Patents

Literature

171 results about "Concurrent testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Research and literature on concurrency testing and concurrent testing typically focuses on testing software and systems that use concurrent computing. The purpose is, as with most software testing, to understand the behaviour and performance of a software system that uses concurrent computing, particularly assessing the stability of a system or application during normal activity.

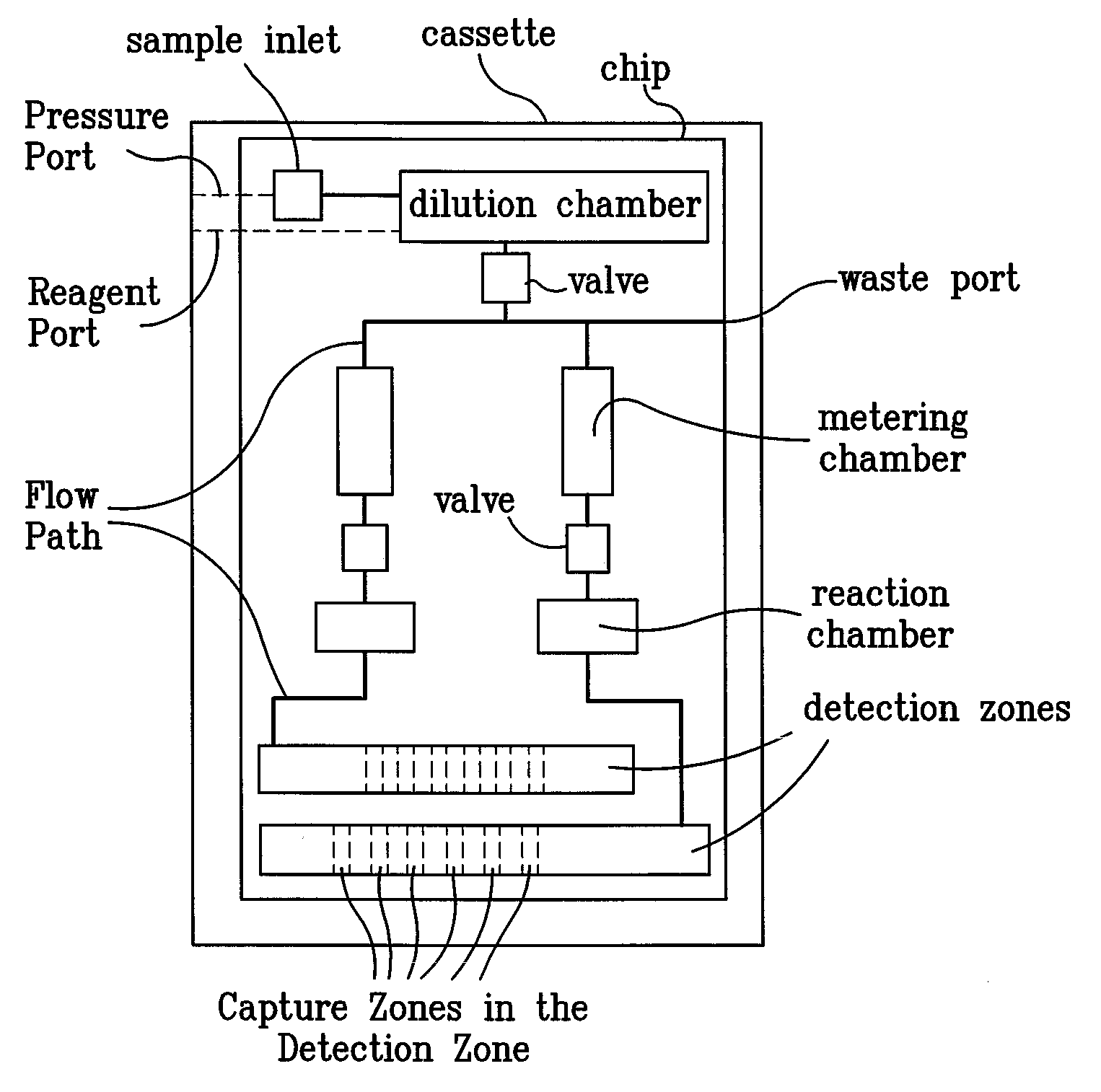

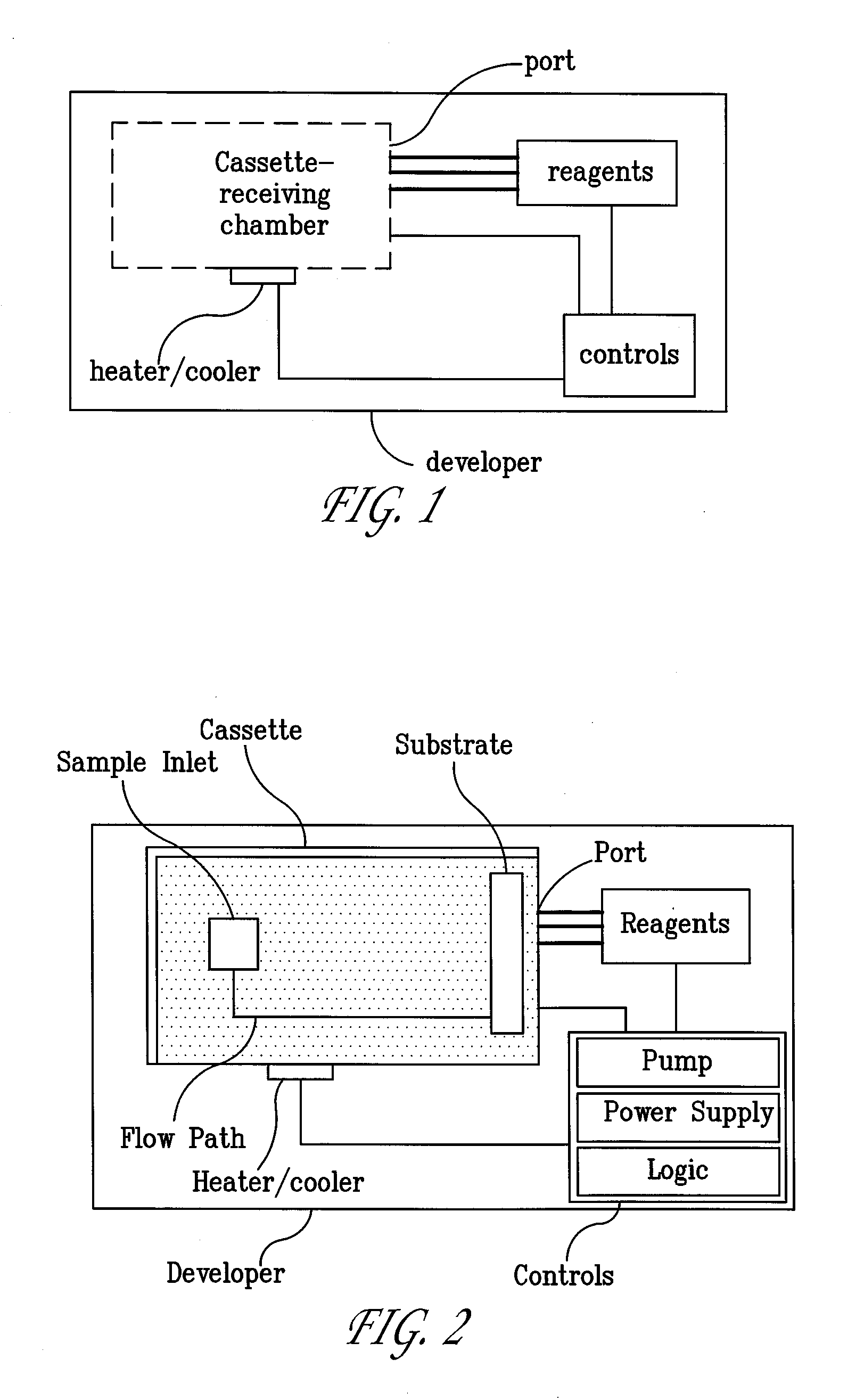

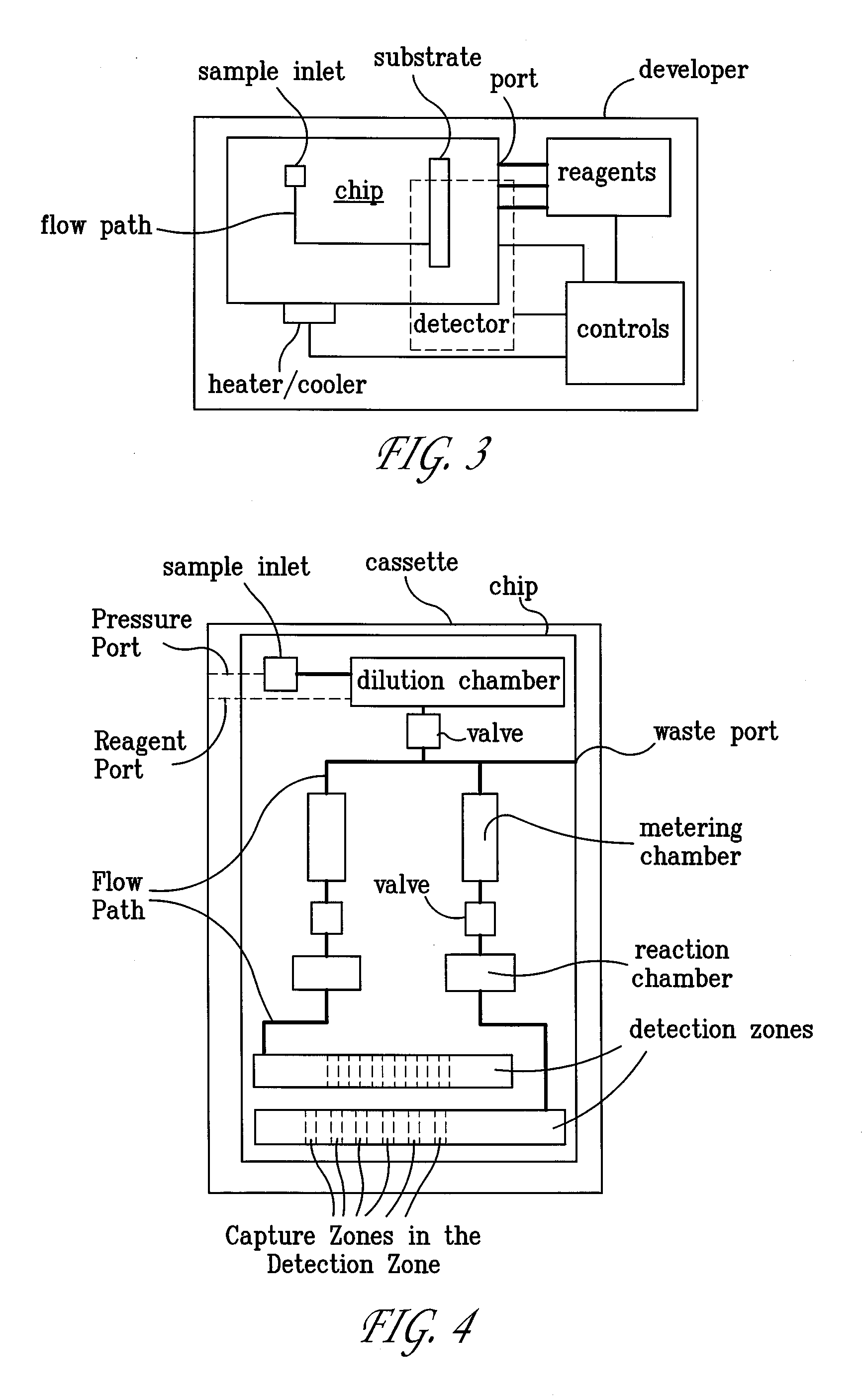

Systems and Methods For Testing using Microfluidic Chips

InactiveUS20080280285A1Easy to controlReduce materialBioreactor/fermenter combinationsHeating or cooling apparatusAntigenRNA Sequence

Disclosed are methods, devices and systems for biological and chemical sample processing using microfluidic chips. The disclosed microfluidic chips contain at least two detection zones for interacting with pre-selected RNA sequences, DNA sequences, antibodies, or antigens to determine their presence in the sample. Systems are also described comprising a cassette having at least one port and a sample inlet in fluid communication with a detection zone for interacting with pre-selected RNA sequences, DNA sequences, antibodies, or antigens, or mixtures thereof, if present, in a sample. Methods for concurrent testing of at least two of RNA, DNA, antibody, and antigen in a sample are also described, as are methods for testing for pre-selected pathogens and microfluidic methods.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

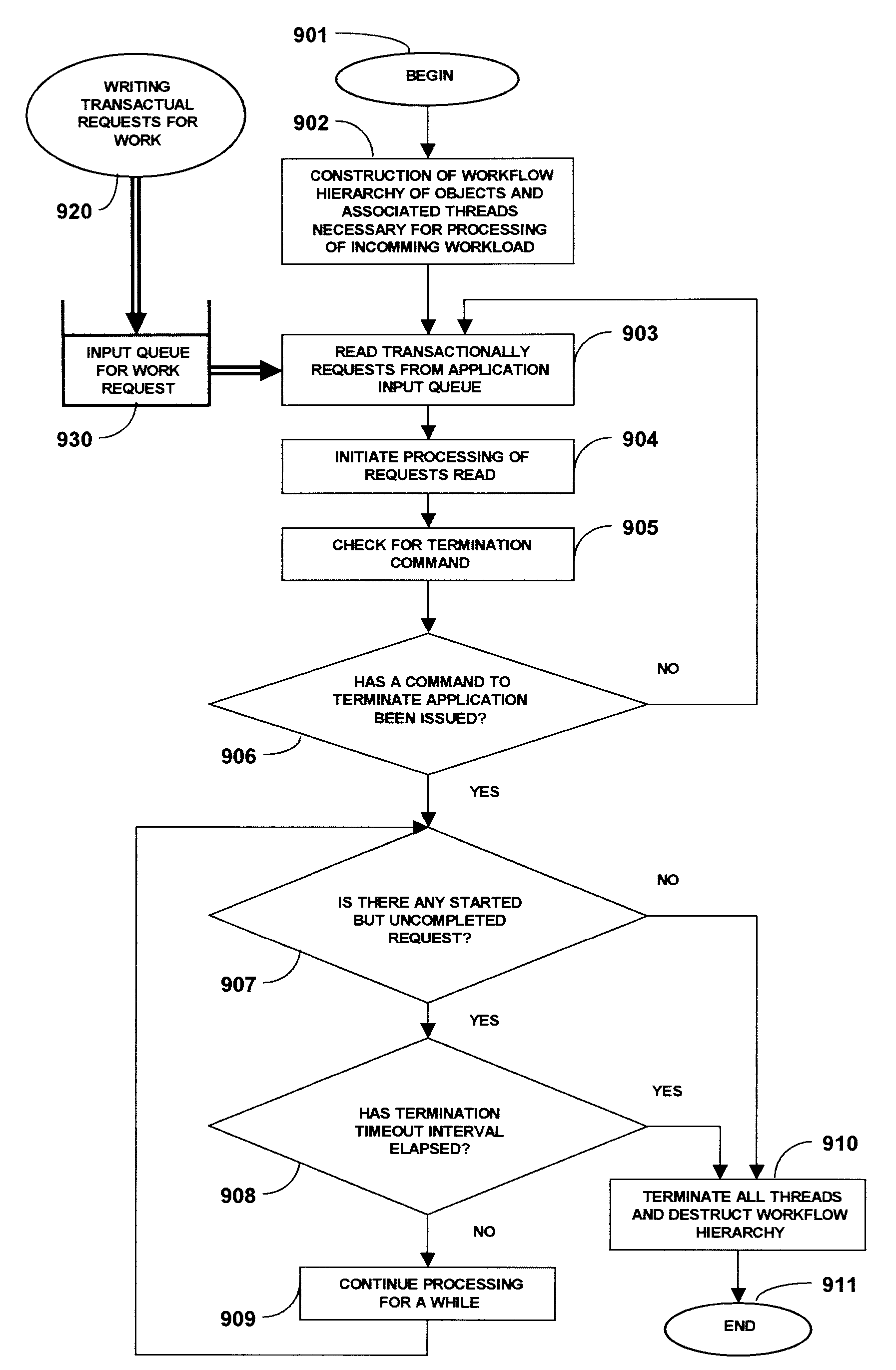

Graphical development of fully executable transactional workflow applications with adaptive high-performance capacity

InactiveUS7272820B2Overcome limitationsResource allocationVisual/graphical programmingGraphicsTransactional workflows

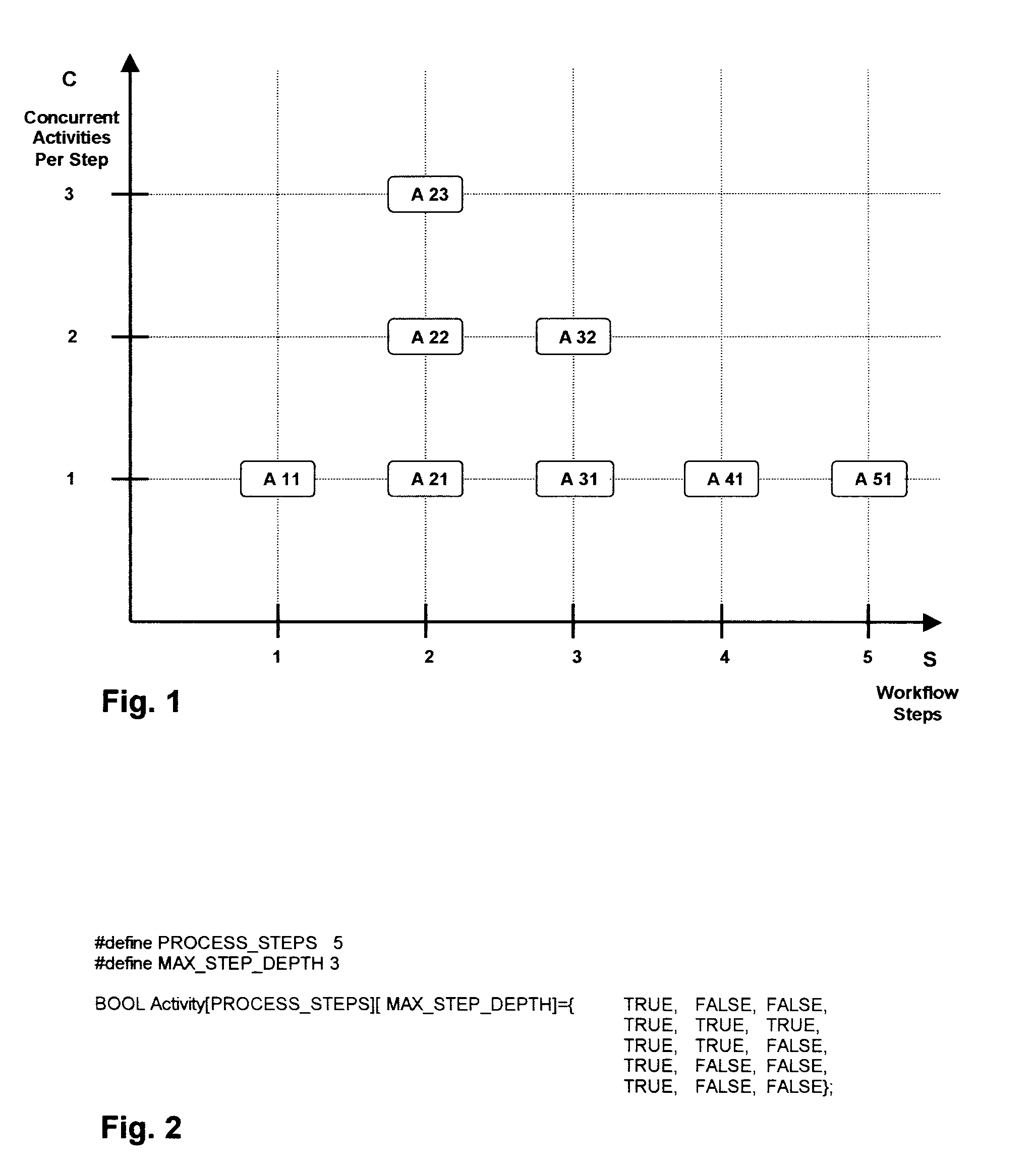

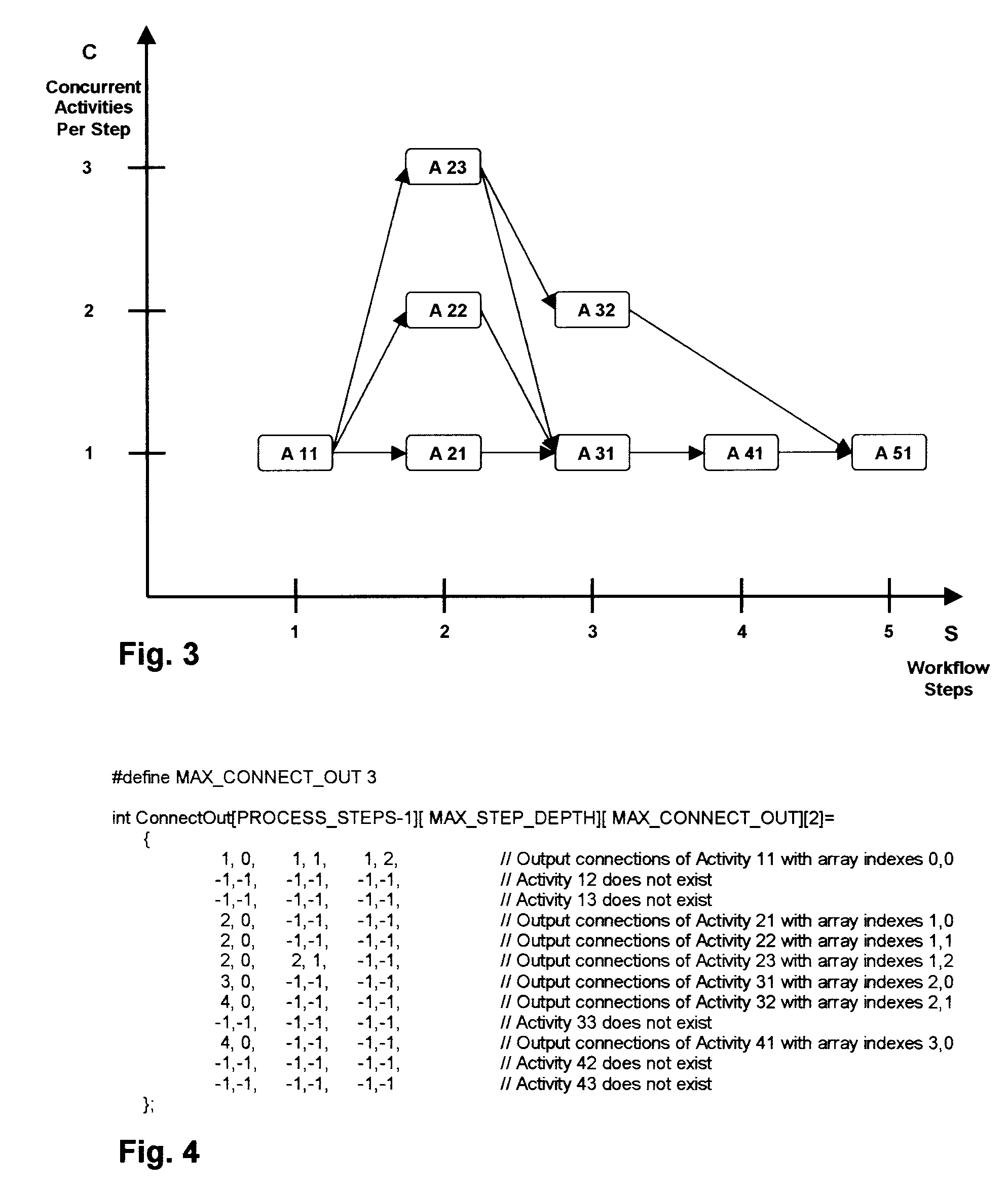

This invention is about engineering approach to development of transactional workflow applications and about ability of this way produced applications to concurrently process large number of workflow requests of identical type with high speed. It provides methods and articles of manufacture: for graphical development of fully executable workflow application; for producing configuration of class objects and threads with capacity for concurrent processing of multitude of requests of identical type for transactional workflow and for concurrent execution and synchronization of parallel workflow-activity sequences within processing of a workflow request; for application self-scaling up and self-scaling down of its processing capacity; and for real-time visualization of application's thread structures, thread quantity, thread usage, and scaling-enacted changes in threads structure and quantity.

Owner:EXTRAPOLES

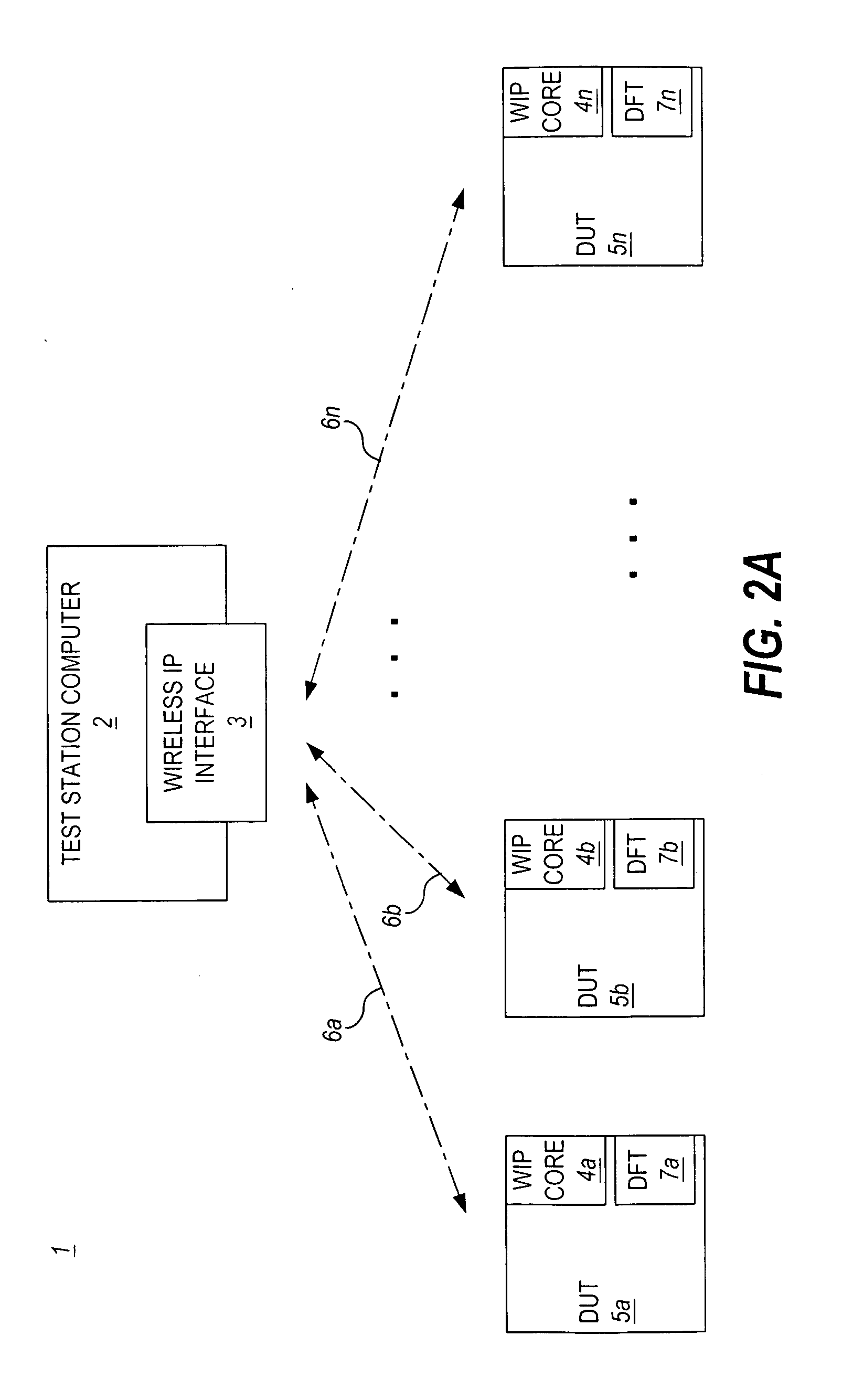

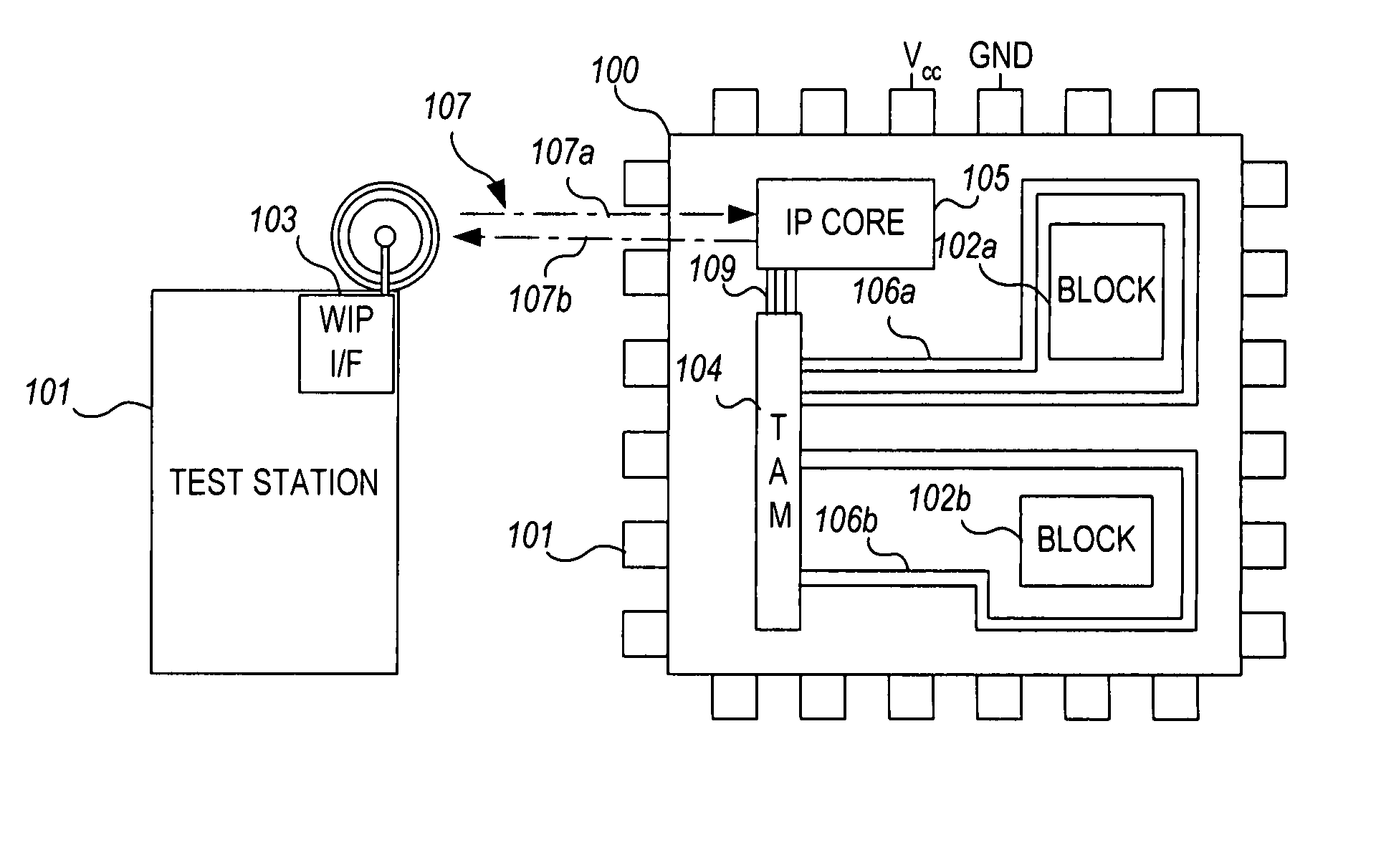

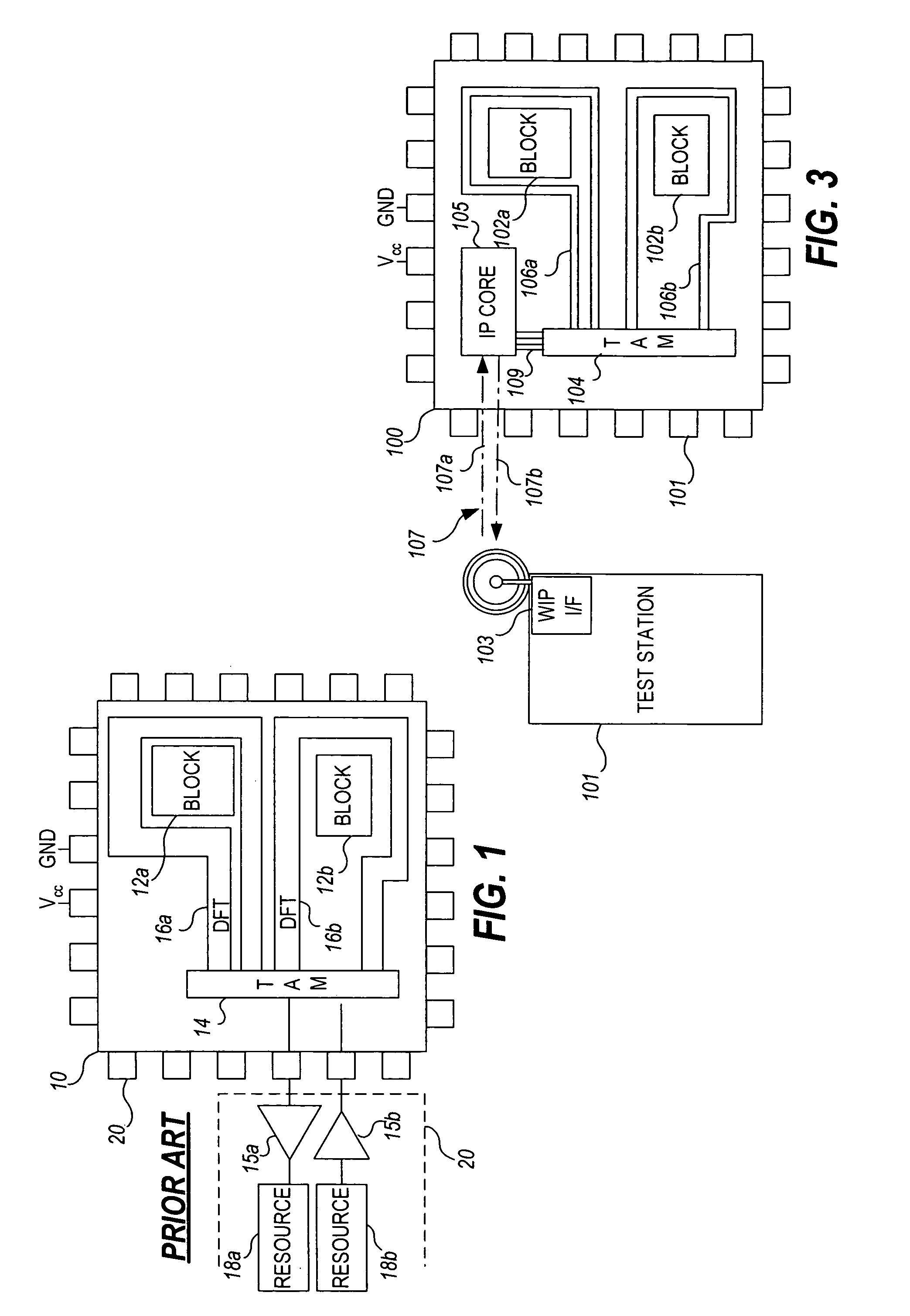

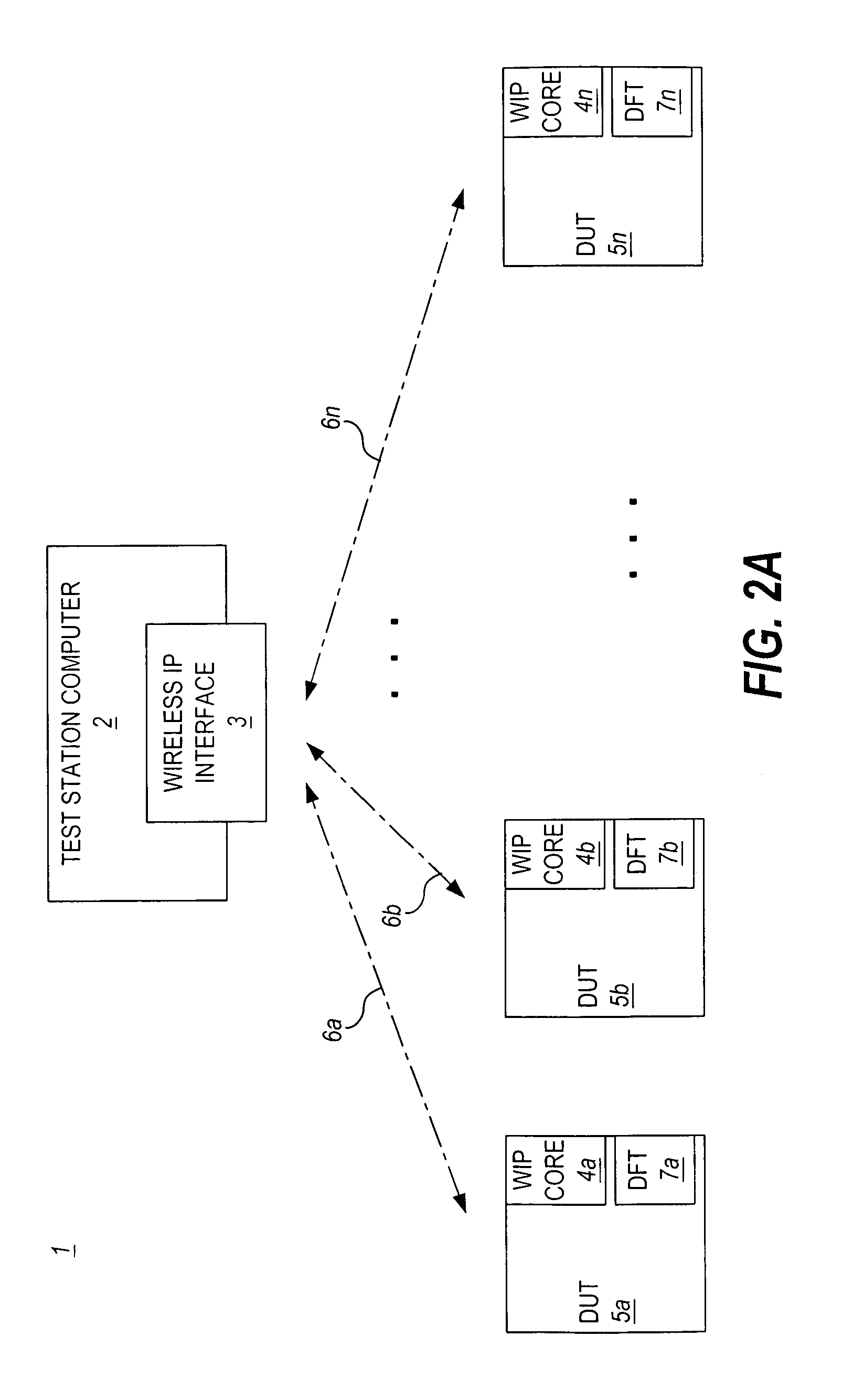

Wireless no-touch testing of integrated circuits

ActiveUS20050193294A1Immediate cost-reduction impactIncrease speedDigital circuit testingSemiconductor/solid-state device testing/measurementCircuit under testEngineering

