Electromagnetic steam boiler

A steam boiler and electromagnetic technology, applied in the direction of steam generation, steam generation method, lighting and heating equipment, etc., can solve the problems of low power saving efficiency, unreasonable boiler structure design, etc., improve the safety factor, avoid easy aging and easy Leakage, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

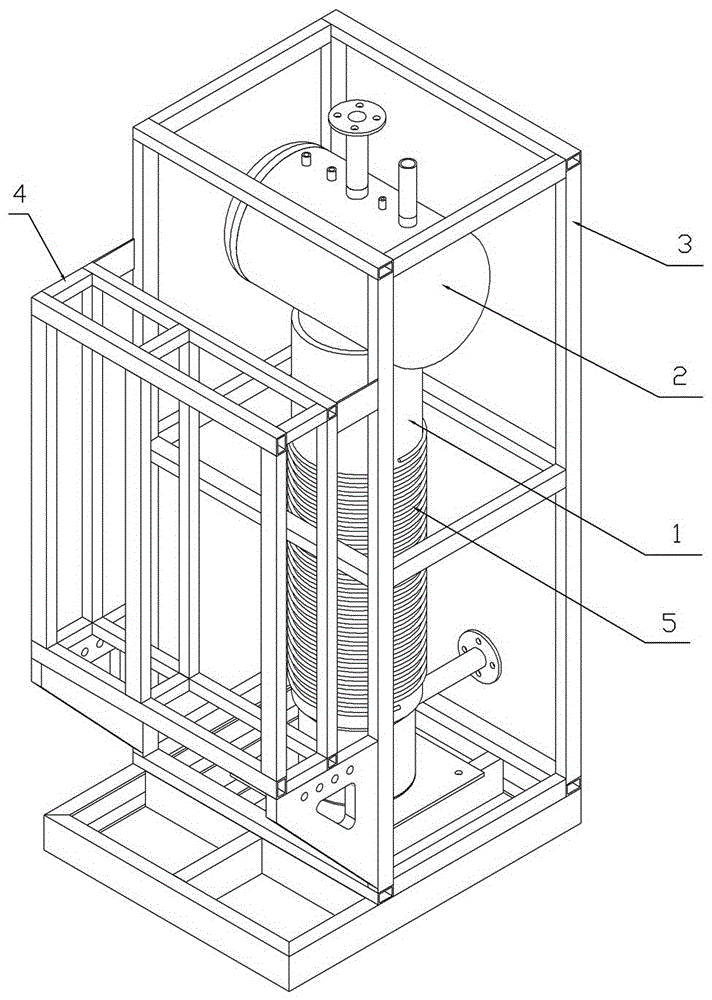

[0034] see figure 1 , Figure 5, the electromagnetic steam boiler of this embodiment, the power design of electromagnetic heating is 10~30KW, adopts a heating tube, design rated current 15~45A, electromagnetic coil adopts 25mm 2 The electromagnetic wire is wound 62 to 48 turns, the diameter of the coil is 169 mm, and the height of the coil is 1100 mm.

