 minutes, add the solvent NMP to continue grinding for a period of time, and then apply the mixed slurry on the current collector. pressed into a pole plate, and dried to obtain an activated carbon negative electrode.

[0034] Assemble a super lead-acid battery, use the carbon electrode as the working electrode, and the saturated calomel electrode as the reference electrode, and investigate the hydrogen evolution characteristics of the activated carbon electrode in the range of -0.9~-0.4V at a scan rate of 10mV / s. Compared with ordinary electrolyte super batteries, the new electrolyte super lead-acid battery carbon negative electrode hydrogen evolution is reduced by about 20%.

Embodiment 3

[0036] Add 100ppmBi in 5M sulfuric acid 2 o 3 , 100ppmPb(NO 3 ) 2 , 1g / LZnSO 4 And 5g / L citric acid to make electrolyte.

[0037]Prepare activated carbon, conductive agent, and adhesive (PVDF) according to the ratio of 8:1:1. After fully grinding in the mortar for 30 minutes, add the solvent NMP to continue grinding for a period of time, and then apply the mixed slurry on the current collector. pressed into a pole plate, and dried to obtain an activated carbon negative electrode.

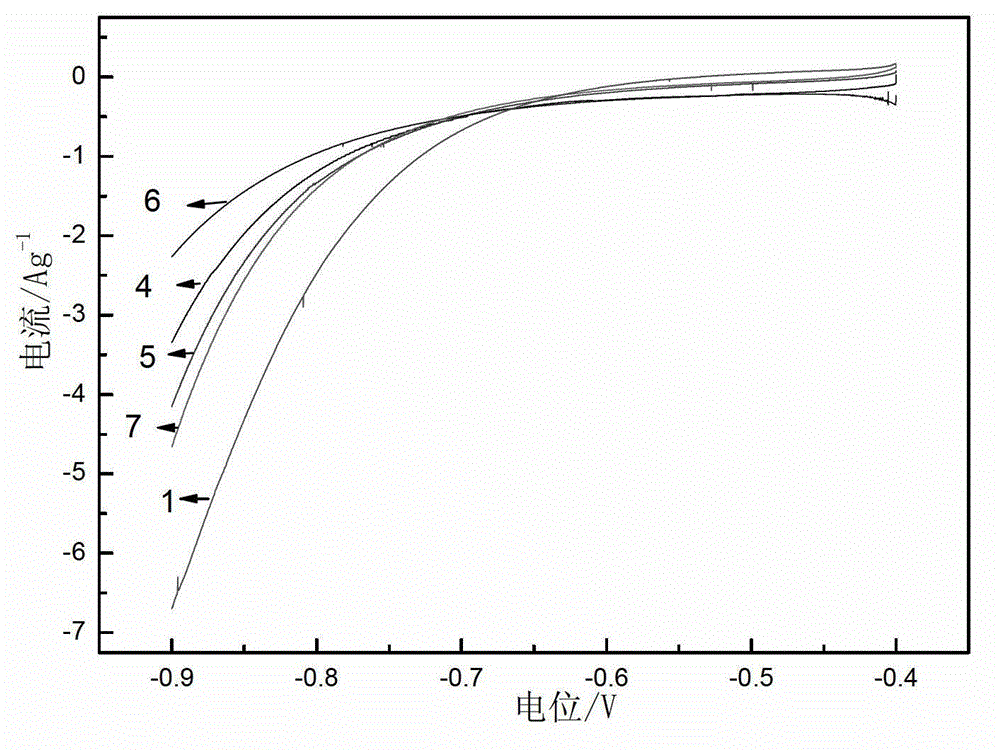

[0038] Assemble a super lead-acid battery, use the carbon electrode as the working electrode, and the saturated calomel electrode as the reference electrode, and investigate the hydrogen evolution characteristics of the activated carbon electrode in the range of -0.9~-0.4V at a scanning speed of 10mV / s. Compared with ordinary electrolyte super batteries, the new electrolyte super lead-acid battery carbon negative electrode hydrogen evolution is reduced by 50%-60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com