Cloth grass washing process

A linen and process technology, applied in the field of washing technology, can solve problems such as urban groundwater intrusion, and achieve the effect of reducing pollution and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

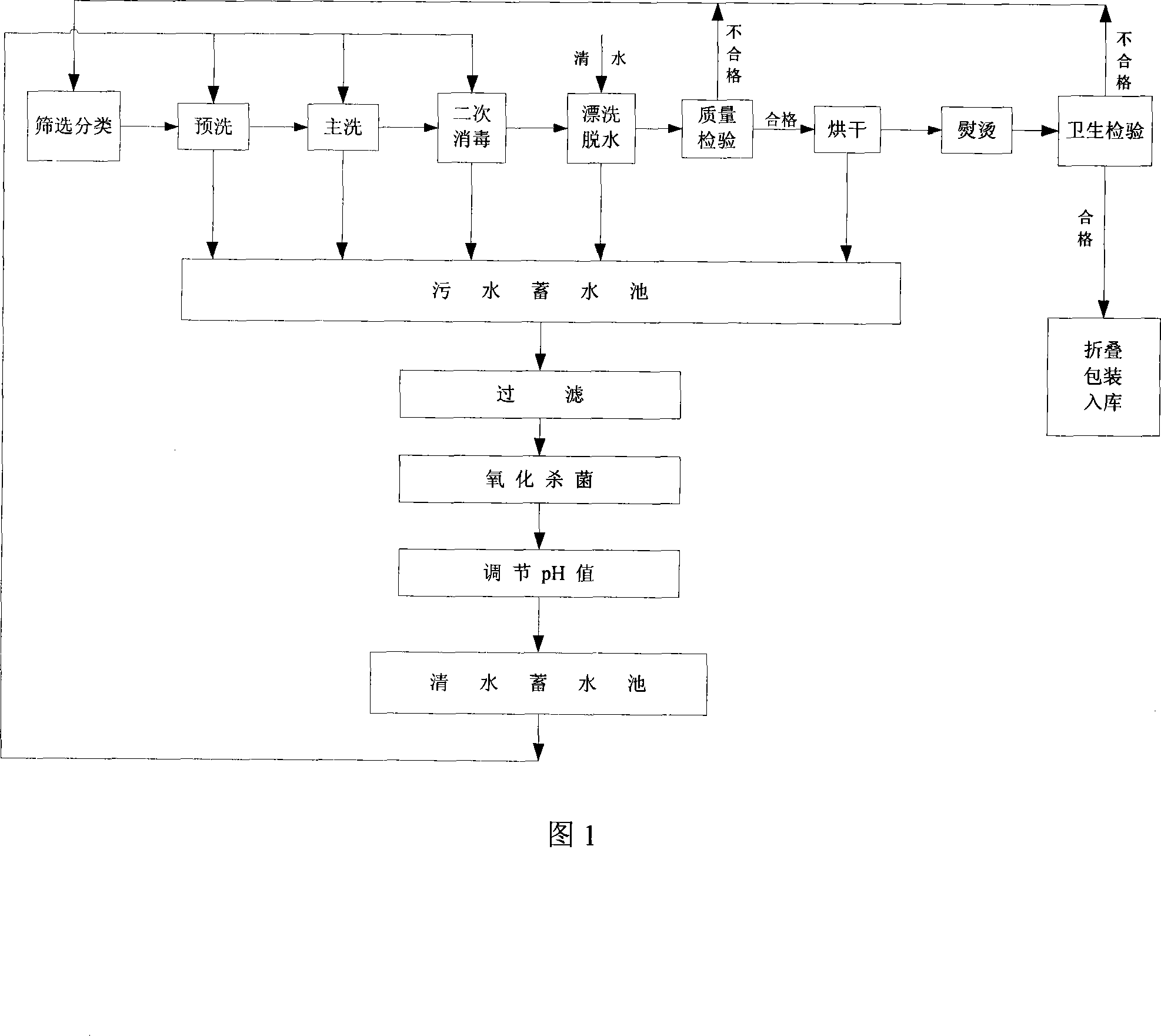

[0023] Fig. 1 shows the process flow chart of linen washing process of the present invention. Firstly, the linen to be washed is classified according to texture and degree of dirt; when classified according to texture, it is classified into bed sheets, towels, surgical fabrics, white coats, etc., and according to the degree of dirt, it can be divided into heavy dirt, medium dirt and light dirt. After classification, the linen is disinfected first, and then the linen is preliminarily washed with the water in the clear water reservoir. The equipment used is a tunnel washing machine, the washing water temperature is 30-80°C, and the washing time is 5-10 minutes. The ratio of the main lotion: detergent: carburetor: oxygen bleaching liquid: softener: acid neutralizer = 0.75~2:0.25~1:0~1:0~0.75:0~1:0.25 ~0.5, discharge the pre-washed sewage into the sewage storage tank. Then use the water in the clear water reservoir to further wash the prewashed linen. The equipment used is a tunn...

Embodiment 2

[0026] In the pre-wash and main wash stages, different detergent ratios should be selected according to the different textures of the linen. Taking bed sheets, towels, surgical fabrics, and white coats as examples, the ratios are listed in the table below.

[0027] main lotion

Embodiment 3

[0029] The waste water in the sewage storage tank is treated as follows: first use polyferric sulfate with a mass concentration of 600mg / l for flocculation and sedimentation, then filter the supernatant, and use ozone with a concentration of 8mg / l to oxidize and sterilize. After the pH value reaches 7.0-7.5, it is discharged into the clear water reservoir for standby. Sampling tests were carried out on the water quality before and after wastewater treatment, and the results are listed in the table below.

[0030] pH

[0031] The various water quality indicators in the table above indicate that the treated wastewater can be used for laundry water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com