Method for predicting ammonia process flue gas desulphurization efficiency based on multiple parameters

A technology for desulfurization efficiency and prediction methods, applied in separation methods, chemical instruments and methods, biological neural network models, etc., can solve problems such as only reflection, measurement deviation, and no precedent

- Summary

- Abstract

- Description

- Claims

- Application Information

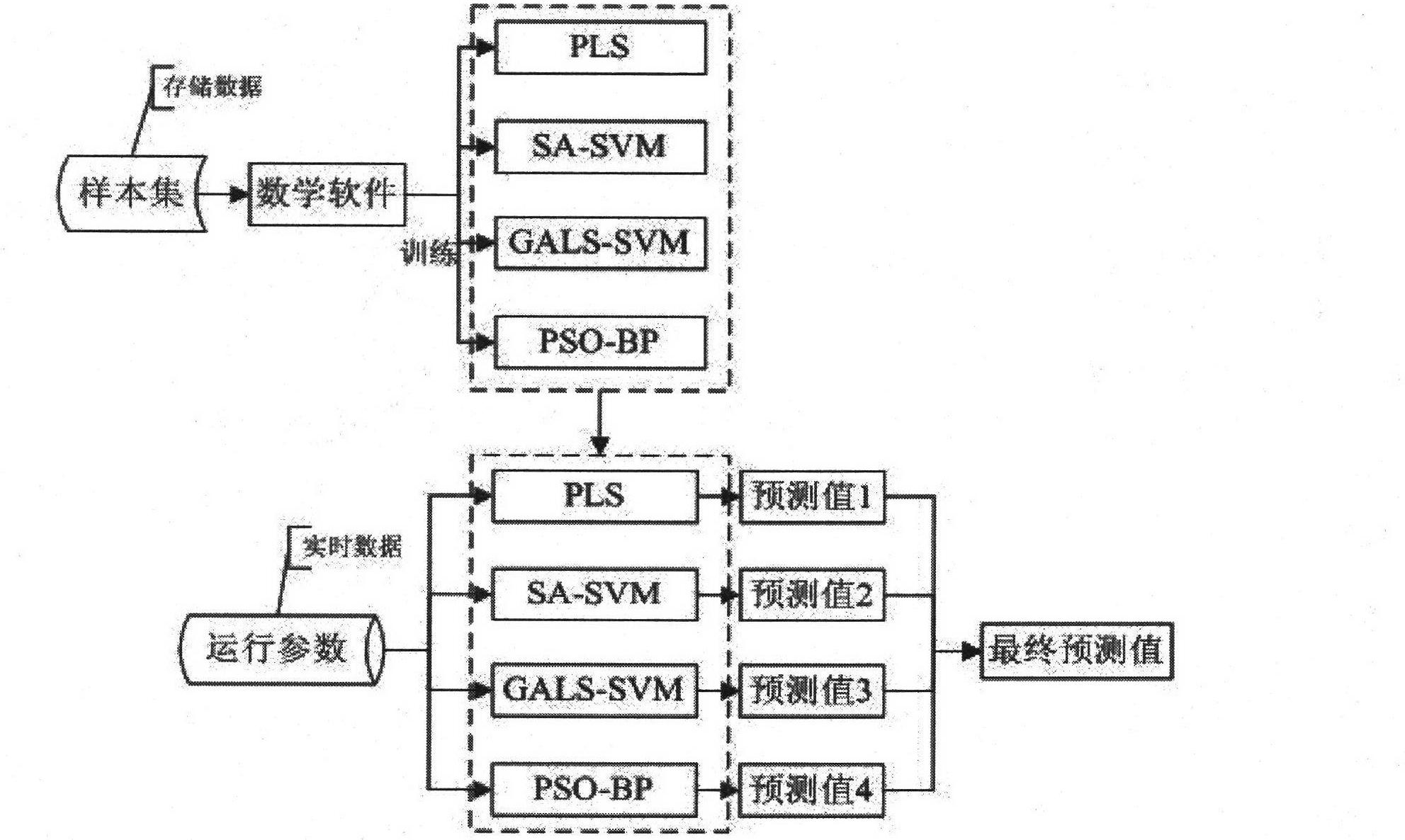

AI Technical Summary

Problems solved by technology

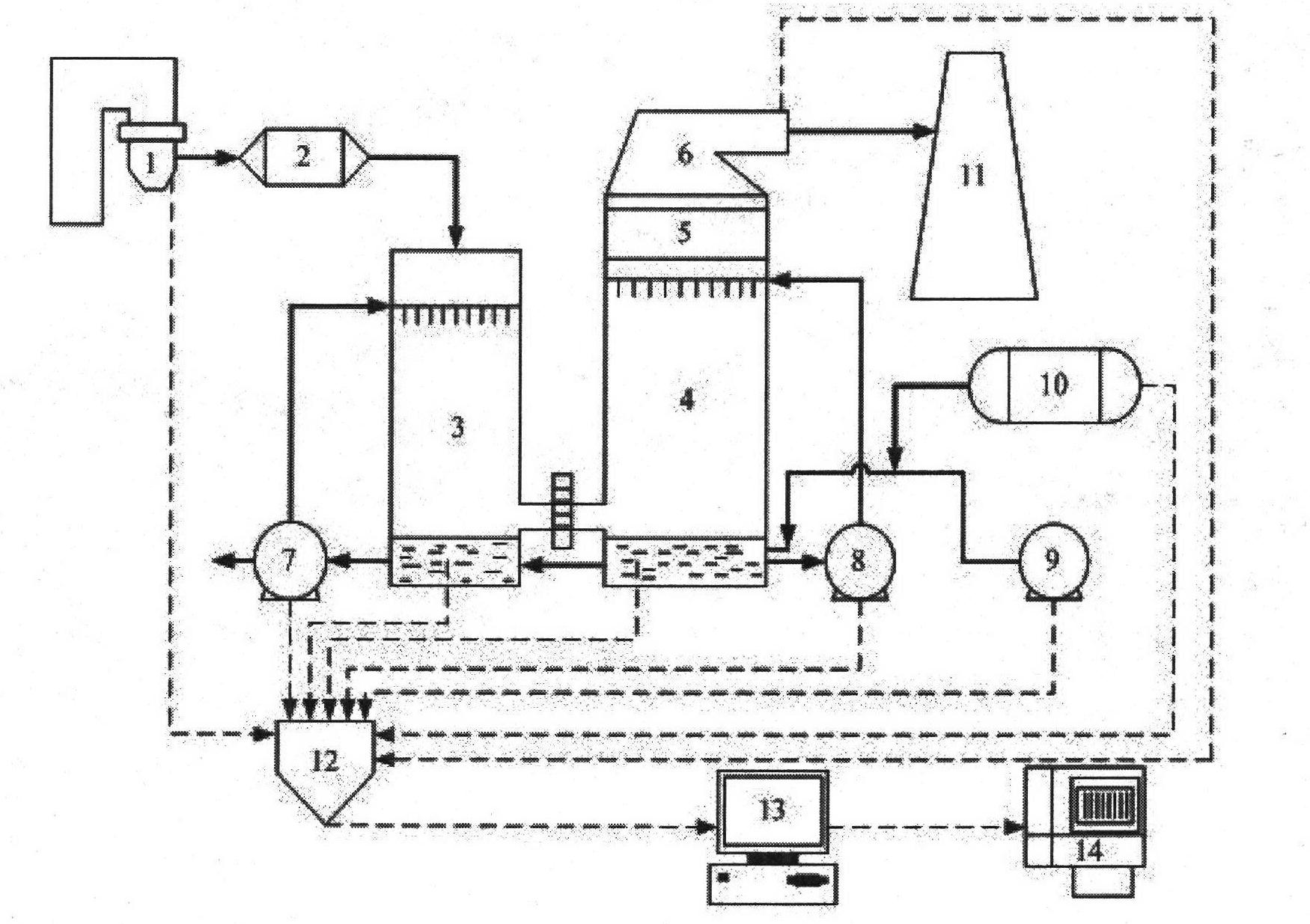

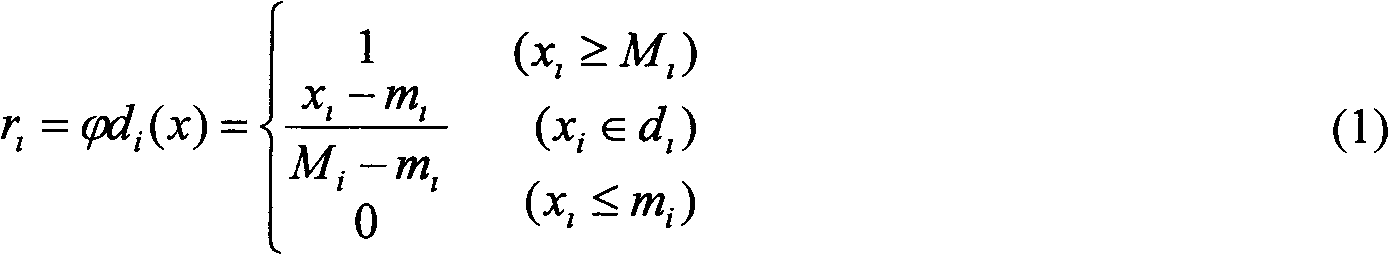

Method used

Image

Examples

Embodiment 1

[0186] Example 1: Using the flue gas volume, circulation pump flow rate, concentration pump flow rate, ammonia concentration, absorption liquid concentration, liquid-gas ratio, inlet flue gas temperature, ammonia consumption, and spray slurry of an ammonia-based flue gas desulfurization system in a domestic power plant The above four models were trained with 1500 sets of operating parameters such as density, pH value of spray tower slurry, and pH value of pre-scrubber slurry, and then tested with 100 sets of operating parameters. The results are shown in Table 1 (partial test samples).

[0187] Table 1

[0188]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com