Common-current collector plate group with positive plates opposite to negative plates and common-current collector module battery

A technology of positive and negative pole pieces and fluid modules, which is applied in the field of positive and negative pole pieces facing common collector fluid plate groups and common fluid module batteries, which can solve the problem of battery manufacturing yield, battery service life, battery pole piece and battery life. It is difficult to ensure the consistency of the unit, the number of connected parts of the battery pack is large, and the charge and discharge efficiency is reduced, so as to improve the adaptability to high temperature environment, shorten the battery life, and improve the high current charge and discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, combining detailed implementation methods and specific operating procedures, but the scope of protection of the present invention is not limited to the following Example.

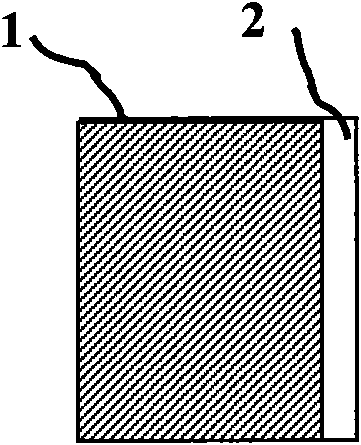

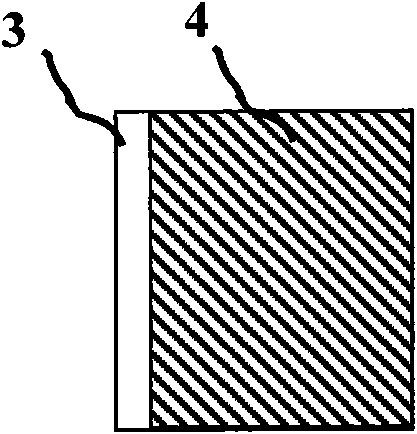

[0031] Such as Figure 1 to Figure 6As shown, the present embodiment relates to a positive and negative plate opposite common current collector electrode plate group, including a number of positive plates 1, negative plates 4 and current collectors 6 in which the number of positive plates 1 is increased by one, and the positive plate 1 has a Conductive substrate exposed segment 2, negative electrode sheet 4 has conductive substrate exposed segment 3 at one end thereof, and the conductive substrate exposed segment 2 of all positive electrode sheets 1 is connected to one side of current col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com