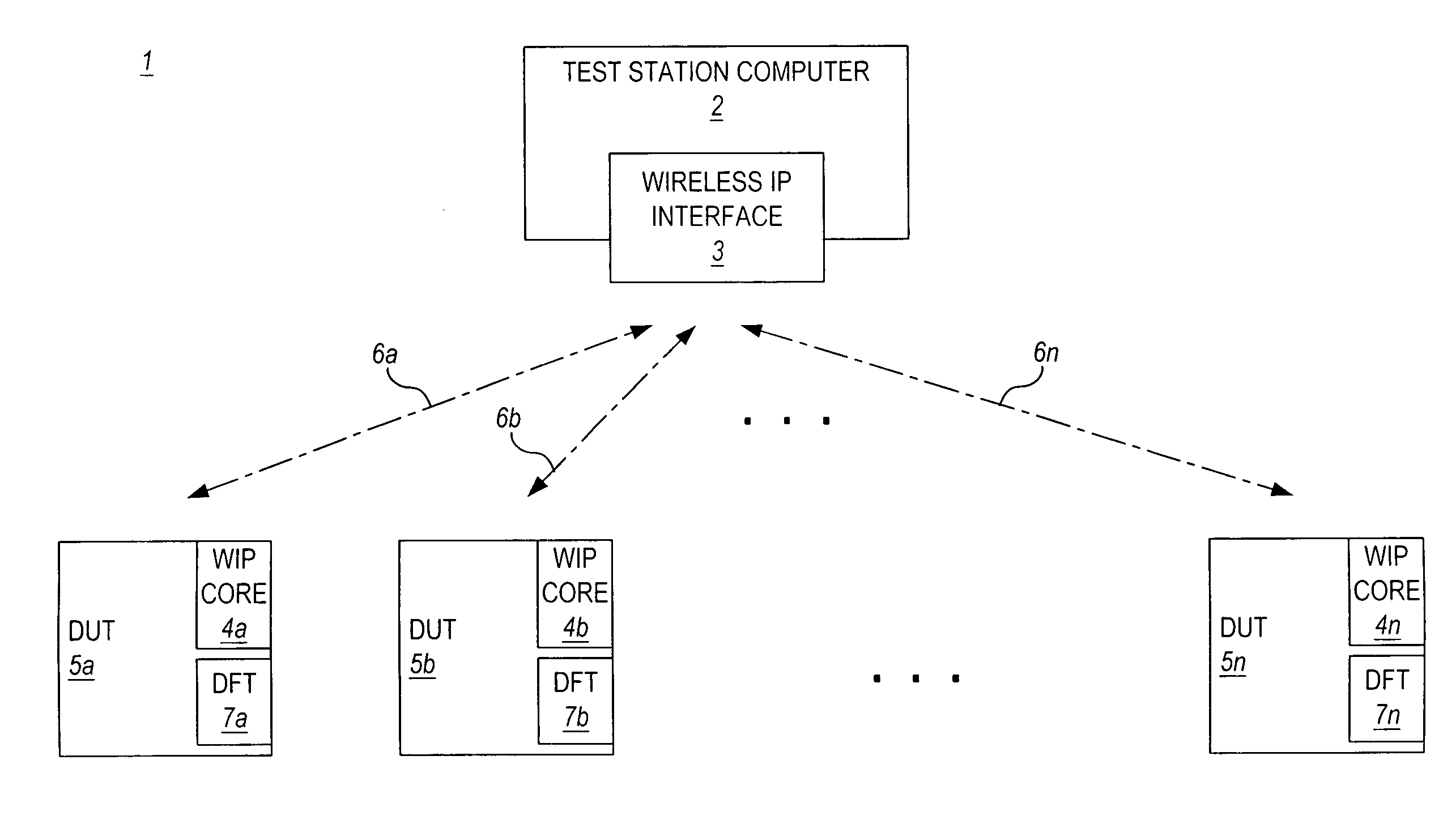

A wireless integrated circuit test method and system is presented. The invention allows testing of one or more integrated circuits configured with a wireless interface and a test access mechanism which controls input of test data received over a wireless connection from a test station to test structures which test functional blocks on the integrated circuit. Via the wireless connection, multiple integrated circuits or similarly equipped devices under test can be tested simultaneously. The invention also enables concurrent testing of independently testable functional blocks on any given integrated circuit under test.

Owner:ADVANTEST CORP

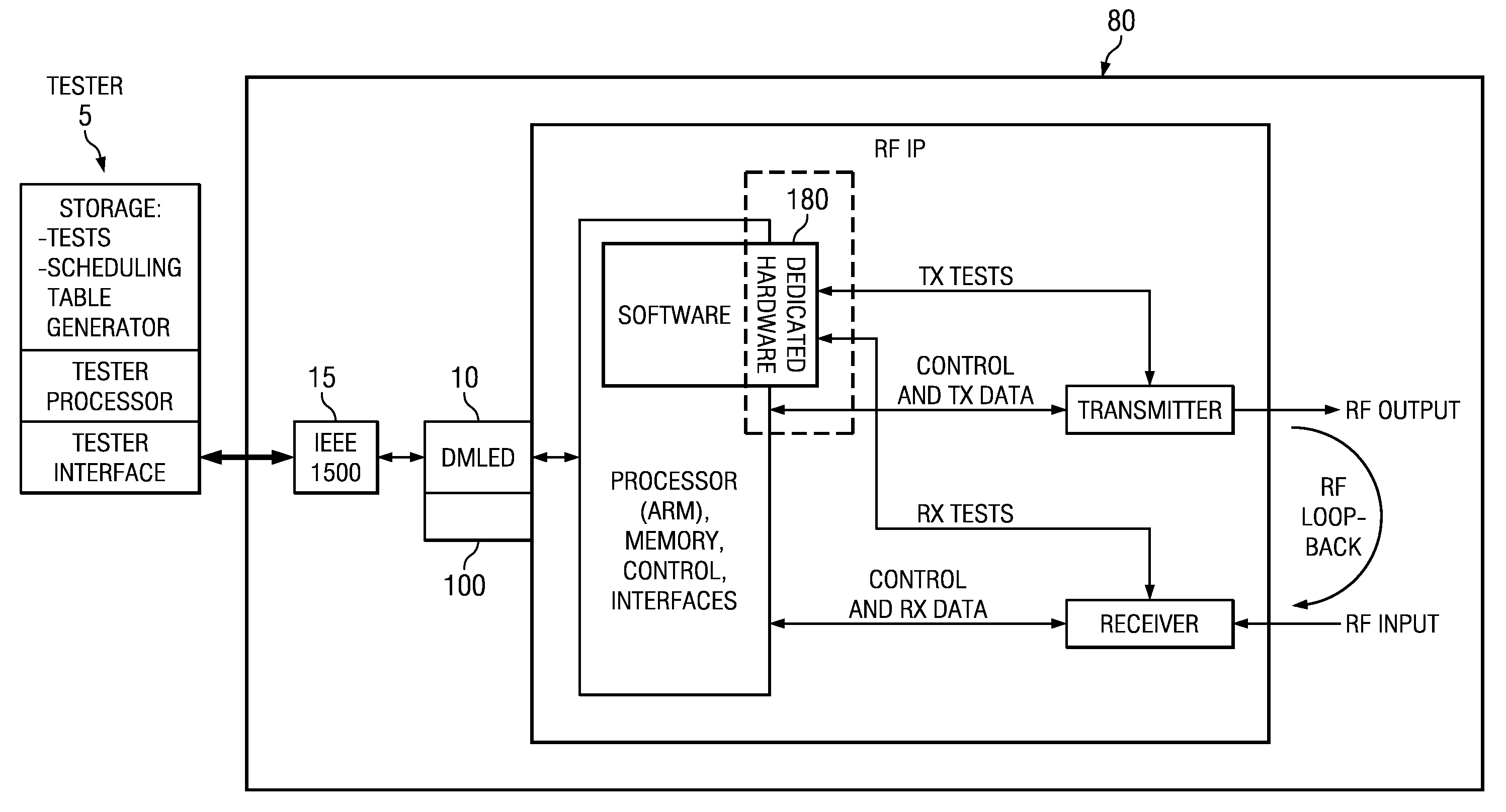

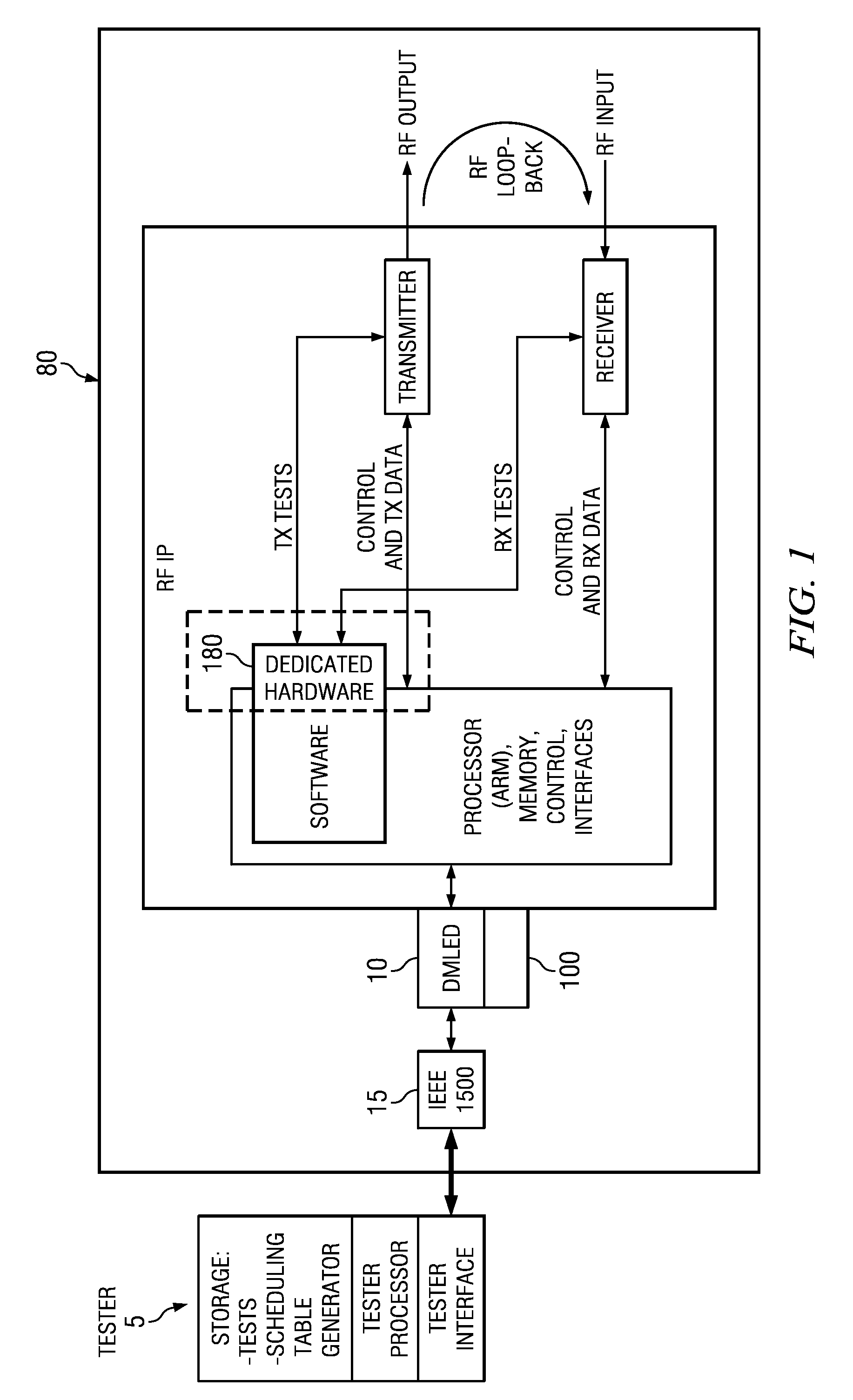

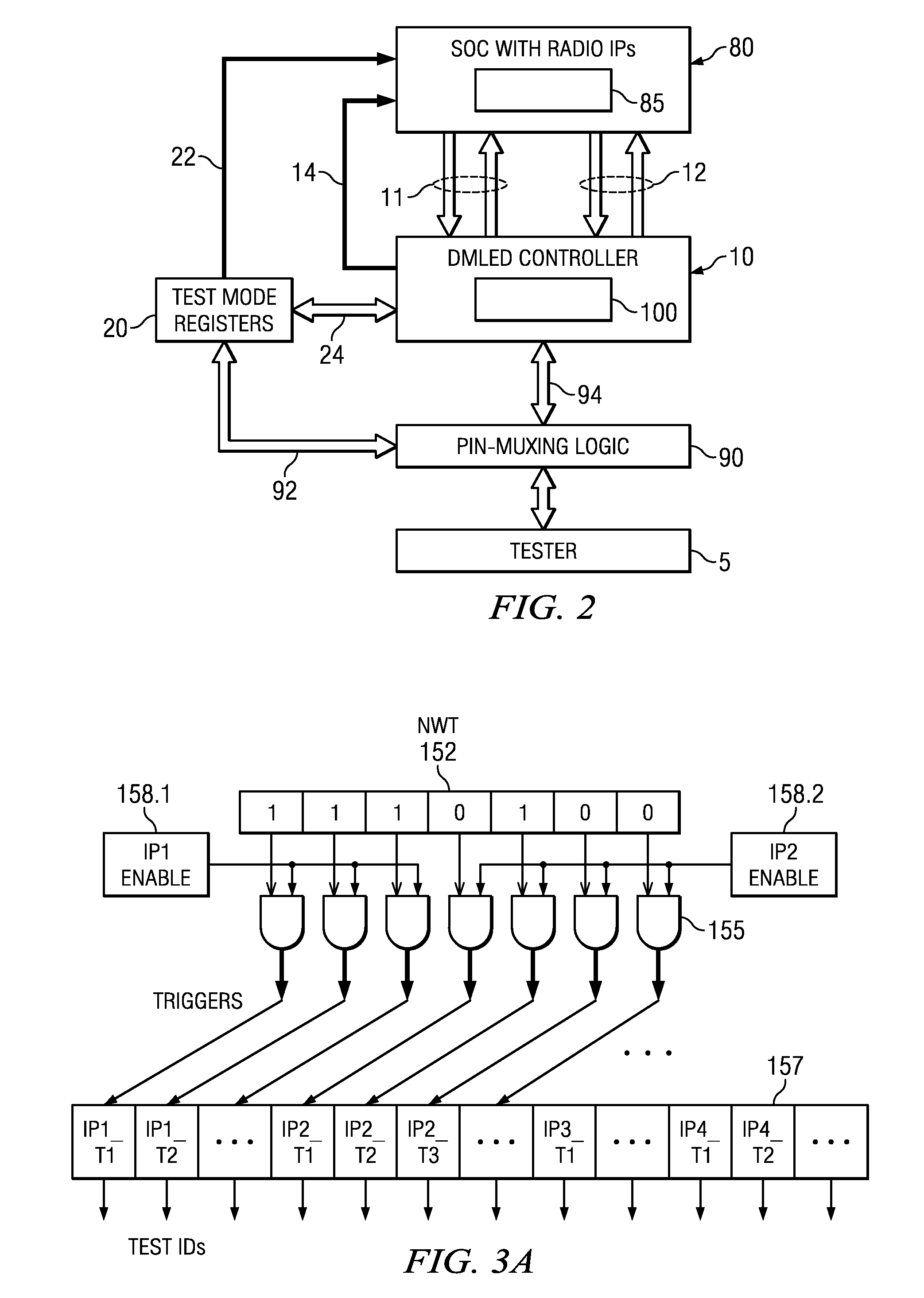

Built-in self-test methods, circuits and apparatus for concurrent test of RF modules with a dynamically configurable test structure

ActiveUS20120191400A1Resistance/reactance/impedenceSpecial data processing applicationsEngineeringBuilt-in self-test

A testable integrated circuit chip (80, 100) includes a functional circuit (80) having modules (IP.i), a storage circuit (110) operable to hold a table representing sets of compatible tests that are compatible for concurrence, and an on-chip test controller (140, 150) coupled with said storage circuit (110) and with said functional circuit modules (IP.i), said test controller (140, 150) operable to dynamically schedule and trigger the tests in those sets, whereby promoting concurrent execution of tests in said functional circuit modules (IP.i). Other circuits, wireless chips, systems, and processes of operation and processes of manufacture are disclosed.

Owner:TEXAS INSTR INC

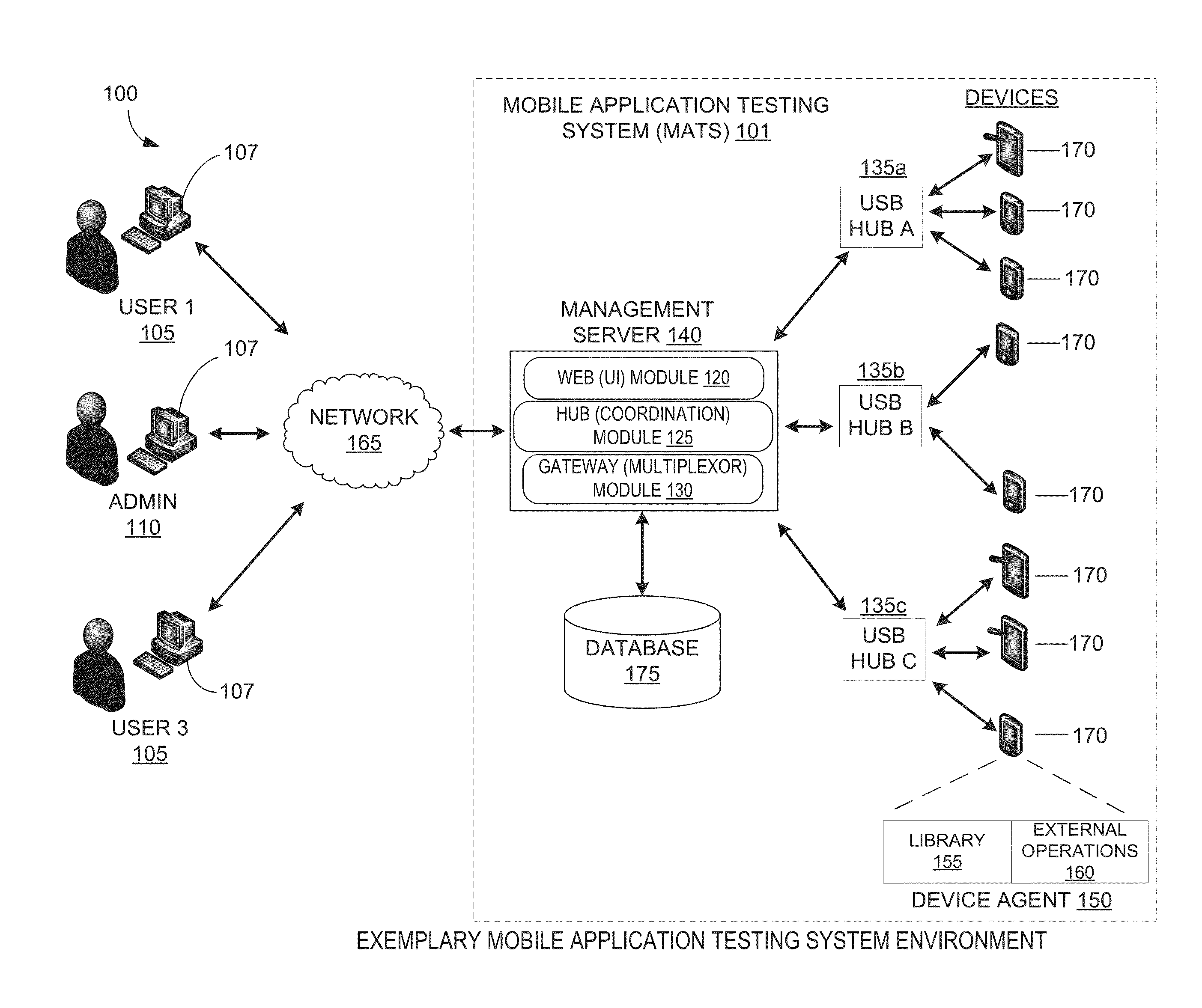

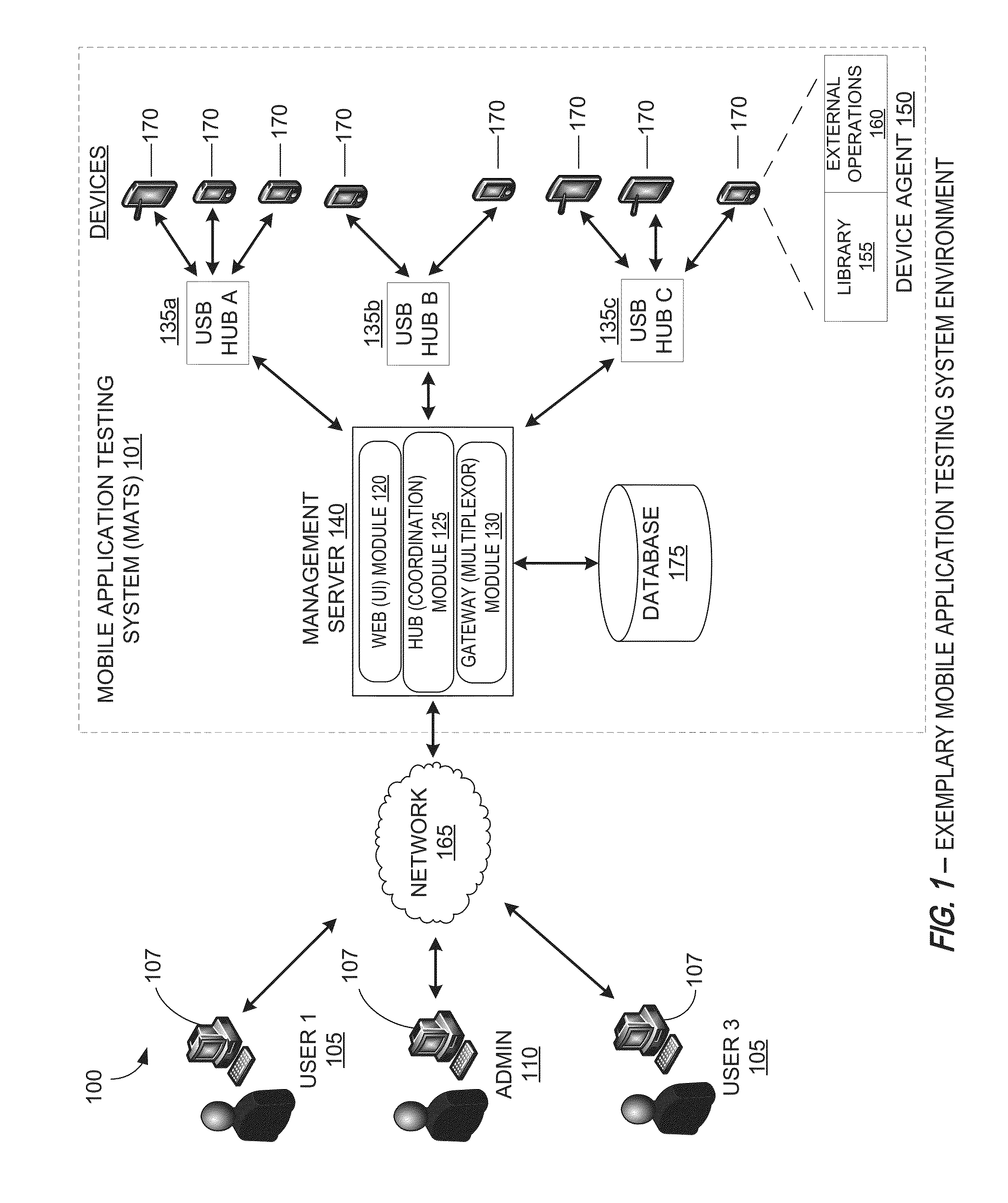

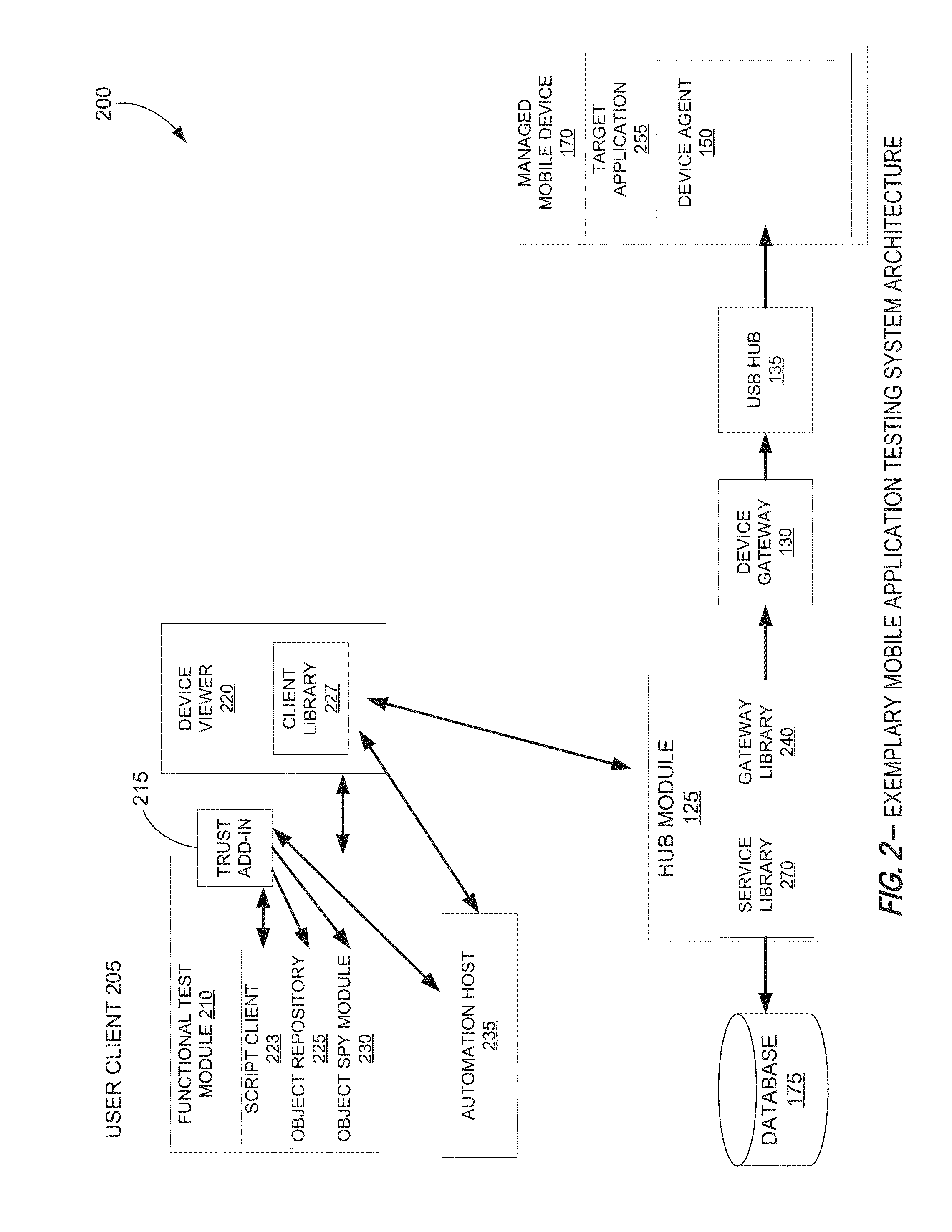

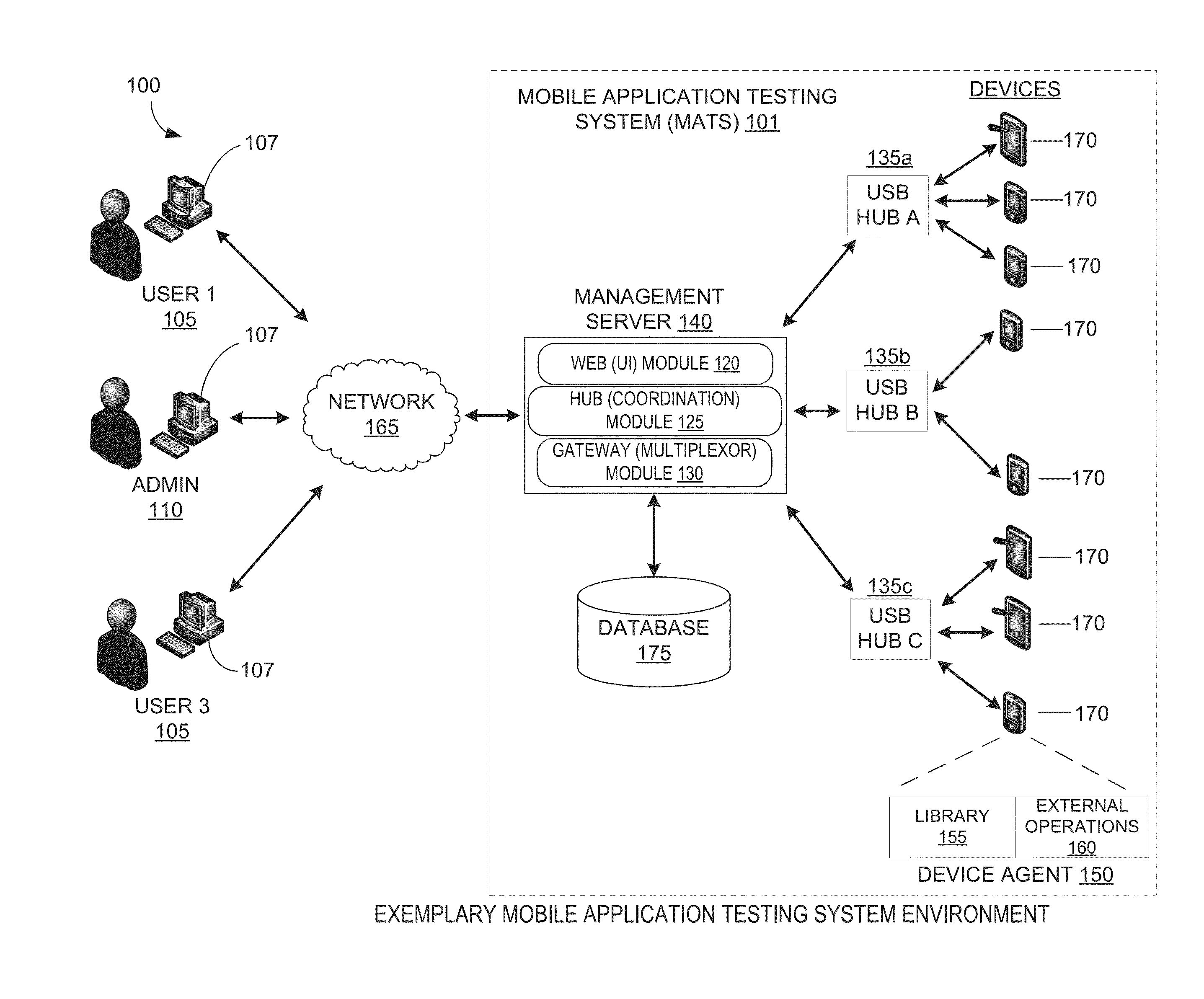

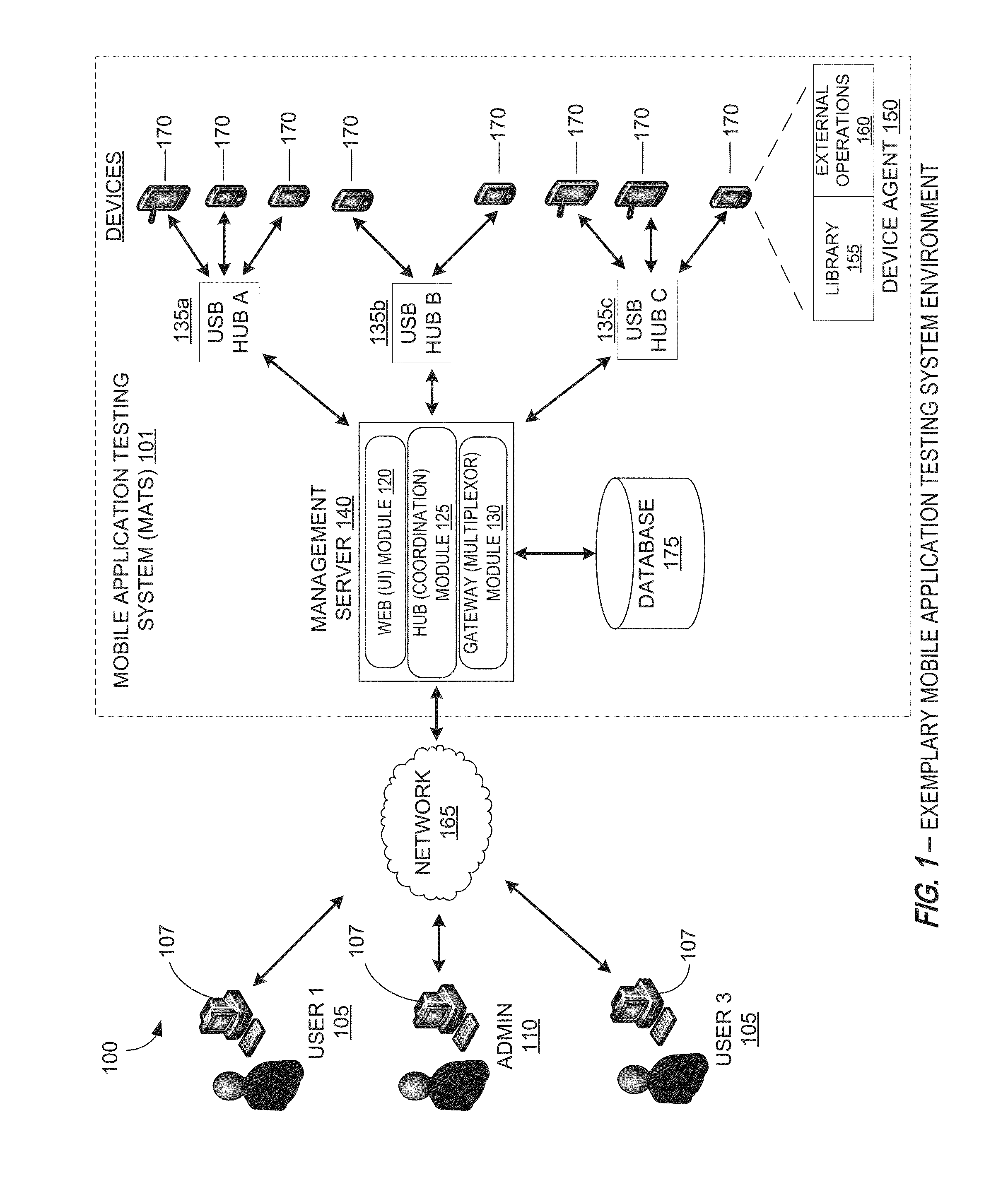

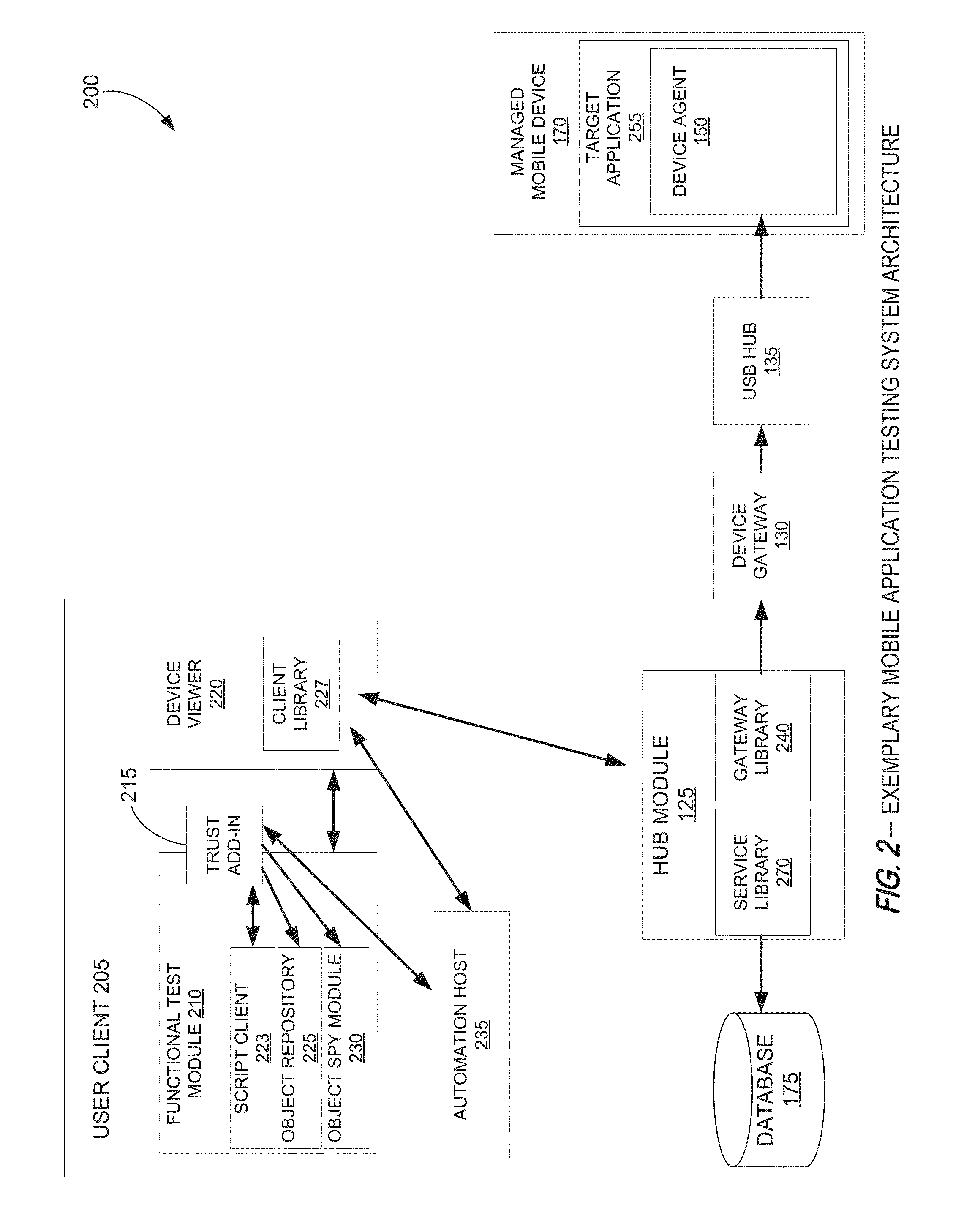

Systems, methods, and apparatuses for testing mobile device applications

ActiveUS9189378B1Easy to optimizeExtensive collectionSoftware testing/debuggingSpecific program execution arrangementsDevice typeUser device

Aspects of the present disclosure generally relate to systems and methods for facilitating optimization of mobile application testing. In one embodiment, a mobile application testing system (MATS) allows simultaneous communication to a plurality of devices regardless of device type and operating system. Accordingly, the MATS performs mobile testing without “jail-breaking” or removing various components of the user device. In one embodiment of the present disclosure, the MATS enables users to securely test mobile applications by supporting data routing behind a security firewall utilizing a transition of communications protocols. Further, various protocols provide a data tunnel allowing multiple concurrent testing sessions for multiple users via an authentication scheme. Additionally, concurrent testing sessions may include single app testing on multiple devices or a plurality of apps testing on a plurality of devices.

