Lithium metal battery negative electrode surface modification method

A technology for lithium metal batteries and negative electrodes, which is applied in the field of modification of the negative electrode surface of lithium metal batteries, can solve the problems of inability to induce uniform nucleation of lithium, poor lithophilicity, etc., and achieve improved electrochemical performance, improved cycle performance, and uniform current density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for modifying the negative electrode surface of a lithium metal battery, comprising the following steps:

[0023] 1) Weigh lithium bromide and lithium nitrate in proportion, dissolve them in tetraethylene glycol dimethyl ether solvent, seal them with plastic wrap and place them in a glove box at room temperature (H 2 O, O 2 All less than 0.01ppm) Stir evenly to obtain a clear and transparent polishing electrolyte;

[0024] 2) Assemble the lithium symmetric battery. During the assembly process, add the polished electrolyte obtained in step 1) into the lithium symmetric battery to wet the diaphragm;

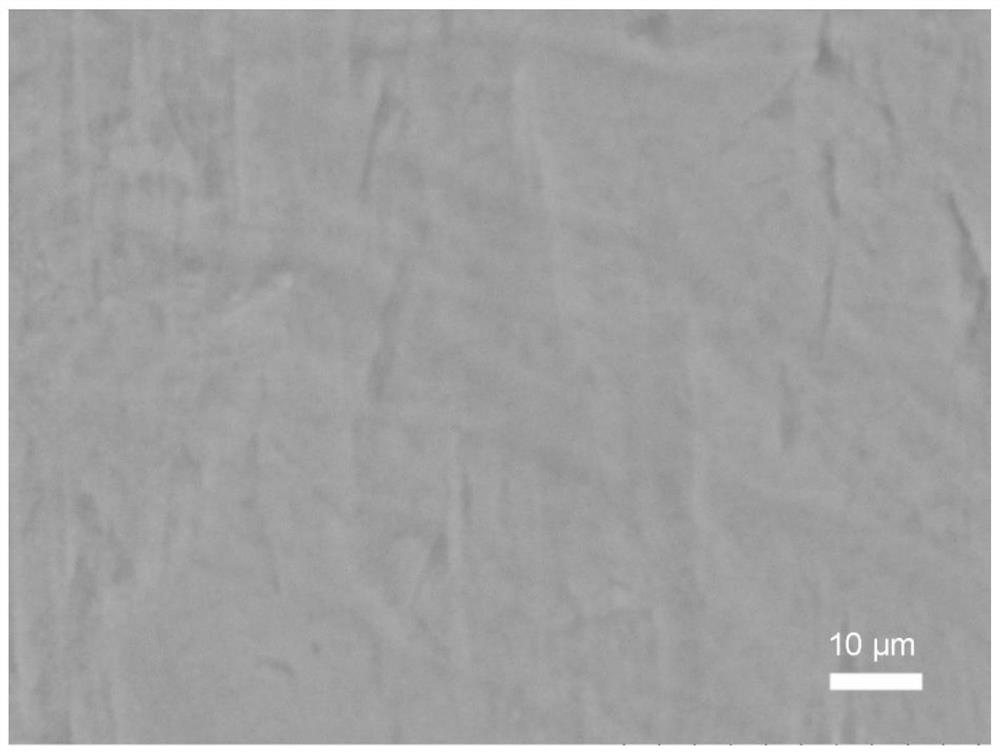

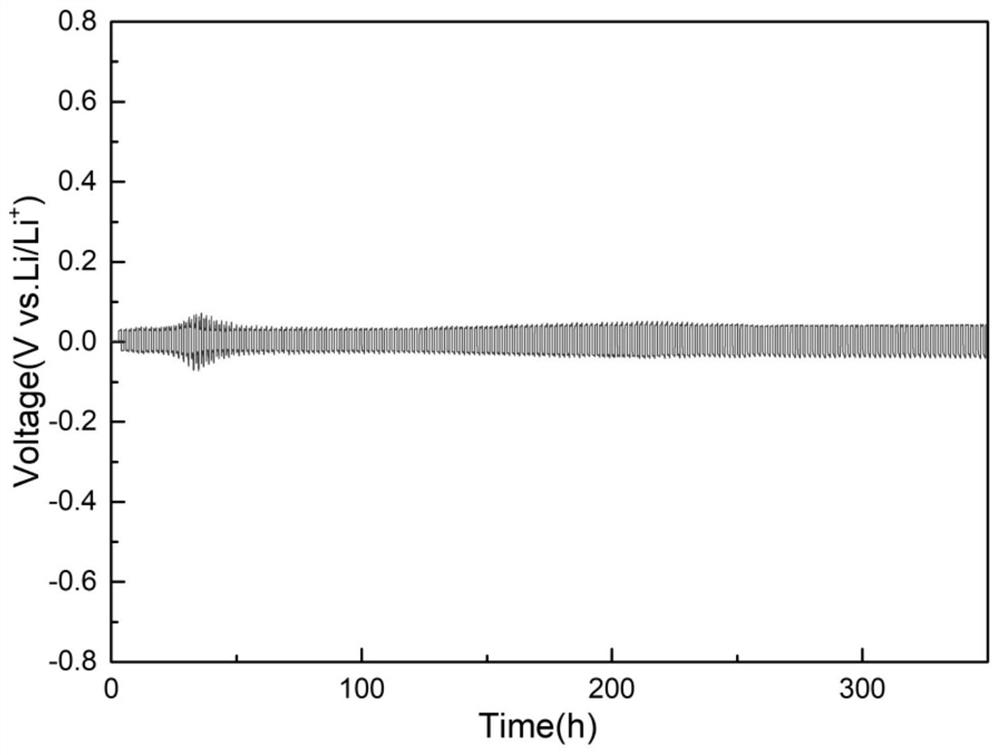

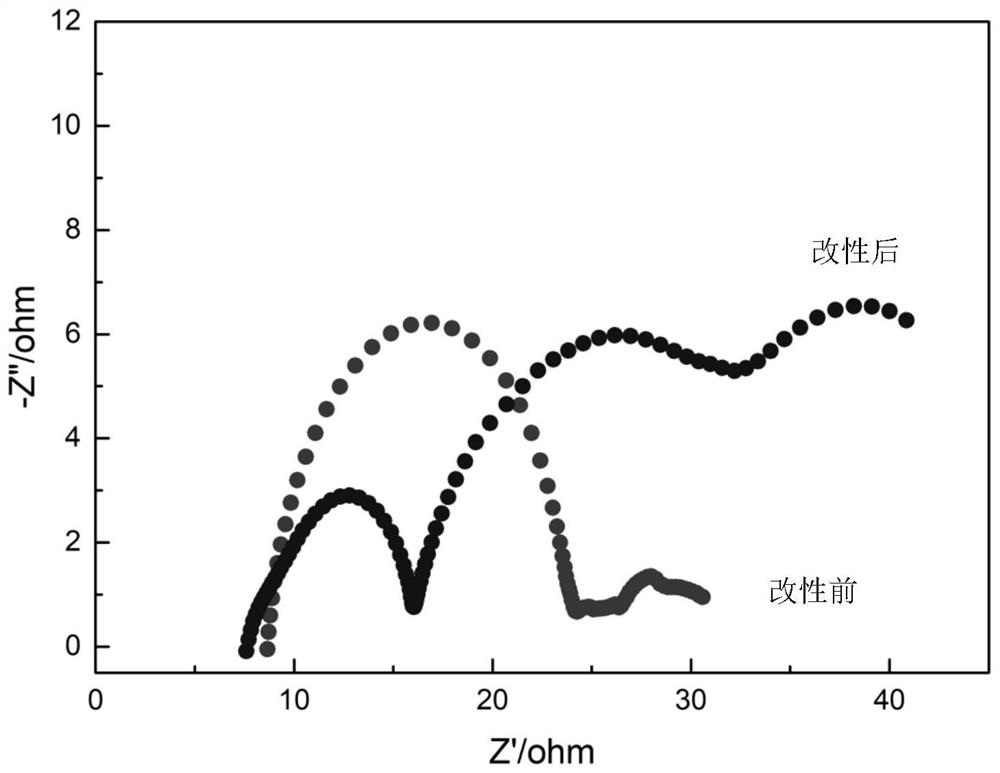

[0025] 3) Discharge the lithium symmetric battery assembled in step 2) at the set current density and discharge time, polish the surface of the negative electrode, and disassemble the lithium symmetric battery after completion to obtain the modified lithium metal (negative electrode );

[0026] 4) The lithium metal modified in step 3) is used in the subsequent ba...

Embodiment 2

[0031] A method for modifying the negative electrode surface of a lithium metal battery, comprising the following steps:

