Automatic detergent dishwashing composition

a technology of automatic dishwashing and detergent, applied in the field of detergents, can solve the problems of grit formation during the dishwashing process, affecting the shine of grit, and affecting the appearance of washed items, so as to prevent grit formation in the automatic dishwashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

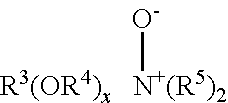

Method used

Image

Examples

example

[0196]The compositions tabulated below are introduced into a multi-compartment pouch having a first compartment comprising the solid composition (in powder form) and a liquid compartment superposed onto the powder compartment comprising the liquid compositions. The film used is Monosol M8630 film as supplied by Monosol. The weight of the solid composition is 17 grams and the weight of liquid compositions is 2.6 gram.

[0197]The pouch also comprises 0.3 mg of active amylase and 2 mg of active protease per gram of product.

IngredientLevel (% wt)Solid compositionSTPP35Carbonate24Silicate7TAED0.5Zinc carbonate0.5SLF181.5Percarbonate15Alcosperse 240D10Processing aidsTo balanceLiquid compositionDPG45SLF1845Neodol 1-93Glycerine2Processing aidsTo balance

[0198]The exemplified pouch is used to wash a soiled load as described herein below in an automatic dishwasher under the conditions described herein below. The washing items present excellent shine.

[0199]Substrates / Soils[0200]Corning ware round...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com