Contact type array tiny pit electrochemical machining method

A contact and array technology, applied in electrochemical machining equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of poor machining accuracy and localization, and achieve the effect of high speed and high electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

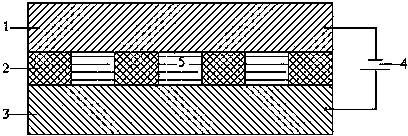

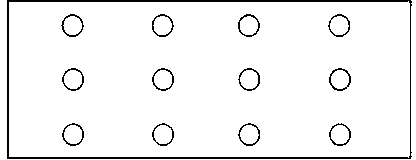

[0033] The implementation of the present invention-"the method of contact electrolytic machining array micro-pits" will be described in detail below in conjunction with the accompanying drawings.

[0034] The present invention adopts the method of contact type electrolytic machining array tiny pits, comprising the following steps:

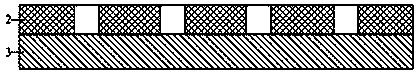

[0035] (a), the photoresist pattern 2 that needs electrolysis is made on the workpiece anode 3 surface by means of a photomask;

[0036] (b), the workpiece anode 3 and the tool cathode 1 are respectively connected to the positive and negative poles of the power supply 4;

[0037] (c), the workpiece anode 3 is immersed in the electrolyte 5;

[0038] (d), the tool cathode 1 is in contact with the photoresist film 2 on the workpiece anode 3;

[0039] (e), switch on the power supply 4 to carry out electrolytic machining.

[0040] The photoresist film on the cathode of the above tool and the anode of the workpiece contacts the micro pits of the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com