Owner:MOBILE LABS

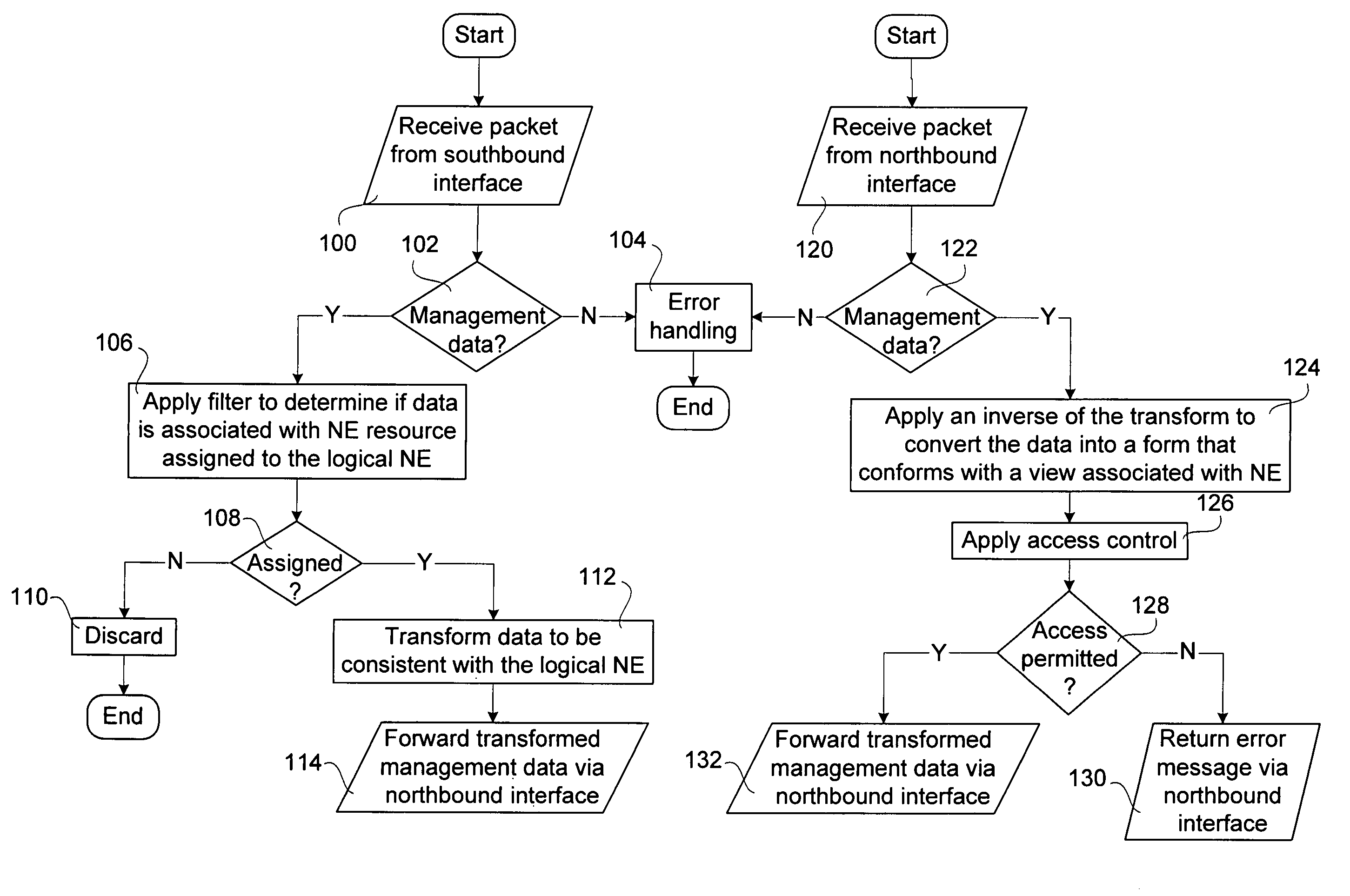

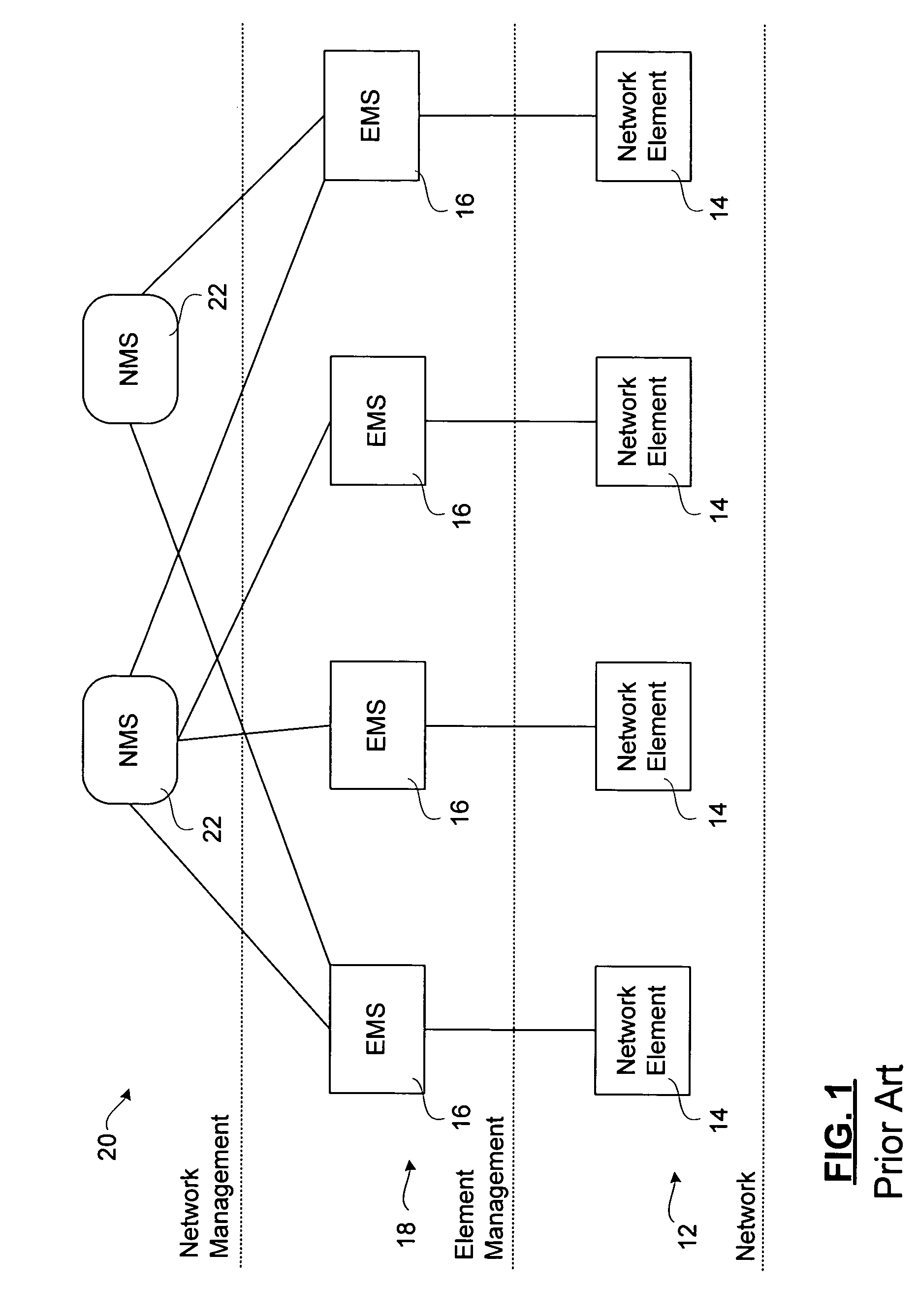

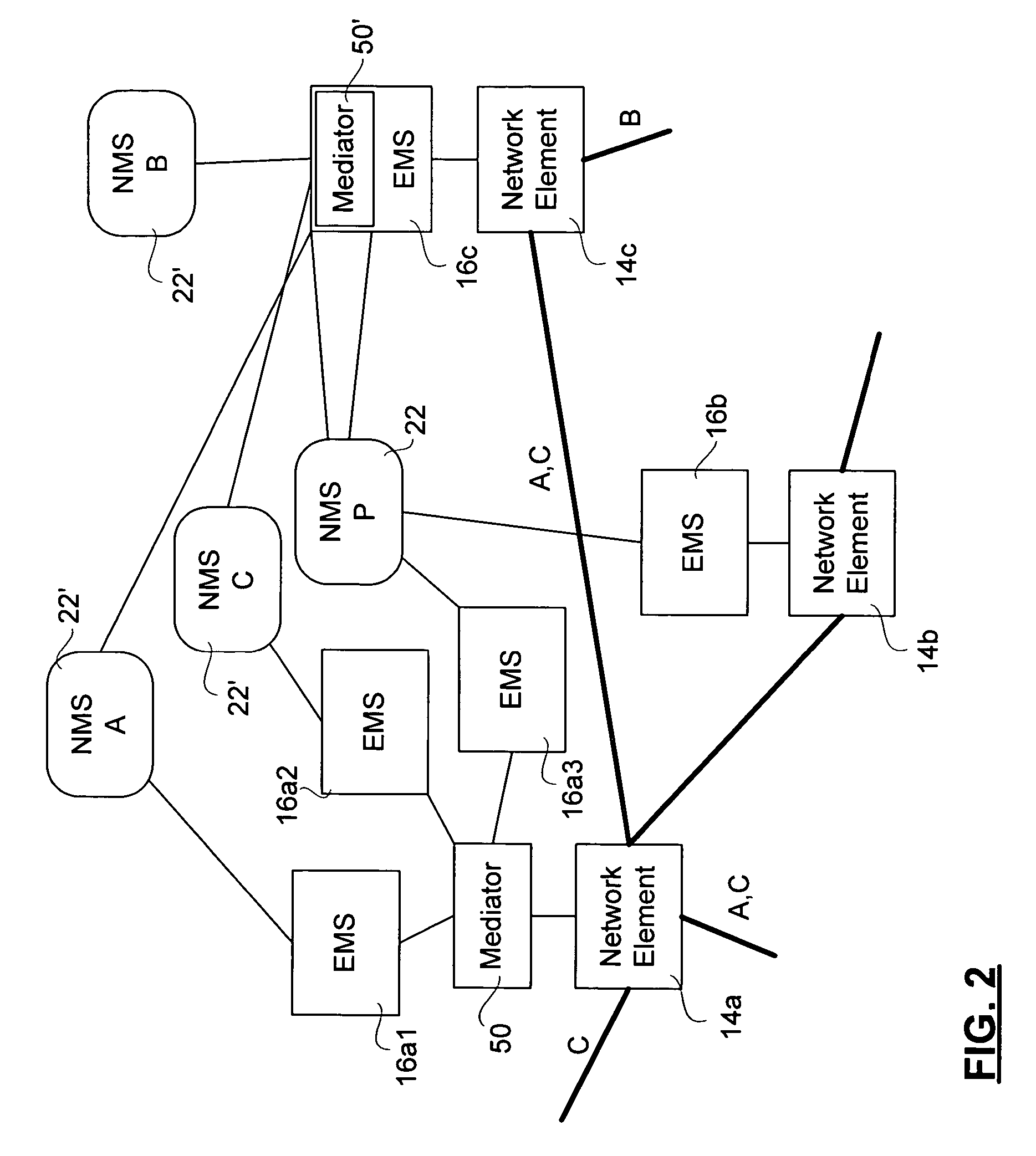

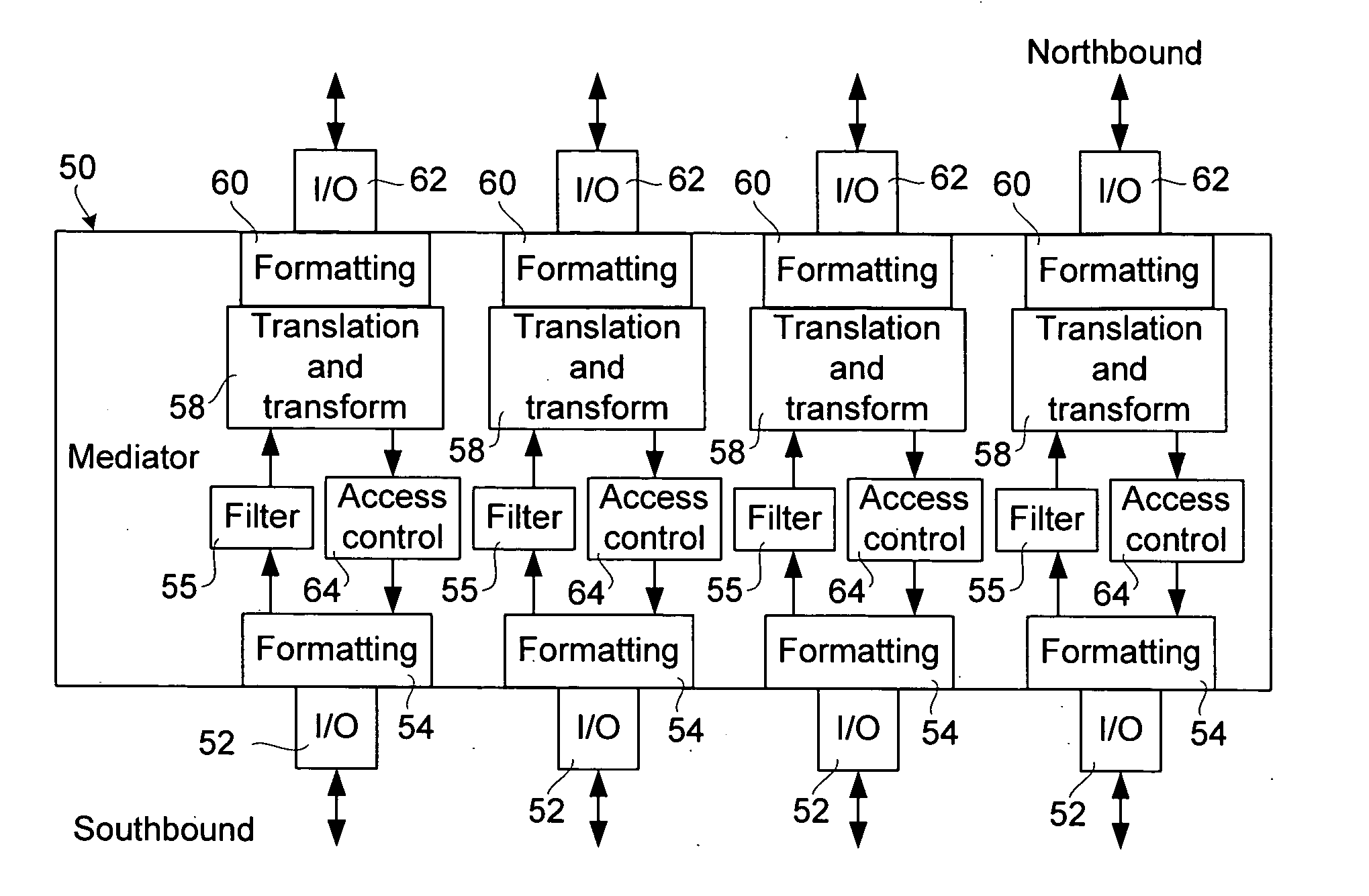

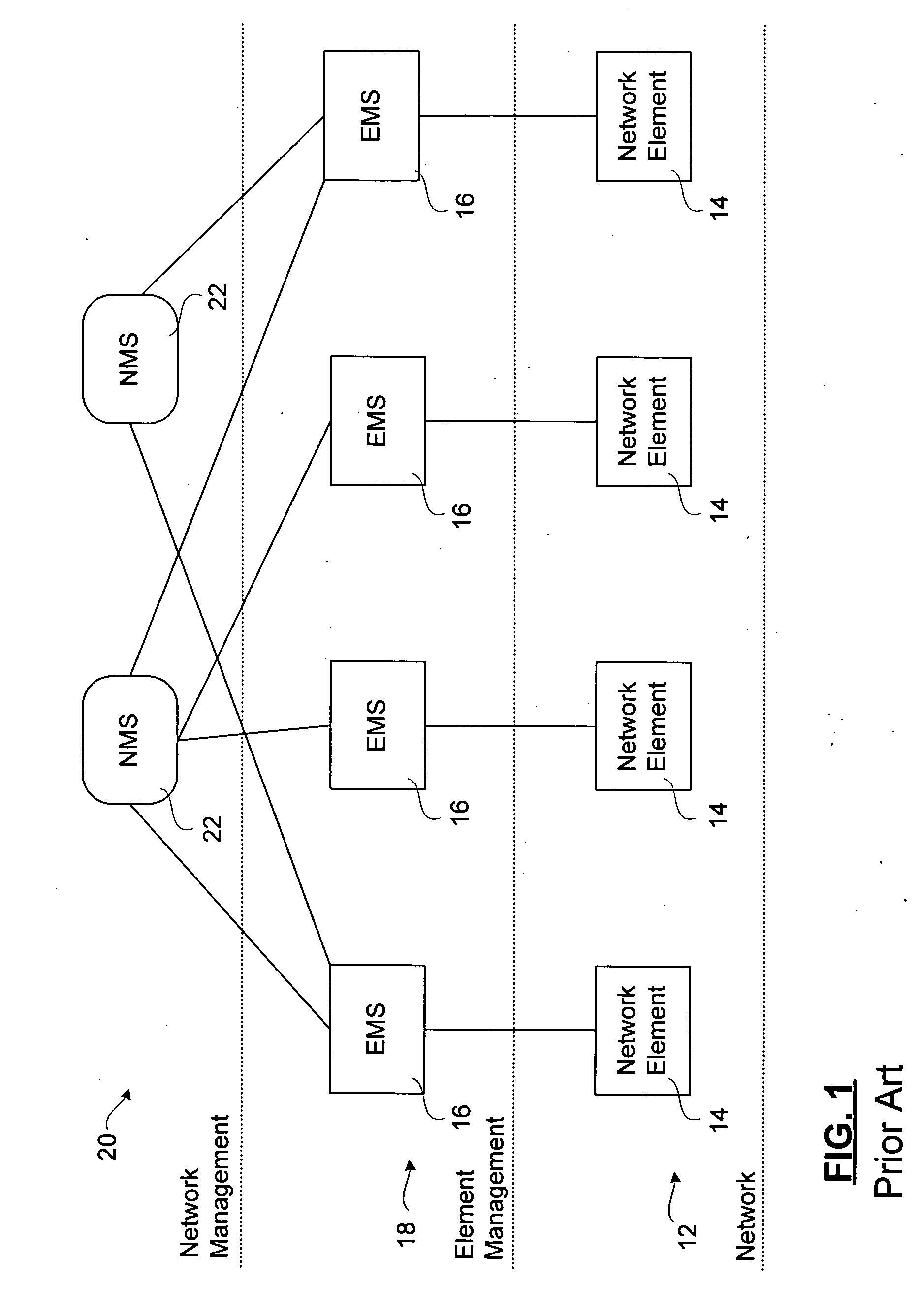

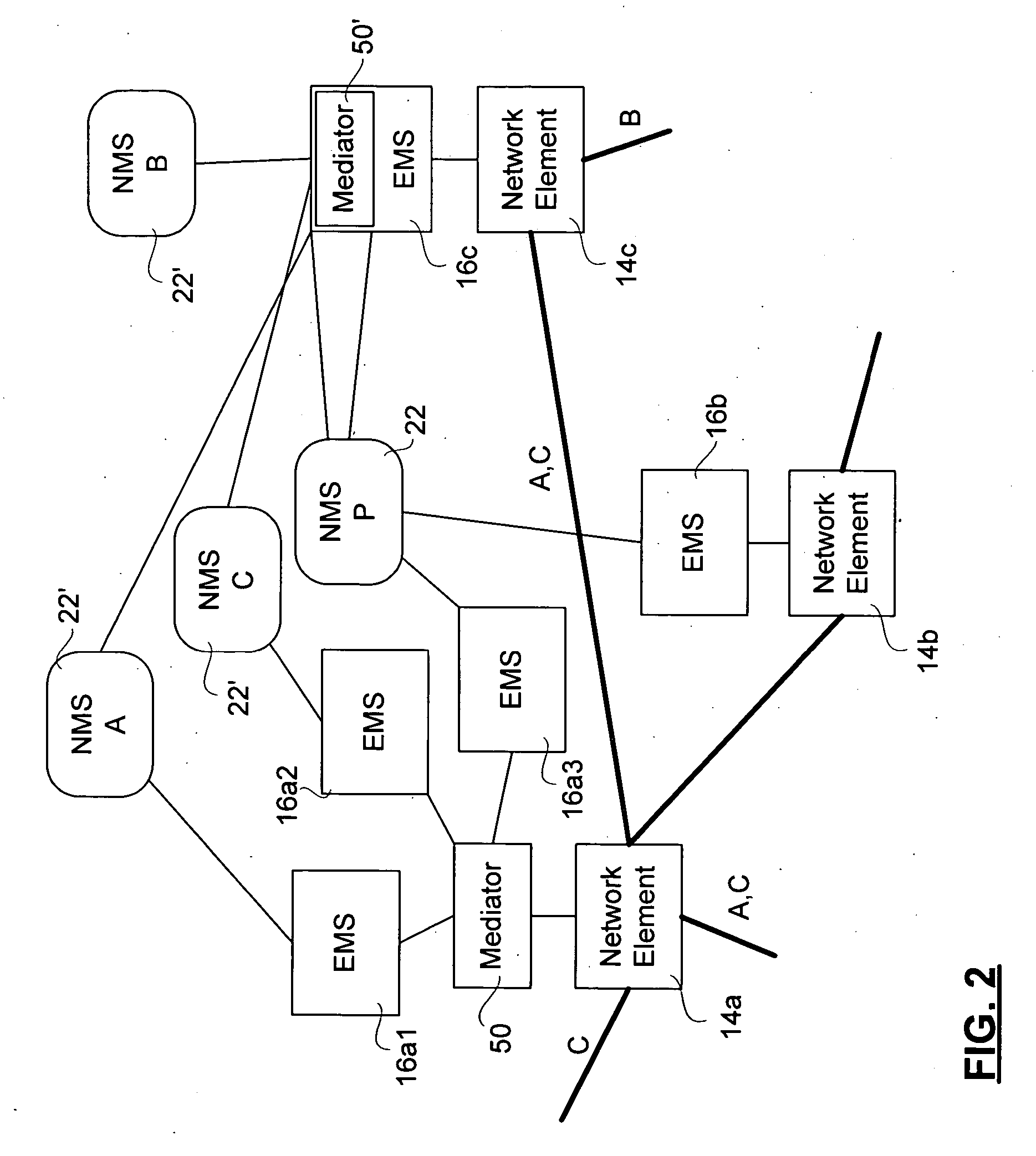

Method and apparatus for efficient communication of management data in a telecommunications network

InactiveUS7925727B2Valid reportDigital data processing detailsMultiple digital computer combinationsTelecommunications networkElement management system

A mediator for efficiently exchanging management data in a hierarchical management network for managing network elements of a data transport network partitions resources of the network elements among a plurality of management representations of the network elements and selectively forwards management data associated with respective management representations to a higher level of the hierarchy. The mediator modifies the management data so that the higher level (i.e. a northbound element management system or a network management system) receives the management data in a view consistent with the management representation of the network element. Client-based management representations may be created to permit clients to manage selected resources of a network element, and testing-based management representations may be created to facilitate concurrent testing of a network element.

Owner:RPX CLEARINGHOUSE

Wireless no-touch testing of integrated circuits

ActiveUS7181663B2Count is minimizedShorten test timeDigital circuit testingSemiconductor/solid-state device testing/measurementEngineeringWireless connectivity

A wireless integrated circuit test method and system is presented. The invention allows testing of one or more integrated circuits configured with a wireless interface and a test access mechanism which controls input of test data received over a wireless connection from a test station to test structures which test functional blocks on the integrated circuit. Via the wireless connection, multiple integrated circuits or similarly equipped devices under test can be tested simultaneously. The invention also enables concurrent testing of independently testable functional blocks on any given integrated circuit under test.

Owner:ADVANTEST CORP

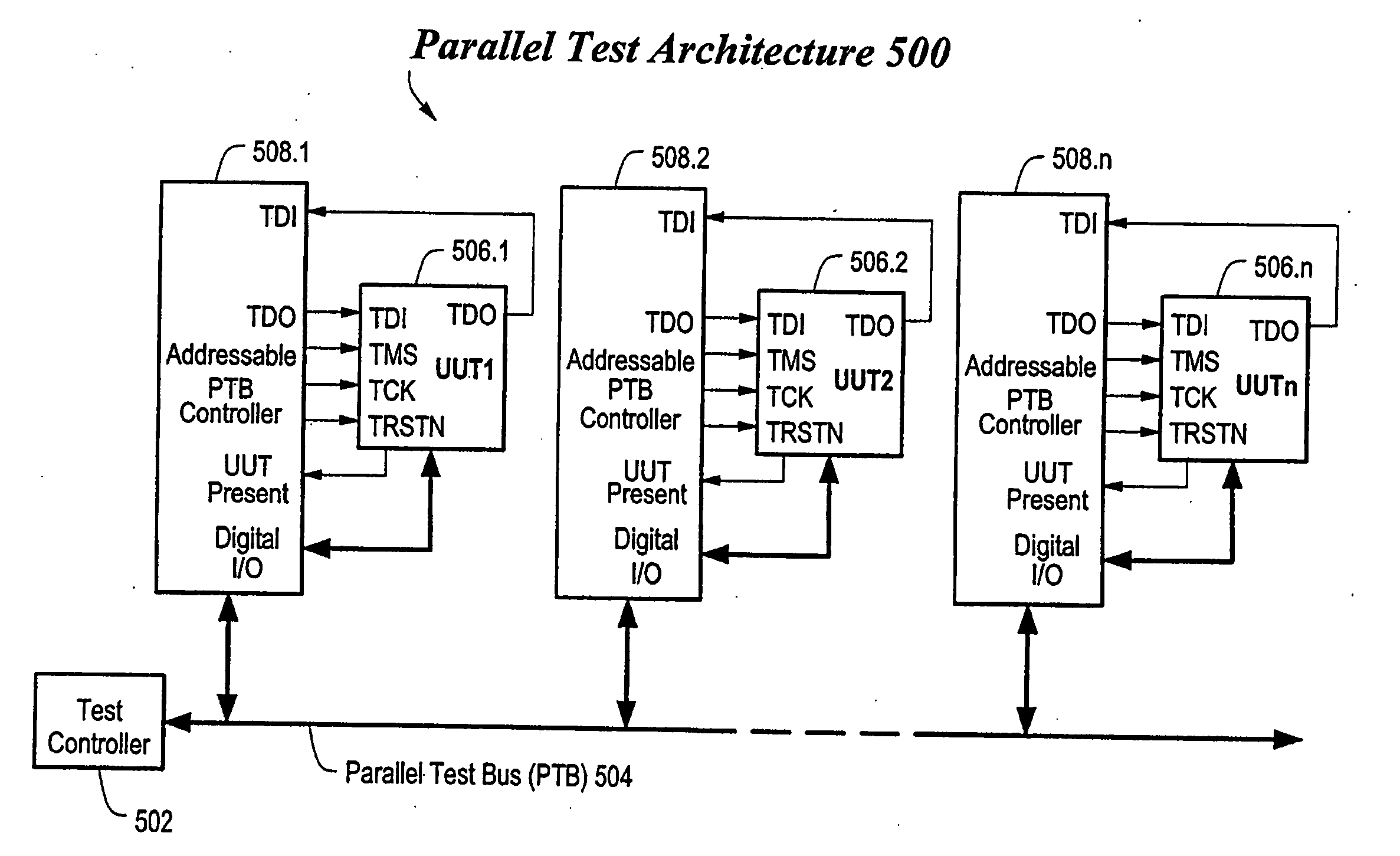

Method and apparatus for optimized parallel testing and access of electronic circuits

InactiveUS20060107160A1Easy accessIncreased “ parallel ” testingElectronic circuit testingDetecting faulty computer hardwareMaster controllerJoint Test Action Group

