Light emitting diode

一种电极、LED芯片的技术,应用在半导体器件、电气元件、电路等方向,能够解决非均匀电流密度、电流密度高等问题,达到均匀密度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

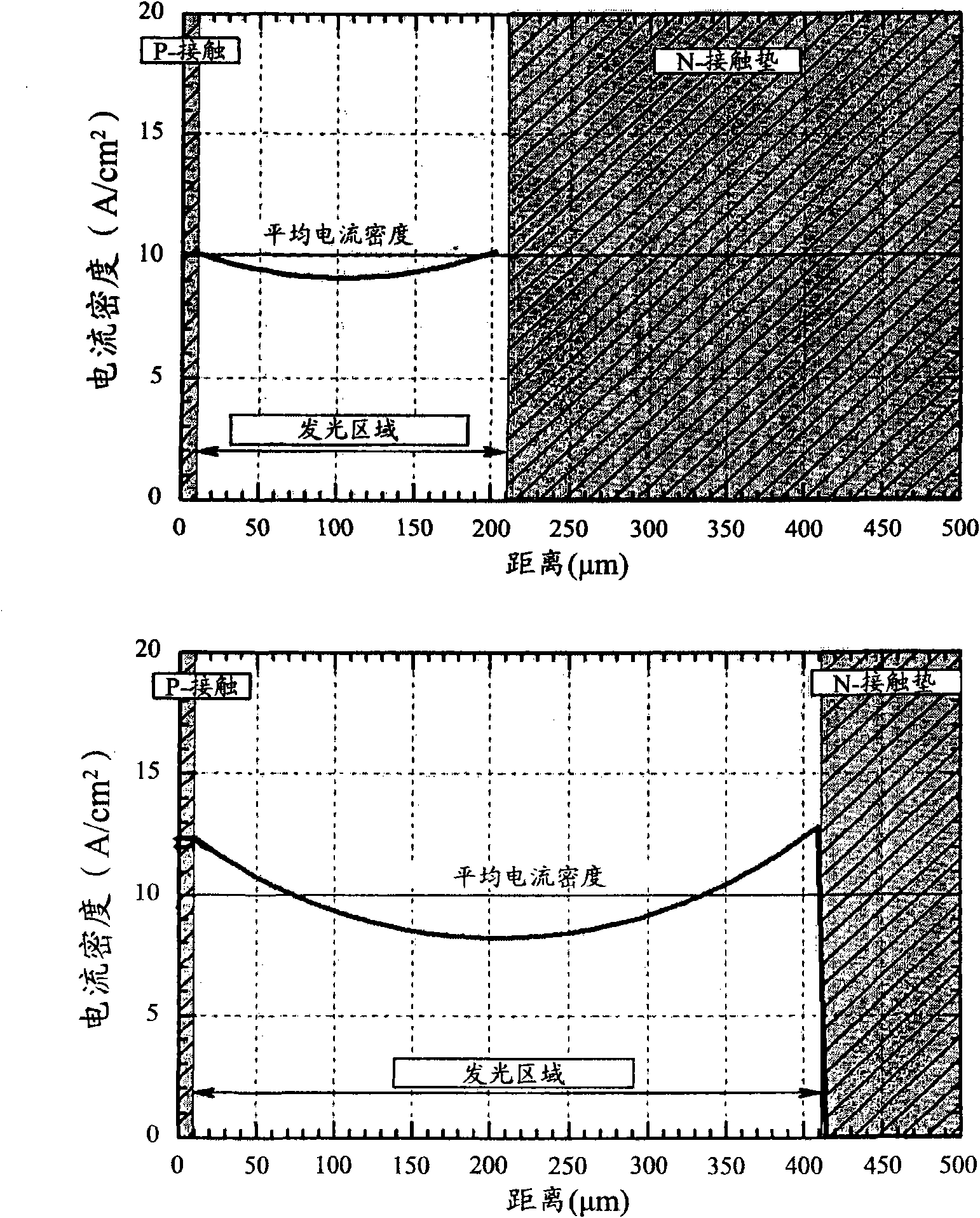

[0019] figure 1 The calculated current densities in linear LED chips with lengths of 200 μm (upper graph) and 400 μm (lower graph) are shown. The current spreading length was 200 μm in both cases. As seen in the figure, the current density is non-uniform in both cases due to the large horizontal dimension relative to the current spreading length, with the uniformity becoming higher with increasing chip length. In the second case it can be seen that the current density is far from uniform.