[0032] 1) Weigh 0.25mmol (0.0217g) lithium bromide (LiBr) and 5mmol (0.3447g) lithium nitrate (LiNO 3 ), dissolved in 5 mL of tetraethylene glycol dimethyl ether (TEGDME), sealed with plastic wrap and stirred at room temperature for 2 hours to obtain a clear and transparent polishing electrolyte.

[0033] 2) Use the CR2032 battery case to assemble a lithium symmetrical battery, put a lithium sheet (d=15.6mm) in the positive electrode case, then put in the PP diaphragm, and then add 50 μL of the polishing electrolyte obtained in step 1) to wet the diaphragm , and then assemble the battery sequentially according to the order of lithium sheet, gasket, shrapnel, and negative electrode shell, and seal the assembled lithium symmetrical battery with a tablet press.

[0034]3) Put the lithium symmetric battery assembled in step 2) at 0.05mA / cm 2 Discharge for 10...

Embodiment 3

[0039] A method for modifying the negative electrode surface of a lithium metal battery, comprising the following steps:

[0040] 1) Weigh 0.15mmol (0.0130g) lithium bromide (LiBr) and 4mmol (0.2758g) lithium nitrate (LiNO 3 ), dissolved in 5 mL of tetraethylene glycol dimethyl ether (TEGDME), sealed with plastic wrap and stirred at room temperature for 2 hours to obtain a clear and transparent polishing electrolyte.

[0041] 2) Use the CR2032 battery case to assemble a lithium symmetrical battery, put a lithium sheet (d=15.6mm) in the positive electrode case, then put in the PP diaphragm, and then add 50 μL of the polishing electrolyte obtained in step 1) to wet the diaphragm , and then assemble the battery sequentially according to the order of lithium sheet, gasket, shrapnel, and negative electrode shell, and seal the assembled lithium symmetrical battery with a tablet press.

[0042] 3) Put the lithium symmetric battery assembled in step 2) at 0.01mA / cm 2 Discharge for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com