Reliable method for inspecting and researching HIC (hydrogen-induced cracking) sample cracks

A crack and reliable technology, which is applied in the preparation of test samples, material inspection products, test metals, etc., can solve the problems of inability to judge the source of cracks and ensure the reliability of HIC crack research, and achieve the effect of avoiding missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0051] Taking X52MS acid-resistant pipeline steel as the detection object, the chemical composition of the test coil C: 0.05; Si: 0.24; Mn: 1.14; P: 0.009; S: 0.0008; Cr: ≤0.30; Cr+Cu: 0.29; Cr+Mo+Mn: 1.37; the rest is Fe, of which CEpcm: 0.19; Ceq: 0.30; the wall thickness of the steel pipe is 12mm. The HIC test procedure of the X52MS steel grade LSAW pipe in this embodiment is as follows:

[0052] 1. Processing HIC samples.

[0053] 1.1 Sample size;

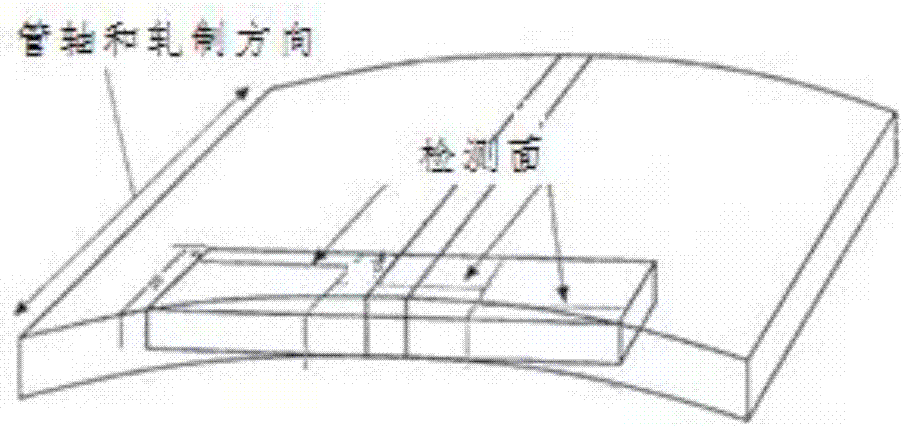

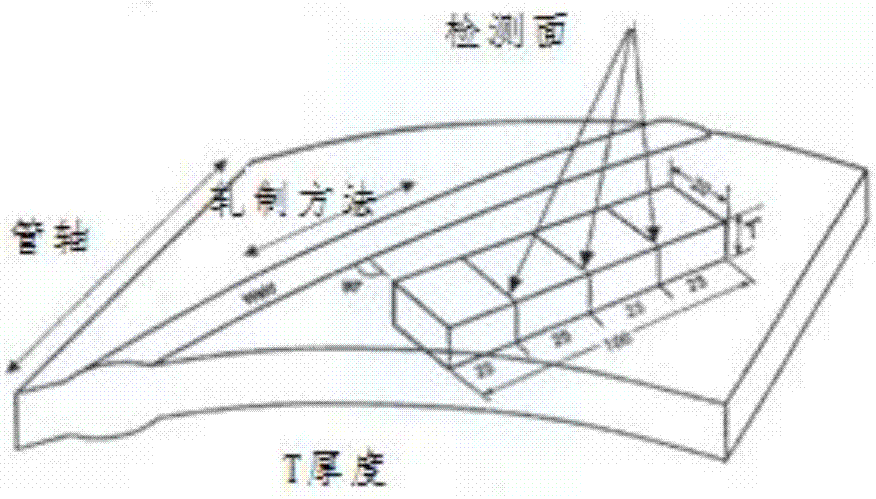

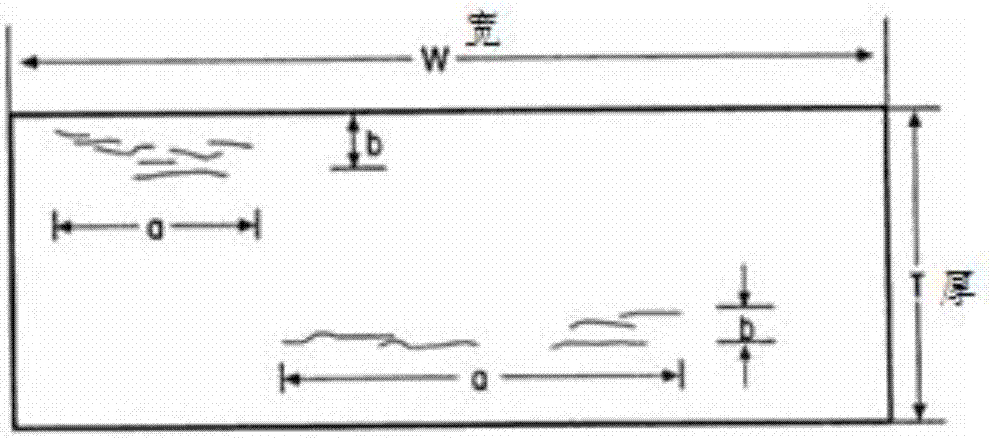

[0054] It shall be 100 ± 1 mm long and 20 ± 1 mm wide, and the wall thickness of the specimen shall be the entire wall thickness of the pipe, up to 30 mm. A maximum of 1 mm is allowed to be removed from the inner and outer surfaces, and the specimen blank shall not be leveled. For small diameter, thin wall electric resistance welded pipe and seamless line pipe, the thickness of the test pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com