Owner:INTELLITECH INC

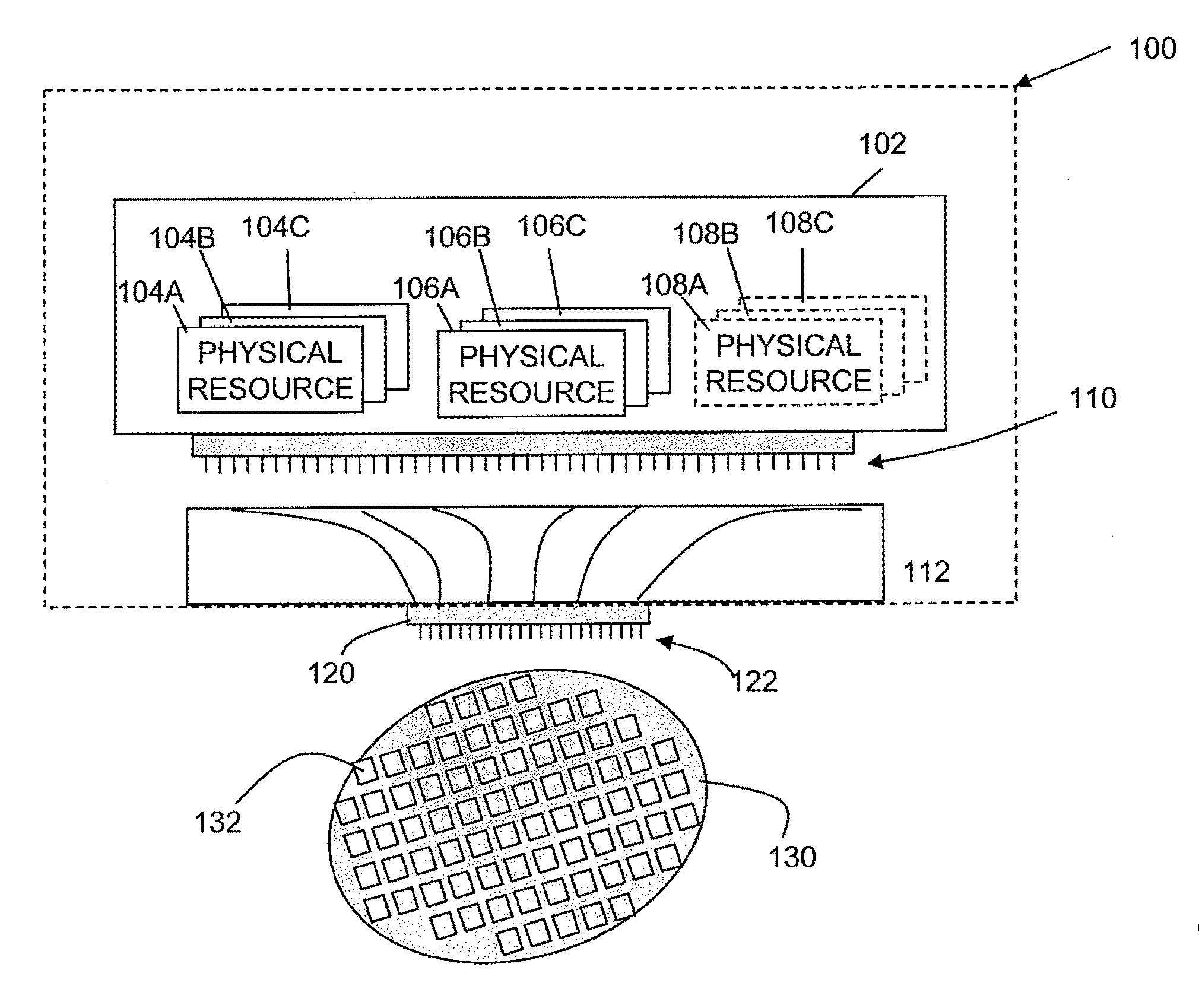

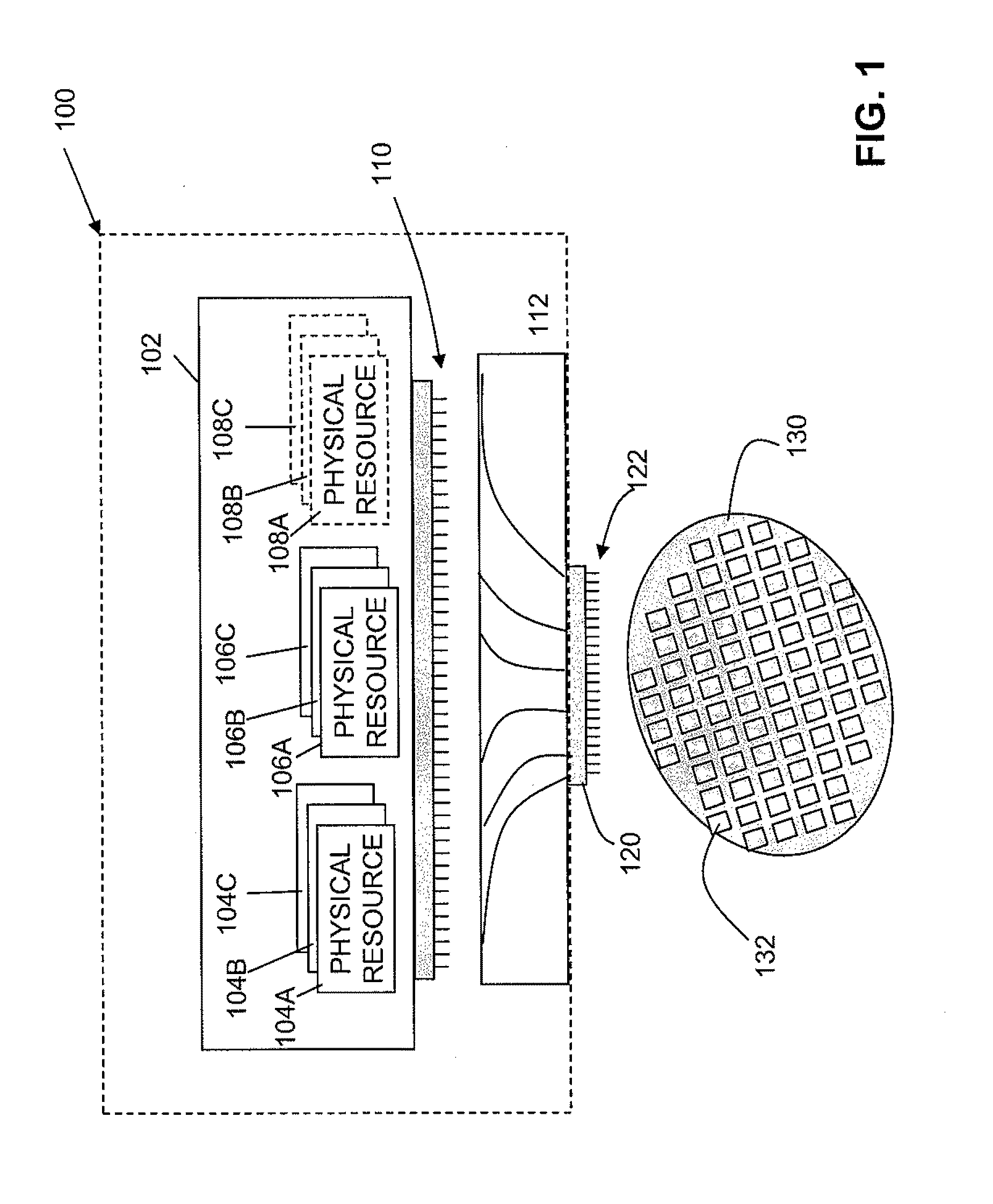

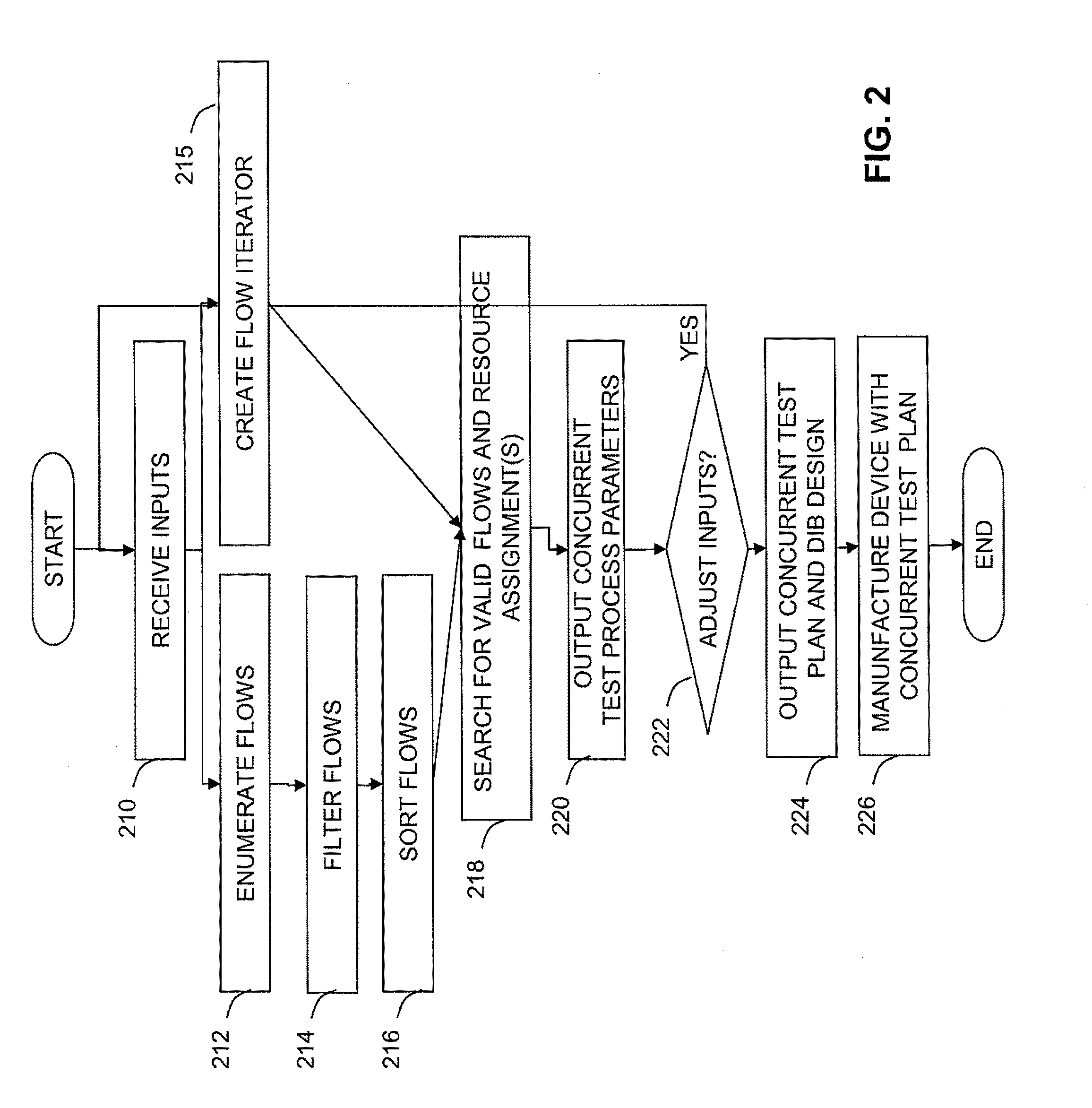

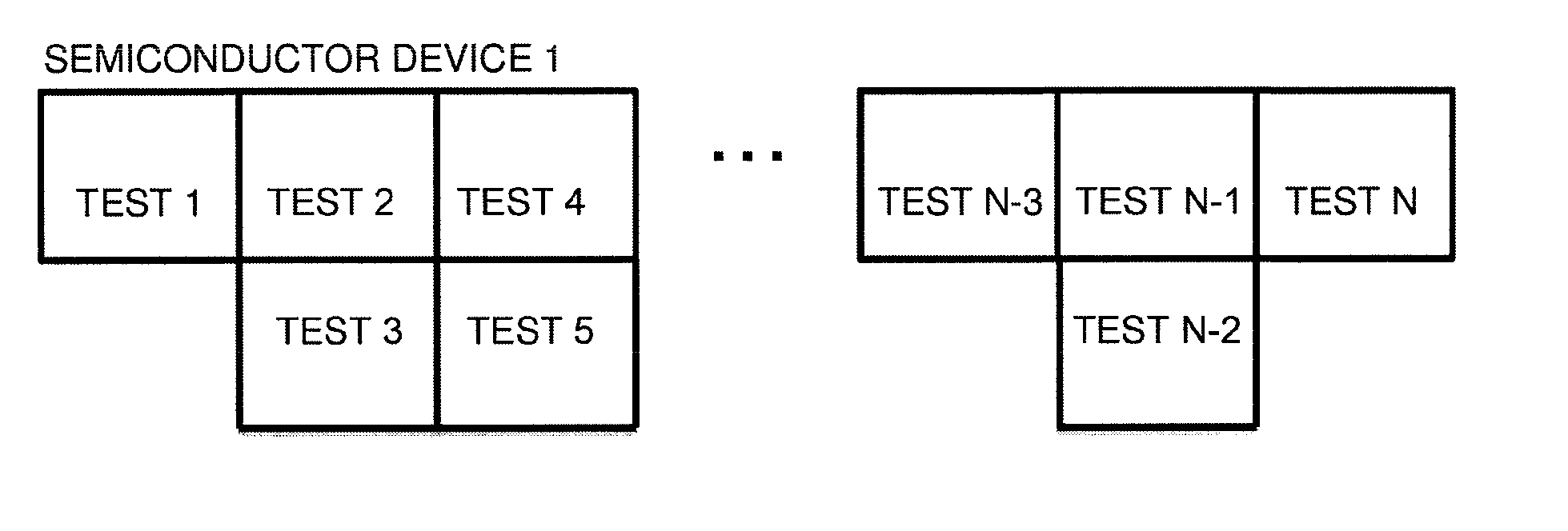

System for concurrent test of semiconductor devices

ActiveUS20110275170A1Avoid confictSemiconductor/solid-state device testing/measurementResistance/reactance/impedencePower semiconductor deviceTest engineer

A tool to aid a test engineer in creating a concurrent test plan. The tool may quickly map test system resources to specific pins to satisfy the requirements of a concurrent test. The tool may project test time when such a mapping is possible. When a mapping is not possible, the tool may inform its user, including making suggestions of additional resources that could allow the test system to perform the test or suggestions for other variations in input parameters that would allow a mapping. The tool employs an assignment process in which groups of associated pins are identified, along with associated resource requirements for each group. Groups of test system resources that collectively fulfill a higher level requirement are identified and the assignment is made by mapping resource sets to resource groups, using ordering and matching heuristics to reduce processing time.

Owner:TERADYNE

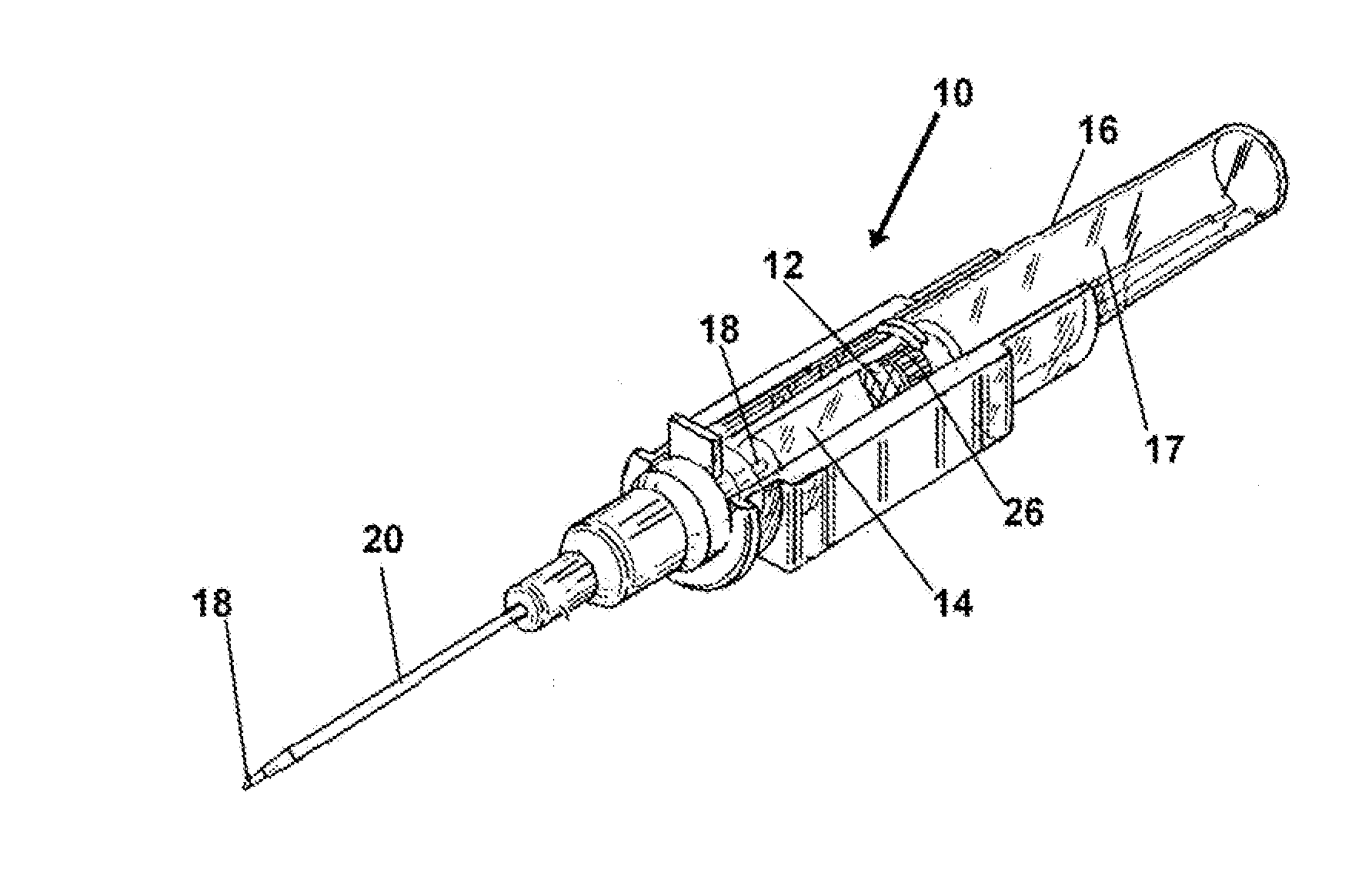

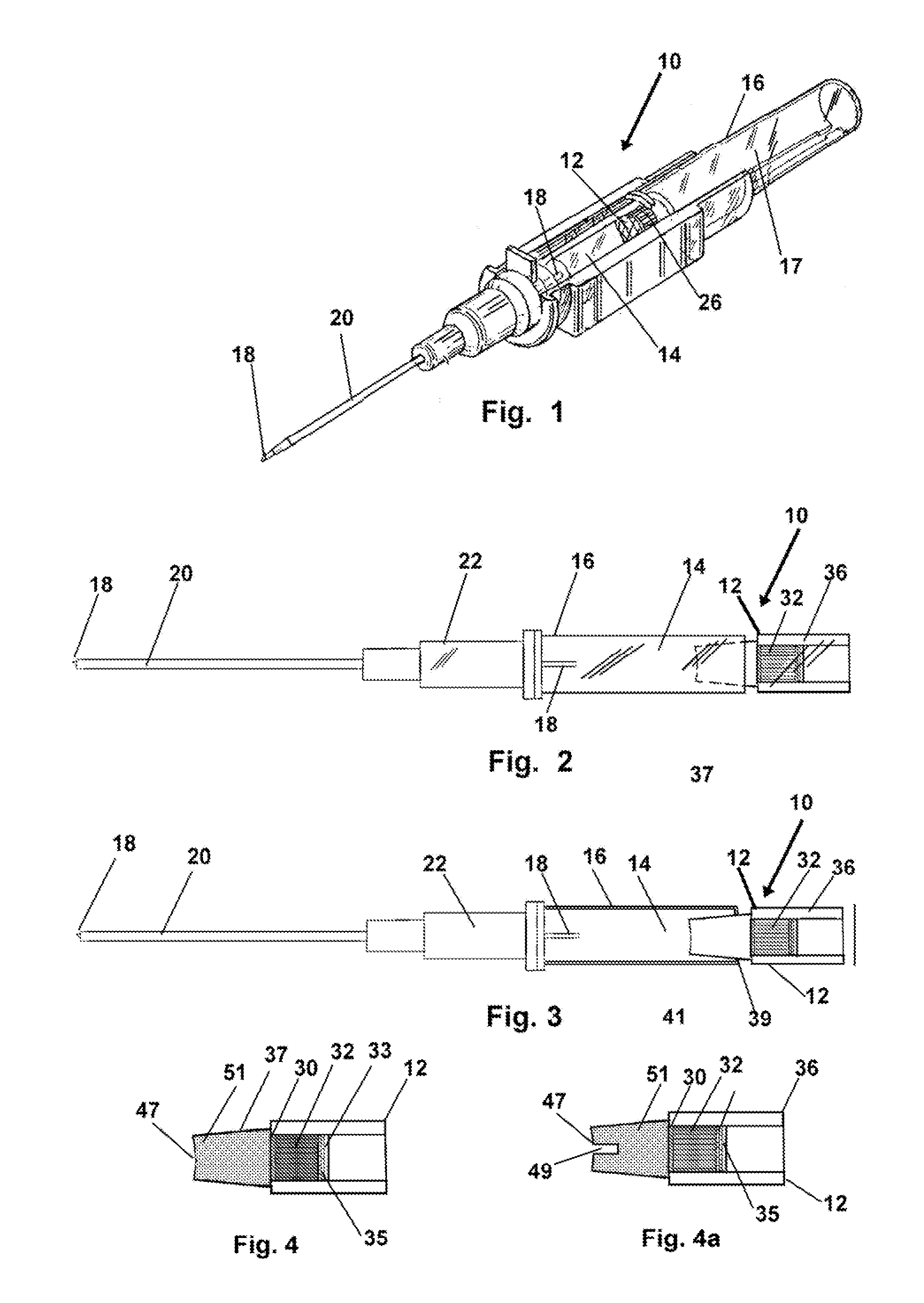

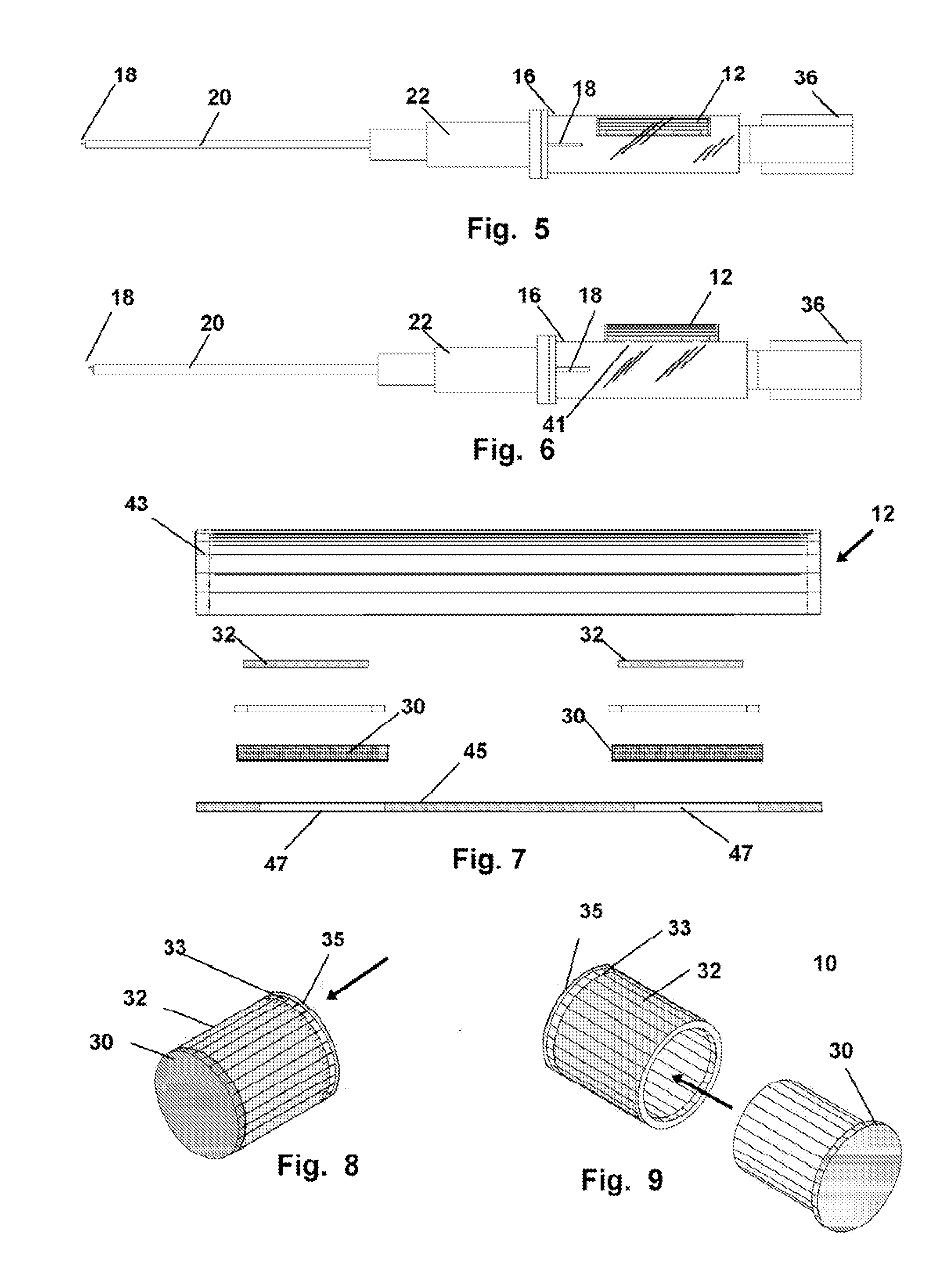

Catheter Insertion Device with Blood Analyzer

ActiveUS20150359473A1Easy to viewQuick analysisGuide needlesDiagnostic recording/measuringVeinIntravenous catheter

A device and method yielding a blood analysis employable in combination with an introducer for a catheter for a concurrent testing of blood from the introducer flash chamber during placement of a venous catheter. The device employs a colorimetric blood analysis to provide the user a visually discernable alert to the results of tested blood concurrent with the placement of the catheter with the introducer.

Owner:KURIN INC

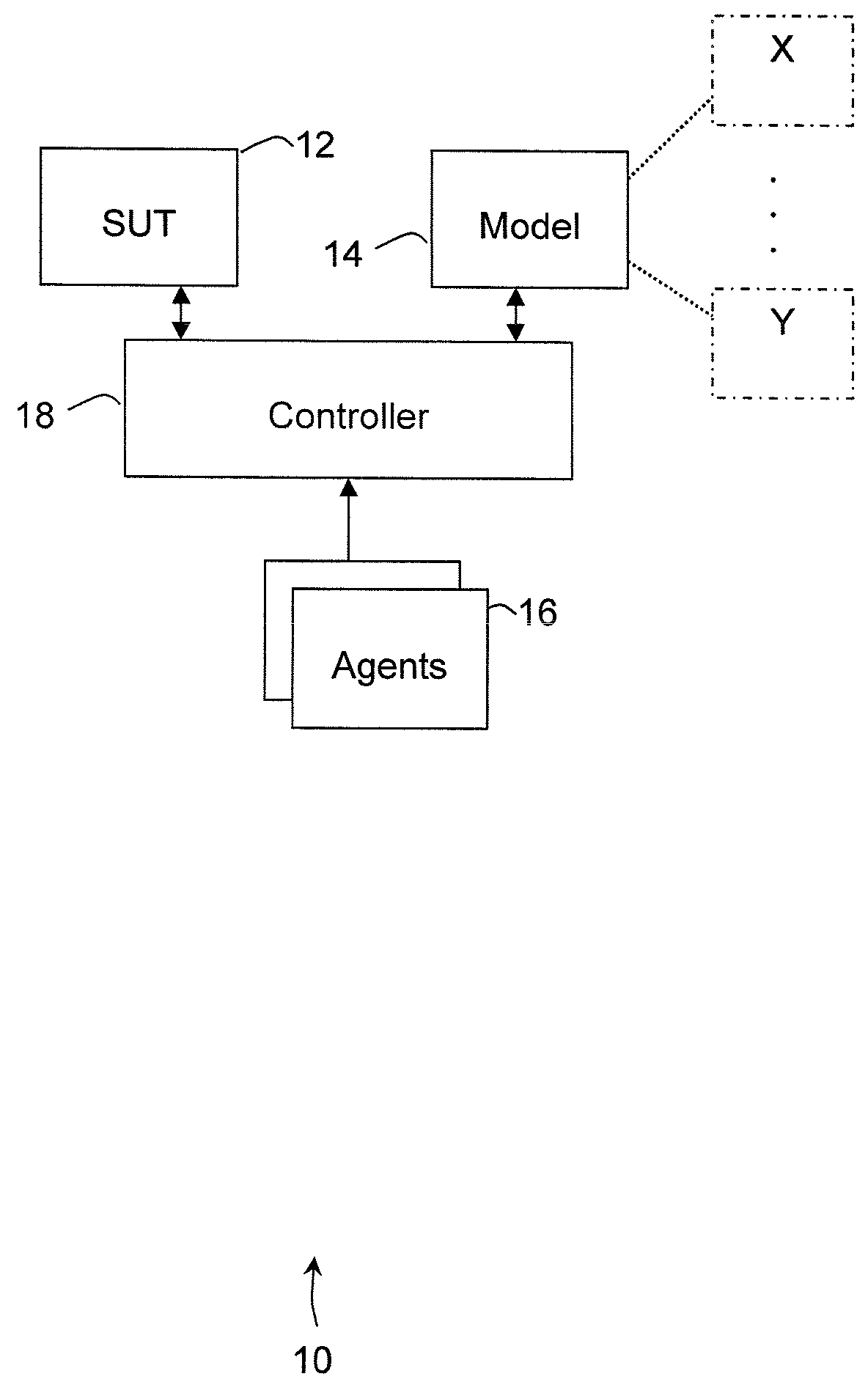

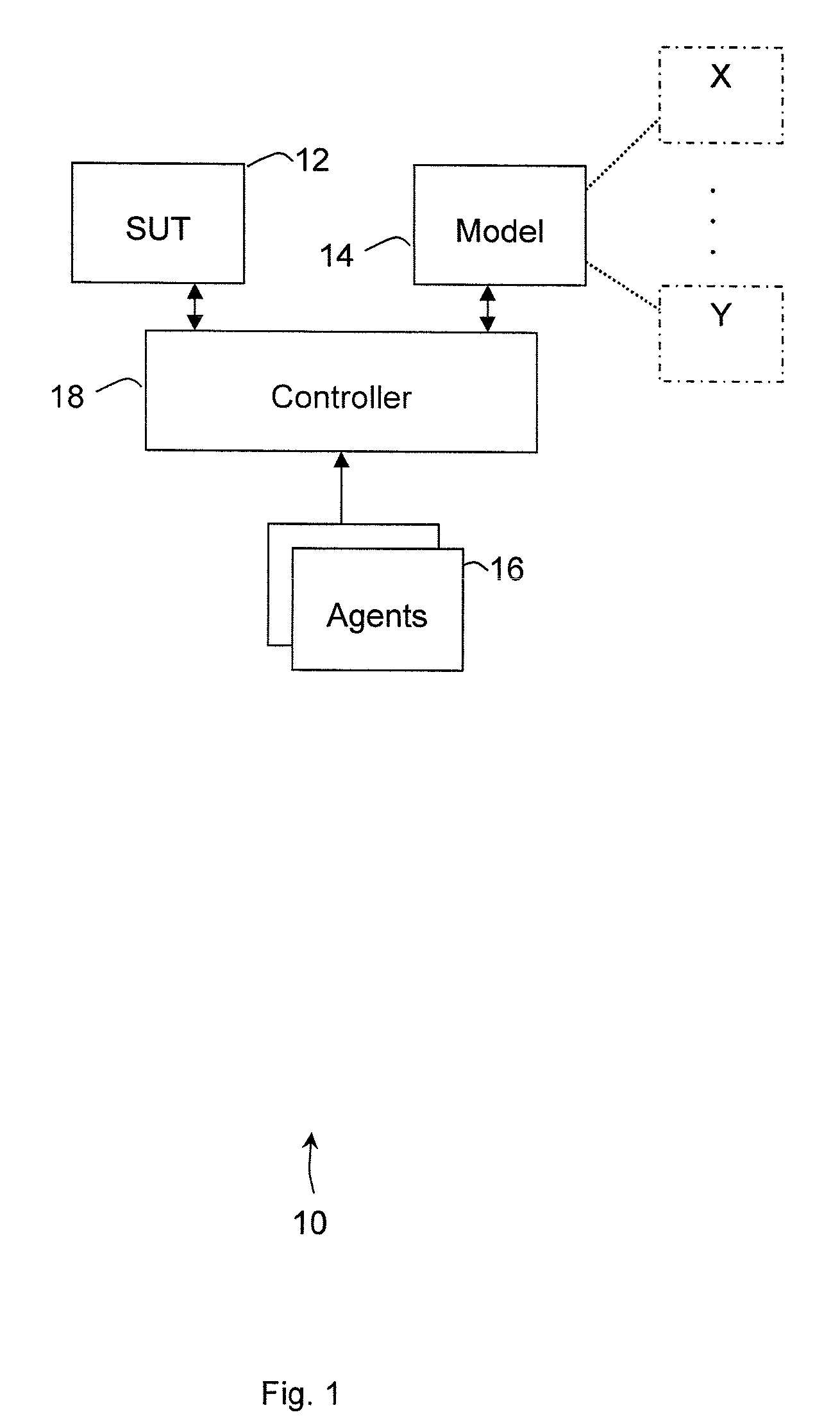

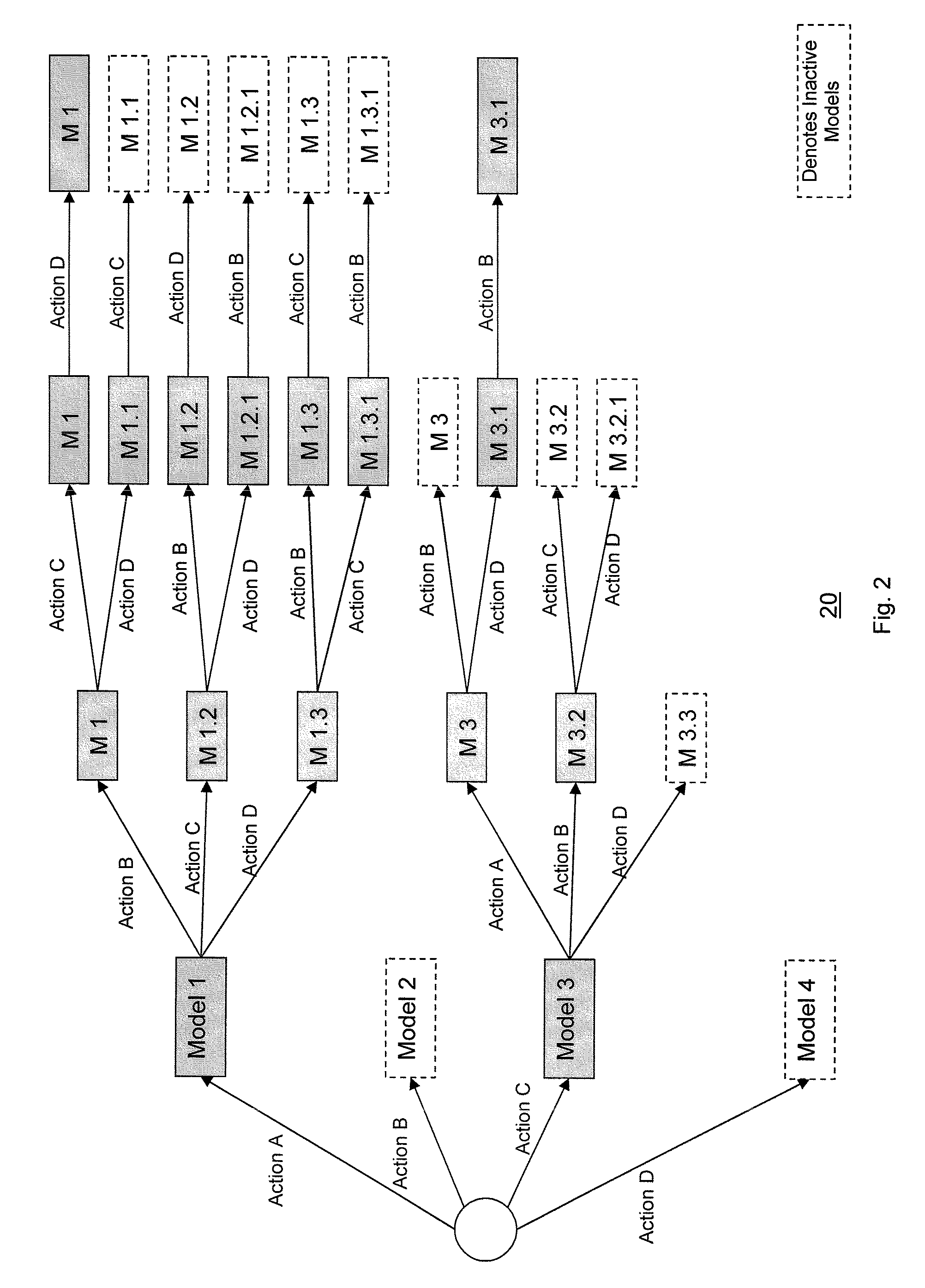

Method and apparatus for concurrency testing within a model-based testing environment

InactiveUS7539980B1Error detection/correctionSpecific program execution arrangementsSoftware systemTest failure

A method and apparatus for concurrency testing within a model-based testing environment is provided. One implementation involves concurrency testing within a model-based software system testing environment, by receiving concurrent test service requests; duplicating a model representing software under test, based on the number of requests; sending the concurrent requests to each of the duplicated models sequentially but in different orders; storing the outcomes of each of the models; comparing the outcomes from the models to the outcome from the software system under test; and if all comparisons fail, then indicating test failure.

Owner:IBM CORP

Method and apparatus for efficient communication of management data

InactiveUS20060026272A1Valid reportDigital data processing detailsMultiple digital computer combinationsElement management systemData transport

A mediator for efficiently exchanging management data in a hierarchical management network for managing network elements of a data transport network partitions resources of the network elements among a plurality of management representations of the network elements and selectively forwards management data associated with respective management representations to a higher level of the hierarchy. The mediator modifies the management data so that the higher level (i.e. a northbound element management system or a network management system) receives the management data in a view consistent with the management representation of the network element. Client-based management representations may be created to permit clients to manage selected resources of a network element, and testing-based management representations may be created to facilitate concurrent testing of a network element.