Embodiment 2

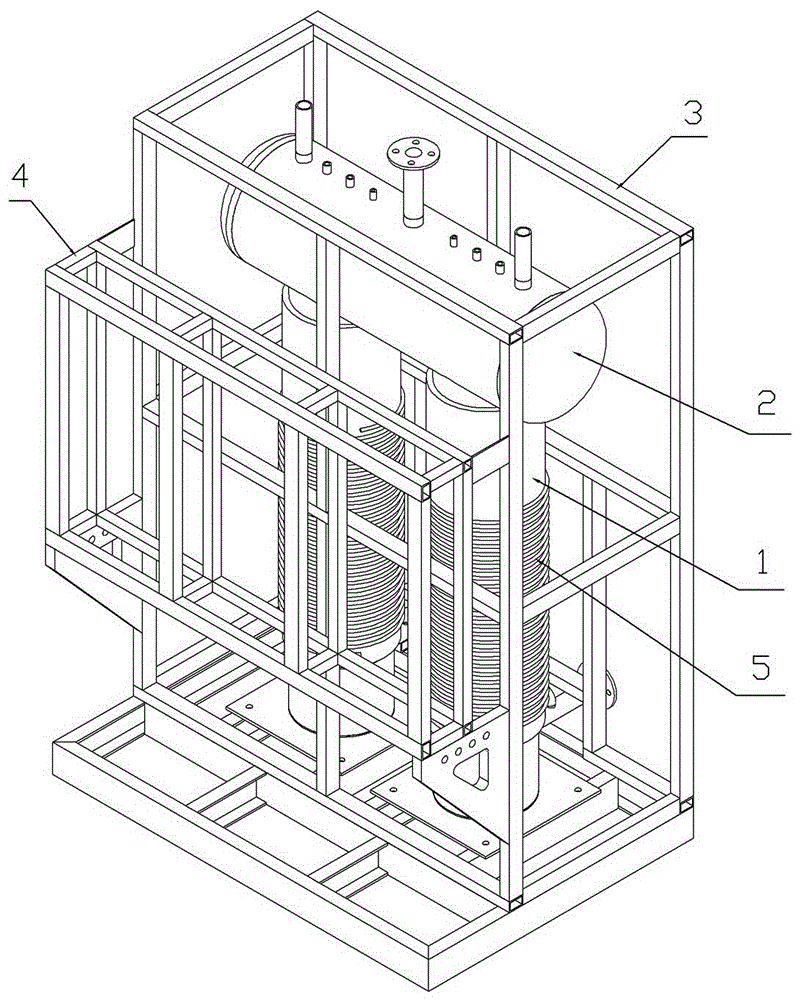

[0036] see figure 2 , the electromagnetic steam boiler of this embodiment, the power of electromagnetic heating is designed to be 50 ~ 80KW, two heating tubes are used, the design rated current is 80A ~ 120A, and a heating coil is wound outside each heating tube, and the electromagnetic coil adopts 35mm 2 The electromagnetic wire is wound 45 to 38 turns, the diameter of the coil is 229 mm, and the height of the coil is 900 mm.

Embodiment 3

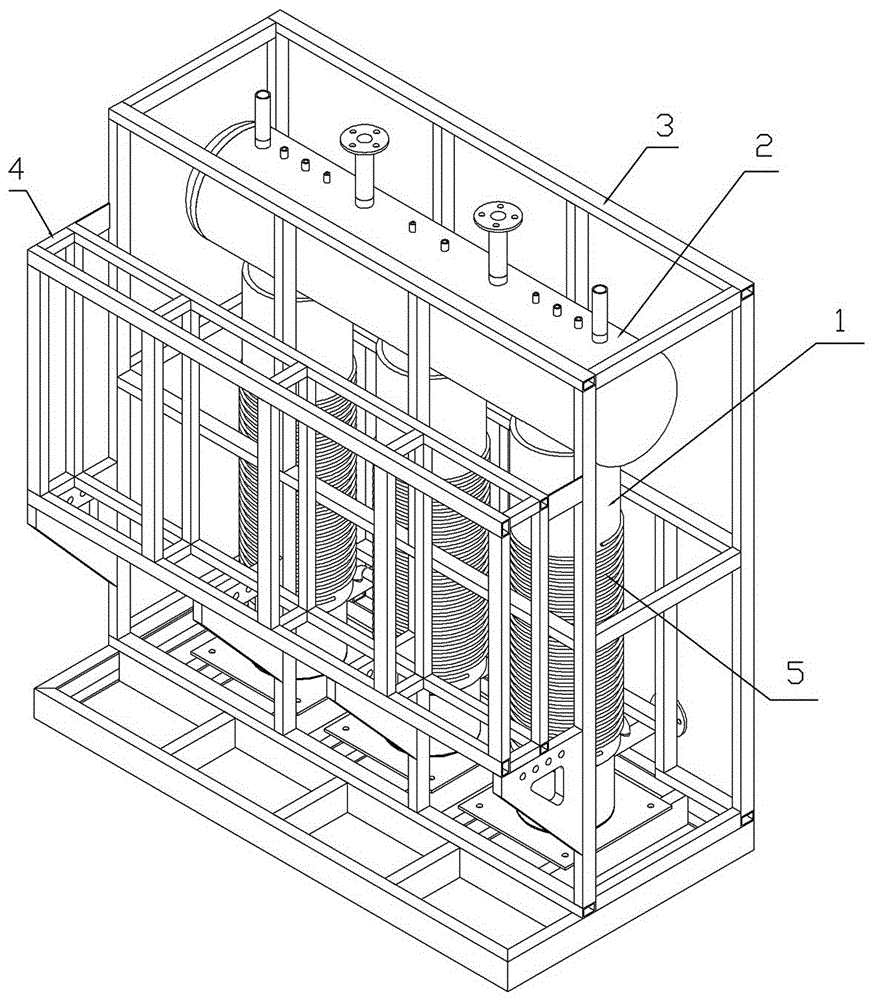

[0038] see image 3 , the electromagnetic steam boiler of this embodiment, the electromagnetic heating power design is 90~120KW, adopts three heating tubes, design rated current 135~180A, each heating tube is wound outside a heating coil, and electromagnetic coil adopts 50mm 2 The electromagnetic wire is wound 24 to 30 turns, the diameter of the coil is 355 mm, and the height of the coil is 720 mm.

[0039] The electromagnetic steam boiler described in the present invention replicates the specifications of its unit circuit, and by increasing the number of heating tubes, a high-power steam boiler with four heating tubes, five heating tubes, and six heating tubes can be made. Such as Figure 4 As shown, it is an electromagnetic steam boiler with four heating tubes; Figure 5 It is an electromagnetic steam boiler with six heating tubes.

[0040] In the electromagnetic steam boiler of the present invention, after the heating tube 1 is sprayed with anti-rust paint, it is treated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com