Series-parallel combined high-efficient hydrogen oxygen electrolytic bath

An electrolytic cell, hydrogen and oxygen technology, applied in the field of electrolytic cells, can solve the problems of low utilization rate of electrolytic materials, large bypass parasitic current, affecting the life of electrolytic cells, etc., and achieve the effect of consistent life, consistent current density, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

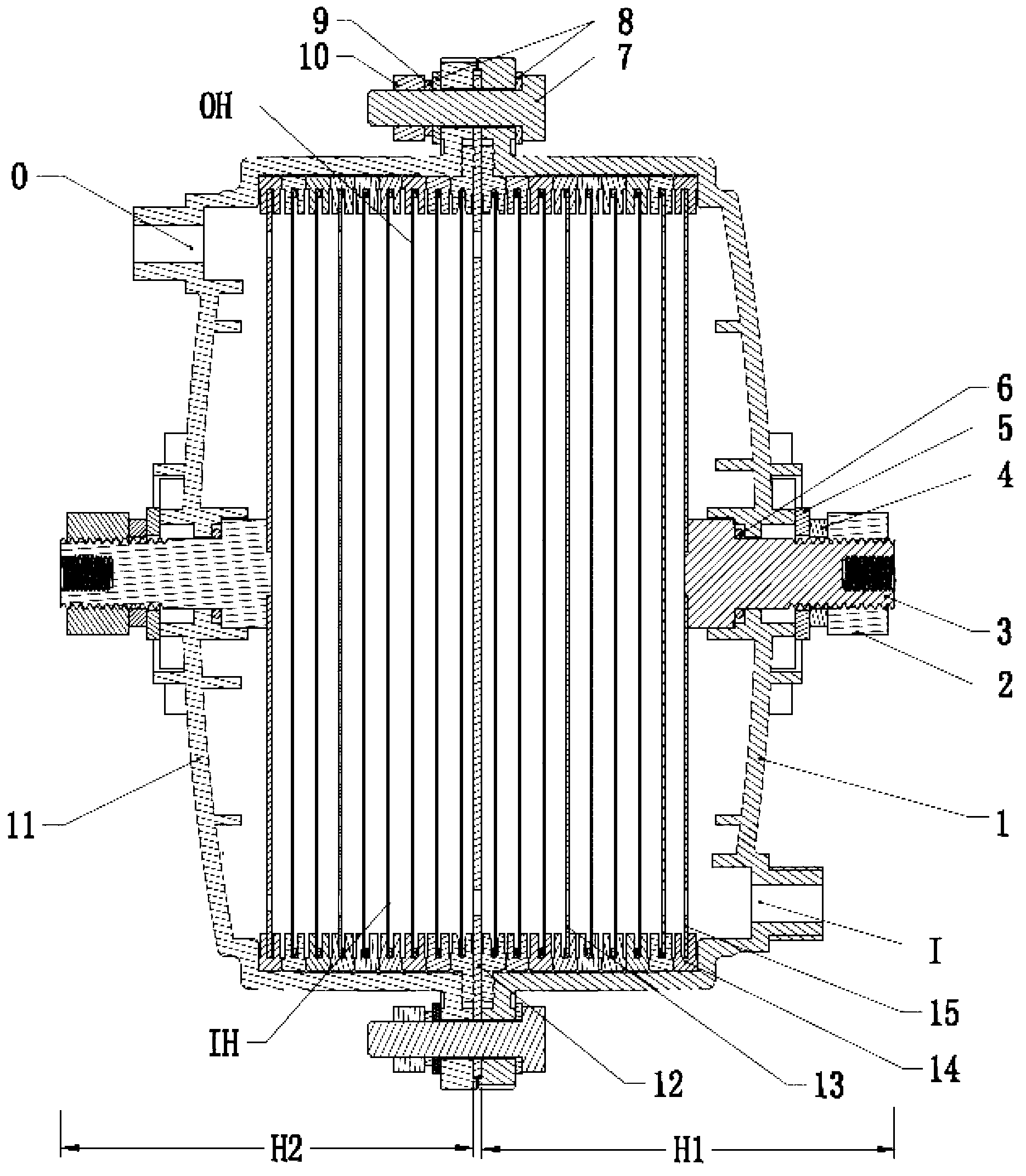

[0015] The present invention is described in detail in conjunction with the accompanying drawings.

