A twisted-blade blower or vacuum pump

A blower, vacuum pump technology, applied in the direction of pumps, pump components, mechanical equipment, etc., can solve the problem of low work efficiency, achieve the effect of improving work efficiency, ensuring permeability and filtering effect, and stabilizing the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

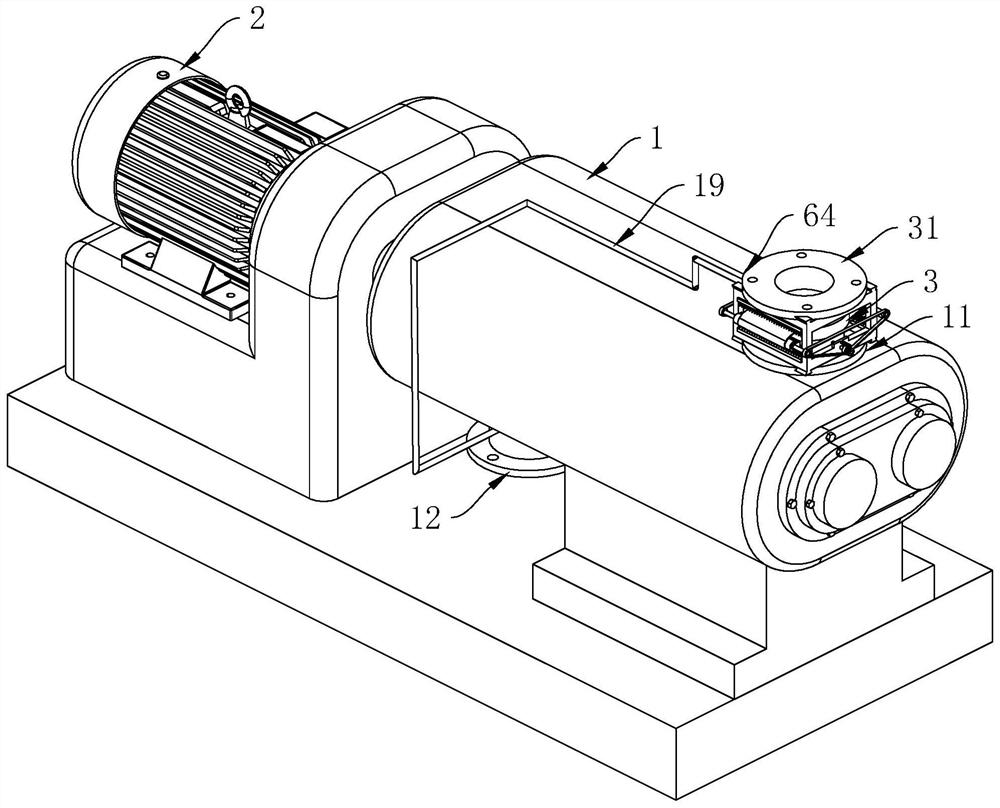

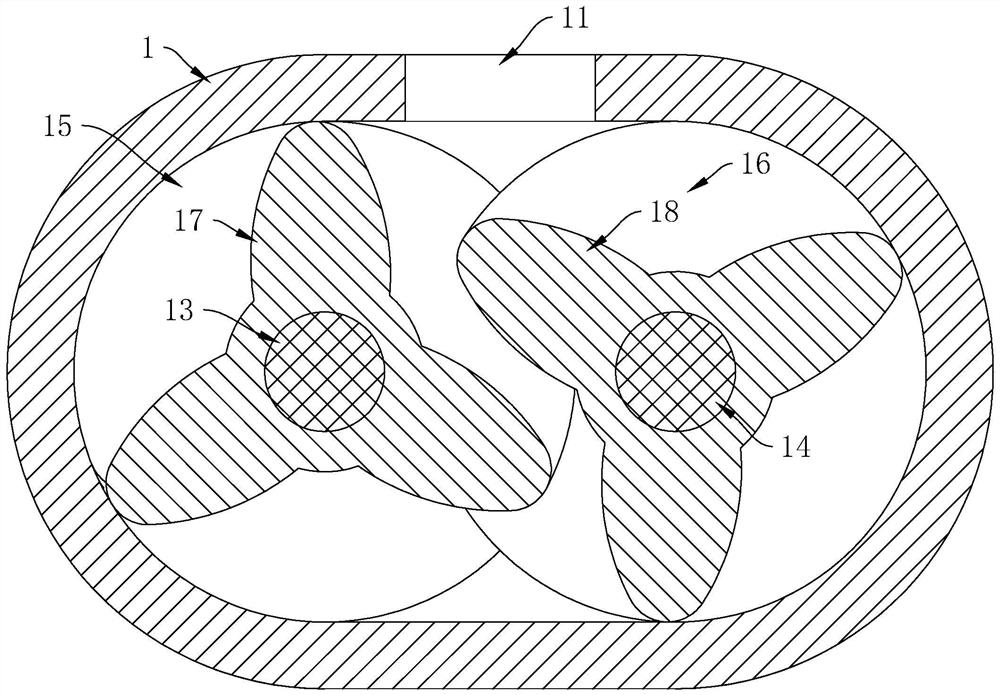

[0036] Example 1: as figure 1 , figure 2 As shown, a twist-blade blower or vacuum pump includes a body 1 and a motor 2. The upper end of the body 1 is provided with an air inlet 11 and the lower end is provided with an exhaust port 12. A driving shaft 13 and a driven shaft 14 are connected horizontally in the body 1, and the outer walls of the driving shaft 13 and the driven shaft 14 are respectively provided with a driving twisting blade 15 and a driven twisting blade 16.

