Dishwasher and method for cleaning wash ware

A technology for cleaning parts and dishwashers, used in automatic machines, commercial dishwashers, dishwashers and in the field of cleaning parts in dishwashers, can solve problems such as uneconomical and insufficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

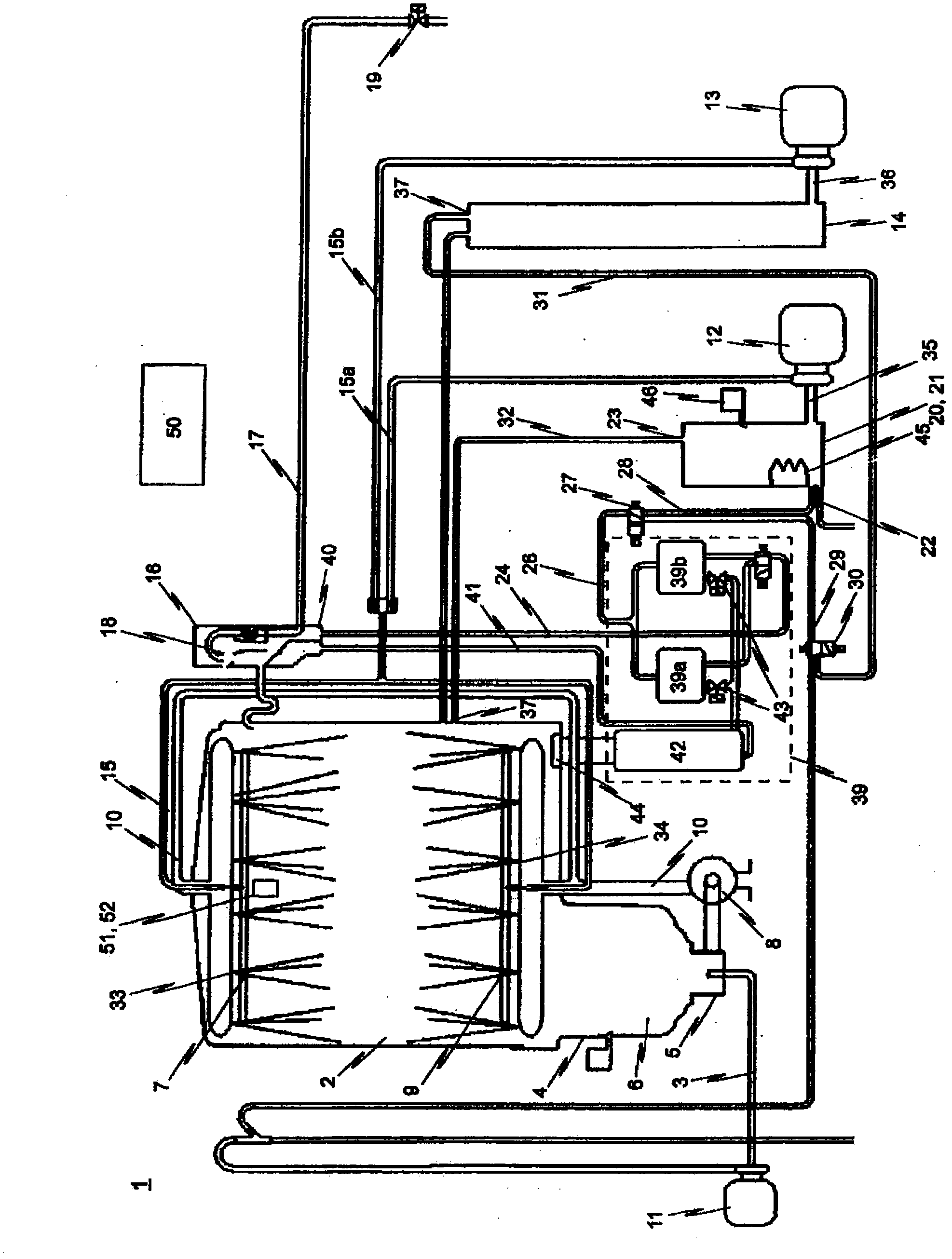

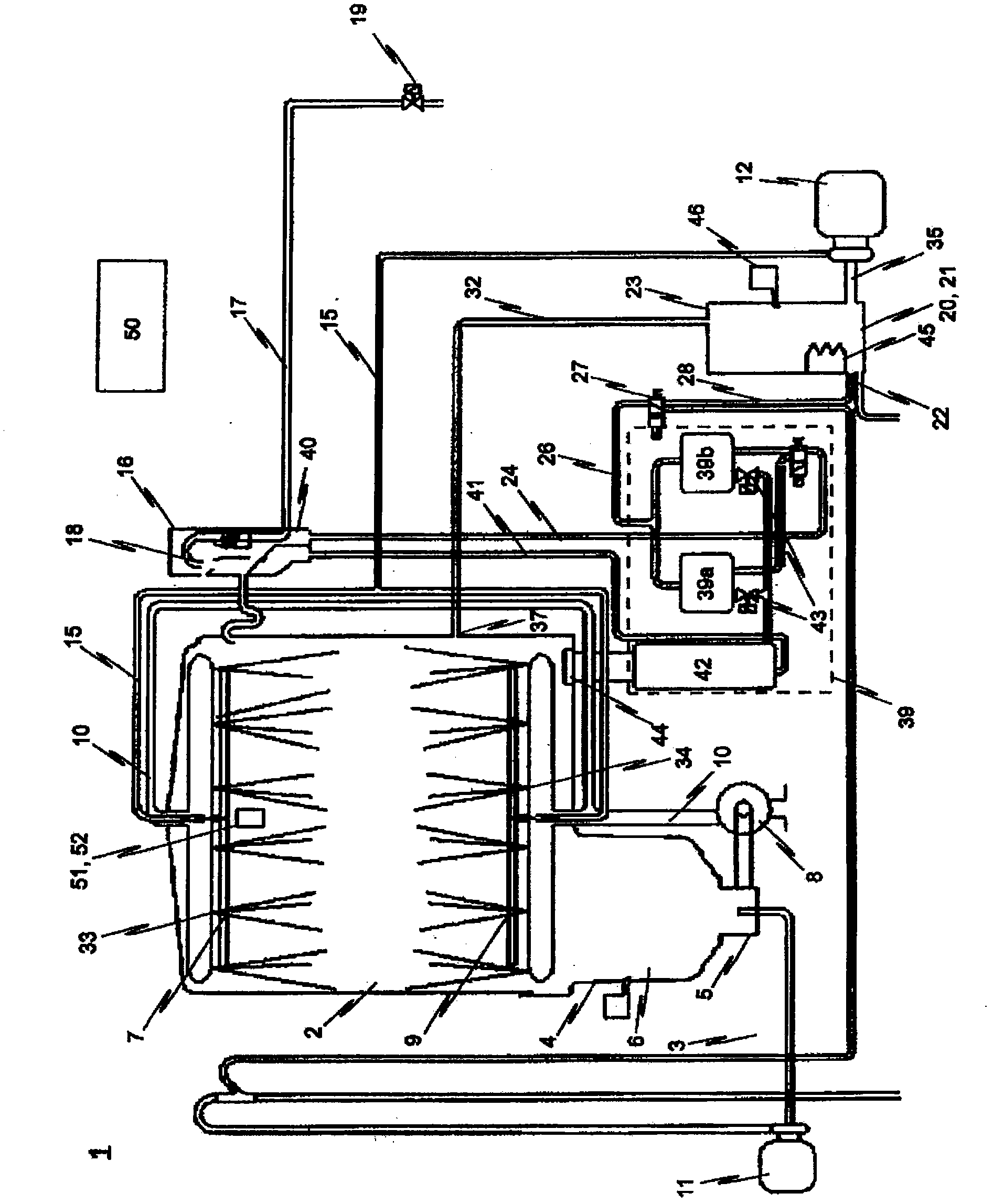

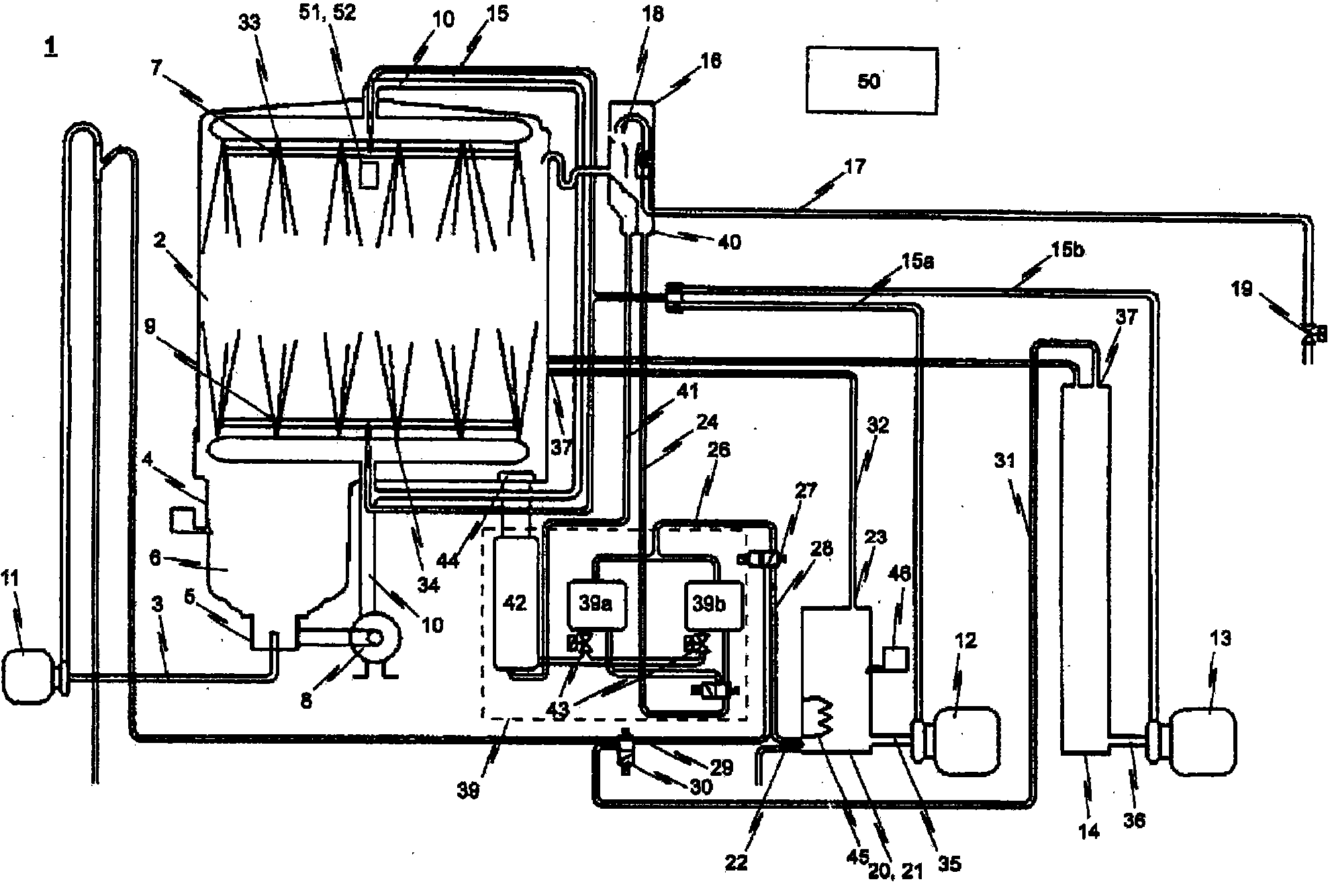

[0022] The dishwasher 1 according to the present invention has a processing chamber 2 (not shown in the figure) for cleaning washing parts. A cleaning water tank 4 is provided under the processing chamber 2, wherein fluid can flow back from the cleaning chamber 2 to the cleaning water tank 4 under the action of gravity. The cleaning water tank 4 is covered at the transition part from the cleaning water tank 4 to the processing chamber 2 by using a filter screen (not shown). The cleaning water tank 4 is equipped with a cleaning liquid 6, which is usually water. When appropriate, the cleaning agent can be automatically added to the cleaning liquid 6 in a controlled manner through a cleaning agent metering device (not shown in the figure) in. The cleaning liquid 6 can be delivered to the cleaning nozzles 33 and 34 (for example, nozzles in the upper and lower rotatable cleaning arms) via the cleaning pipe system 10 by the cleaning pump 8 and through these cleaning nozzles 33 and 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com