Testing method for rock surface static contact angle and rock surface wettability dynamic change testing method utilizing testing method for rock surface static contact angle

A technology of static contact angle and test method, which is applied in the field of dynamic change test of rock surface wettability and test field of rock surface static contact angle, can solve the problems that the dynamic change of contact angle is difficult to accurately grasp, and the value is inaccurate, etc., to achieve The effect of long continuous test time and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

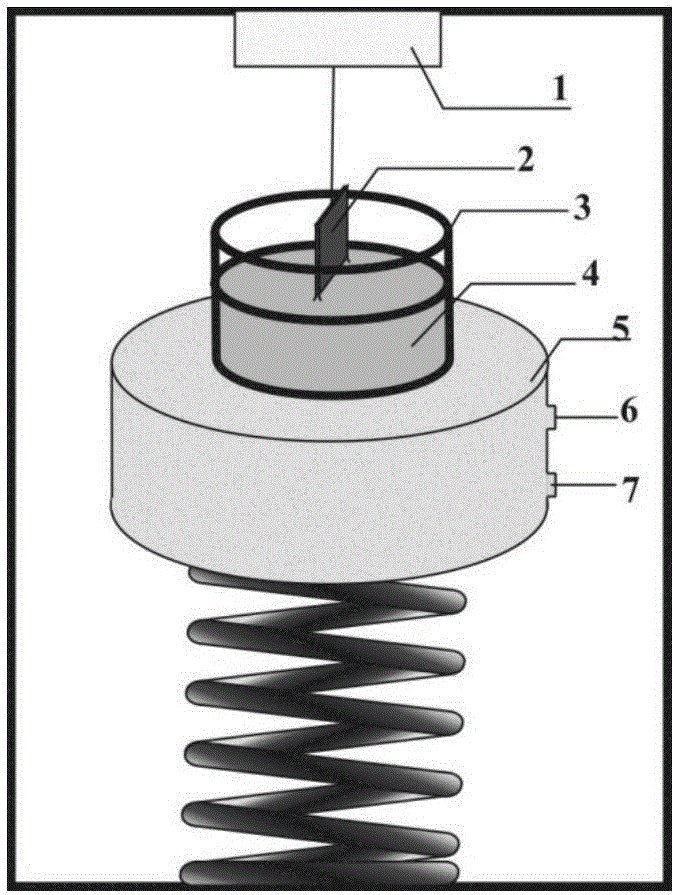

Method used

Image

Examples

Embodiment 1

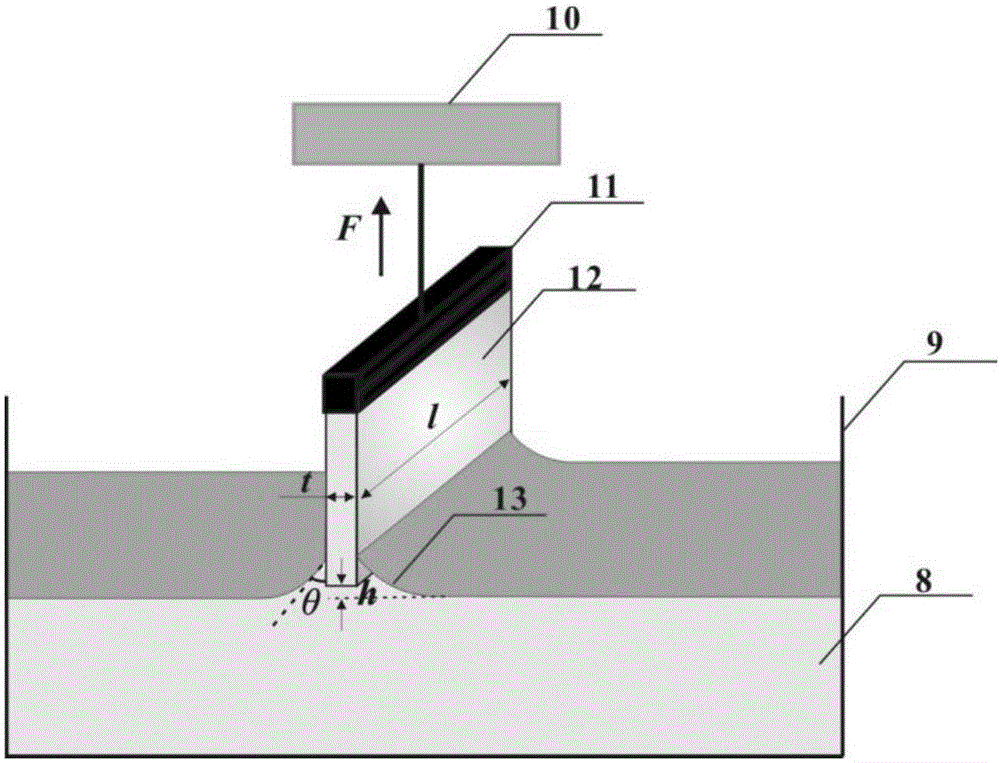

[0069] In this example the wettability of doubly distilled water on glass slides (cover glass, quartz slide) of two different sizes was determined. Before the test, put double distilled water into the cleaned sample cell to keep the temperature for 1 hour; clamp the cleaned and dried glass piece and hang it on the micro balance for immediate test; -1 The rate rises slowly until the liquid level just touches the lower surface of the glass sheet. During the rising process, the liquid level is always parallel to the lower surface of the suspended glass sheet, and the test table remains without vibration; when the liquid level just touches the lower surface of the glass sheet, due to the secondary Distilled water wets the surface of the glass sheet, forming a meniscus on the surface of the glass sheet, and records the force (F) exerted by the glass sheet on the double-distilled water through the reading of the microbalance; through formula calculation, the double-distilled water on...

Embodiment 2

[0083] According to the method of Example 1, the change law of the static contact angle on the quartz surface with the prolongation of the contact time was tested.