Owner:RPX CLEARINGHOUSE

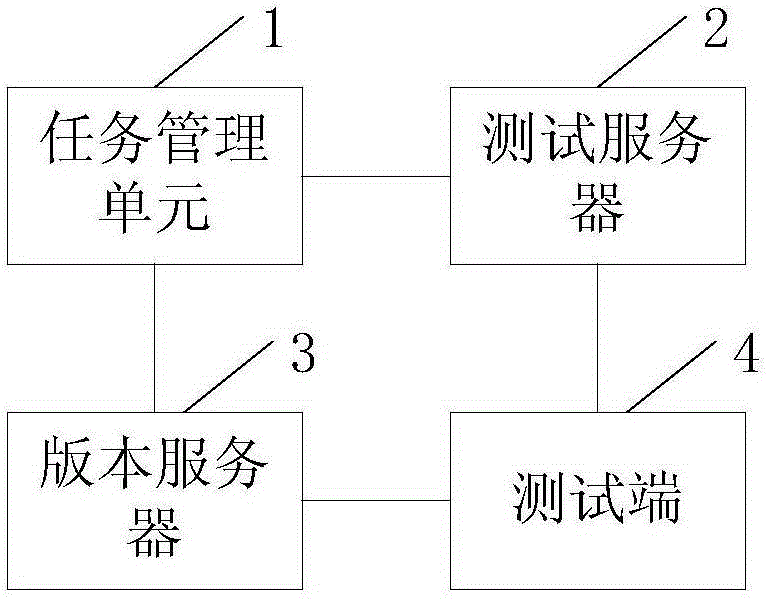

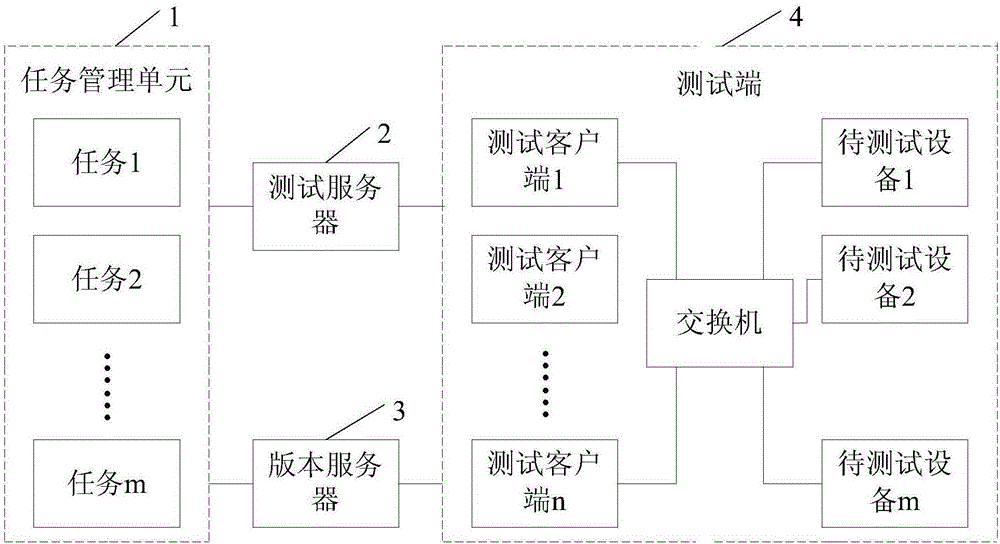

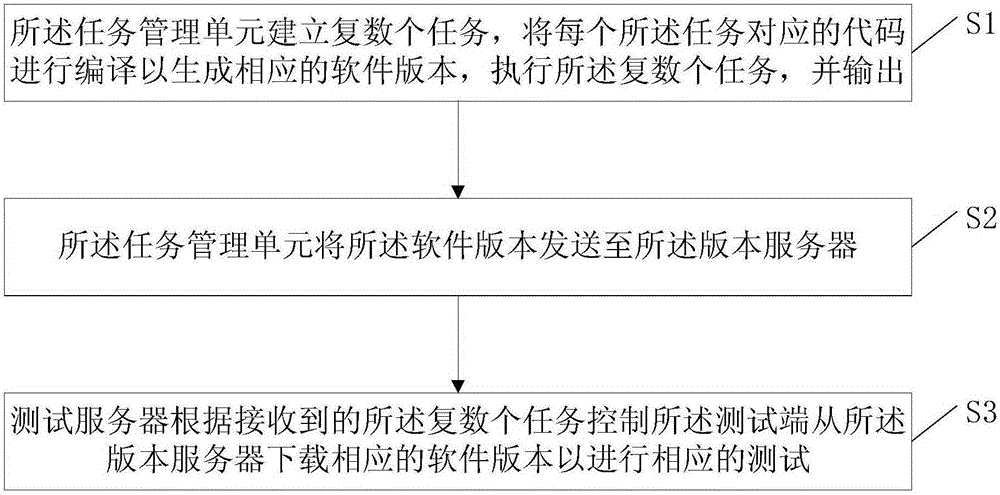

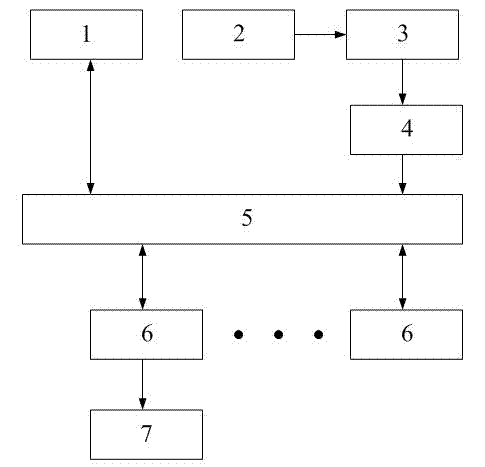

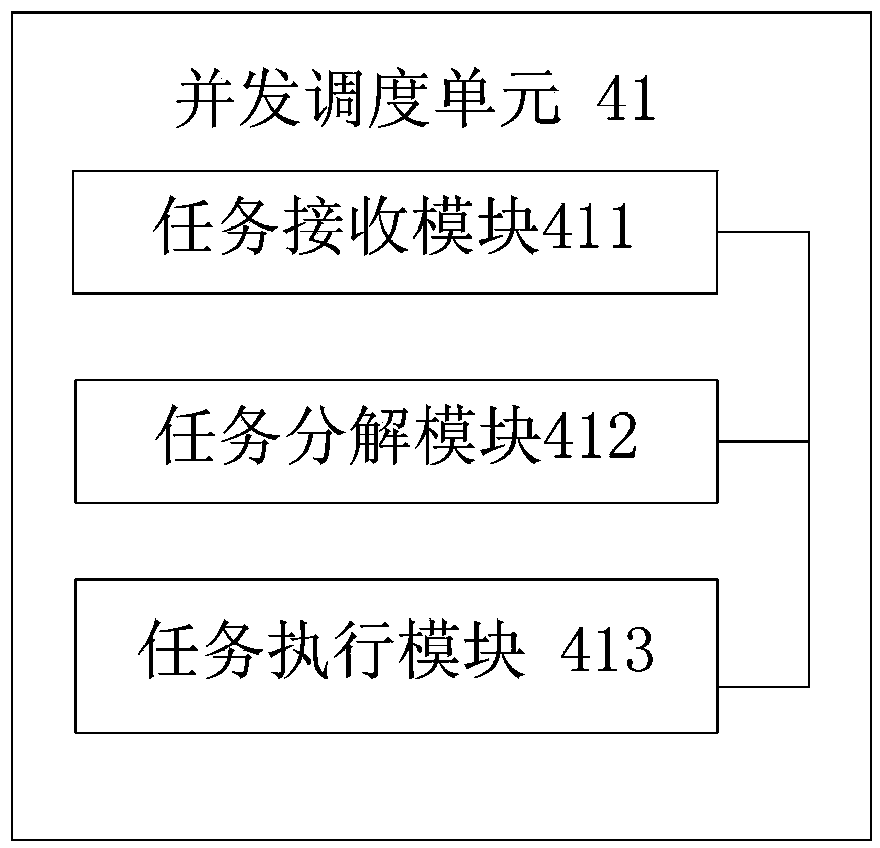

Multipletask integrated automatic test system and method

ActiveCN105183644AReasonable distributionImprove test efficiencySoftware testing/debuggingTest efficiencySoftware engineering

The present invention discloses a multitask integrated automatic test system and method. The multitask integrated automatic test system comprises a task management unit, for establishing a plurality of tasks, compiling the code corresponding to each task to generate corresponding software versions, and performing a plurality of tasks and outputting; A version of server, connected to the task management unit, for storing the software version; A test terminal, connected to the version server, for downloading the corresponding software version; A test server, respectively connected to the task management unit and the test terminal, for controlling the test terminal according to a plurality of received tasks to download the corresponding software version to conduct corresponding tests. The multipletask integrated automatic test system can create a plurality of tasks and manage of the plurality of tasks by the task management unit, and can carry out concurrency test on theplurality of tasks by the testing server, thereby improving test efficiency.

Owner:深圳国芯人工智能有限公司

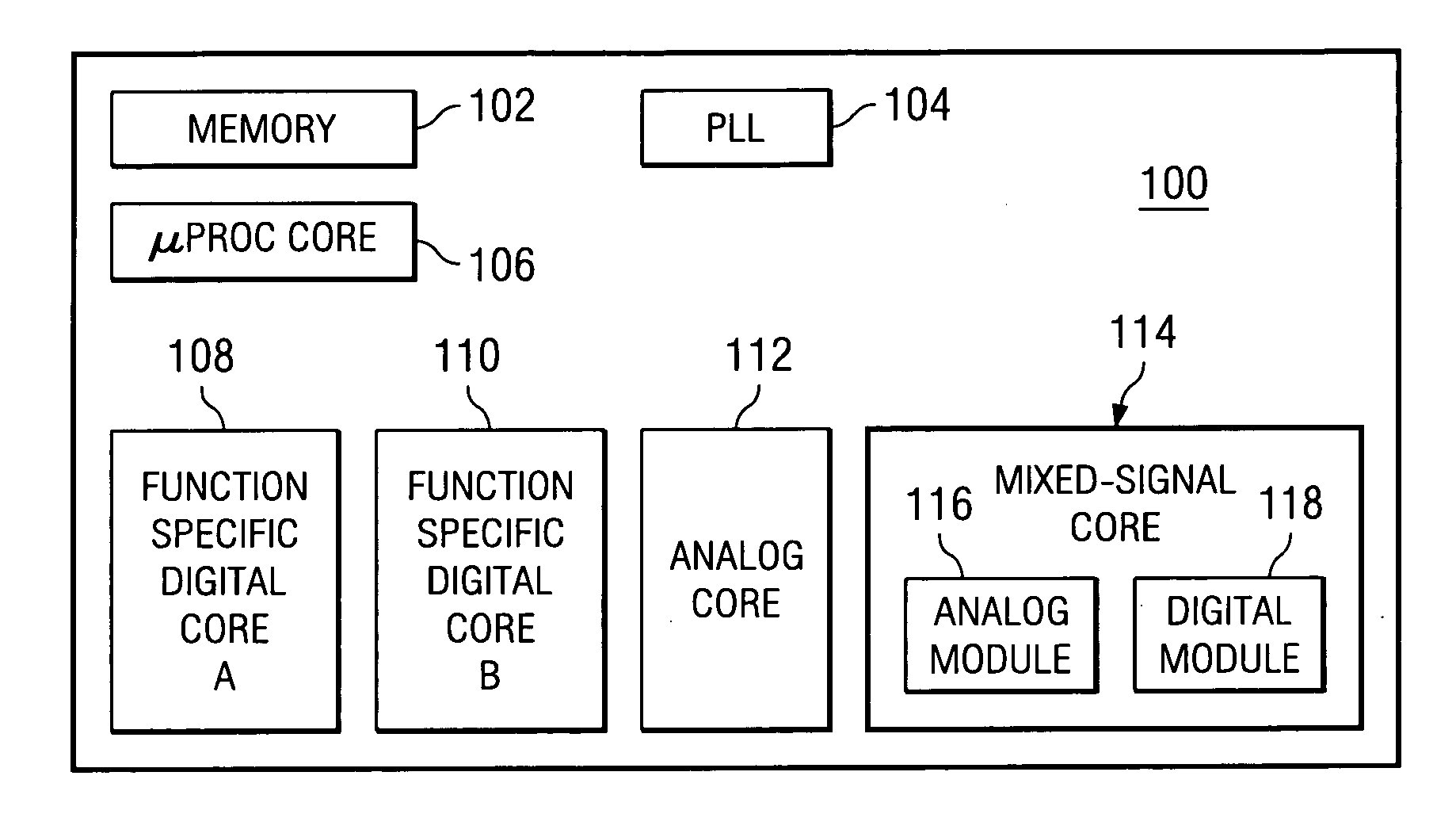

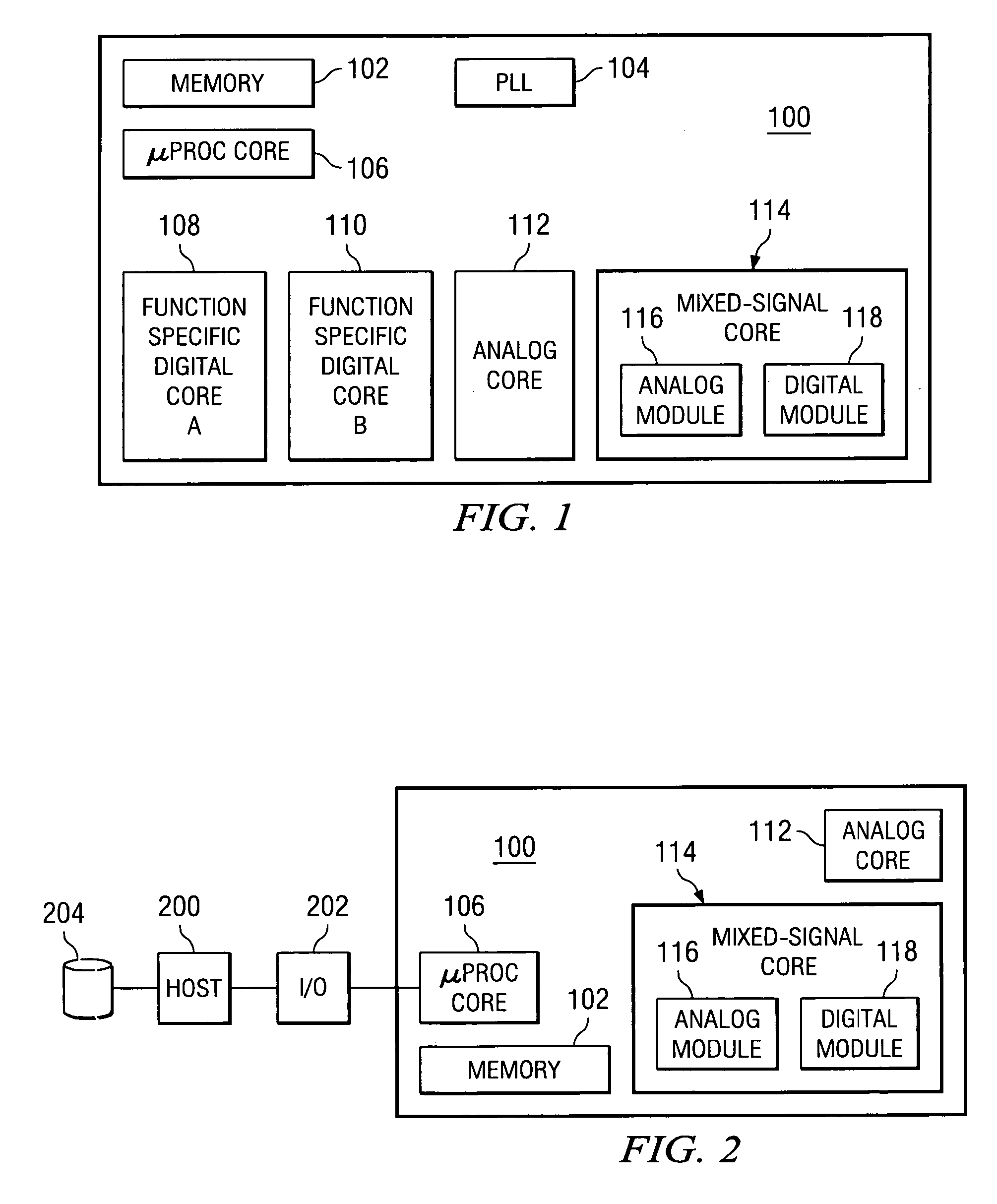

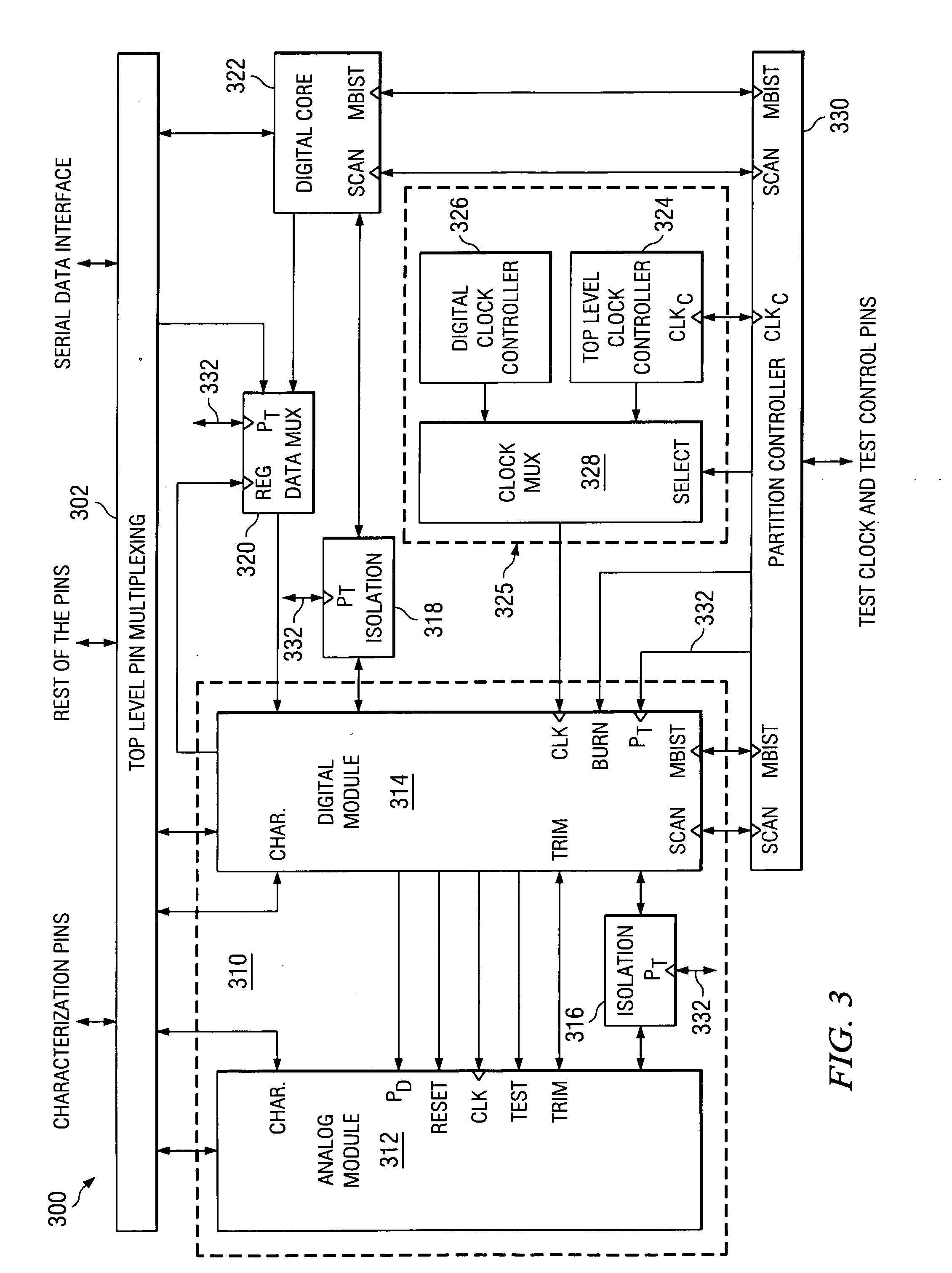

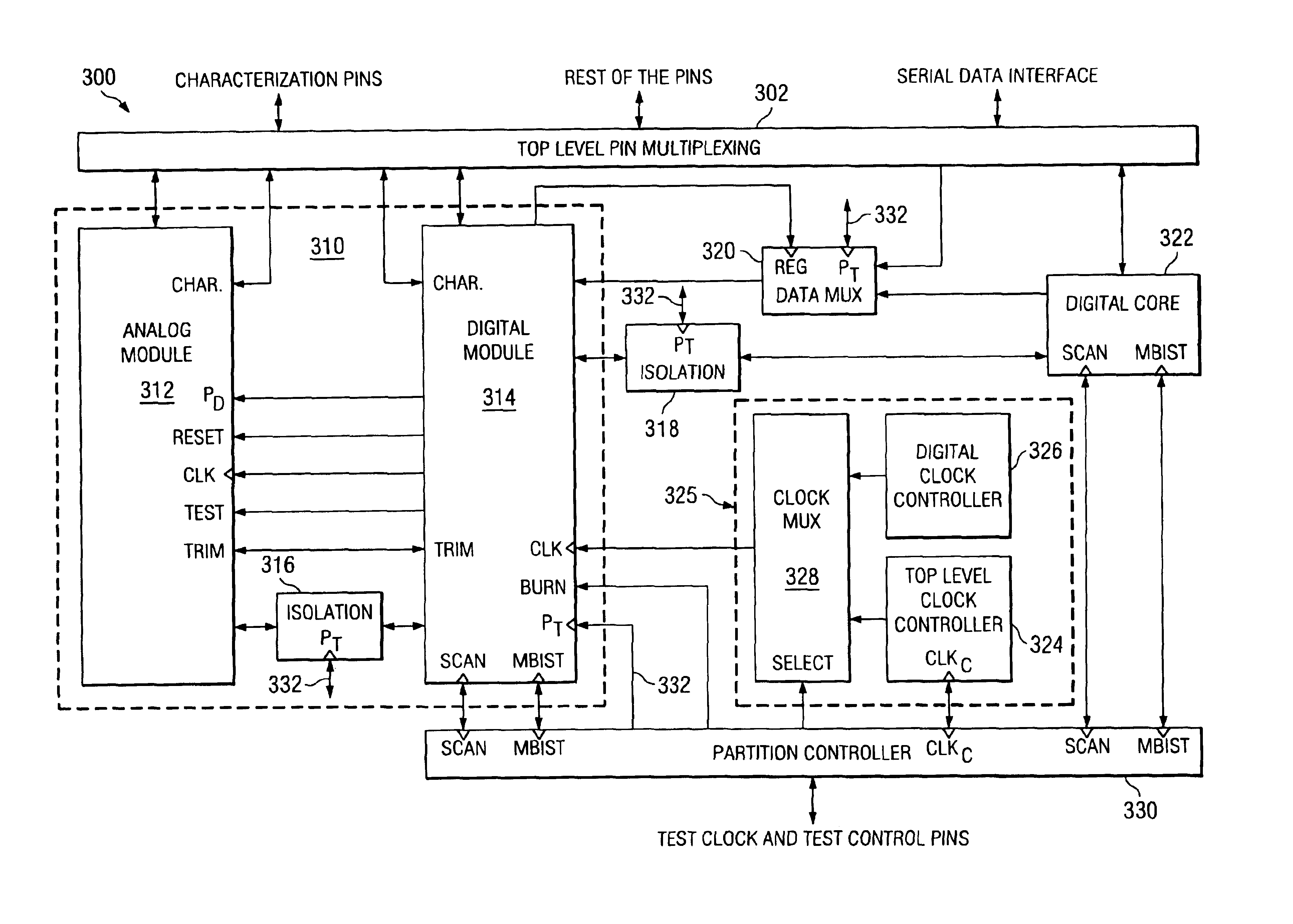

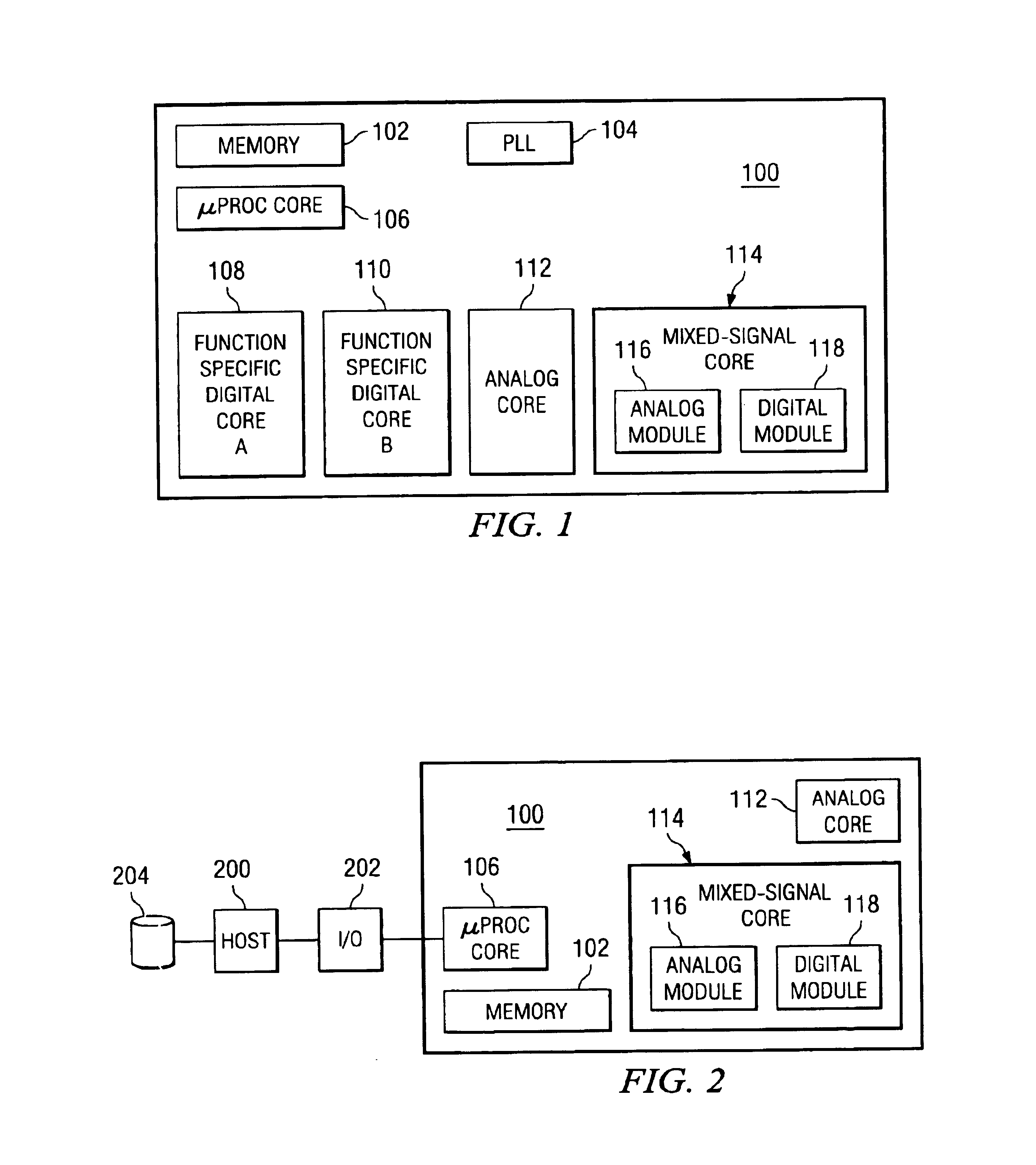

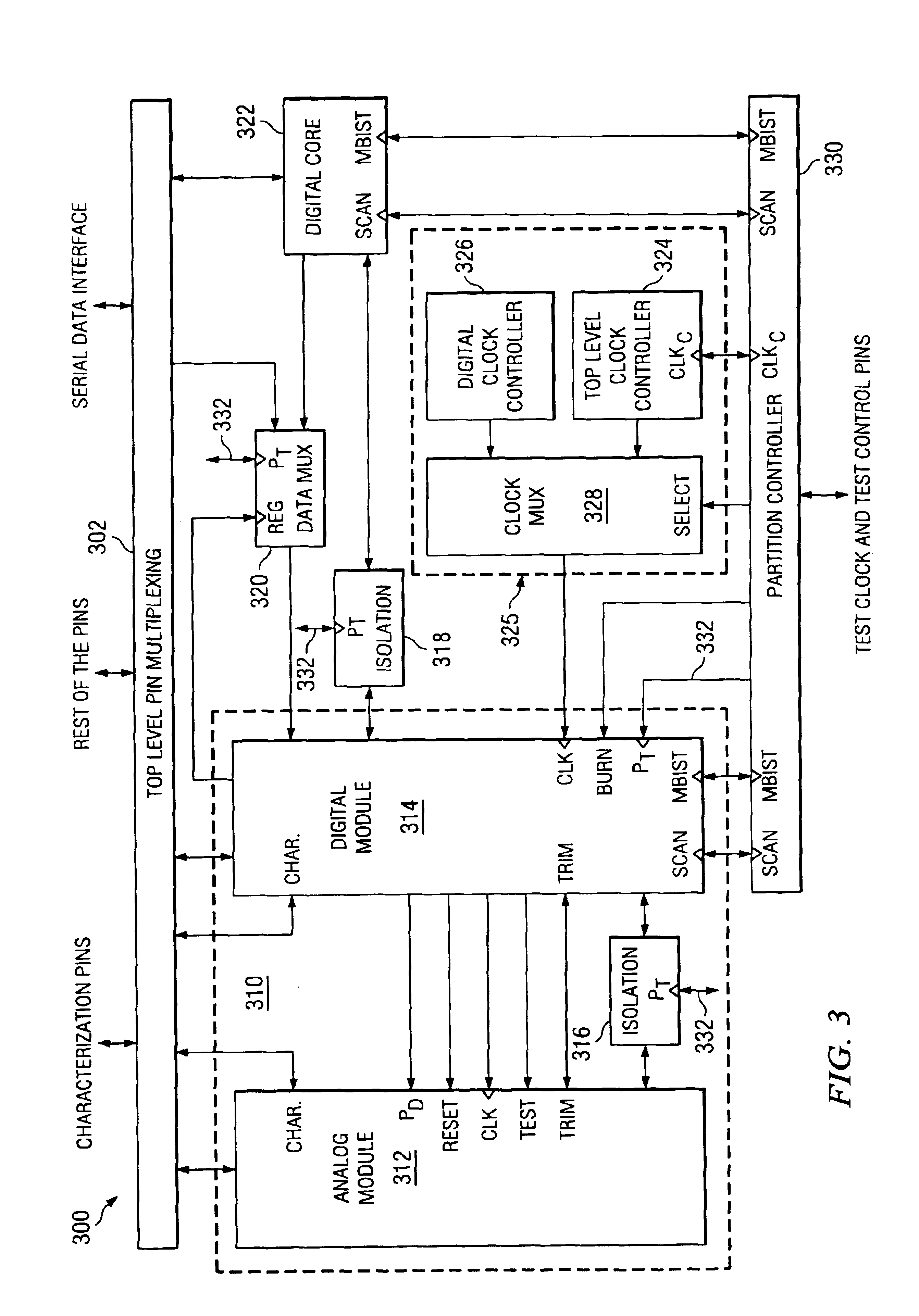

Mixed-signal core design for concurrent testing of mixed-signal, analog, and digital components

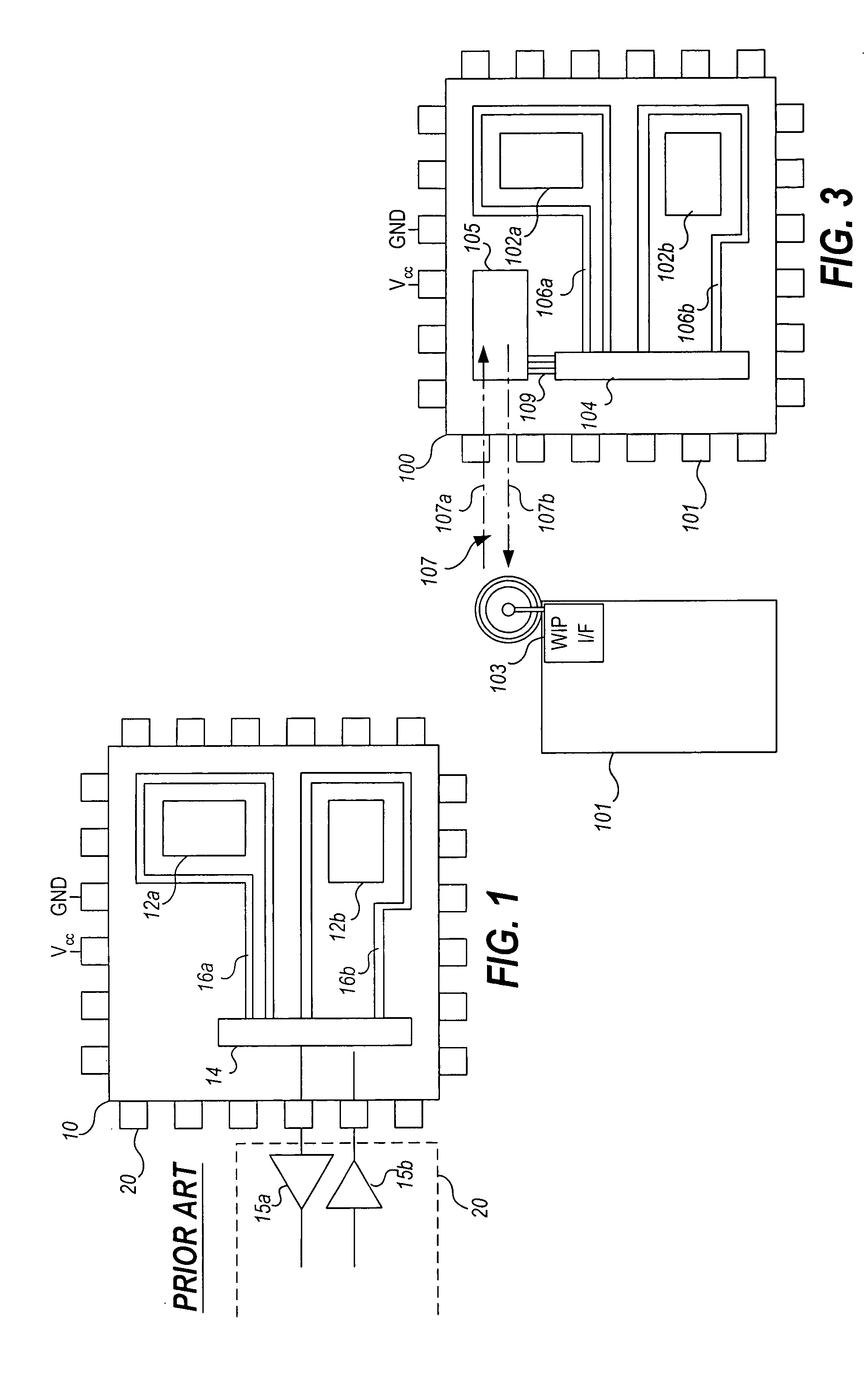

ActiveUS20050065747A1Shorten test timeReducing test development timeDigital circuit testingResistance/reactance/impedenceDigital interfaceTested time

A mixed-signal core disclosed herein is designed for efficient concurrent testing analog, mixed-signal, and digital components. One tester may test all components and, thereby, reduce test time without losing full test coverage. An analog module includes all the analog and mixed-signal components of the mixed-signal core, while a first digital module includes digital components required for functional / parametric verification of the mixed-signal components within the analog module. A first virtual boundary connects the analog and the first digital modules to gate the signal transfer during testing. A second digital module includes the remaining digital components of the mixed-signal core, whereby a second virtual boundary separates it from the first digital module. This type of partitioning enables the mixed-signal core to have three modes of operation, wherein the first mode of operation provides digital interface characterization testing of the first and second digital module and analog characterization / trimming testing of the analog module. In the second mode of operation, concurrent testing of the analog module and the first and second digital module is conducted; wherein analog characterization / trimming testing is performed on the analog module and digital interface characterization testing is performed on the first digital module, while SCAN / BIST testing is performed on the second digital module. In the third mode of operation, non-concurrent testing of the analog module, the first digital module, and the second digital module is enabled; wherein SCAN / BIST testing of the first digital module and the second digital module is enabled, while the analog module is powered down.

