Thyristor driving circuit and driving method thereof

A technology for driving circuits and driving methods, applied in circuits, electrical components, electronic switches, etc., can solve problems such as power circuit out of control, achieve the effects of reducing electromagnetic radiation, ensuring reliability, and avoiding high-temperature burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention discloses a thyristor driving circuit and a driving method of the thyristor driving circuit. The specific implementation manners of the invention will be further described in conjunction with preferred embodiments below.

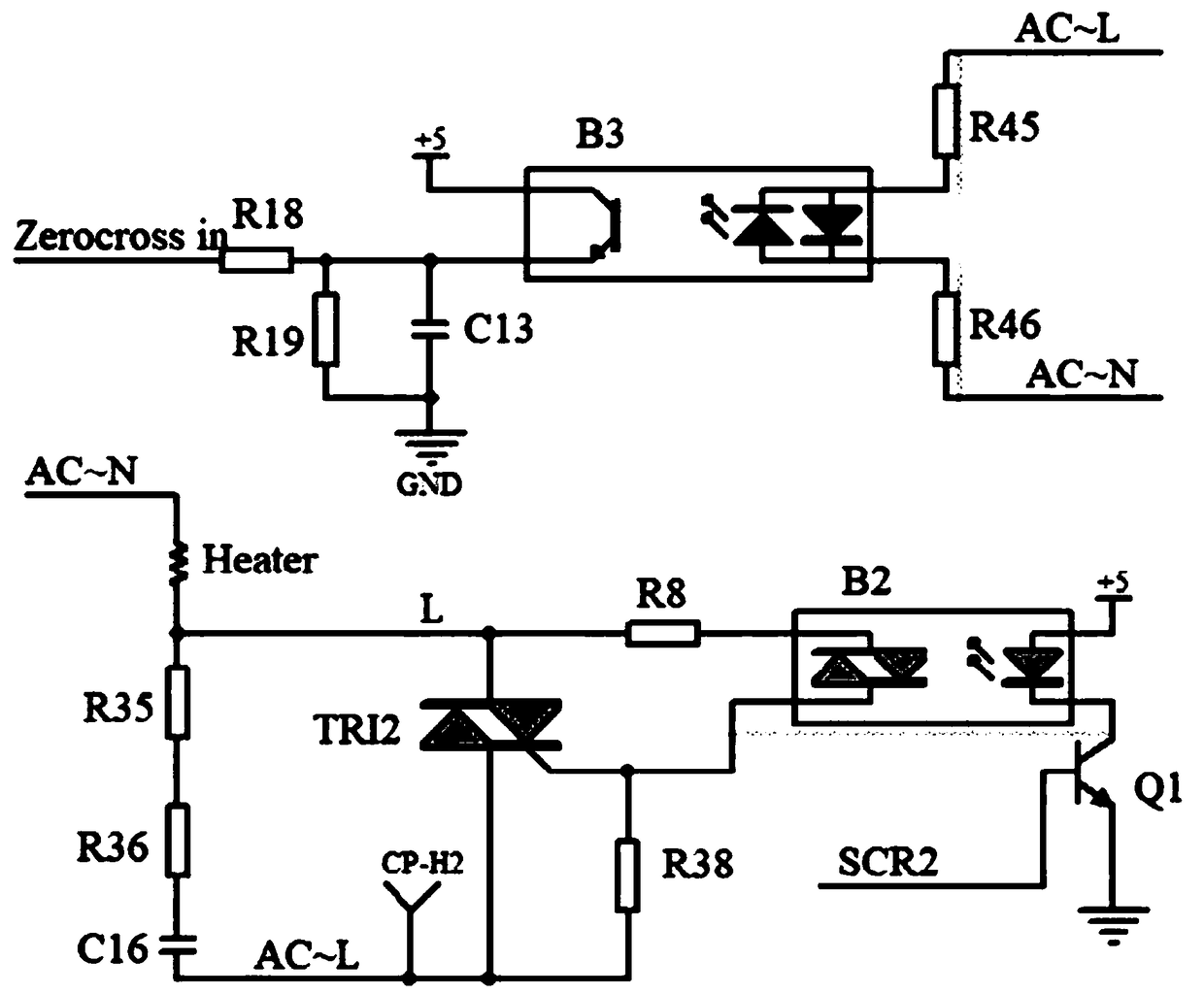

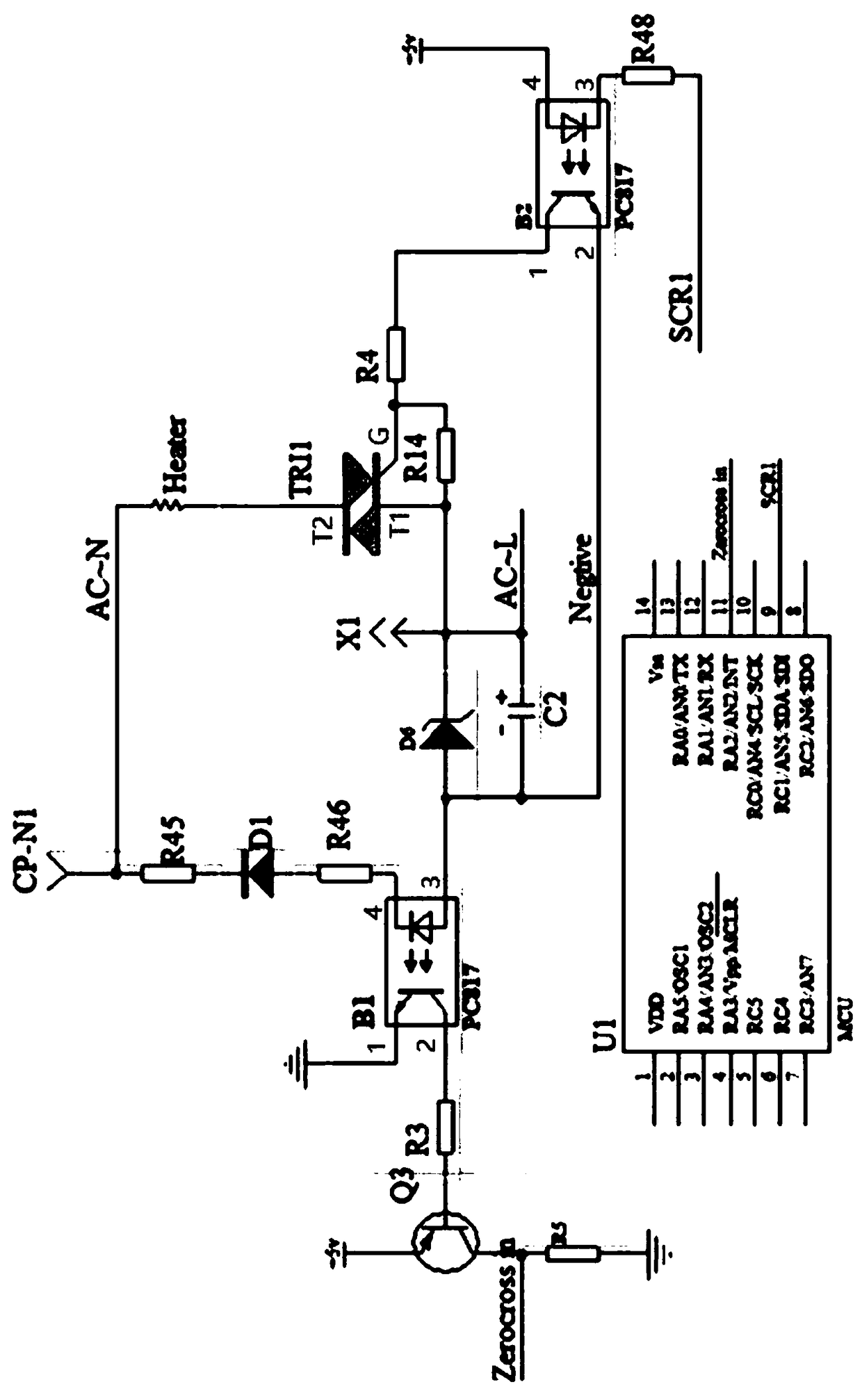

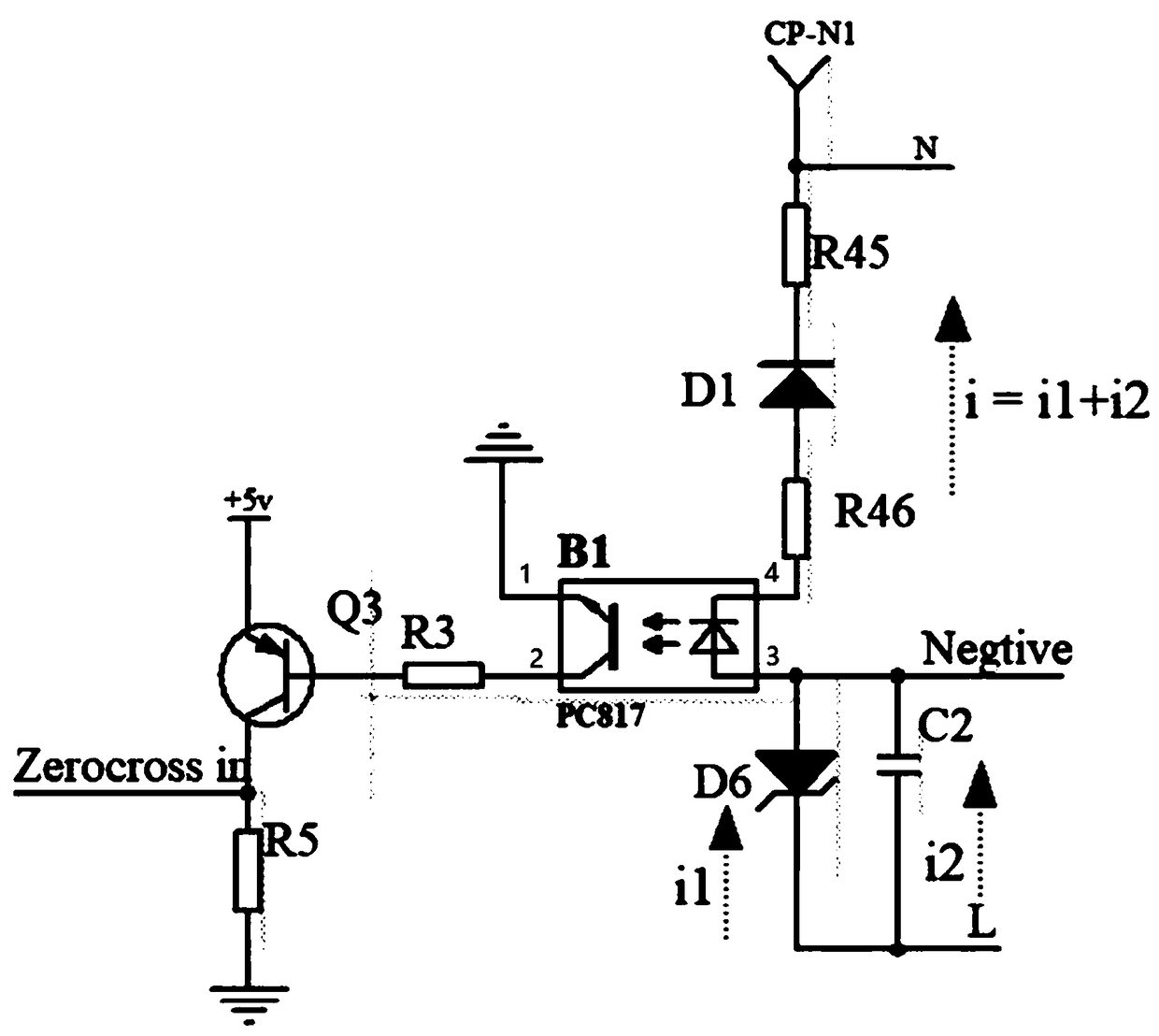

[0037] see attached Figure 2 to Figure 5 , figure 2 and image 3 The circuit structure of the thyristor drive circuit is shown respectively, Figure 4 shows the waveform of the zero-crossing signal, Figure 5 An optimized trigger mode (multi-segment trigger segment) is shown.

[0038] Preferably, the thyristor drive circuit includes an MCU chip U1, a zero-crossing signal circuit, and a thyristor trigger circuit, and the thyristor drive circuit is used to drive the heating element Heater, wherein:

[0039] The strong current side circuit structure of the zero-crossing signal circuit includes a resistor R45, a resistor R46, a rectifier diode D1, and a low-voltage isolation optocoupler B1. One end of the resistor R46 is connected to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com