[0037] like figure 1 , figure 2 As shown, the driving twisted vane 15 and the driven twisted vane 16 respectively include three evenly distributed driving vanes 17 and driven vanes 18, and the driving vanes 17 and the driven vanes 18 are twisted from the front end to the rear end toward the side approaching each other , and form a twist angle of 30-120°.

[0038]When the above-mentioned blower is working, the motor 2 is used to control the synchronous high-speed rotation of the driving shaft 13 and t...

Embodiment 2

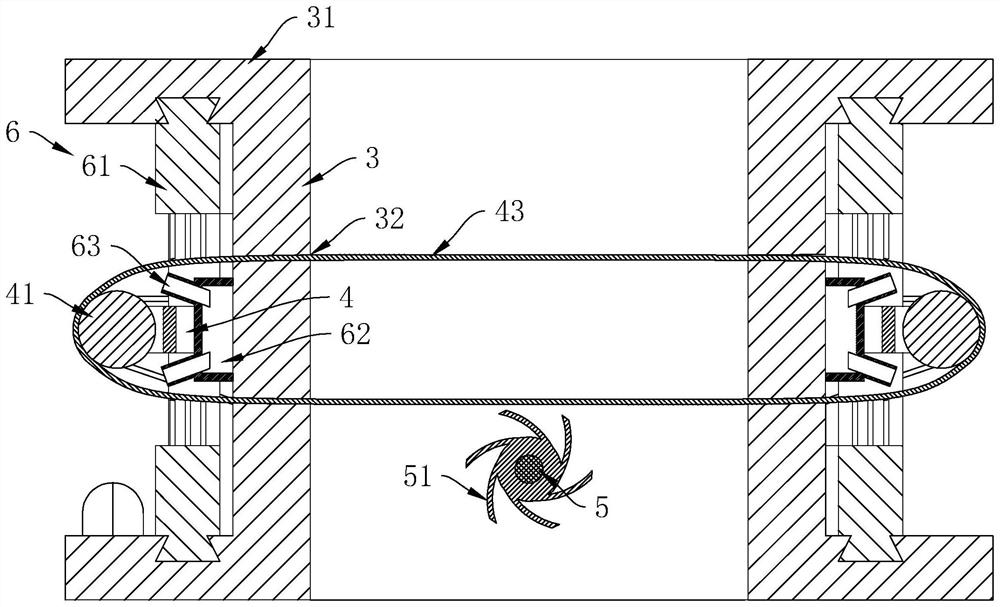

[0057] Example 2: as image 3 , Figure 4 As shown, the blower in this embodiment can also be used as a vacuum pump. When used as a vacuum pump, the air inlet pipe 3 is covered by a sealing cover, so that a sealed chamber is formed between the air inlet pipe 3 and the sealing cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com