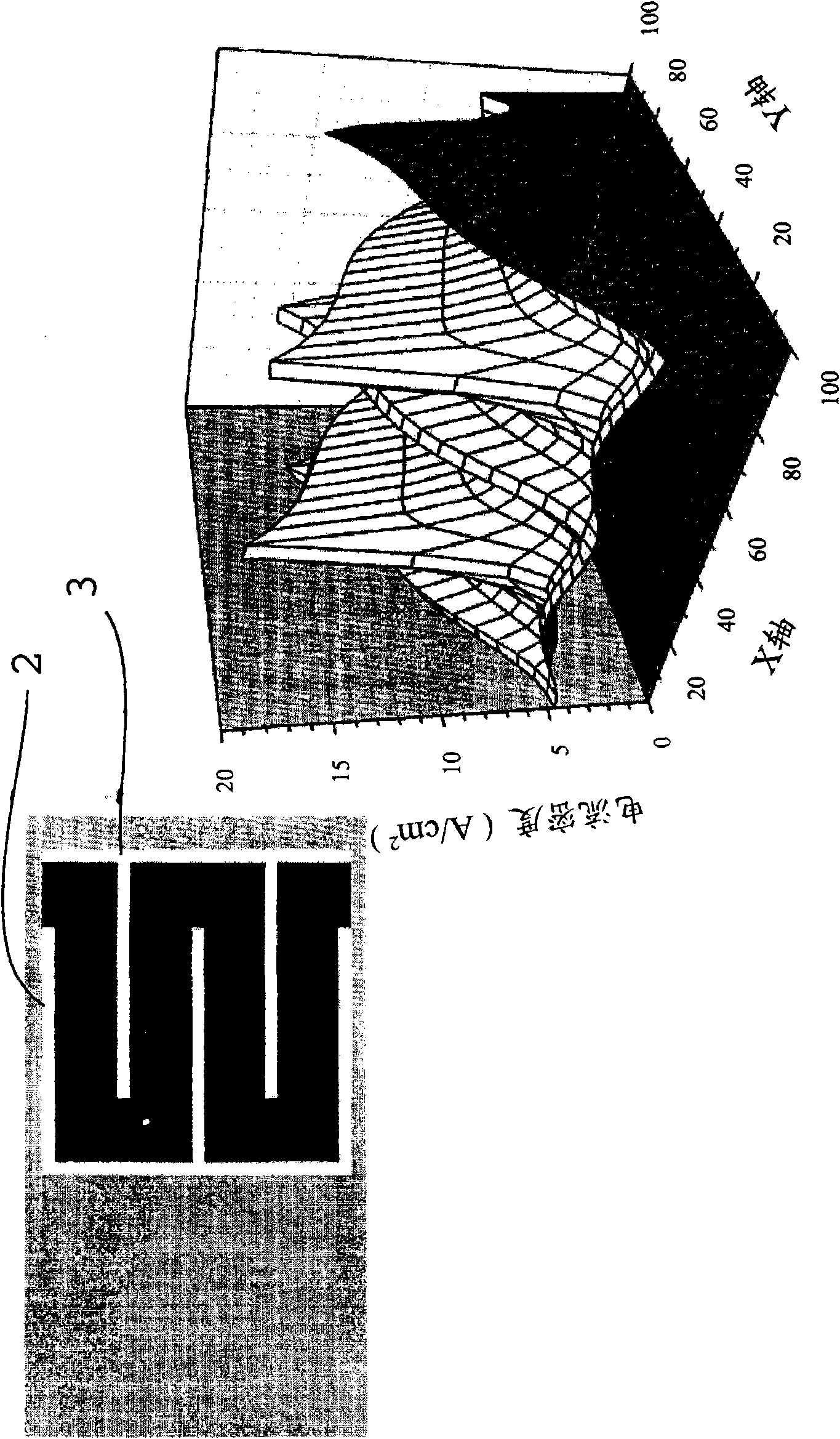

[0020] figure 2 The interdigitated electrodes 2, 3 of the LED design are arranged to provide a distance between electrodes that is less than the current spreading length. Nevertheless, as in figure 2 As seen in the graph of , the current density over the chip area is very inhomogeneous with very strong local maxima at the ends of the electrodes' finger-like protrusions.