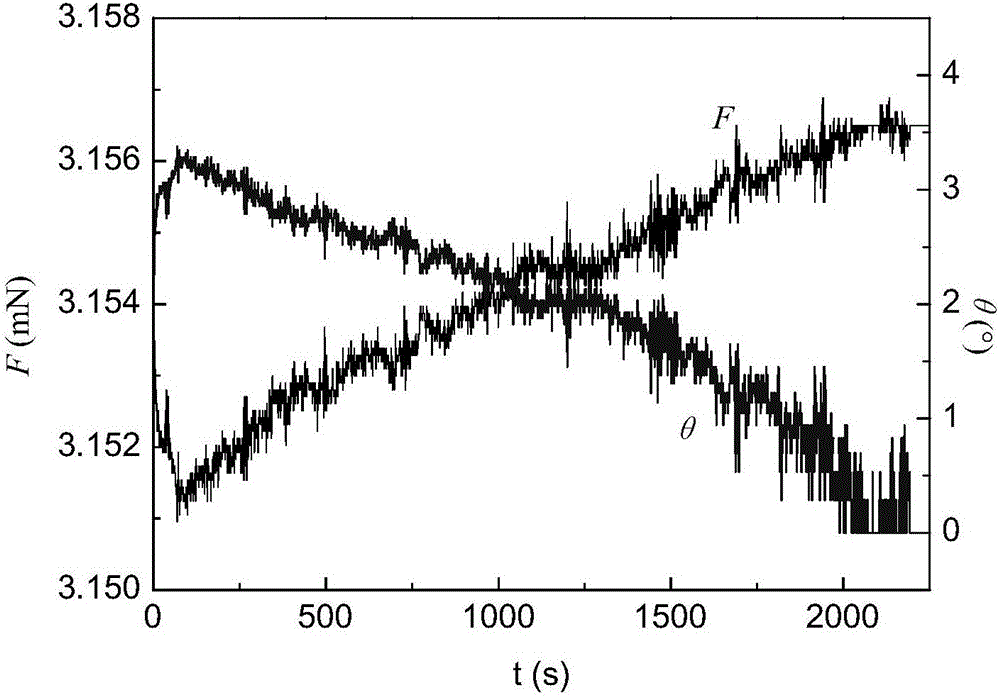

[0084] The reading that the microbalance records is multiplied by the acceleration of gravity (g=9.8N / kg) to obtain the force size F of the quartz plate, and the contact angle θ of the aqueous solution on the surface of the quartz plate is obtained by the method in example 1 under different contact time conditions, and the quartz plate The relationship curve between the force F of the sheet and the contact angle of the aqueous solution on the quartz sheet and the contact time is as follows: image 3 shown.

[0085] image 3 It shows the micro-changes of the force F and contact angle θ of the quartz sheet with the prolongation of the contact time, indicating that this test method has high sensitivity and can record micro-changes of the contact angle, which is helpful for understanding the dynamic change law of roc...

Embodiment 3

[0087] Test the contact angle of different pH value solutions on the quartz surface by the method of example 2. Get the relationship between the contact angle θ and the pH value of different pH value aqueous solutions on the quartz plate by the method introduced in Example 2, as Figure 4 shown.

[0088] Such as Figure 4 Shown: When pH=2.3, the force on the quartz plate is the minimum, and the contact angle is the maximum. When the pH>2.3, as the pH value of the solution increases, more electrically neutral silanol groups on the quartz surface dissociate to form negatively charged silanol groups, so the force on the quartz surface increases and the hydrophilicity increases; When the pH+ When the concentration is very high, some of the electrically neutral silanol groups on the quartz surface are transformed into positively charged silanol groups with stronger hydrophilicity, which shows that the force on the quartz surface is increased and the hydrophilicity is enhanced. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com