Owner:TEXAS INSTR INC

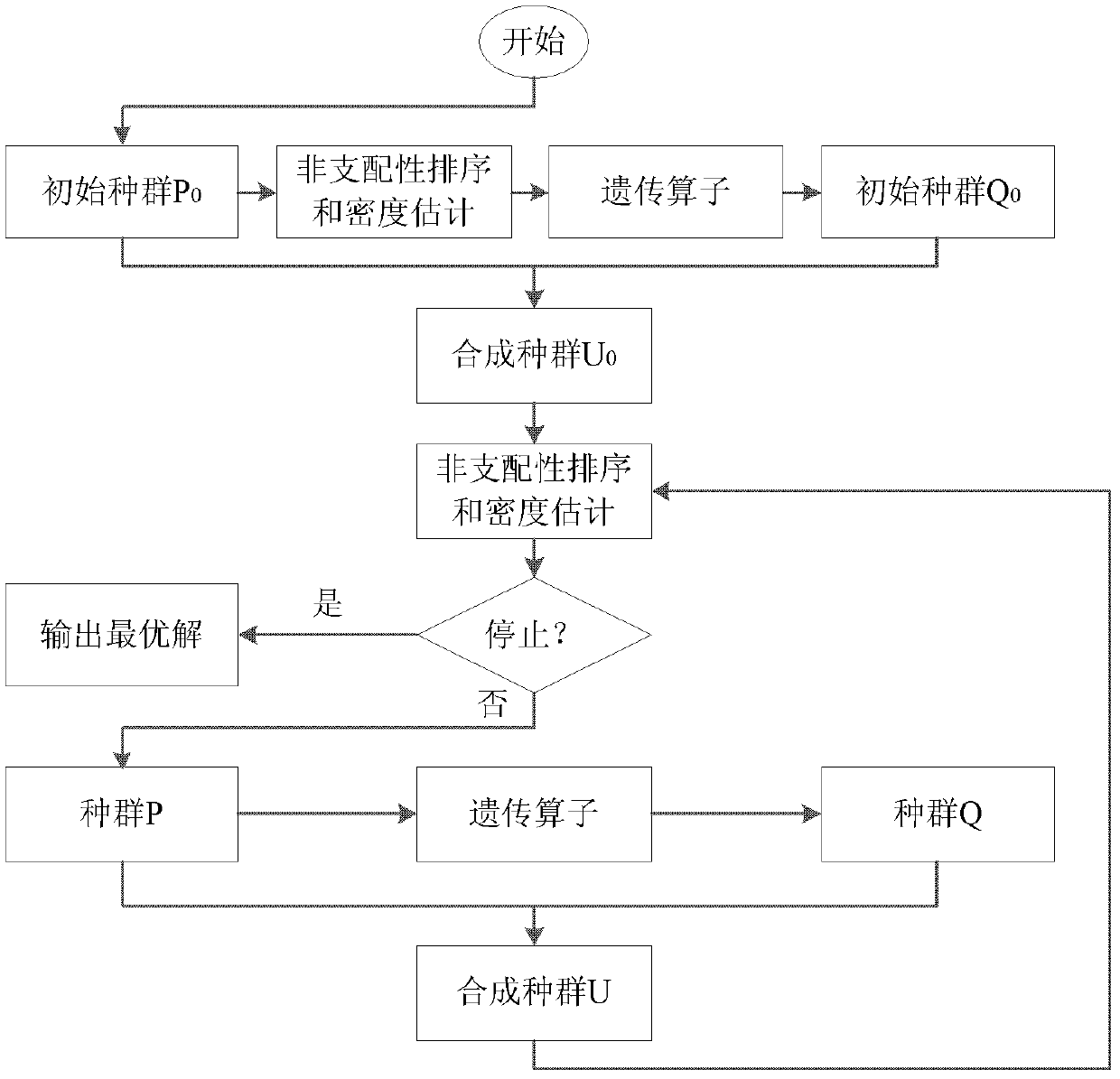

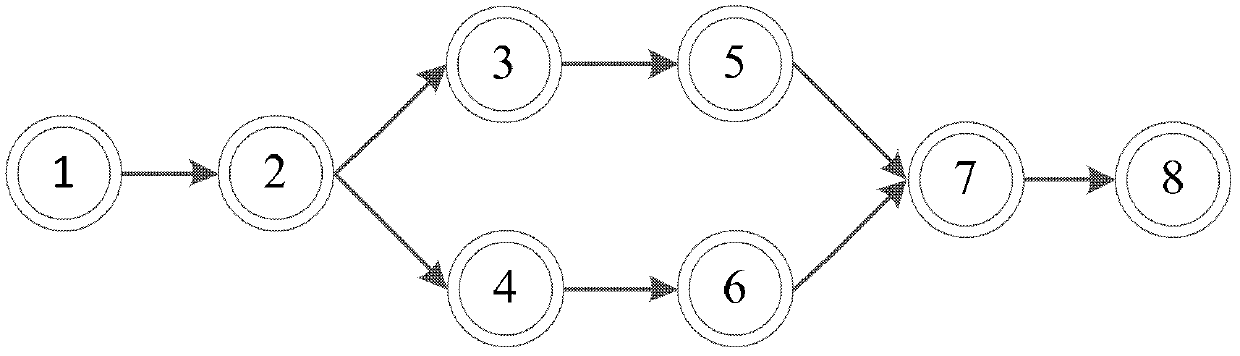

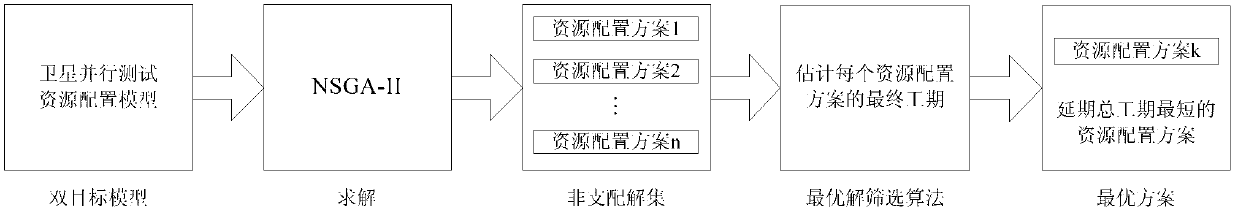

Method for allocating satellite concurrent testing resources based on genetic algorithm

InactiveCN102646061AReduce adjustment costsShort total test durationResource allocationGenetic modelsTest efficiencyGenetics algorithms

The invention discloses a method for allocating satellite concurrent testing resources based on a genetic algorithm. The method comprises four steps of: defining the stability and the total time limit of a resource allocation scheme; solving a dual-objective scheduling model of the allocation of the satellite concurrent testing resources by adopting a non-dominated sorting genetic algorithm (NSGA-II) to obtain a non-dominated solution set; solving the dual-objective scheduling model by adopting an optimal solution filtering algorithm to obtain an optimal resource allocation scheme; and finishing a design. The method for allocating the satellite concurrent testing resources based on a genetic algorithm in an uncertain environment is provided by the invention to obtain a stable resource allocation scheme, so that limitations of the conventional method for allocating the concurrent testing resources are overcome, the aim of optimal allocation of the satellite concurrent testing resources is fulfilled, the test efficiency is improved, and the test cost is reduced. The method has a good practical value and a wide application prospect in the technical field of an aero-space concurrent testing technology.

Owner:BEIHANG UNIV

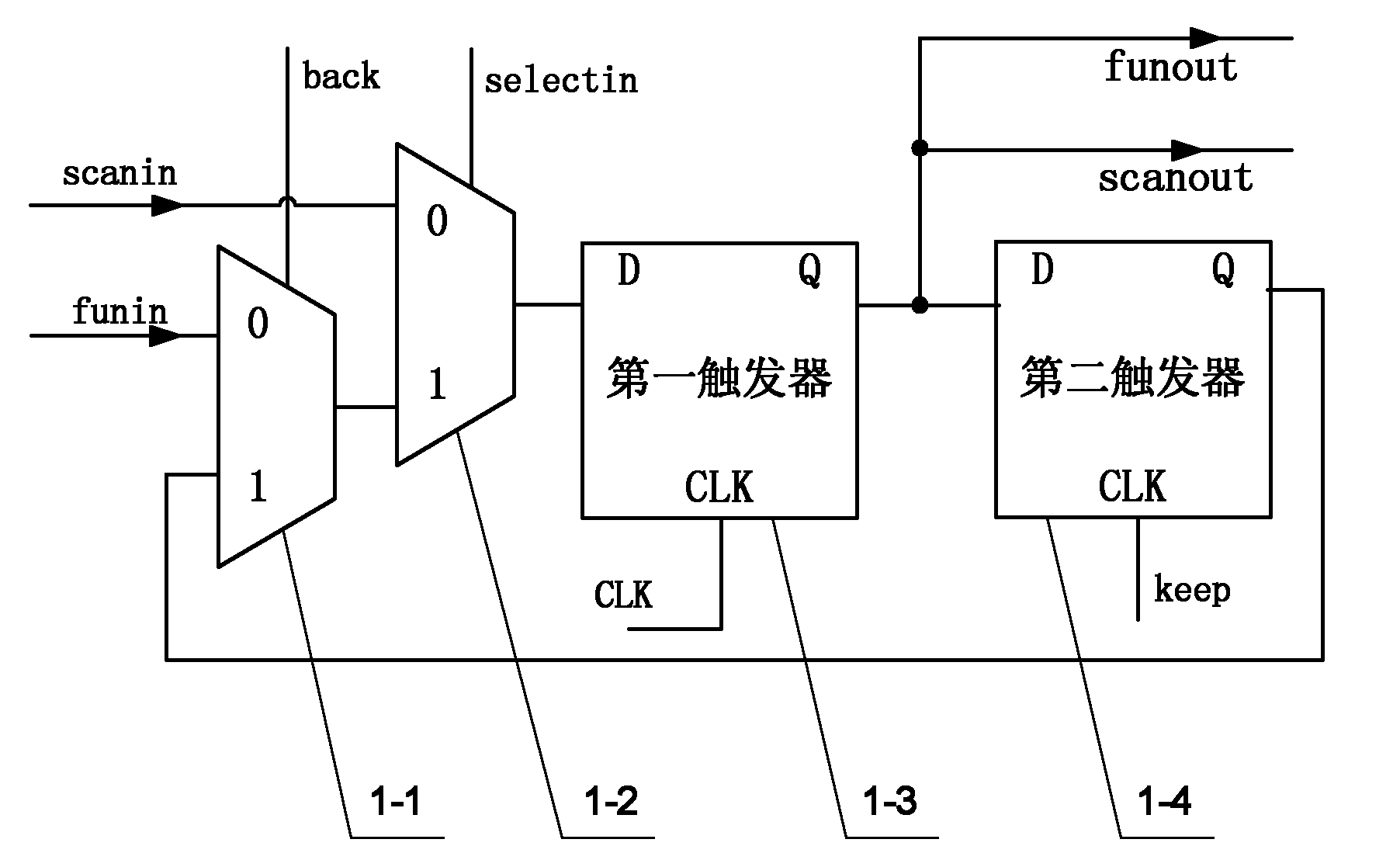

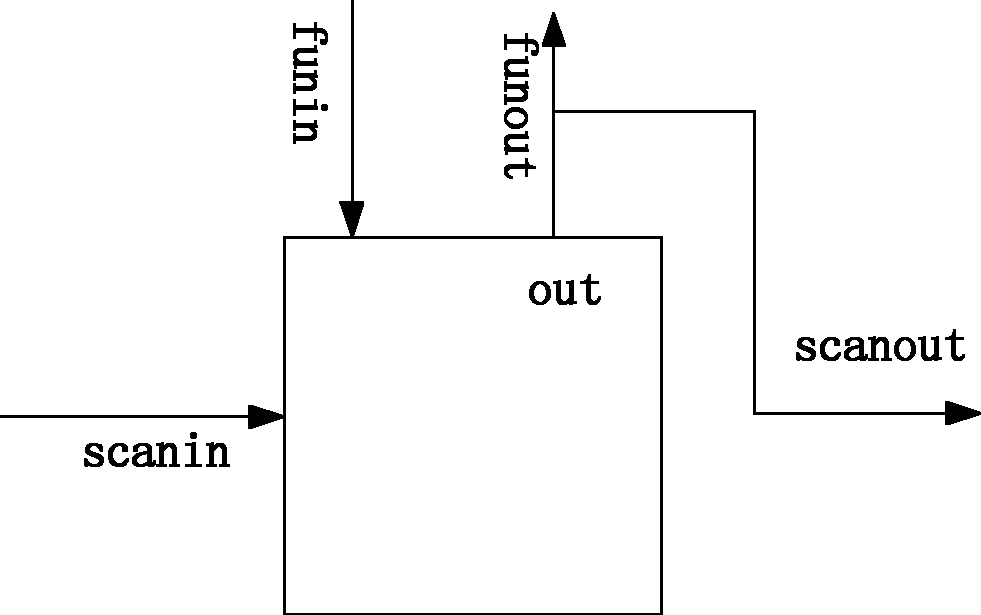

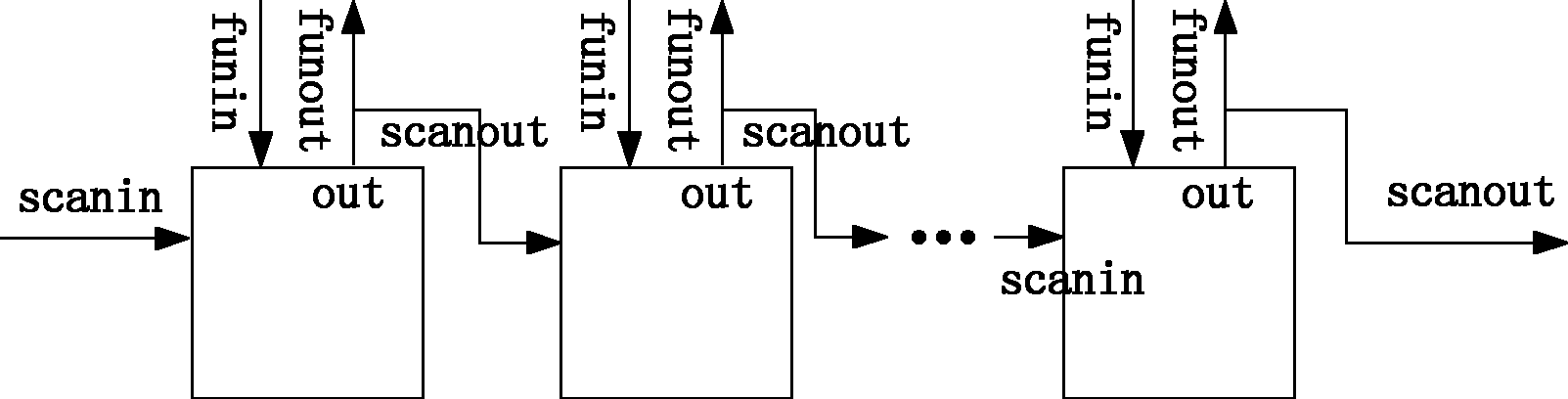

Improved scan chain unit and non-concurrent testing method based on same

InactiveCN102043122ASimple timing controlImprove test efficiencyDigital circuit testingSystem testingMultiplexer

The invention relates to an improved scan chain unit and a non-concurrent testing method based on the same, which belongs to the filed of on-chip system testing and aims at solving the problems that the existing scan chain-based non-concurrent on-line testing method has strict requirements for time sequences, is difficult to control and can not realize the one-step import of multiple groups of test vectors. The improved scan chain unit is used for replacing a D trigger in an on-chip system, and the unit contains two triggers and two selectors, wherein a first trigger is a basic unit which composes the original circuit scan chain and is used for realizing the function same with that of the original D trigger, and a second trigger is introduced for saving data in the testing process; and the two data selectors control the flow direction of data by means of enable ends, a first selector is used for controlling whether data in the second trigger can be transmitted to the first trigger, and a second selector is used for controlling the working state or the scanning state of the first trigger. Thus, multiple groups of test vectors can be input to the unit for continuous testing, and therunning state of the circuit is not changed before and after the test.

Owner:HARBIN INST OF TECH

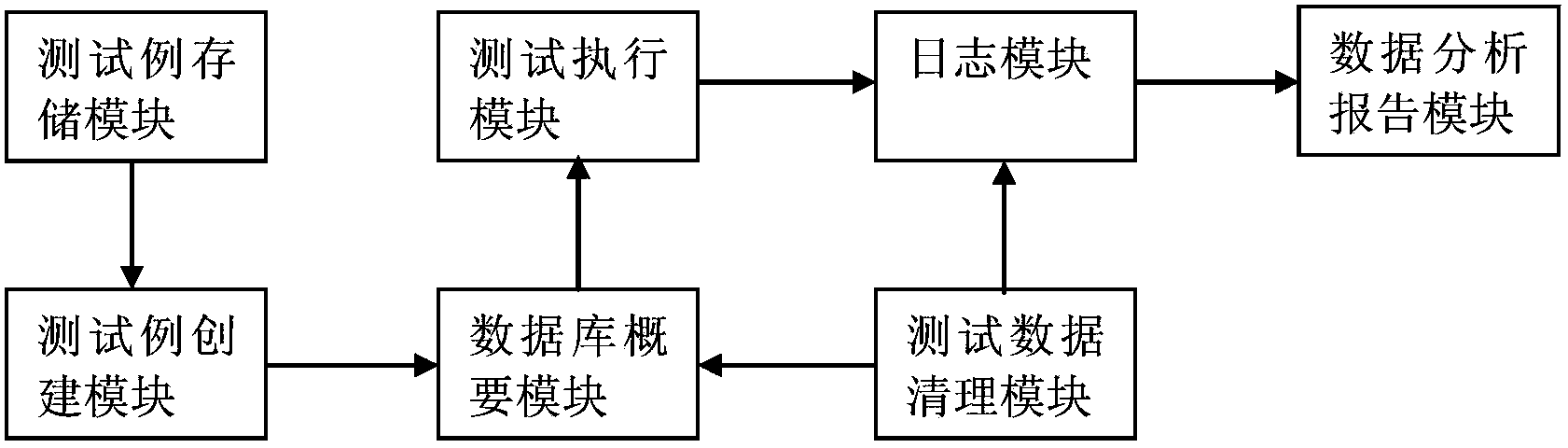

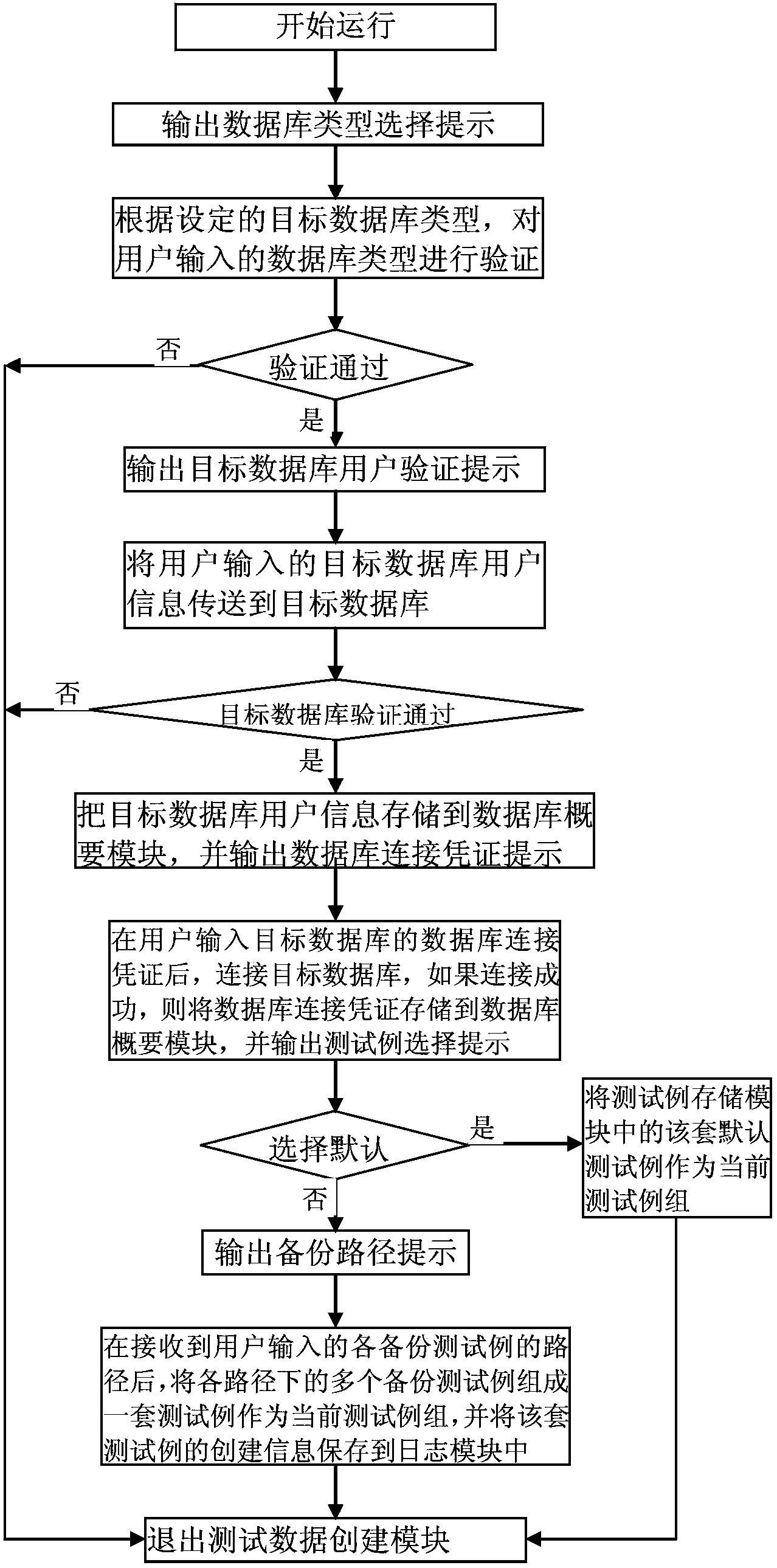

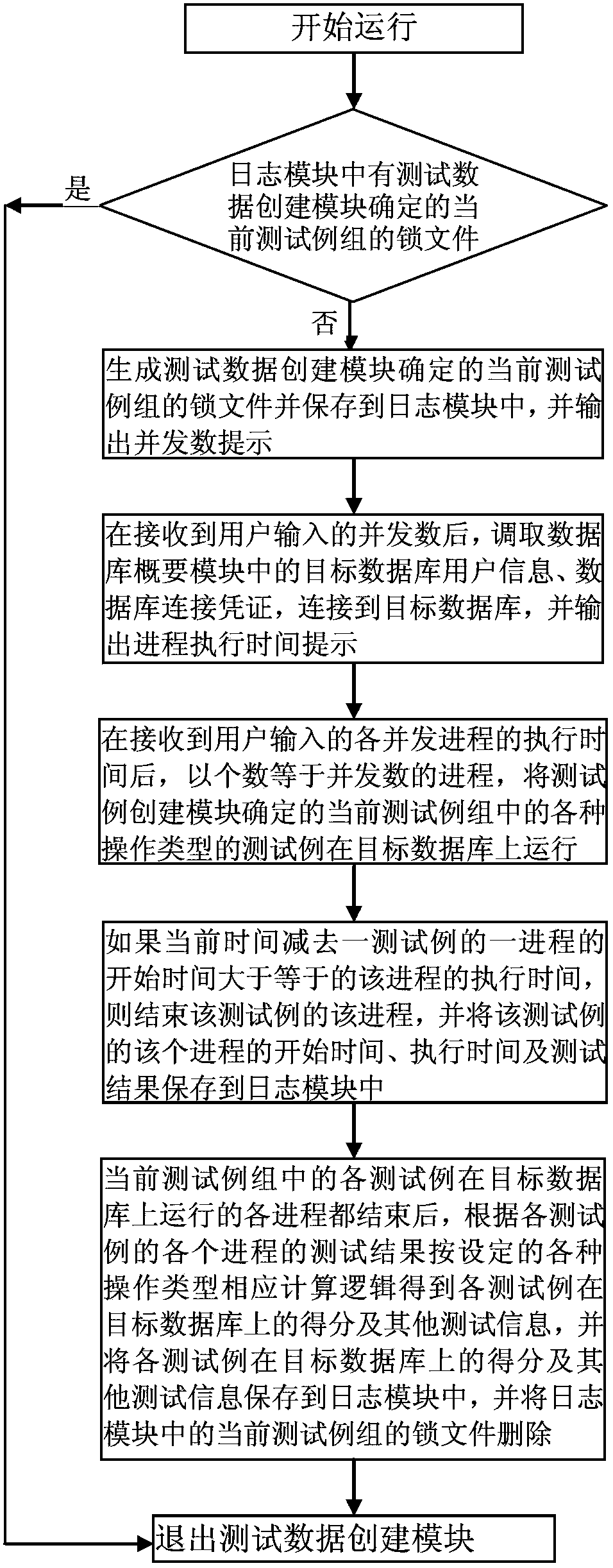

Database performance test system

ActiveCN103425683AComprehensive test indicatorsEasy to testError detection/correctionSpecial data processing applicationsProgramming languageComputer module

The invention discloses a database performance test system. The database performance test system comprises a test case creating module, a test executing module and a data analysis reporting module, wherein the test case creating module is used for determining a current test case group which comprises one or more operation types of test cases; the test executing module is used for conducting concurrent test on a target database according to all the test cases in the current test case group determined by the test data creating module and obtaining the score of each test case in the current test case group on the target database; the data analysis reporting module is used for calculating out the total score of the target database according to set weight of all the operation types on the basis of the scores of all the operation types of test cases in the current test case group on the target database. The database performance test system can self-define test data and test cases, rapidly and easily test database performance, and conduct comparison test on various types of databases.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Parallel concurrent test system and method

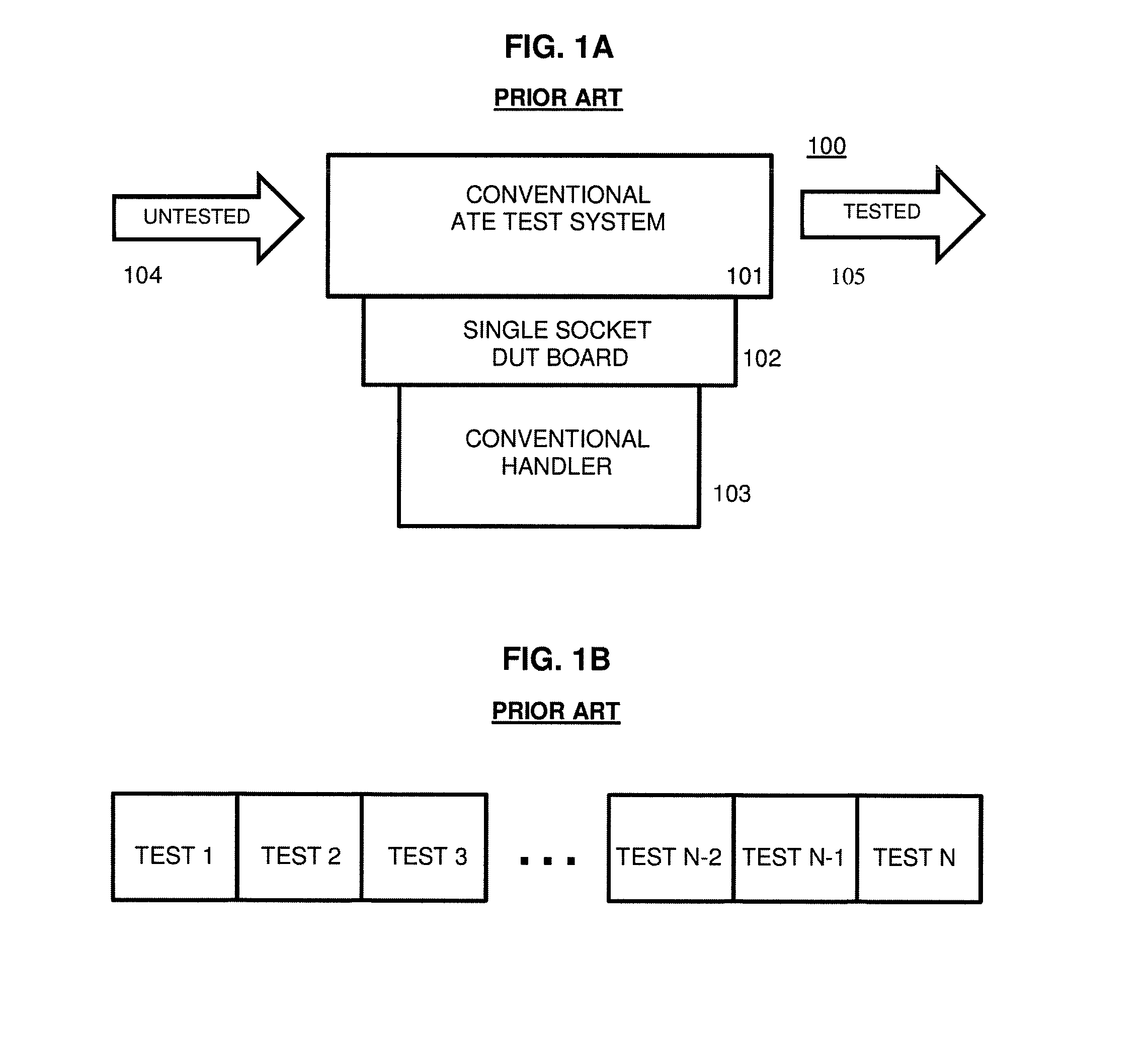

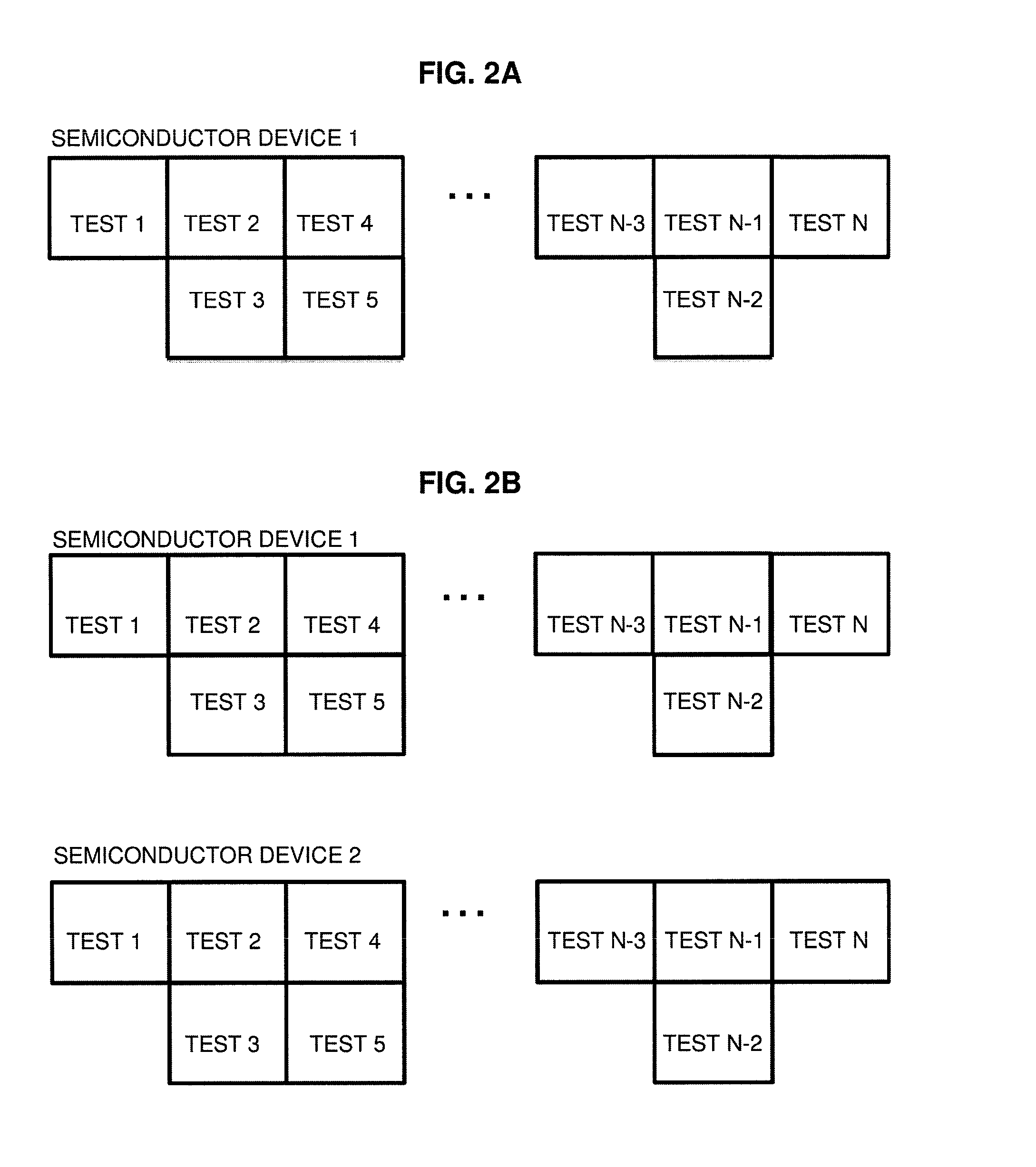

ActiveUS20140218063A1Short test timeEfficient executionAutomated test systemsIndividual semiconductor device testingTest designElectricity

Owner:CELERINT

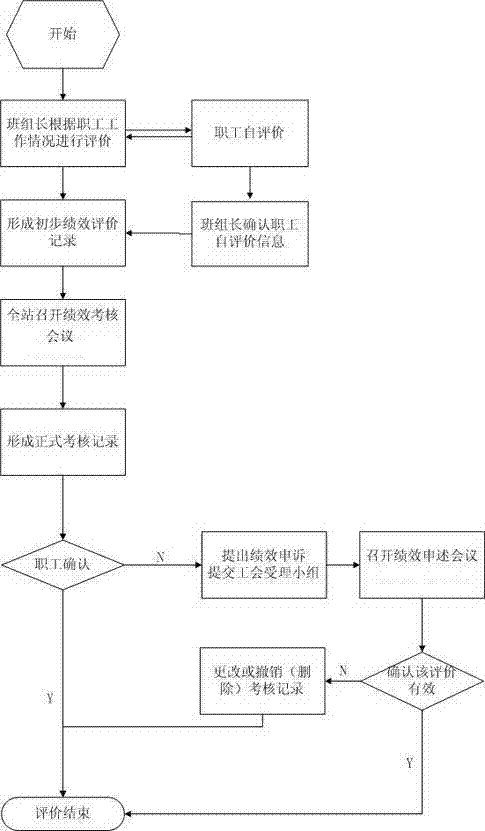

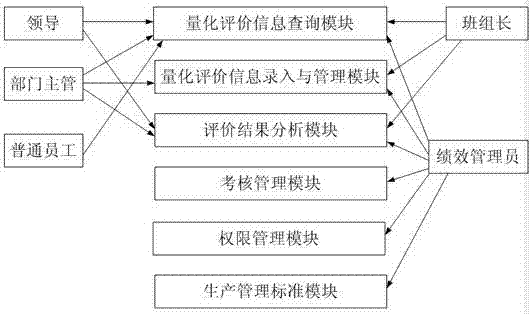

Method for realizing quantitative evaluation system of production process

InactiveCN103577928ARealize digital evaluationReduce labor intensityResourcesEvaluation resultDecomposition

The invention discloses a method for realizing a quantitative evaluation system of a production process. The method for realizing the quantitative evaluation system of the production process comprises the following steps that (1) a network structure of the quantitative evaluation system of the production process is built; (2) a modularized layout of the quantitative evaluation system of the production process is built, and the quantitative evaluation system of the production process adopts a B / S structure and comprises an authority management module, a quantitative evaluation information input and management module, a quantitative evaluation information inquiry module, an evaluation result analysis module, a production management standard module and an assessment management module. The method for realizing the quantitative evaluation system of the production process has the advantages of achieving the functions of classified management of evaluation standards, rapid input of evaluation information and statistic analysis of the evaluation information, being high in stability and execution efficiency after being tested by multiple users in a high-concurrency mode, classifying and refining all events in the whole production process according to evaluation objects, evaluation items, work categories, work standards and work items, achieving decomposition of the events of a work task, representing the efficiency of work process nodes, and carrying out digital evaluation on the work result.

