Gas remote ignition method and apparatus

An ignition device, gas technology, applied in the direction of combustion ignition, combustion method, lighting and heating equipment, etc., to achieve the effects of convenient replacement, long service life, and avoiding high temperature burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

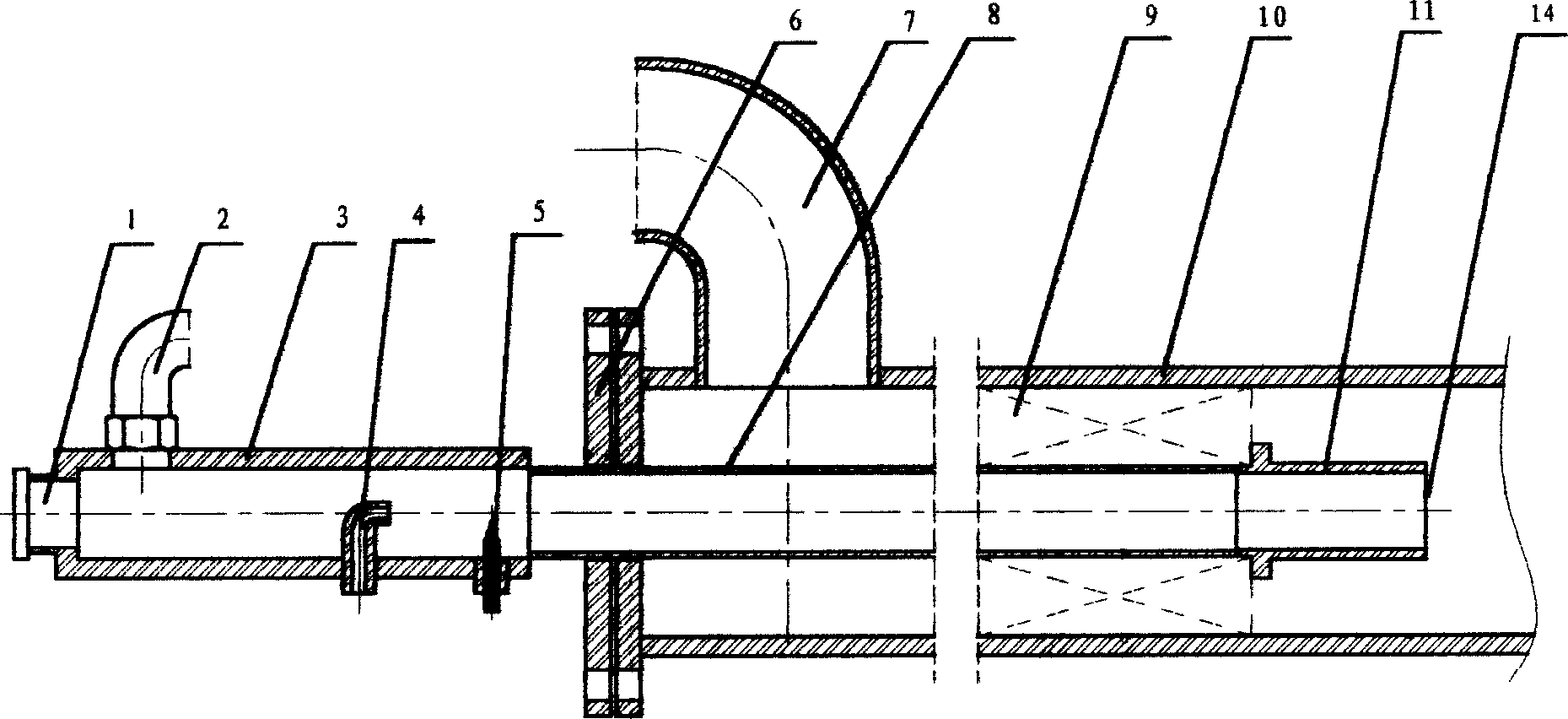

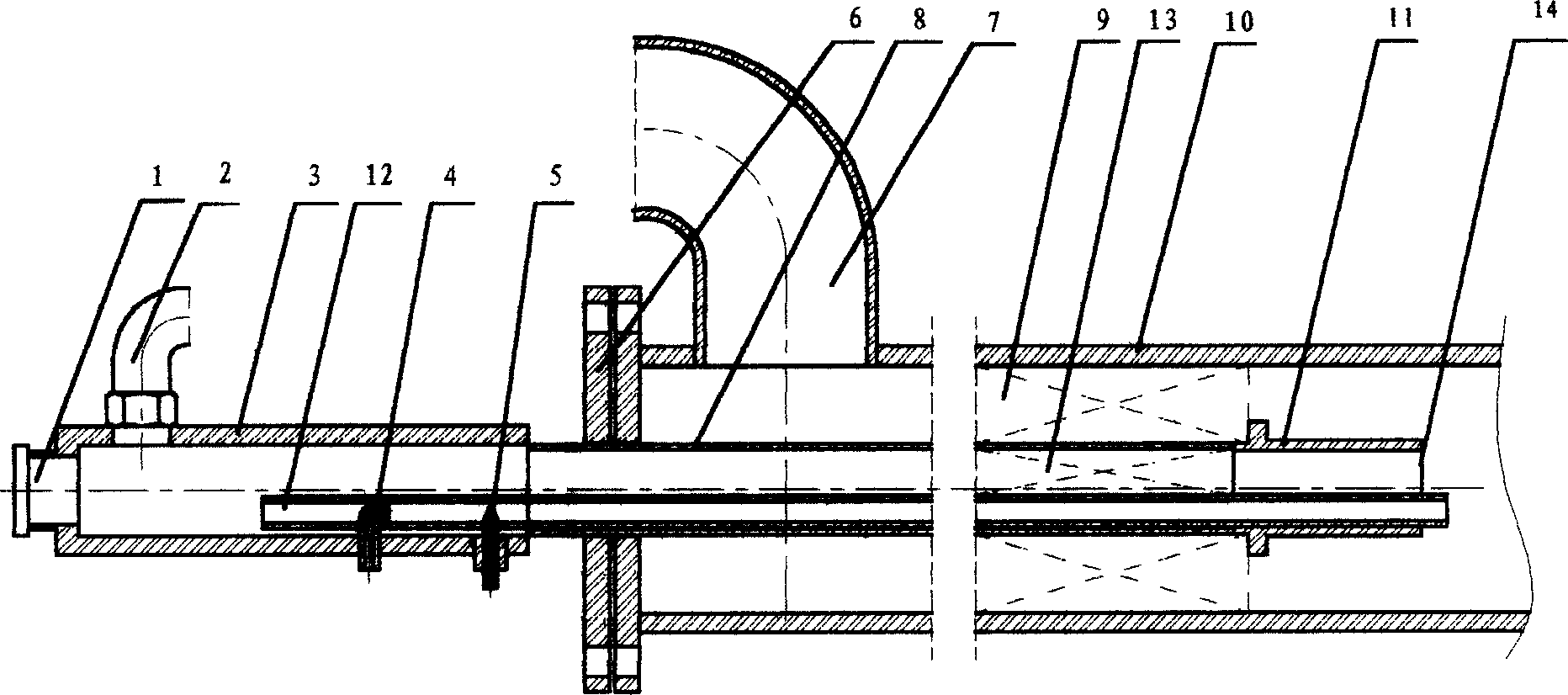

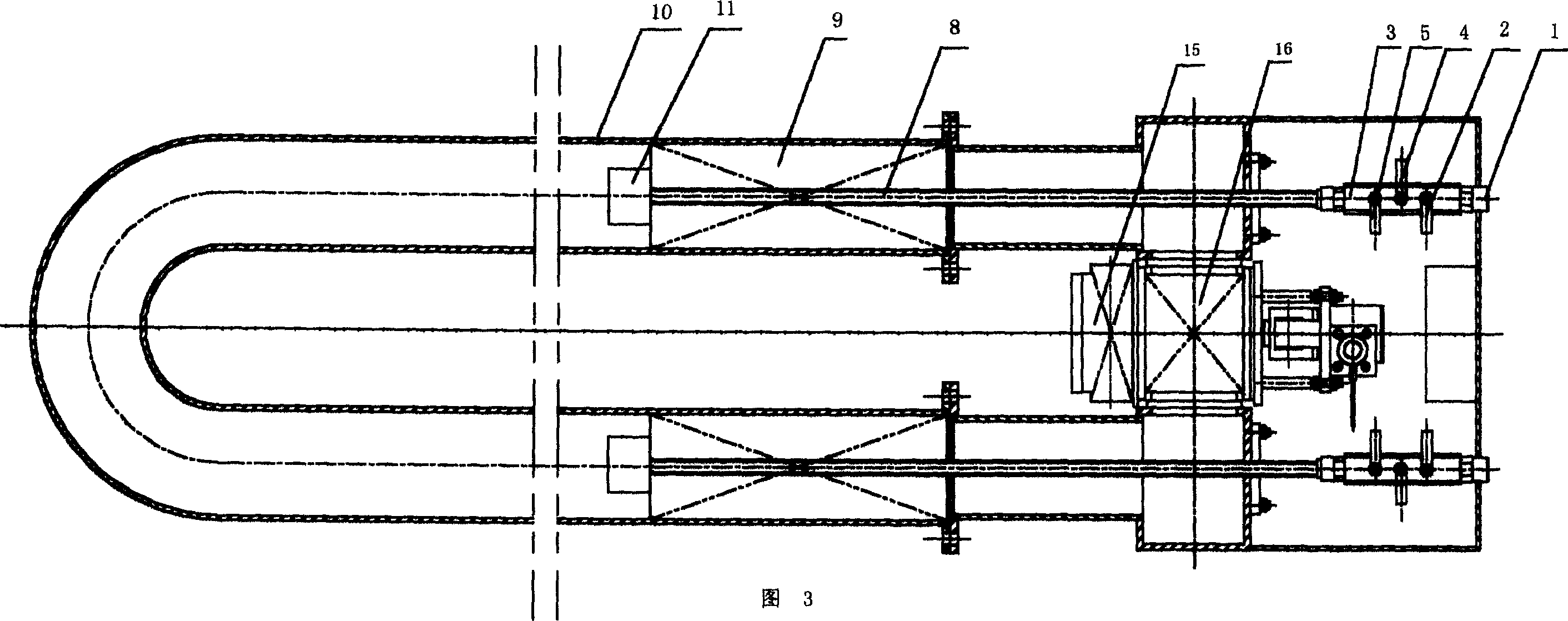

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. attached figure 1 It is an embodiment of the present invention applied to a regenerative gas radiant tube burner, and the figure shows the structure in which the ignition device is combined with one end of the radiant tube. The figure shows that the ignition device 3 is set far away from the burner 11. The front end of the gas pipe 8 is connected to the burner 11, and the rear end is connected to the ignition device 3. There is no heat storage body in the gas pipe 8, and the gas pipe 8 is connected to the radiant tube. A regenerator 9 is arranged between 10, and a gas inlet 2, an ignition air pipe 4, and a high-voltage electric spark head 5 are sequentially arranged in the ignition device 3 along the advancing direction of the kindling. When the ignition starts, first open the combustion-supporting air 7 and the ignition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com