Back coating process of titanium anode plate for producing electrolytic copper foils

A technology of titanium anode plate and back coating, which is applied in the coating process of metal materials, electrodes, coatings, etc., can solve the problems of short service life of titanium anode plate, uneven current density, wavy fold of electrolytic copper foil, etc., and achieve The effect of increasing service life, uniform speed and avoiding coating cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

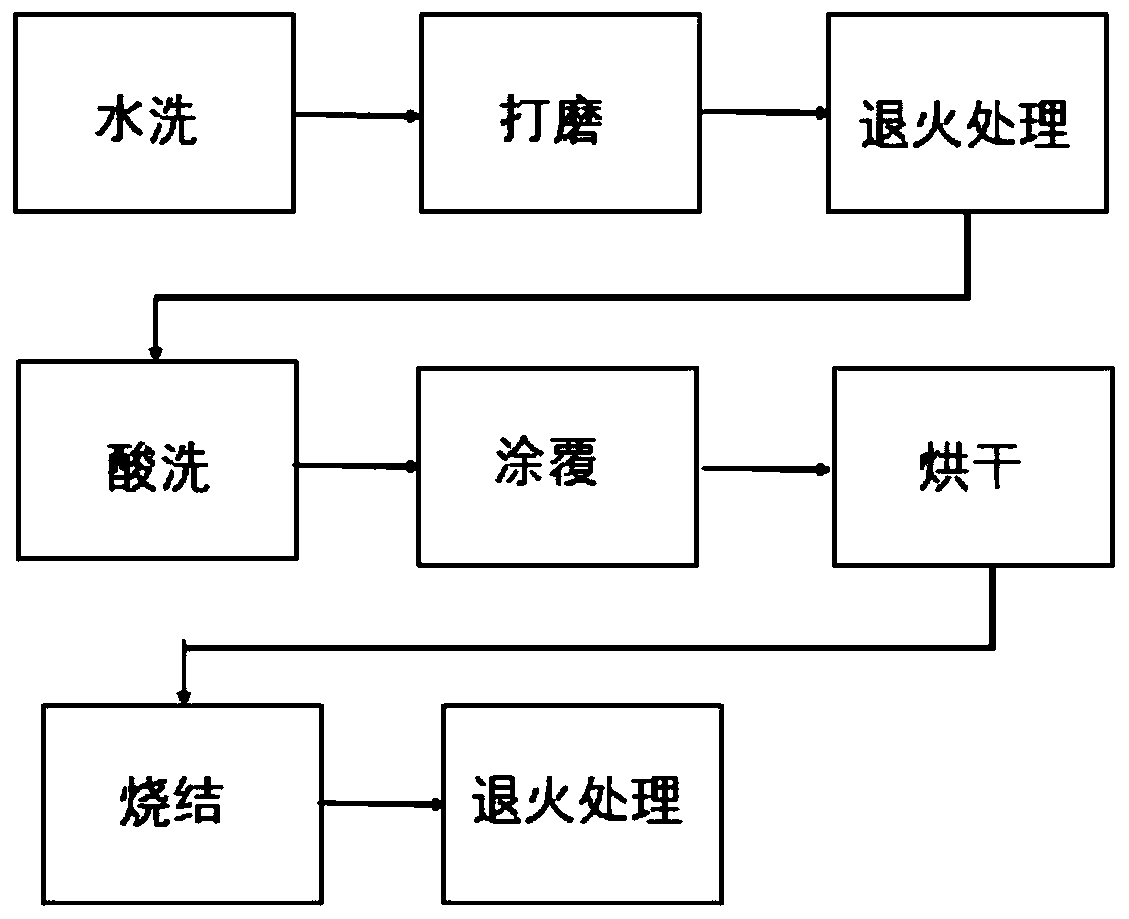

[0060] Example 1 A back coating process for producing titanium anode plates for electrolytic copper foil

[0061] Specifically include the following steps:

[0062] (1) Select a titanium substrate with a smooth surface, good flatness, and no cracks, the length of which is 8m, and the width is 1.5m. The selected titanium substrate is annealed and leveled at a temperature of 500 ° C to obtain Annealed and leveled titanium anode plate;

[0063] (2) The annealed titanium anode plate obtained in step (1) is pickled with 10% oxalic acid for 10 hours. The pickling process is carried out in a boiling state, and finally forms a layer on the surface of the titanium anode. layer of titanium hydride, that is, to obtain the titanium anode plate after pickling;

[0064] (3) Coating a solution of an iridium compound and a tantalum compound with a concentration ratio of 5:1 on the back of the titanium anode plate obtained in step (2), with a coating thickness of 5 μm, to obtain a coated tit...

Embodiment 2

[0071] Example 2 A back coating process for producing titanium anode plates for electrolytic copper foil

[0072] Specifically include the following steps:

[0073] (1) Select a titanium substrate with a smooth surface, good flatness, and no cracks, the length of which is 8m, and the width is 1.5m. The selected titanium substrate is annealed and leveled at a temperature of 600°C to obtain Annealed and leveled titanium anode plate;

[0074] (2) The annealed titanium anode plate obtained in step (1) is pickled with 20% oxalic acid for 10 hours. The pickling process is carried out in a boiling state, and finally forms a layer on the surface of the titanium anode. layer of titanium hydride, that is, to obtain the titanium anode plate after pickling;

[0075] (3) Coating a solution of an iridium compound and a tantalum compound with a concentration ratio of 3.3:1 on the back of the titanium anode plate obtained in step (2), with a coating thickness of 3 μm, to obtain a coated tit...

Embodiment 3

[0082] Example 3 A back coating process for producing titanium anode plates for electrolytic copper foil

[0083] Specifically include the following steps:

[0084] (1) Select a titanium substrate with a smooth surface, good flatness, and no cracks, the length of which is 8m, and the width is 1.5m. The selected titanium substrate is annealed and leveled at a temperature of 550°C to obtain Annealed and leveled titanium anode plate;

[0085] (2) The annealed titanium anode plate obtained in step (1) is pickled with 15% oxalic acid for 15 hours. layer of titanium hydride, that is, to obtain the titanium anode plate after pickling;

[0086] (3) Coating a solution of an iridium compound and a tantalum compound with a concentration ratio of 3:1 on the back of the titanium anode plate obtained in step (2), with a coating thickness of 3 μm, to obtain a coated titanium anode plate;

[0087] (4) Place the back of the coated titanium anode plate obtained in step (3) on a sintering fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com