Owner:STATE GRID CORP OF CHINA +1

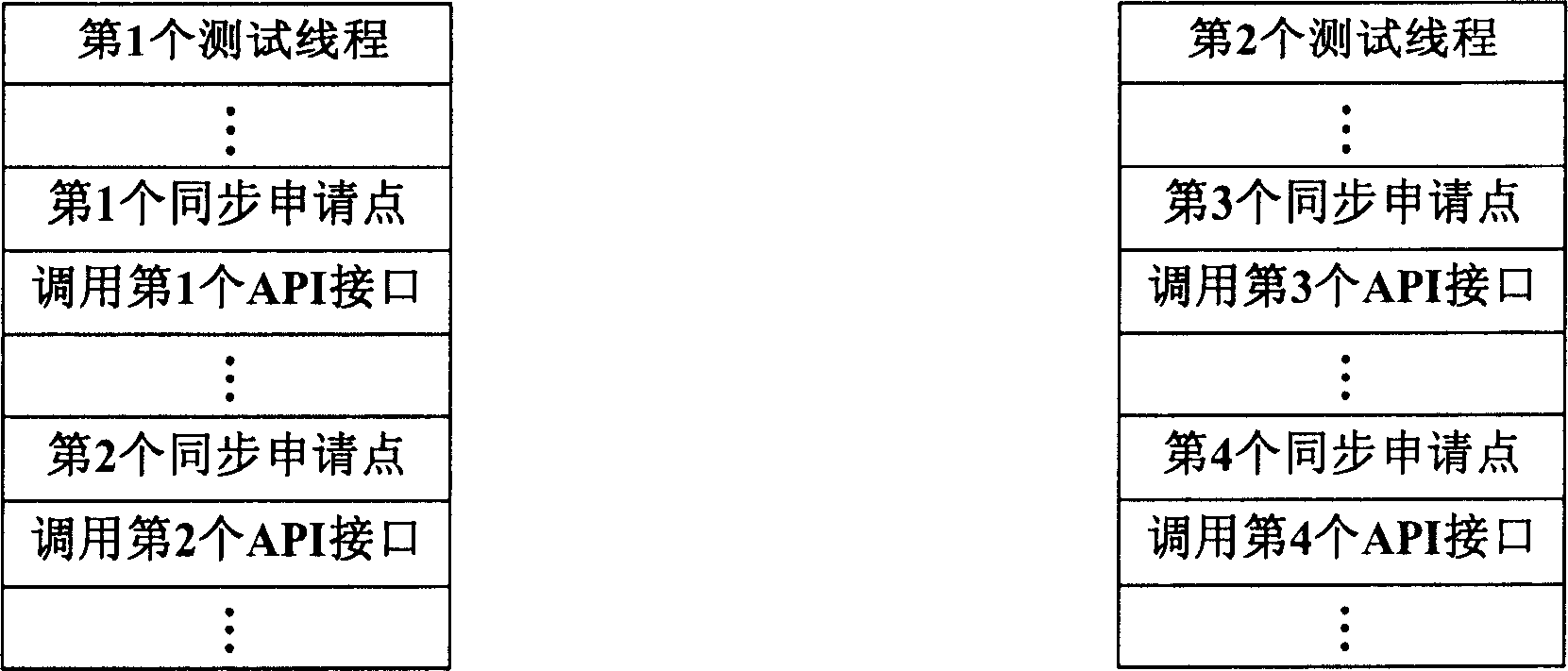

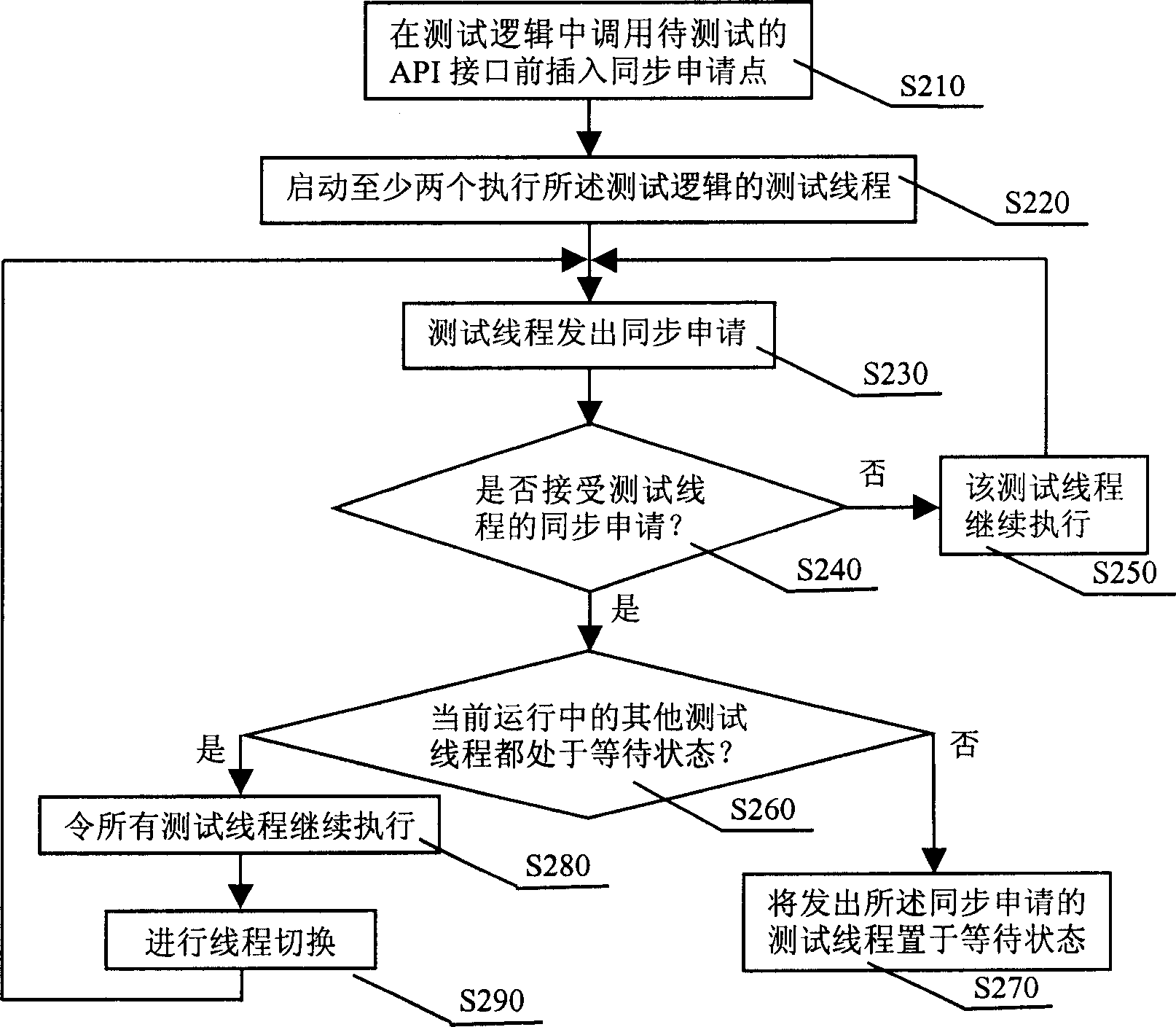

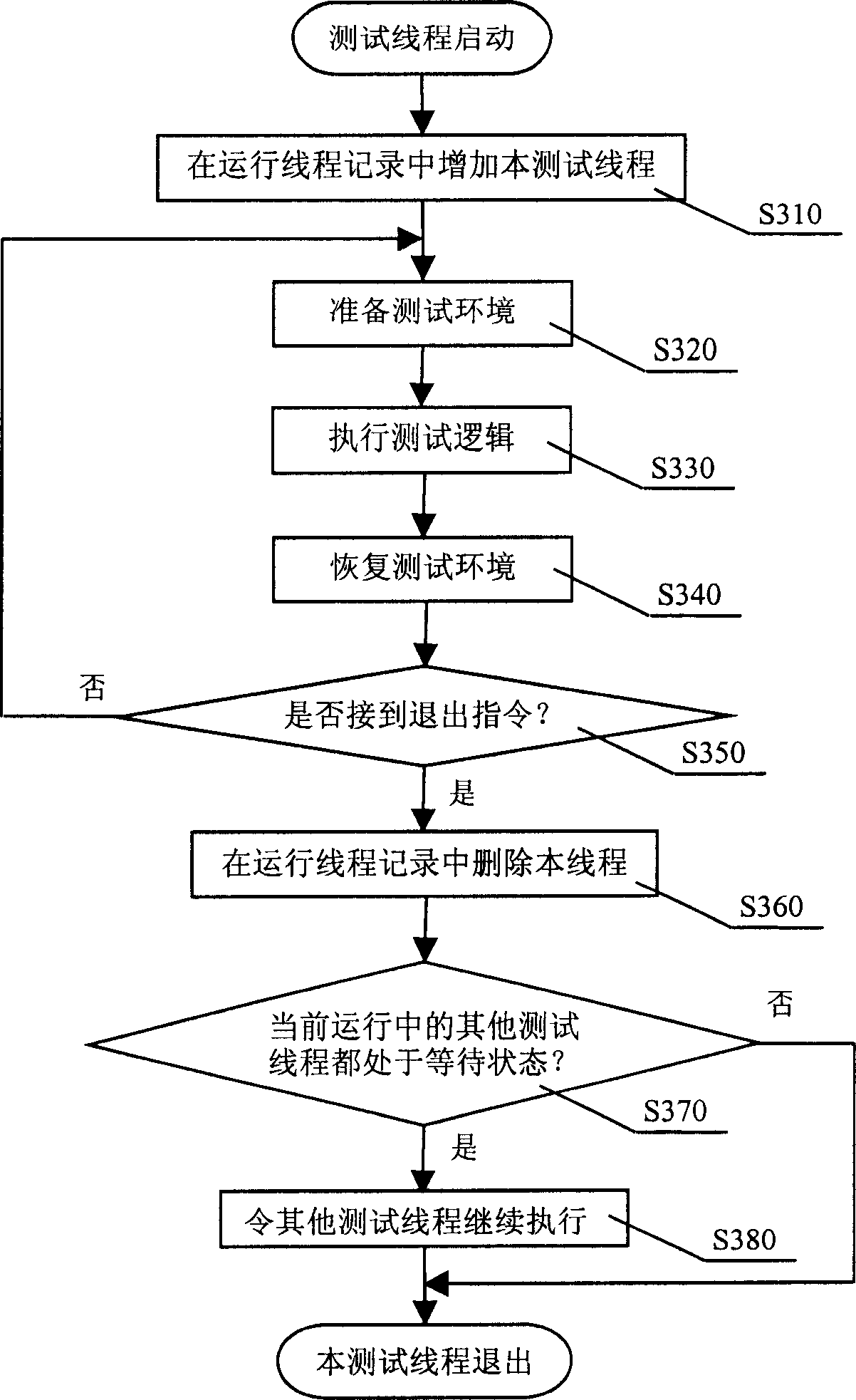

Method for testing multi-thread software concurrent conflict

InactiveCN1855068AShort cycleImprove efficiencyMultiprogramming arrangementsSoftware testing/debuggingApplication softwareCollision test

A method for testing collision of multilinear program software includes inserting synchronous application point before application program interface to be tested and to be called in test logic, operating at least two test linear programs and issuing synchronous application when test linear program is operated up to said point, judging whether said synchronous application is accepted or not and continuously issuing said synchronous application if it is not, continuously executing all test linear program to carry out collision test of test linear program if it is when the other test linear programs are at waiting-state.

Owner:HUAWEI TECH CO LTD

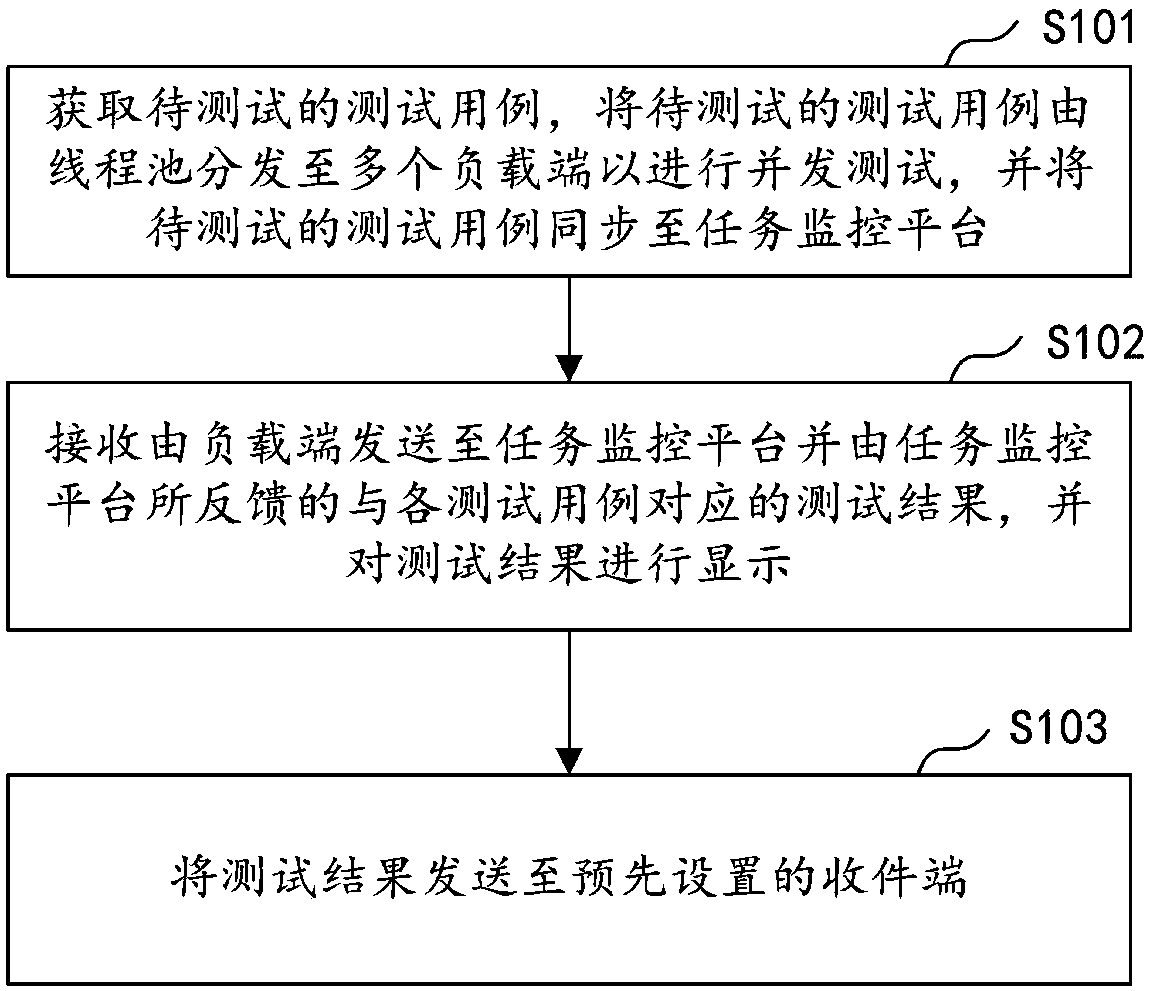

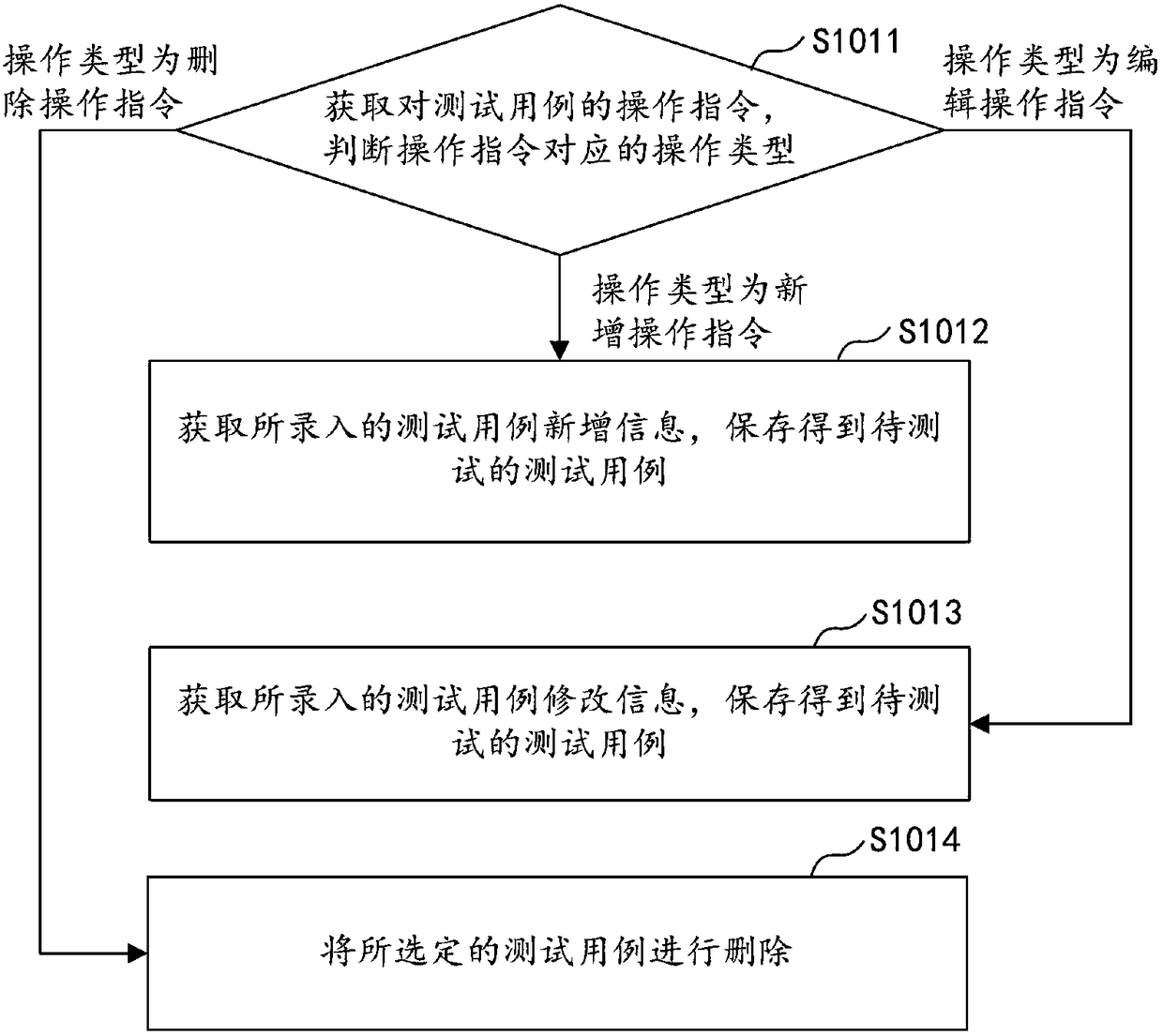

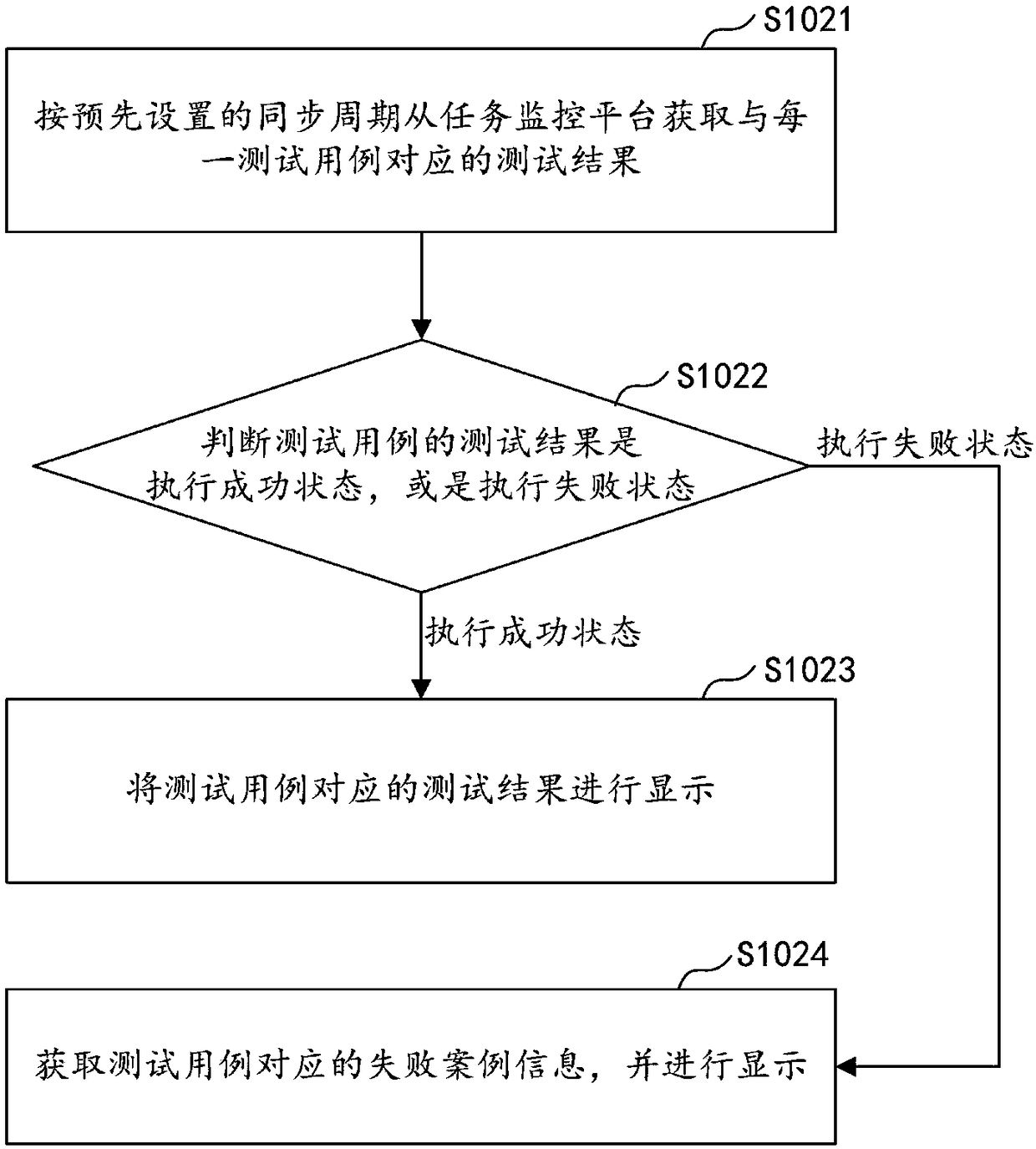

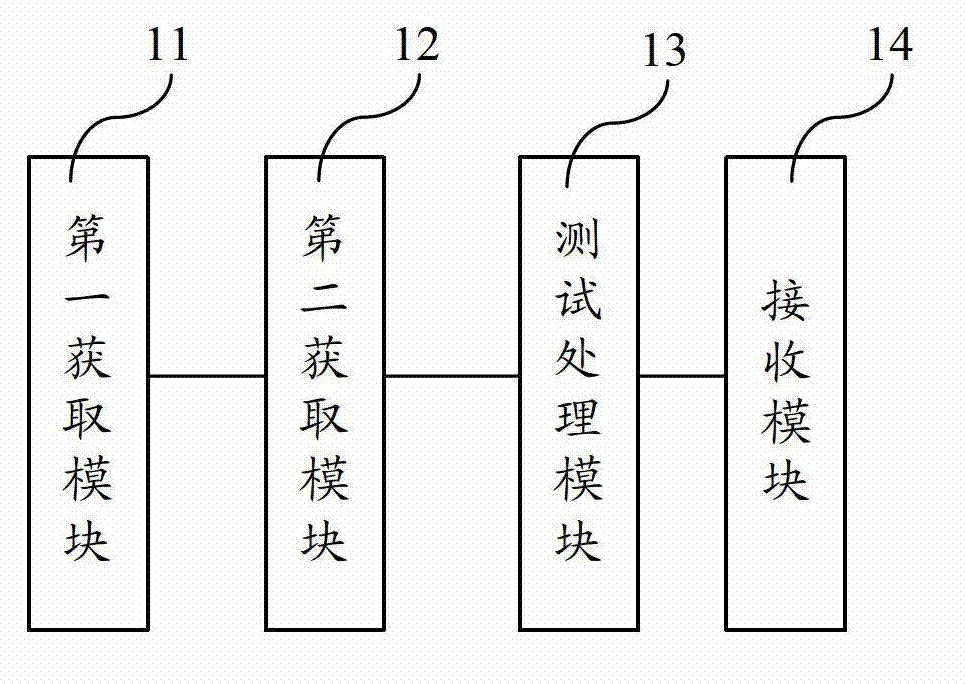

Automatic testing method and device, computer equipment and storage medium

The embodiment of the invention discloses an automatic testing method and device, computer equipment and storage medium. The method comprises the following steps: acquiring to-be-tested test cases, issuing the to-be-tested test cases to multiple load ends through a thread pool, carrying out concurrent testing, and synchronizing the to-be-tested test cases to a task monitoring platform; receiving test results which are sent to the task monitoring platform by the load ends and bed back by the task monitoring platform and respectively correspond to the to-be-tested test cases, and displaying thetest results; and sending the test results to a preset receiving end. According to the method, the test cases are uniformly monitored and issued and uploaded to the platform through an automatic testing platform, and the test results of the test cases are displayed, so that the automation of the testing process is realized.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

Mixed-signal core design for concurrent testing of mixed-signal, analog, and digital components

ActiveUS6925408B2Shorten test timeEfficient testingDigital circuit testingResistance/reactance/impedenceEngineeringTested time

A mixed-signal core designed for efficient concurrent testing analog, mixed-signal, and digital components. One tester may test all components and, thereby, reduce test time without losing full test coverage. An analog module includes all the analog and mixed-signal components of the mixed-signal core, while a first digital module includes digital components required for functional / parametric verification of the mixed-signal components within the analog module. A first virtual boundary connects the analog and the first digital modules to gate the signal transfer during testing. A second digital module includes the remaining digital components of the mixed-signal core, whereby a second virtual boundary separates it from the first digital module. This type of partitioning enables the mixed-signal core to have three modes of operation, using which the analog, mixed-signal and digital components can all be tested.

Owner:TEXAS INSTR INC

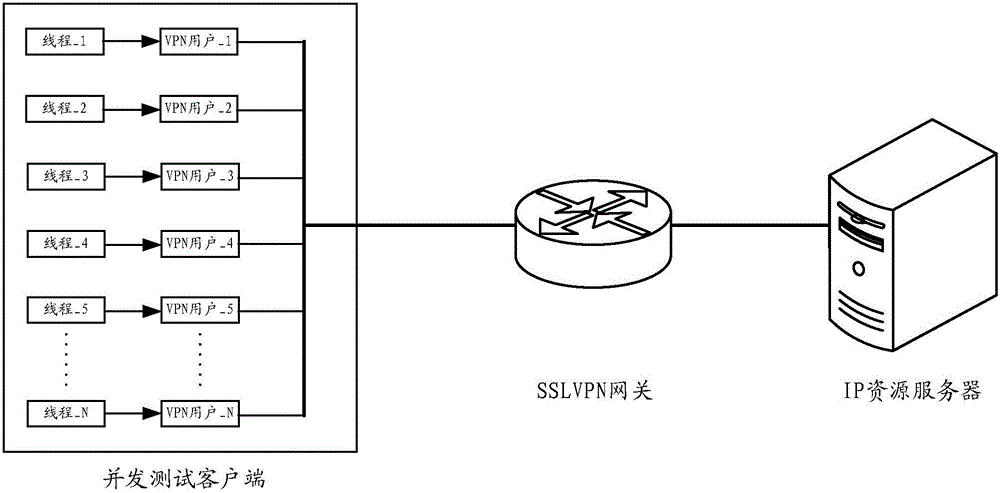

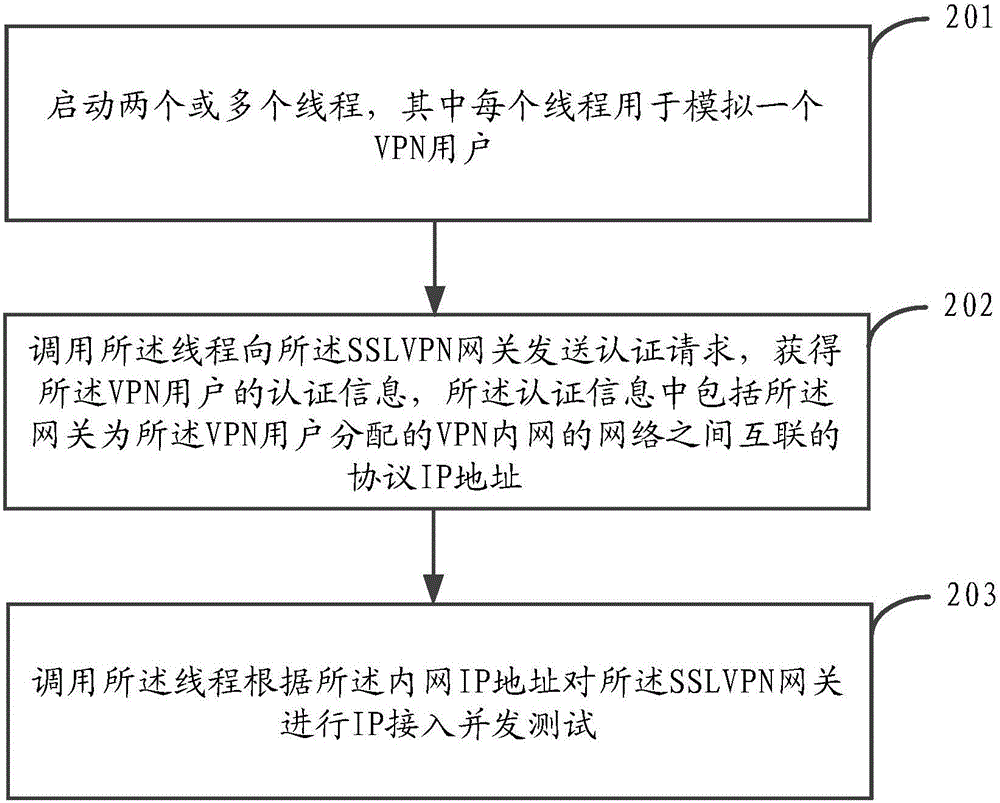

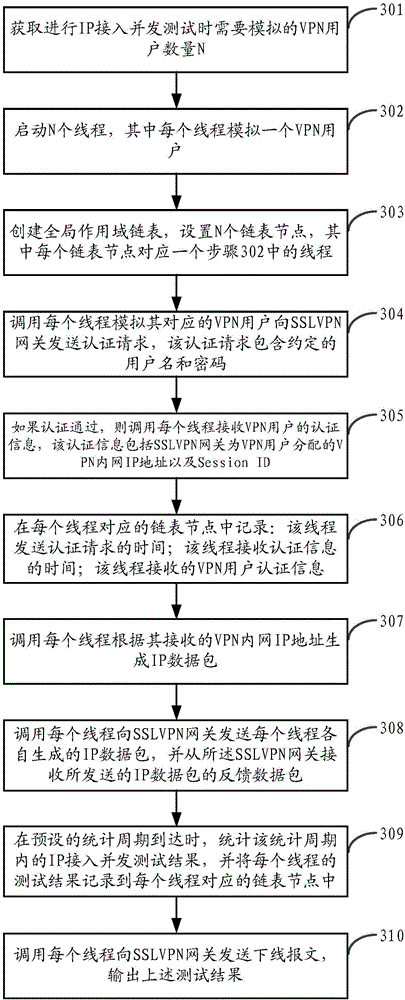

SSLVPN gateway concurrent test method and apparatus

InactiveCN106559289AImplement automated concurrency testingImprove the efficiency of access concurrency testingNetworks interconnectionTest efficiencyIp address

The invention provides a method and apparatus for updating a cache resource. The method is applied to a test client of a security socket layer virtual private network (SSLVPN) gateway and comprises: starting two or more threadings each of which is used for simulating a VPN user; sending an authentication request to the SSLVPN gateway by calling the threading to obtain the authentication information of the VPN user, the authentication information including a VPN internal network interconnection protocol IP address allocated by the gateway to the VPN user; calling the threadings to perform an IP access concurrent test on the SSLVPN gateway according to the internal network IP address. The method and apparatus simulate the VPN authentication process, the authentication information acquisition process and the IP access process of a plurality of VPN users by starting a plurality of threadings on the test client, and realize the automatic concurrency test of IP access SSLVPN gateway on a test client, and improve the SSLVPN gateway IP access concurrent test efficiency.

Owner:HANGZHOU DPTECH TECH

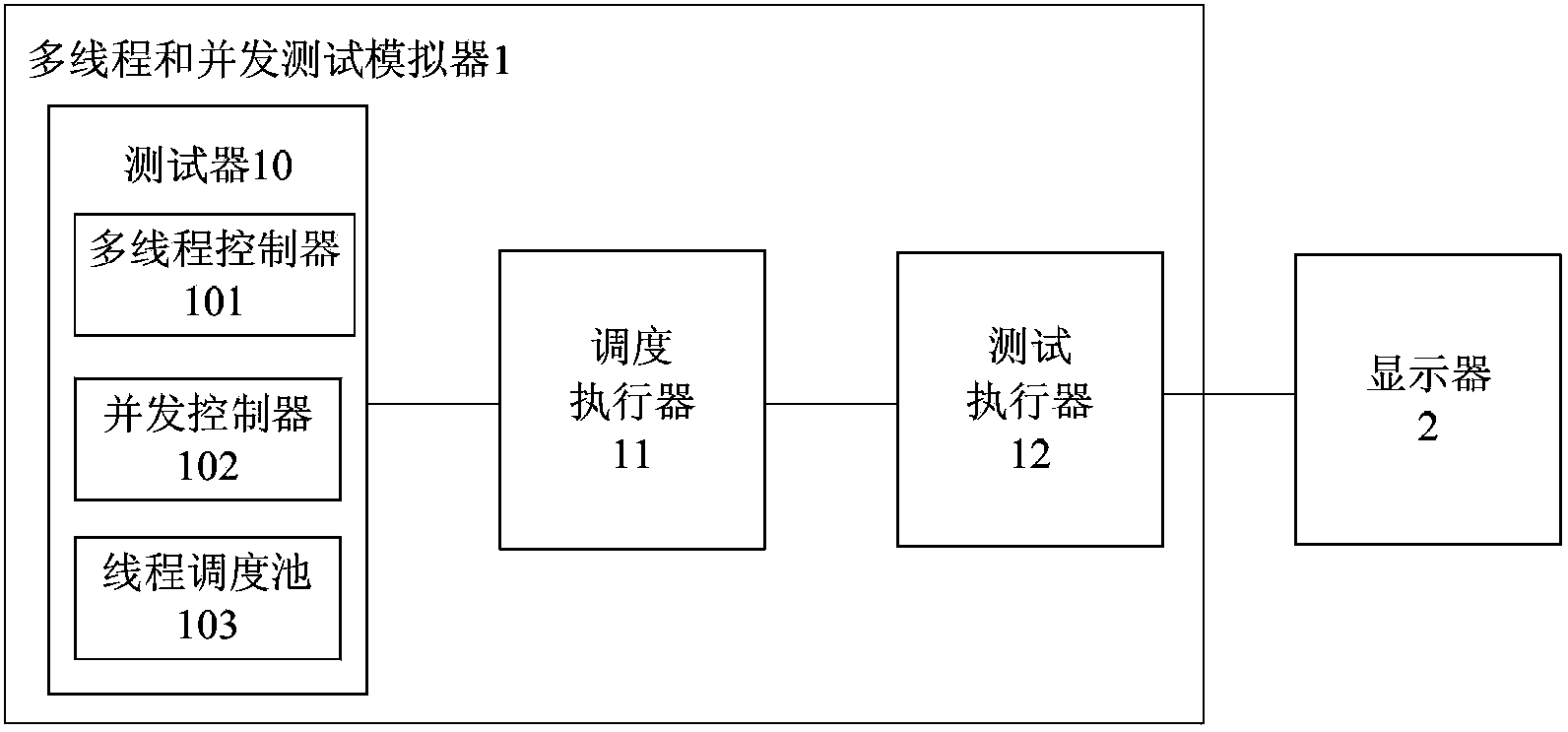

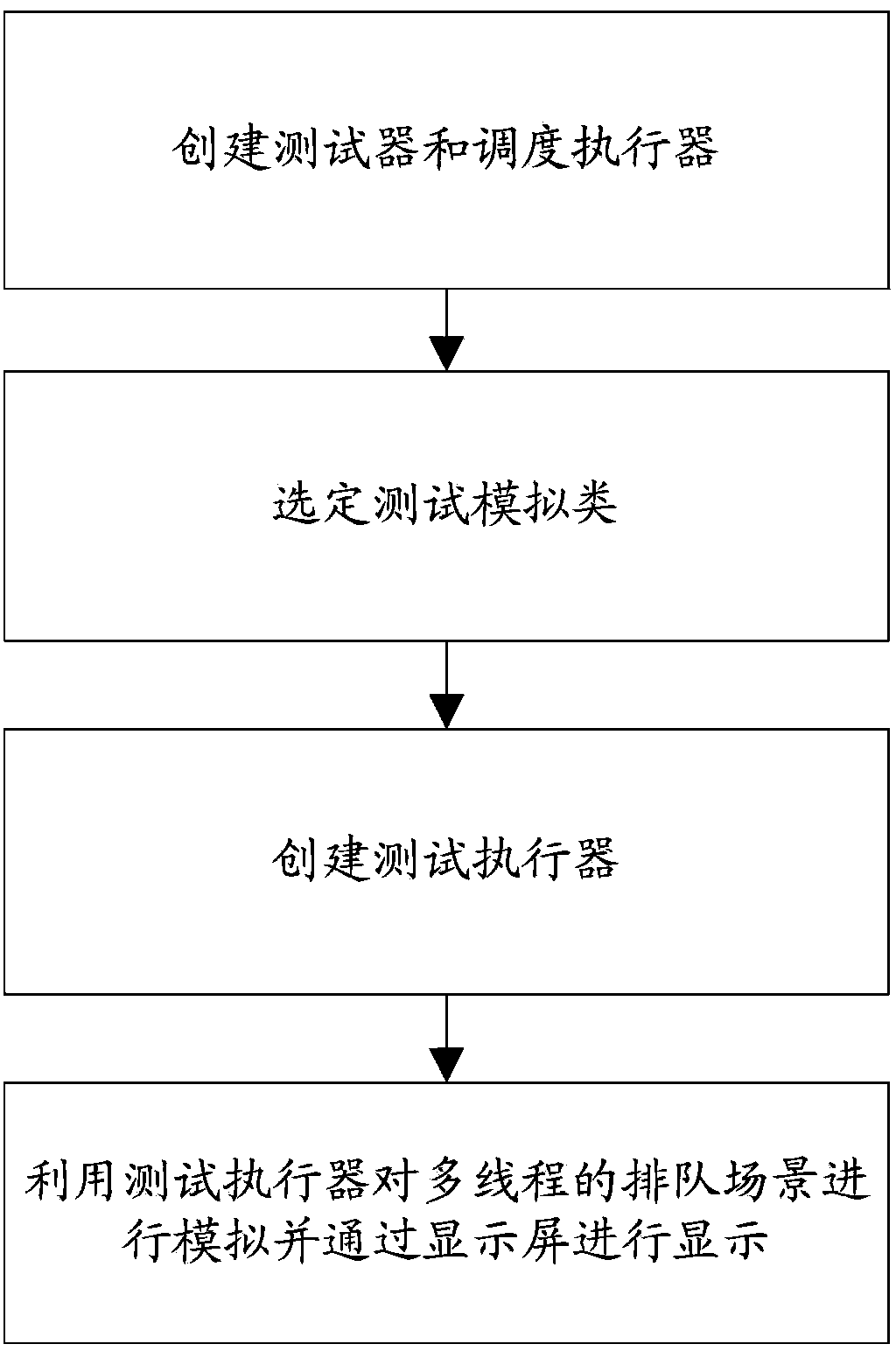

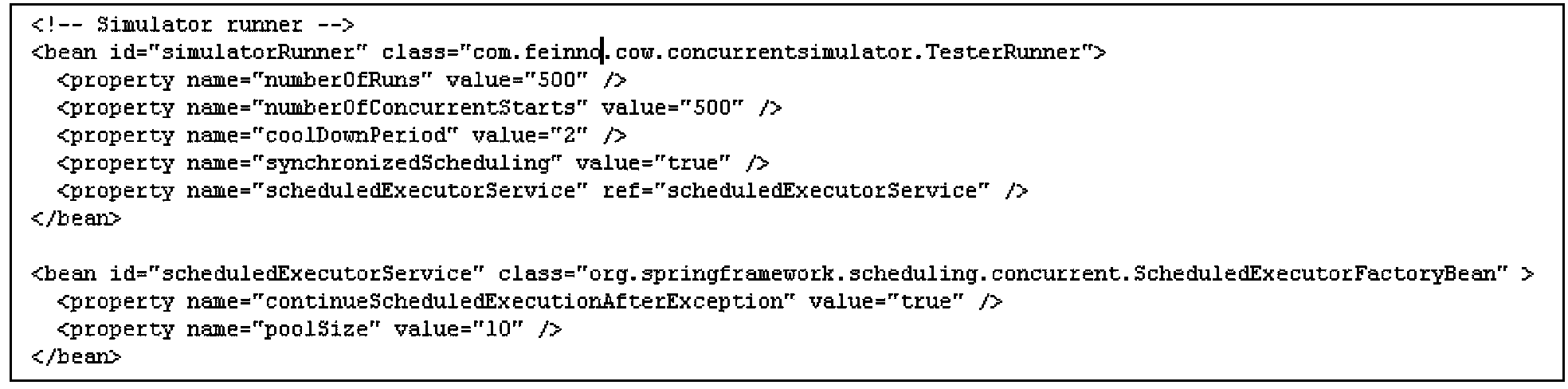

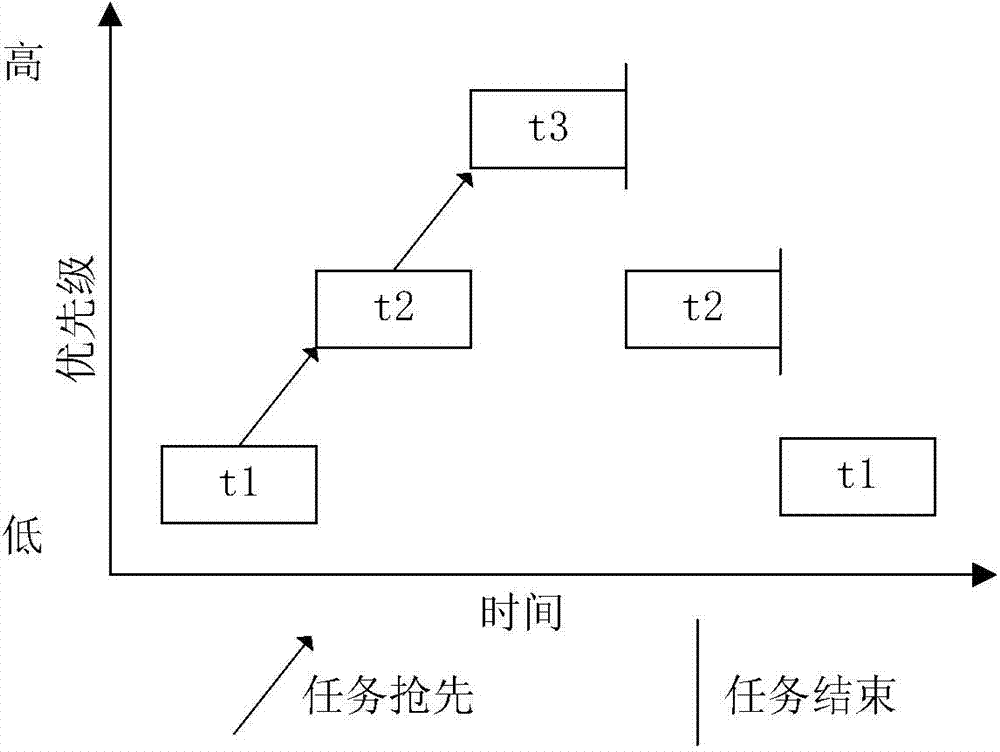

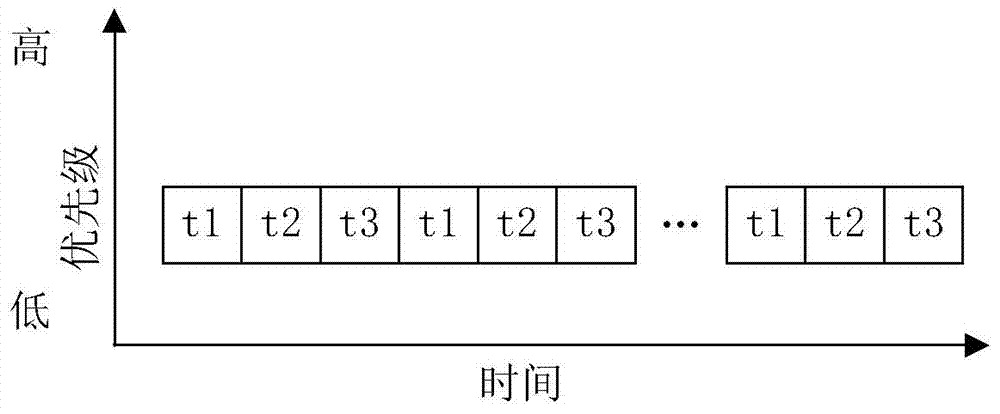

Multithreading and concurrency testing simulator and testing method thereof

ActiveCN103838654AEffective test methodSimple test methodFunctional testingConcurrency controlThread scheduling

The invention discloses a multithreading and concurrency testing simulator and a testing method of the simulator. The testing simulator comprises a tester, a scheduling actuator and a testing actuator, wherein the tester comprises a multi-thread controller, a concurrence controller and a thread scheduling pool, the scheduling actuator is connected with the tester and used for scheduling threads, and the testing actuator is connected with the scheduling actuator and used for simulating the queuing scene of the threads and displaying the queuing scene. An effective low-weight testing process simulator easy to use is provided for developers in the development stage, robustness and performance of a detection system can be detected, configuration is simple, and cost is low. The testing method is simple and easy to use, scripts do not need to be configured, and professional testing techniques are not needed.

