Method for electrolytic synthesis of butanedioic acid and fixed bed electrochemical reaction device

A technology for electrolytic synthesis and succinic acid, applied in electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of high investment in production equipment, low electrolysis time-space yield, dripping and other problems, so as to improve cathode utilization rate and reduce electrolysis efficiency. Energy consumption and the effect of reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

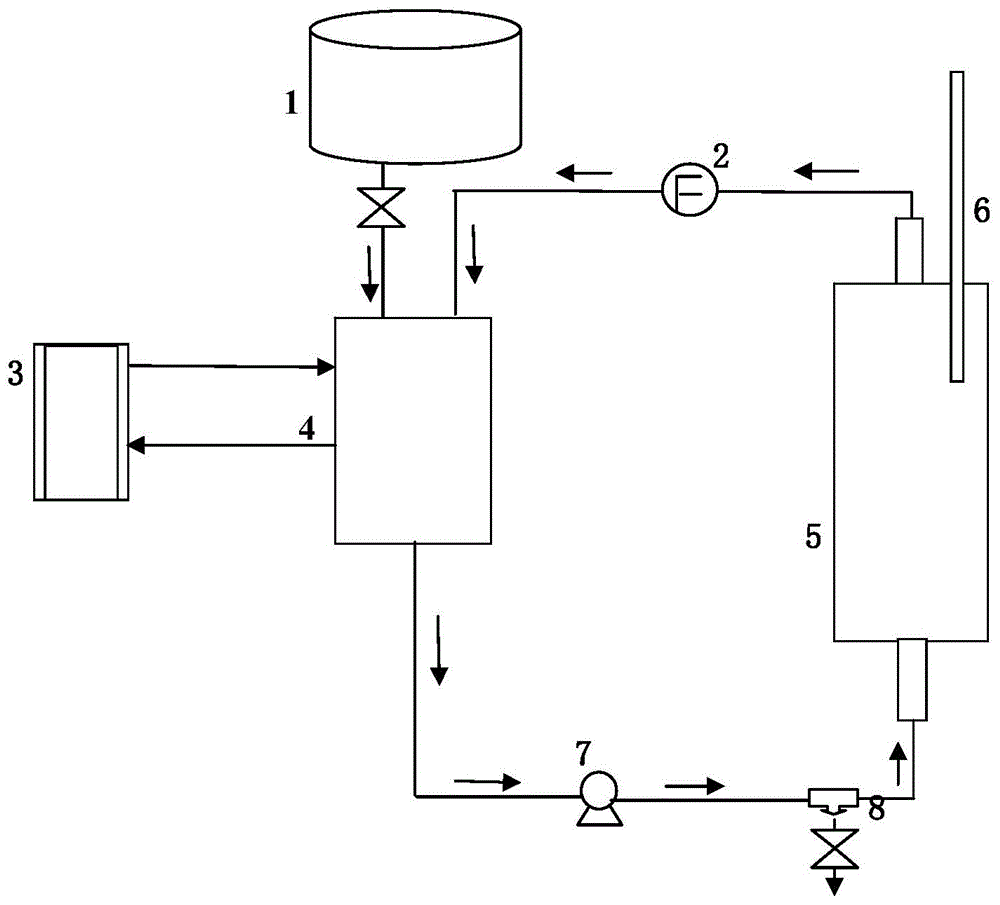

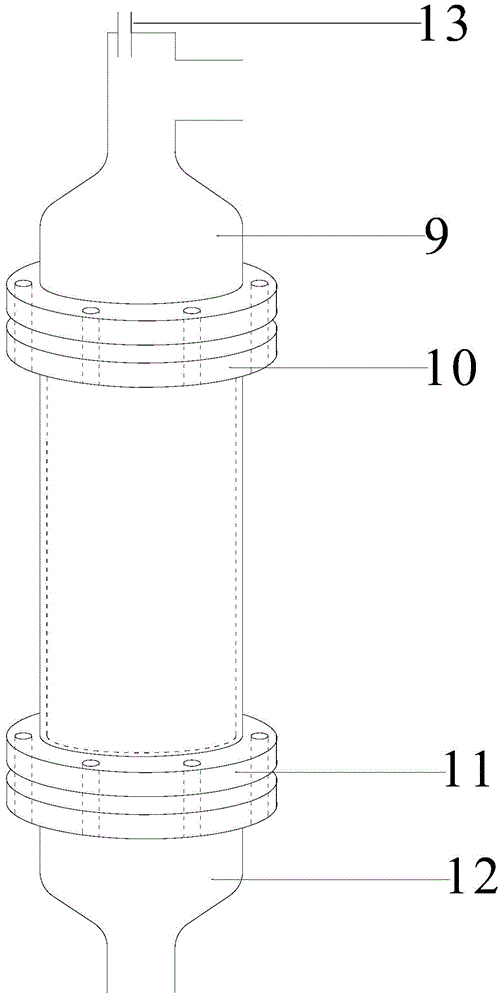

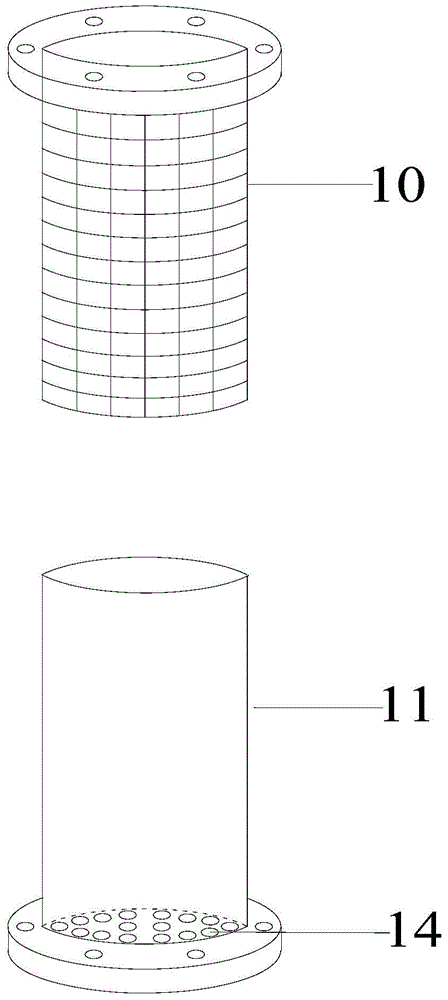

[0032] Example 1 450 g of electrolyte was prepared with deionized water. The initial composition of the electrolyte was 9.8% maleic anhydride mass concentration and 8% sulfuric acid mass concentration. The temperature of the electrolyte is controlled at 50°C; the diameter of the cathode filled titanium pellets is 8mm; the anode current density is 1000A / m 2 , J 阳 / J 阴 =4:1; the electrolysis current flow is 100% of the theoretical electricity. At the beginning of electrolysis, the prepared electrolyte is fed from the high-level liquid storage tank to the circulation tank, and the electrolyte is formed into a closed loop through the magnetic circulation pump. When the temperature is controlled at 50°C, the electrolysis starts. After the electrolysis, the electrolysis solution was placed in the refrigerator, crystallized at 0°C for 75 minutes, filtered, and dried to obtain 38.88g of succinic acid crystals, the purity of succinic acid was 99.68%, the melting point was 184.3°C, an...

Embodiment 2

[0034] The electrolysis device, electrolysis method, electrolysis temperature, current density, initial composition and quality of the electrolyte are the same as in Example 2, and the diameter d of the titanium pellet cathode is 10mm. After the electrolysis, the electrolysis solution was placed in the refrigerator, crystallized at 0°C for 75 minutes, filtered, and dried to obtain 34.42g of succinic acid crystals, the purity of succinic acid was 99.71%, the melting point was 184.6°C, and the electrolysis voltage was 2.7–3.1V. The current efficiency is 64.4%, and the reduction yield of succinic acid is 64.8%.

Embodiment 3

[0036] The electrolysis device, electrolysis method, electrolysis temperature, current density, initial composition and quality of the electrolyte are the same as in Example 2, and the diameter d of the titanium pellet cathode is 6mm. After the electrolysis, the electrolysis solution was placed in the refrigerator, crystallized at 0°C for 75 minutes, filtered, and dried to obtain 39.38g of succinic acid crystals, the purity of succinic acid was 99.57%, the melting point was 184.7°C, and the electrolysis voltage was 2.6–3.0V. The current efficiency is 73.6%, and the reduction yield of succinic acid is 74.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com