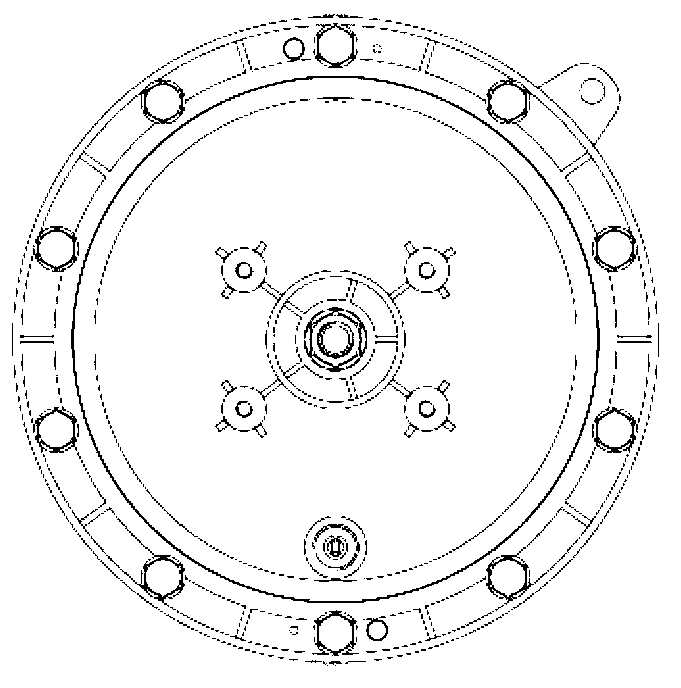

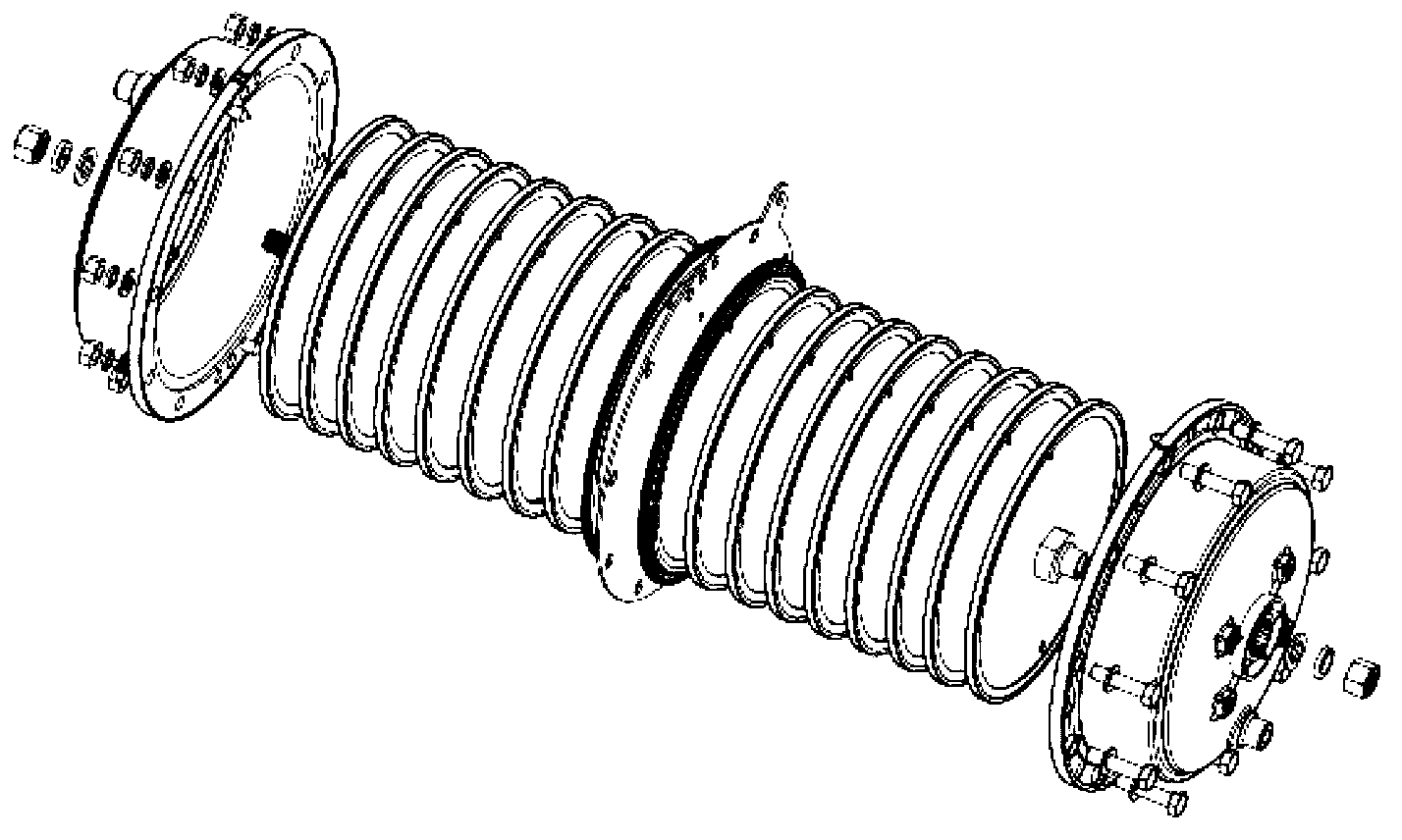

[0016] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes: an electrolytic cell housing (1, 11), a positive electrode plate 12, 16 intermediate electrode plates 13, and two negative electrode plates 15. The electrolytic cell housing is respectively provided with a liquid inlet I and a gas-liquid outlet O , the electrolyzer housing is formed by locking the left housing 11 and the right housing 1 with bolts 7, flat washers 8, spring washers 9 and nuts 10 through screw holes, and the left housing 11 forms a semi-closed left cylinder H2 , the right housing 1 forms a semi-closed right cylinder H1, and the electrolytic cell housing (1, 11) is made of engineering plastics by plastic injection molding; two negative plates 15 have an electrode column as the negative terminal 3 A piece of positive electrode plate 12 is installed at the butt joint of two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com