Renewable devulcanization technological process and use thereof

A process method and application technology, applied in the field of desulfurization treatment, can solve the problems of large steam heating, energy consumption, energy waste, etc., and achieve the effects of reducing water consumption, lowering its own temperature, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

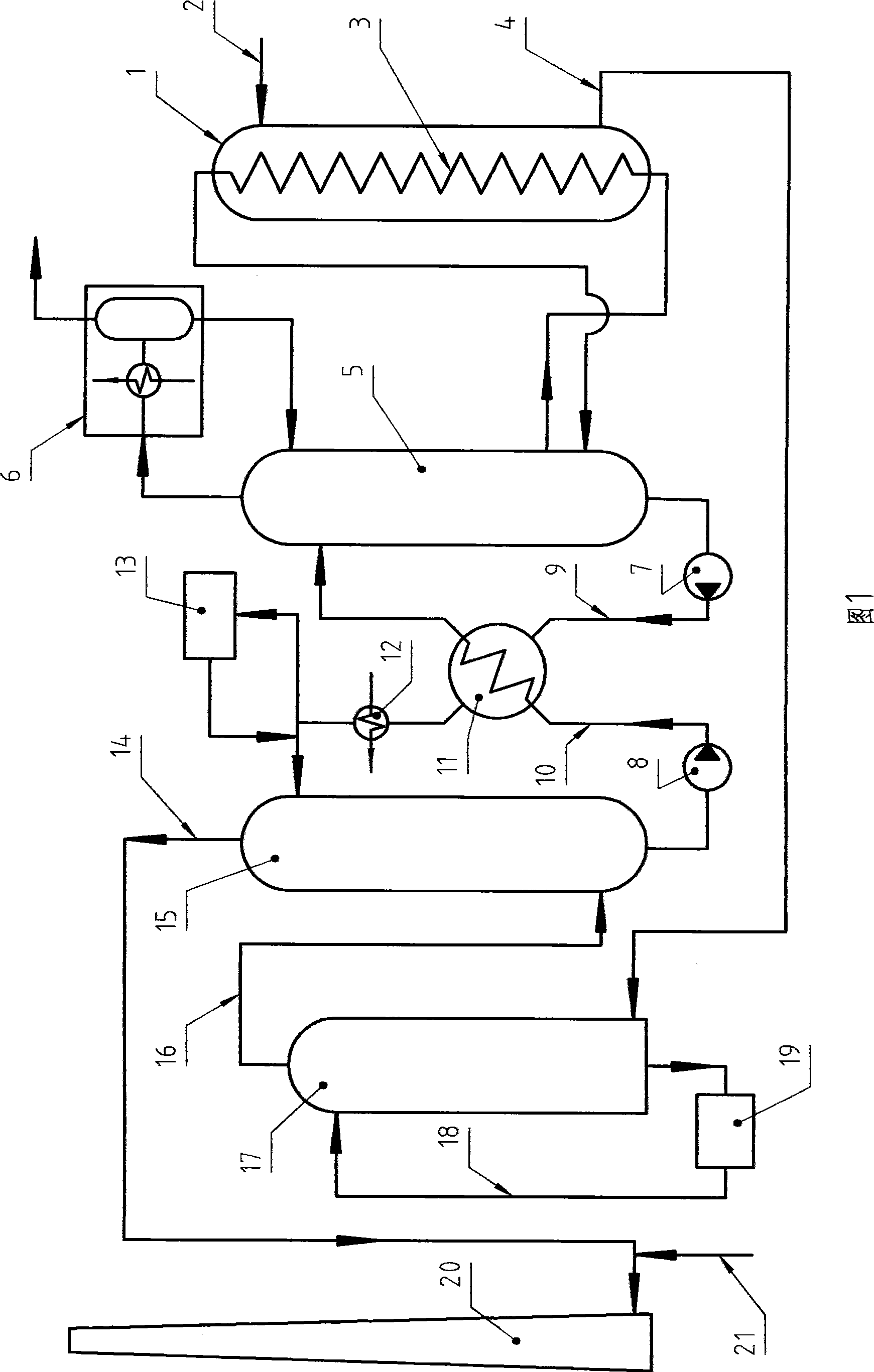

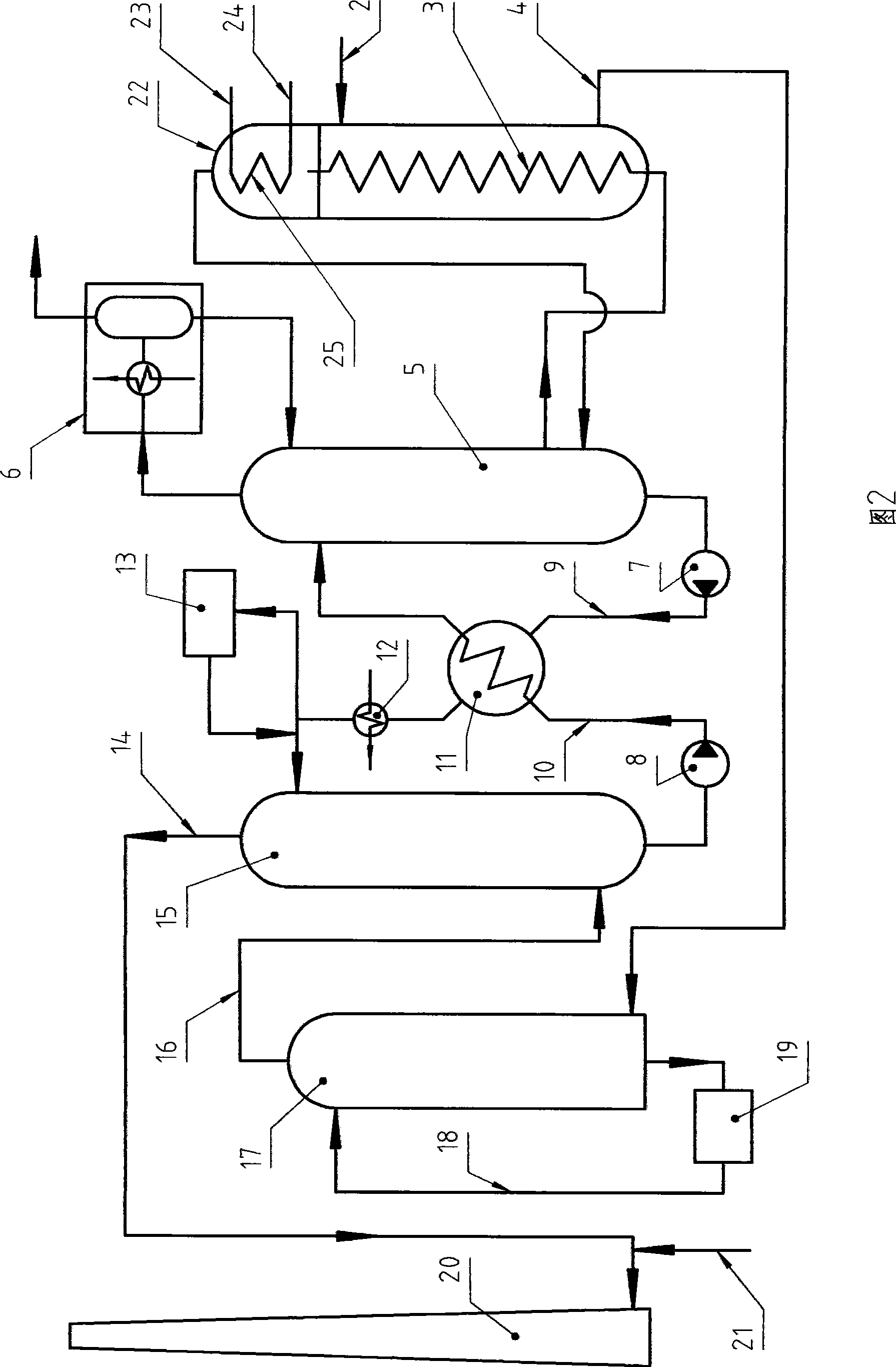

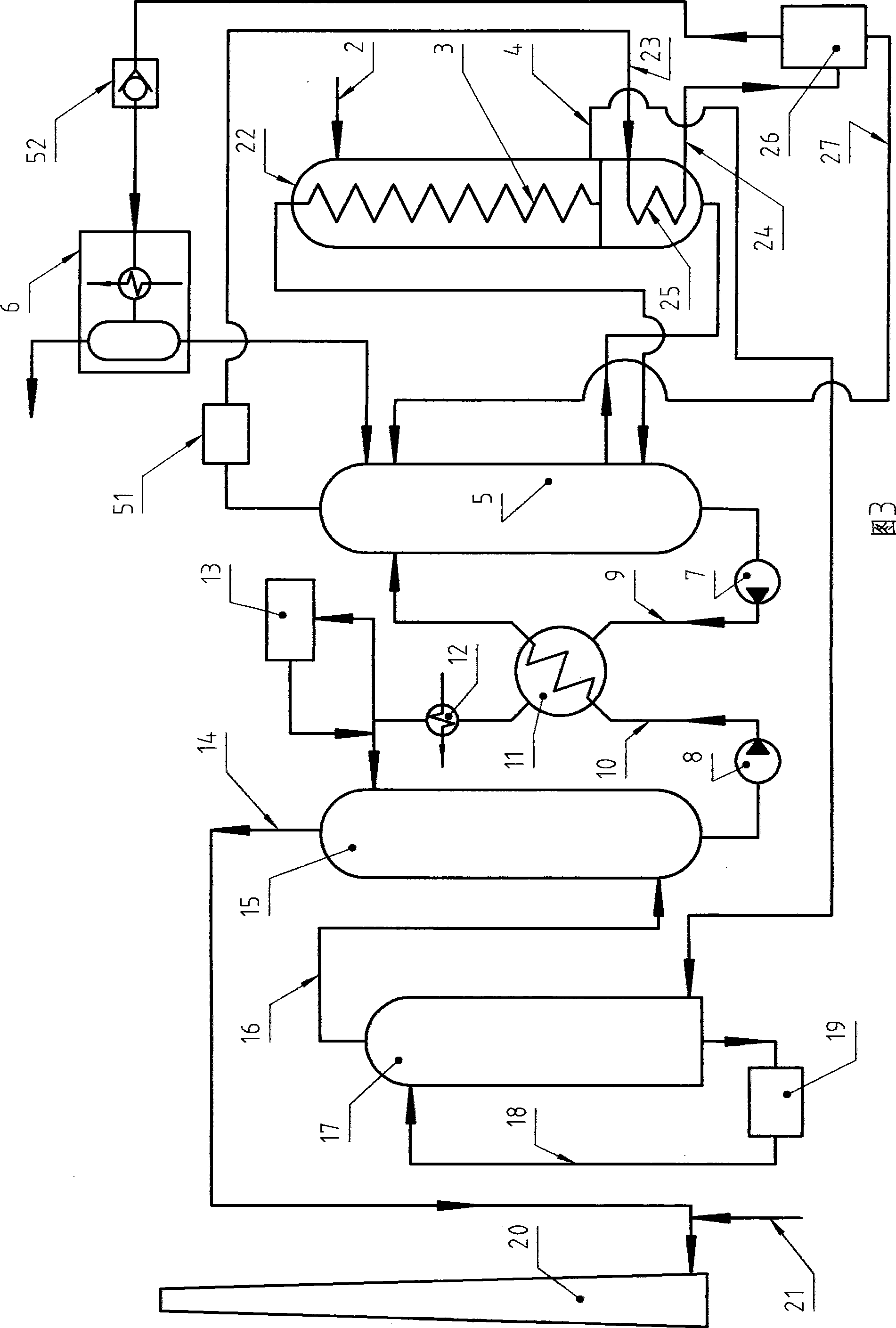

[0028] The specific implementation manner of the present invention can be illustrated by specific examples.

[0029] Fig. 1 is the process flow chart of embodiment one. In the figure, 1 is the reboiler, 2 is the inlet of the flue gas to be desulfurized in the reboiler, 3 is the heat exchanger of the reboiler, and 4 is the outlet of the flue gas to be desulfurized in the reboiler, these are the steps to realize the desorption process The heat energy required is provided by the physical sensible heat carried by the flue gas to be desulfurized. 5 is the desorption tower, and 6 is the SO 2 7 is the amine liquid delivery pump after desorption, 8 is the amine liquid delivery pump to be desorbed, 9 is the amine liquid delivery pipeline after desorption, 10 is the amine liquid delivery pipeline to be desorbed, and 11 is a heat exchanger. 12 is the heat exchanger for further cooling of the desorbed amine liquid, 13 is the amine purification device, 14 is the exhaust channel of the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com