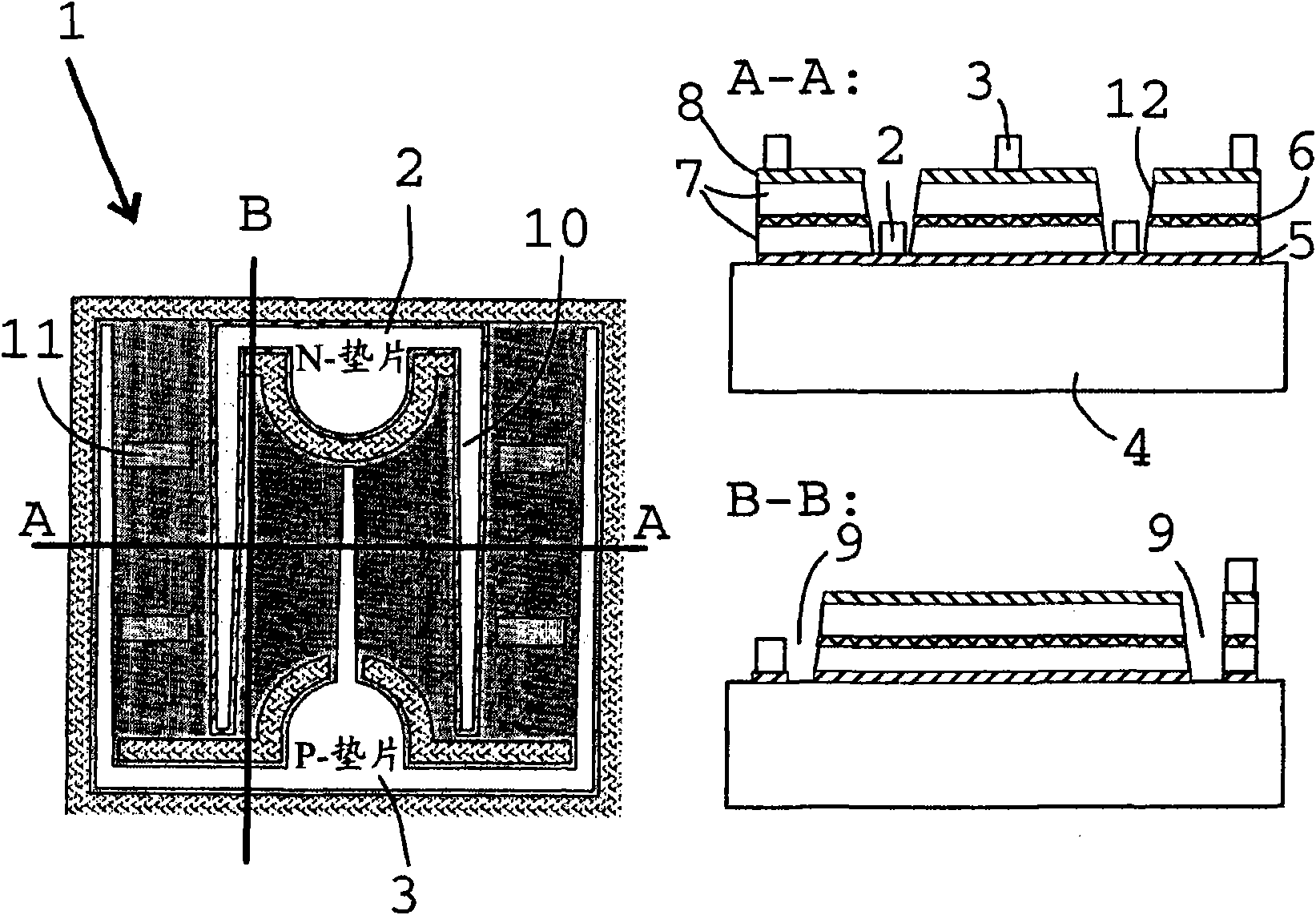

[0021] exist image 3 In the LED chip 1 of , the first electrode 2 and the second electrode 3 establish a modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com