Owner:NEW SINGULARITY INT TECHN DEV

Systems, methods, and apparatuses for testing mobile device applications

ActiveUS9195574B1Easy to optimizeExtensive collectionSoftware testing/debuggingSpecific program execution arrangementsDevice typeUser device

Aspects of the present disclosure generally relate to systems and methods for facilitating optimization of mobile application testing. In one embodiment, a mobile application testing system (MATS) allows simultaneous communication to a plurality of devices regardless of device type and operating system. Accordingly, the MATS performs mobile testing without “jail-breaking” or removing various components of the user device. In one embodiment of the present disclosure, the MATS enables users to securely test mobile applications by supporting data routing behind a security firewall utilizing a transition of communications protocols. Further, various protocols provide a data tunnel allowing multiple concurrent testing sessions for multiple users via an authentication scheme. Additionally, concurrent testing sessions may include single app testing on multiple devices or a plurality of apps testing on a plurality of devices.

Owner:MOBILE LABS

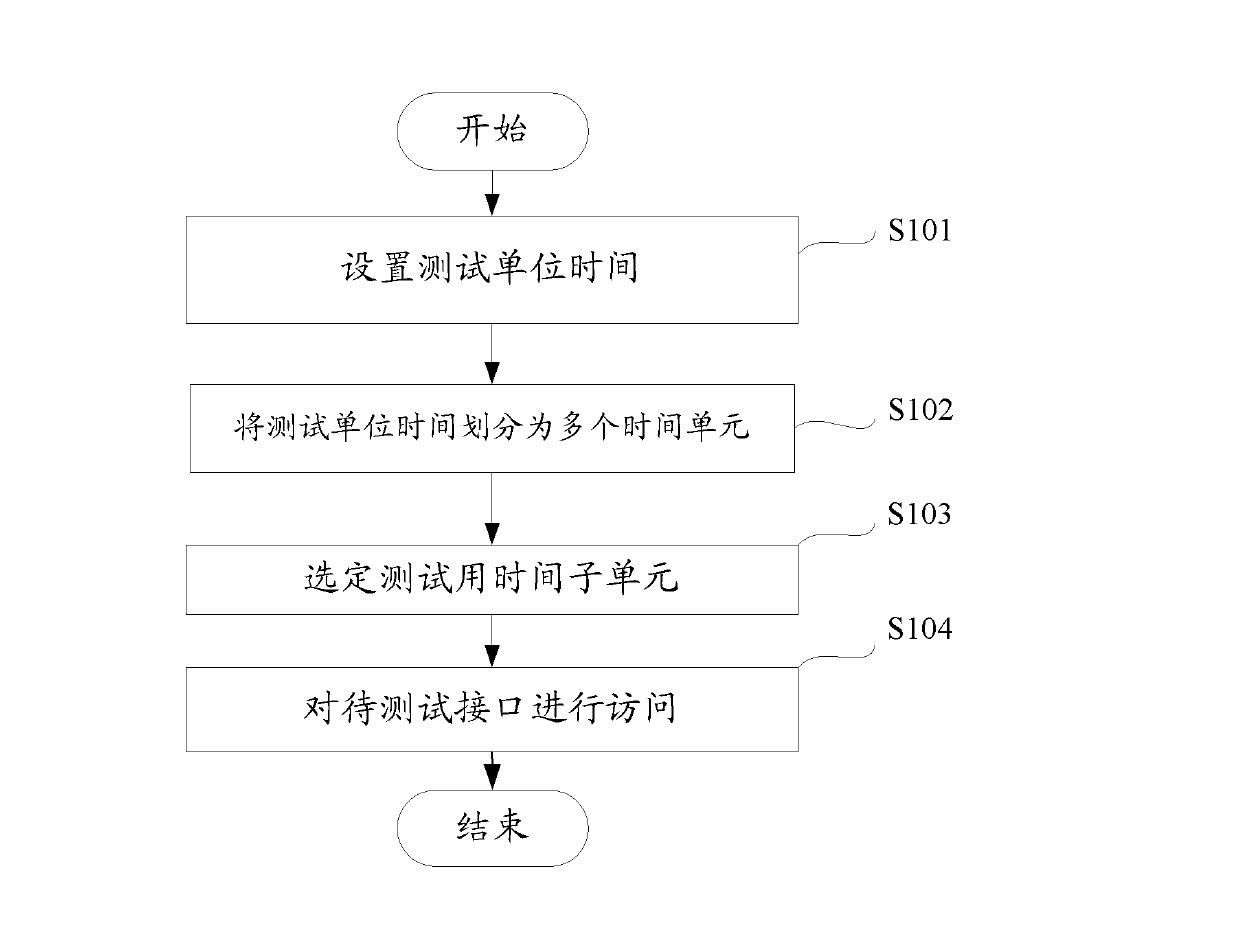

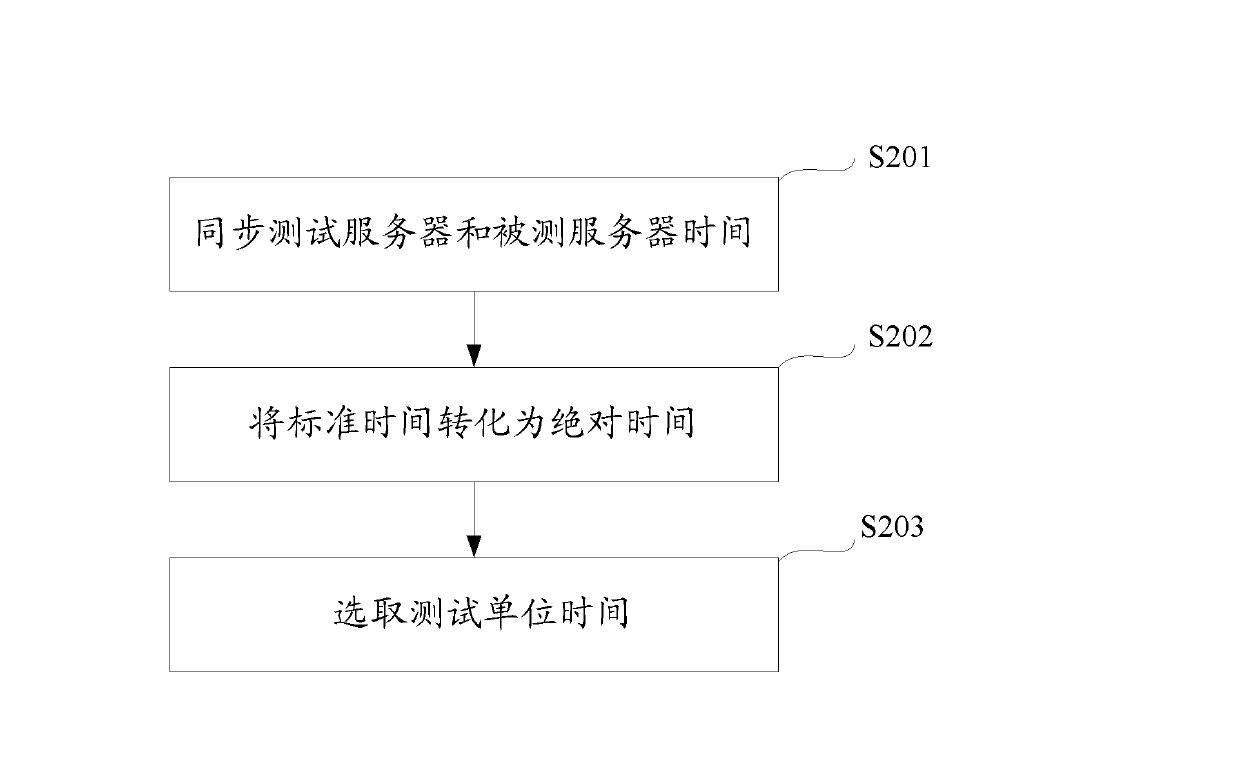

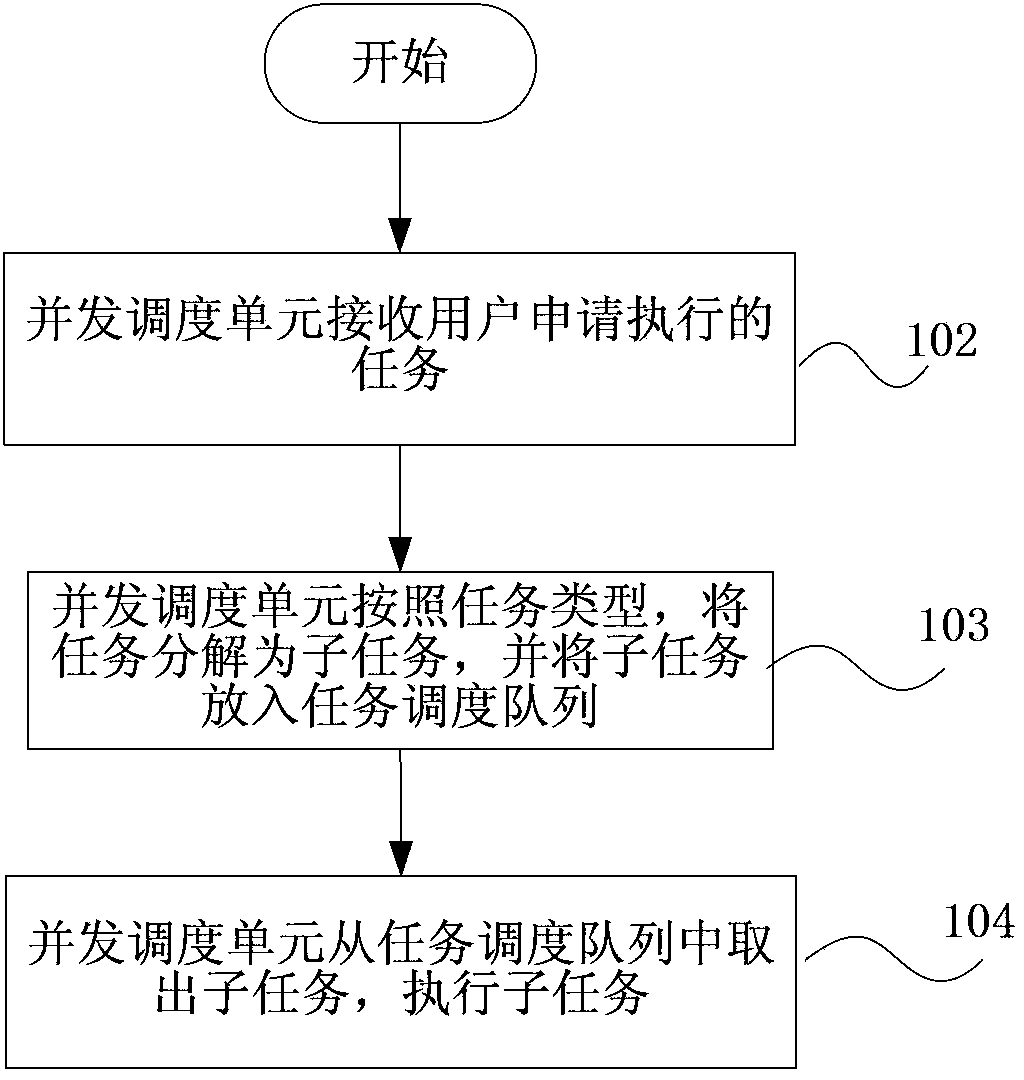

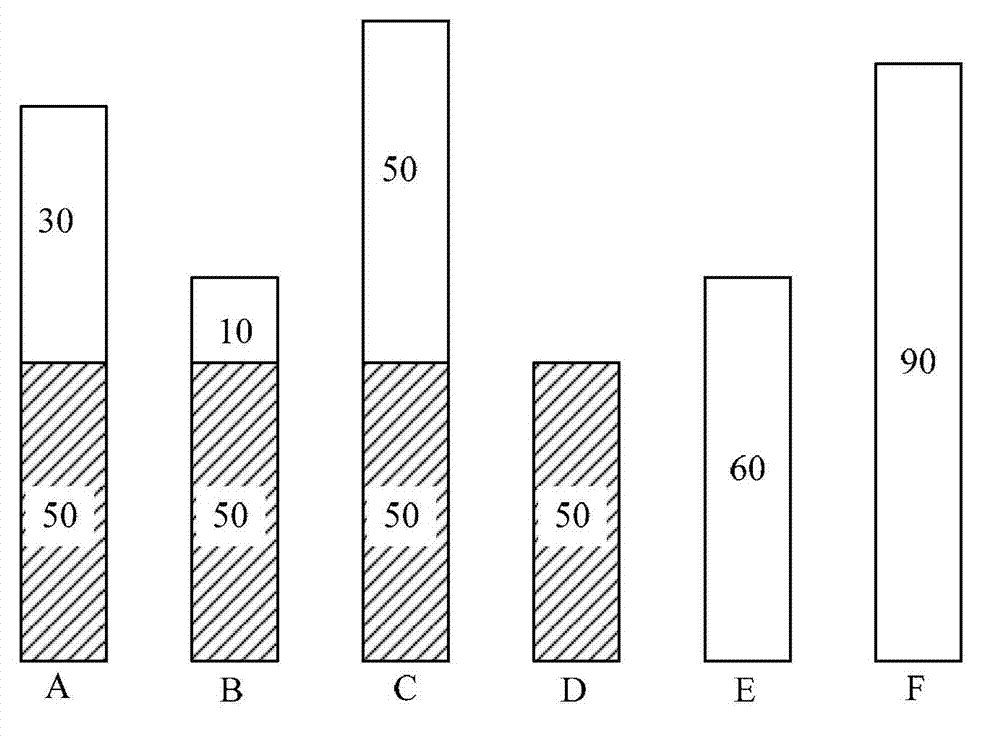

Concurrent testing method and testing server

ActiveCN103379000AConcurrent access implementationAvoid Precision Testing FlawsData switching networksTime criticalDependability

The invention provides a concurrent testing method and testing server. The method comprises the steps of setting testing unit time of the interfaces corresponding to the assess interface variety according to a preset access interface variety of a testing server and unit time of accessing interfaces corresponding to the access interface variety, dividing the testing unit time into a plurality of testing time units, selecting at least one testing time unit regarded as a time subunit used for the concurrent testing of the interfaces corresponding to the access interface variety, and accessing the interfaces corresponding to the access interface variety in the selected time subunit used for the concurrent testing according to preset times of the testing server accessing the interfaces corresponding to the access interface variety in the unit time. The concurrent testing method and testing server for the concurrent testing method based on open interfaces is adopted to achieve the fact that high concurrent testing at a time critical point is carried out on the open interfaces, testing precision is further improved, and the reliability of the operation of a tested platform is improved.

Owner:ALIBABA GRP HLDG LTD

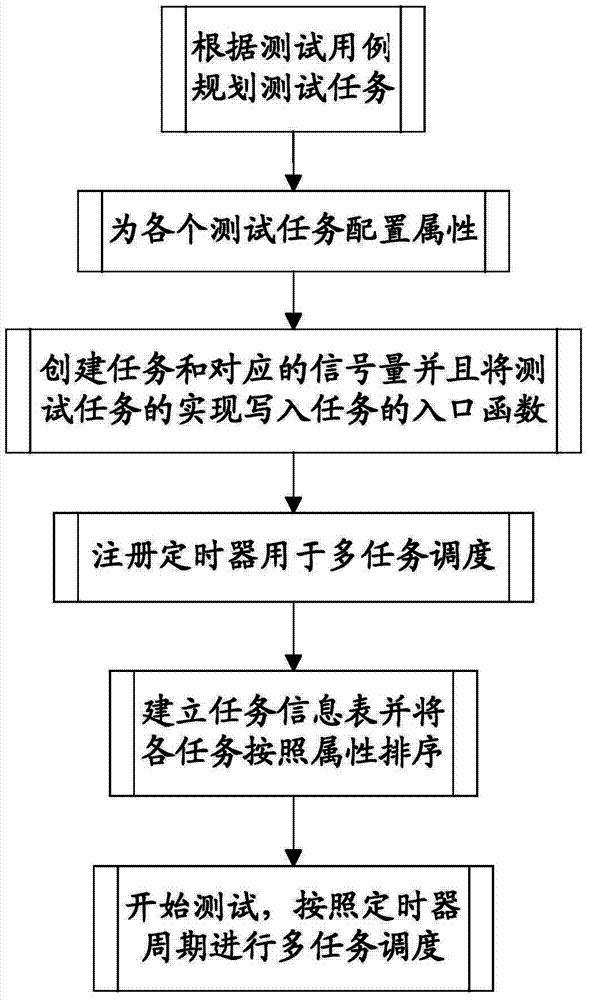

High-real-time concurrent testing method based on multi-task mechanism of VxWorks system

ActiveCN103885881AAvoid Timing DisordersGuaranteed accuracySoftware testing/debuggingStart timeSystem under test

The invention relates to a high-real-time concurrent testing method based on a multi-task mechanism of VxWorks system. The method comprises the following achieving steps that test tasks are planed according to a test case, a task attribute is configured for each test task, the task attribute comprises a task name, a task period, a task priority, starting time and finishing time; the tasks and semaphores corresponding to the tasks are established; a timer is registered for multi-task dispatching, and a task information table is established. According to the high-real-time concurrent testing method based on the multi-task mechanism of the VxWorks system, calculation, logic processing and interaction with the tested system can be completed in determined time, and the multiple concurrent test tasks can be completed in the same time period, so that high-real-time concurrent test requirement of embedded software is met.

Owner:BEIHANG UNIV

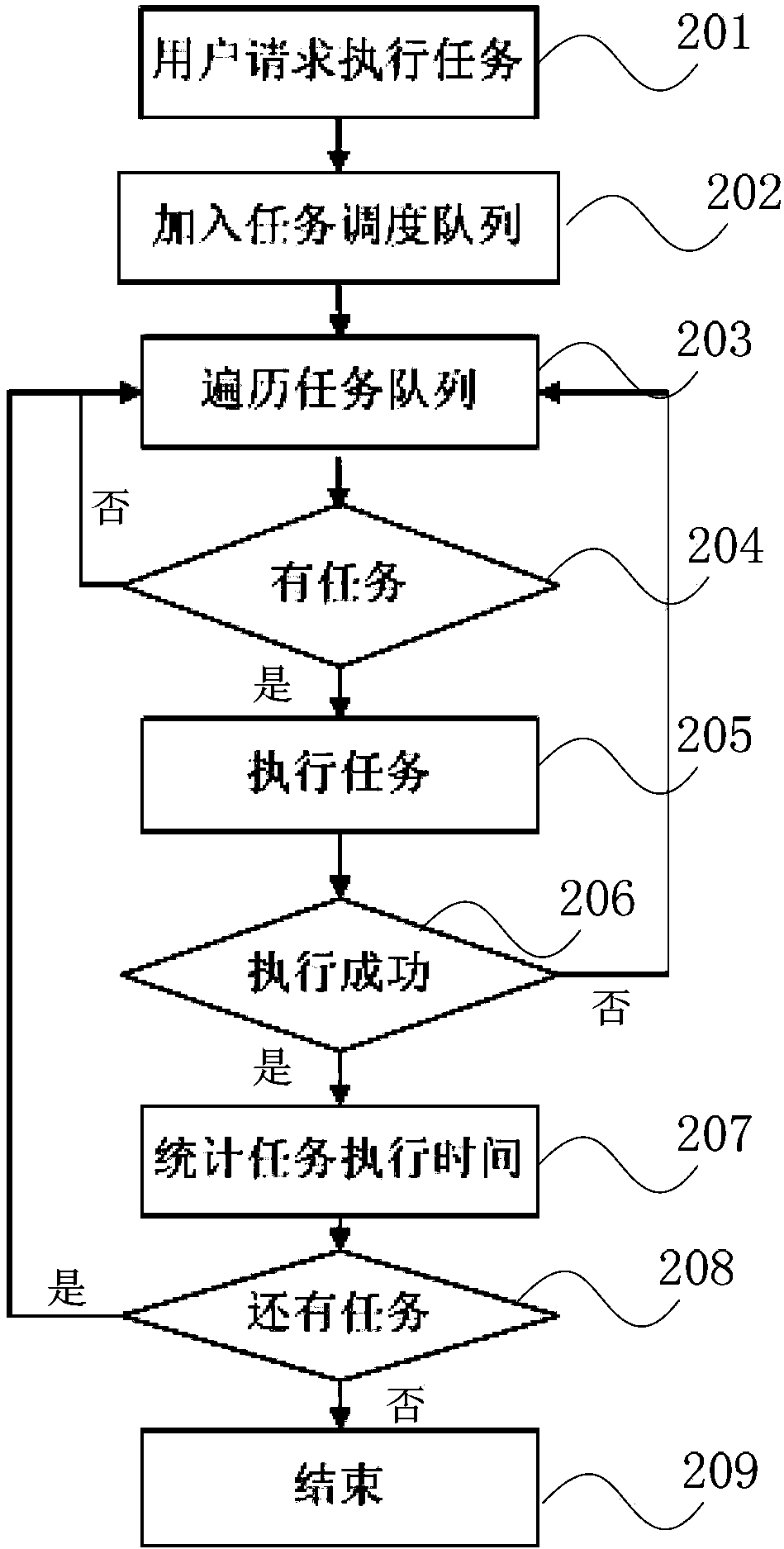

Test method and system for concurrent user access

InactiveCN103870348AGuaranteed accuracyEnsure fairnessError detection/correctionMultiprogramming arrangementsConcurrent userConcurrent testing

The invention discloses a test method and system for concurrent user access. The method includes the steps: receiving executive tasks applied for by users by a concurrent scheduling unit; decomposing the tasks into subtasks by the concurrent scheduling unit according to types of the tasks, and placing the subtasks into task scheduling queues; taking out the subtasks from the task scheduling queues by the concurrent scheduling unit to execute the subtask. The executive tasks are decomposed into the subtasks and respectively executed, task execution is scheduled, the users are not directly scheduled, a large number of concurrent user test tasks can be processed under the condition of high concurrent loads of the users, statistical accuracy of response time of the users is ensured, and fairness of user task execution is also ensured.

Owner:CHINA TELECOM CORP LTD

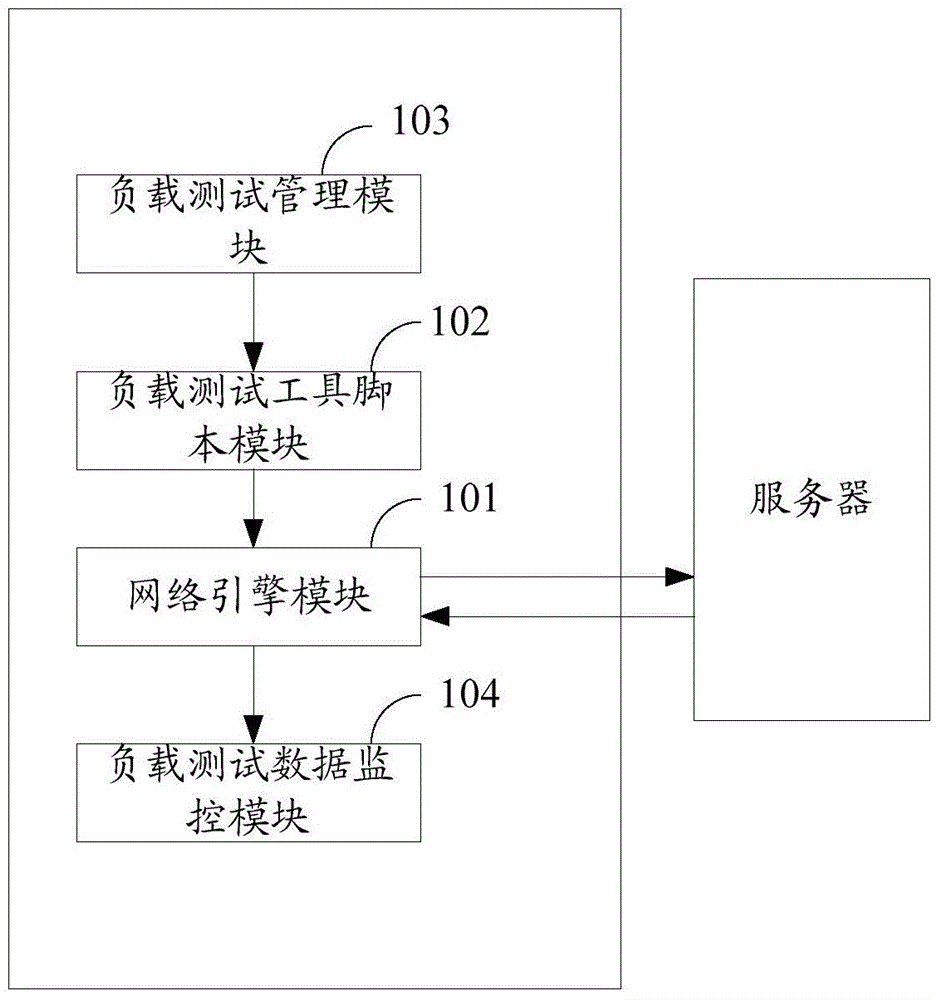

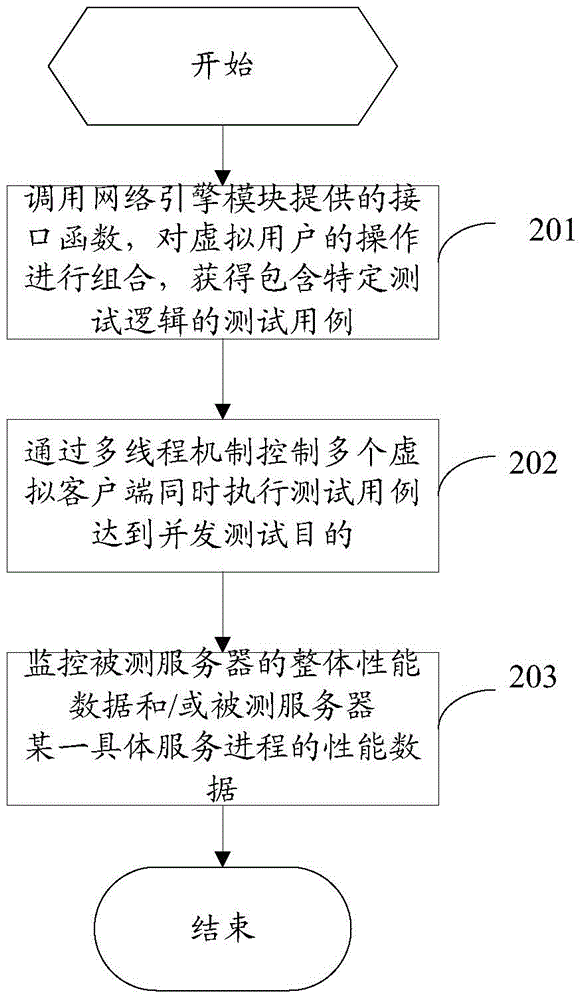

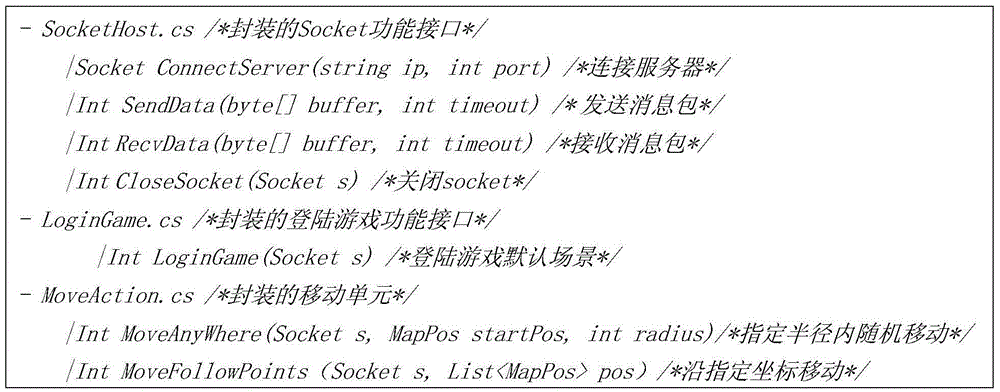

Socket-based server load test method and system

ActiveCN106201854ATo achieve the purpose of concurrent testingSoftware testing/debuggingSpecific testTest script

The invention discloses a socket-based server load test system. The system comprises a network engine module, a load test tool script module, a load test management module and a load test data monitoring module, wherein the network engine module is used for providing socket-based interface functions for test scripts to compile test cases: establishing connection with a tested server, sending a message to the tested server or receiving a message from the server, and providing various operation functions of virtual users; the load test tool script module is used for calling the interface functions provided by the network engine module, and combining the operations of the virtual users to obtain test cases which comprise a specific test logic; the load test management module is used for realizing a load test operation process, simulating a plurality of virtual clients through a multi-thread mechanism to execute the test cases so as to achieve the aim of concurrent test; and the load test data monitoring module is used for monitoring overall performance data of the tested server and / or performance data of a certain specific service process of the tested server. The invention furthermore discloses a socket-based server load test method.

Owner:BEIJING AMAZGAME AGE INTERNET TECH CO LTD

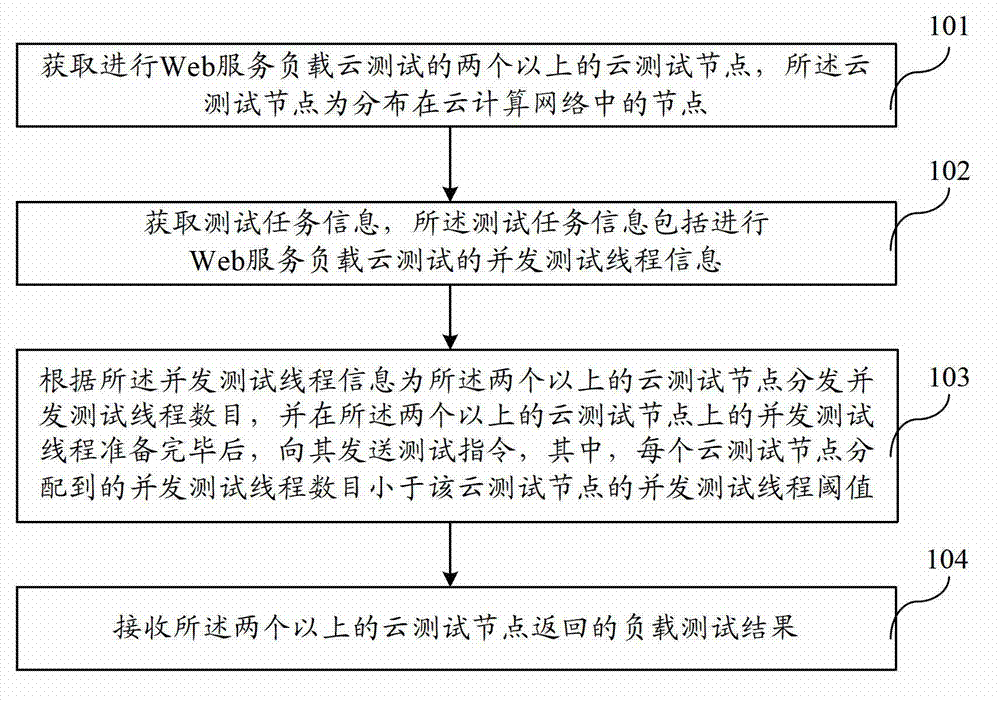

Method and device for Web service load cloud test

The invention provides a method and a device for a Web service load cloud test. The method for the Web service load cloud test comprises the steps of: obtaining more than two cloud test nodes of the Web service load cloud test, wherein the cloud test nodes are nodes distributed in a cloud computing network; obtaining test task information, wherein the test task information comprises concurrent test thread information of the Web service load cloud test; distributing the number of concurrent test threads to the cloud test nodes according to the concurrent test thread information, and sending test commands to the cloud test nodes when the concurrent test threads are prepared on the cloud test nodes, wherein the number of the concurrent test threads distributed to every cloud test node is smaller than the threshold of the concurrent test threads of the cloud test node; and receiving load test results returned by the cloud test nodes. By adopting the technical scheme, the defect of single positions of test nodes can be overcome, and the true concurrent calling of target test services can be realized.

Owner:天航长鹰(江苏)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com