Low-heating-value biomass semi-fluidized bed composite grate combustion furnace

A semi-fluidized bed and biomass technology, applied in the field of combustion furnaces, can solve the problems of low ash melting point, poor variable load capacity, low furnace efficiency, etc., and achieve high-efficiency combustion rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

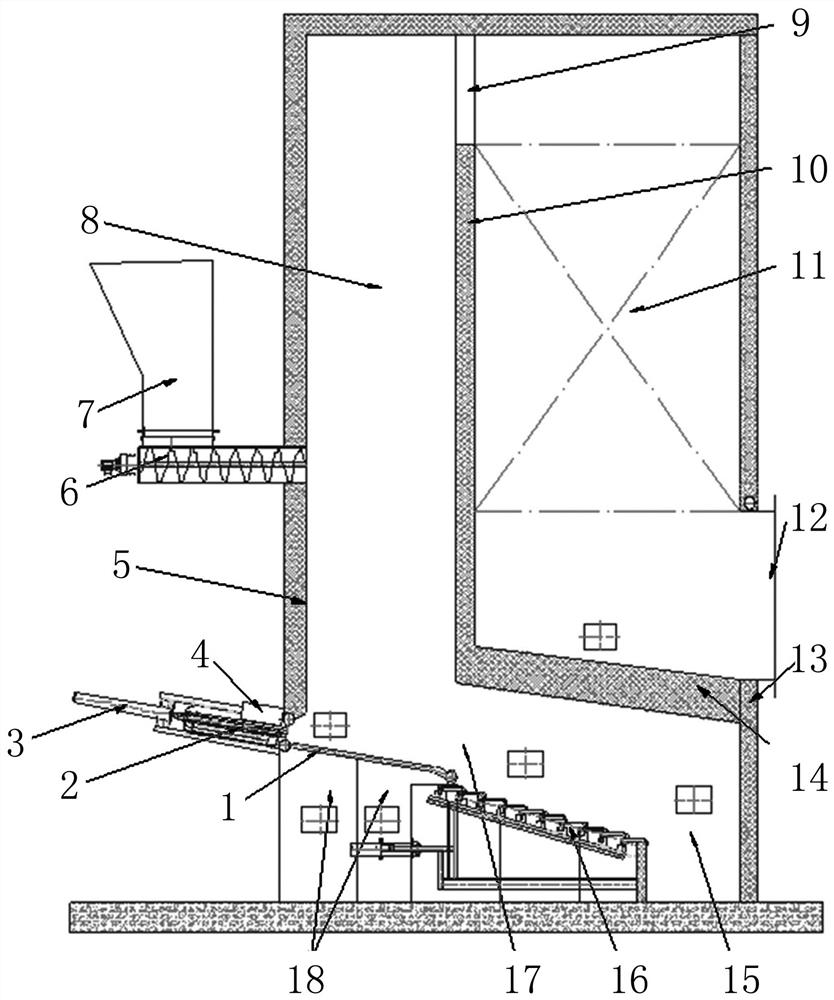

[0018] The low calorific value biomass semi-fluidized bed composite grate combustion furnace includes an auxiliary combustion chamber 17 with a slag grate 16, a slag arch 14 and a slag pit 15, and a main bed combustion chamber 8 communicating with the auxiliary combustion chamber. , the heat exchange chamber 11 communicated with the main bed combustion chamber, the smoke outlet 12 arranged on the outer wall of the heat exchange chamber, the water-cooled hearth 1 arranged inside the main bed combustion chamber, the air chamber 18 arranged below the water-cooled hearth, The feeding mechanism 6 fixed on the furnace wall outside the main bed combustion chamber is the combustion product of the biomass with low calorific value, wherein: the feeding mechanism with the feeding hopper 7 is arranged in the middle of the main bed combustion chamber; the water-cooled hearth is inclined at the In the lower part of the main bed combustion chamber, the water-cooled hearth includes water-coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com