Automatic washing control method and automatic washing control device for dish washing machine

A control method and technology of a control device are applied in washing control programs, washing machines/washing machines for tableware, household cleaning devices, etc., and can solve problems such as failure to function, automatic washing of water and electricity saving, and low accuracy of tableware soiling identification. problem, to achieve the effect of guaranteed cleaning rate, simple design and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

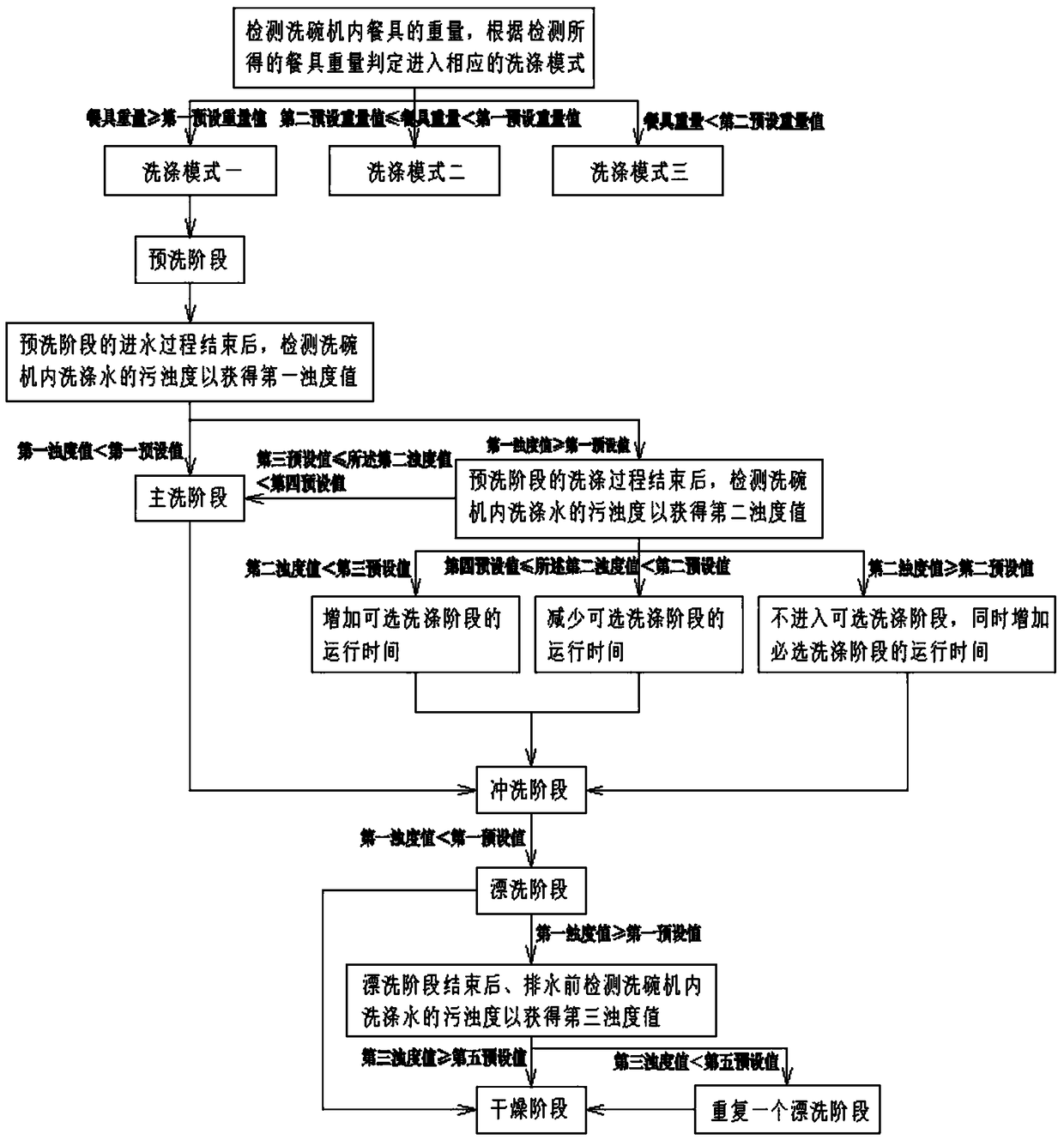

[0058] Embodiment one: if figure 1 As shown, this embodiment is an automatic washing control method for a dishwasher, including:

[0059]Detect the weight of the tableware in the dishwasher, and determine to enter the corresponding washing mode according to the detected weight of the tableware. Specifically, after the dishwasher is started for the first time, it pauses after draining, measures the weight to obtain the first weight value, and sets the washing mode. When the bowl machine is not loaded with tableware, the reference weight is the initial weight value. By definition, tableware weight=first weight value-initial weight value. In this embodiment, after the program is started and the first drainage is completed, the weight W1 is measured by pausing for 30 seconds. When the dishwasher is not loaded with tableware, the reference weight is W0 (fixed value), and the weight of the tableware in the dishwasher is defined as W2, W2=W1-W0. Further, the specific method of obtain...

Embodiment 2

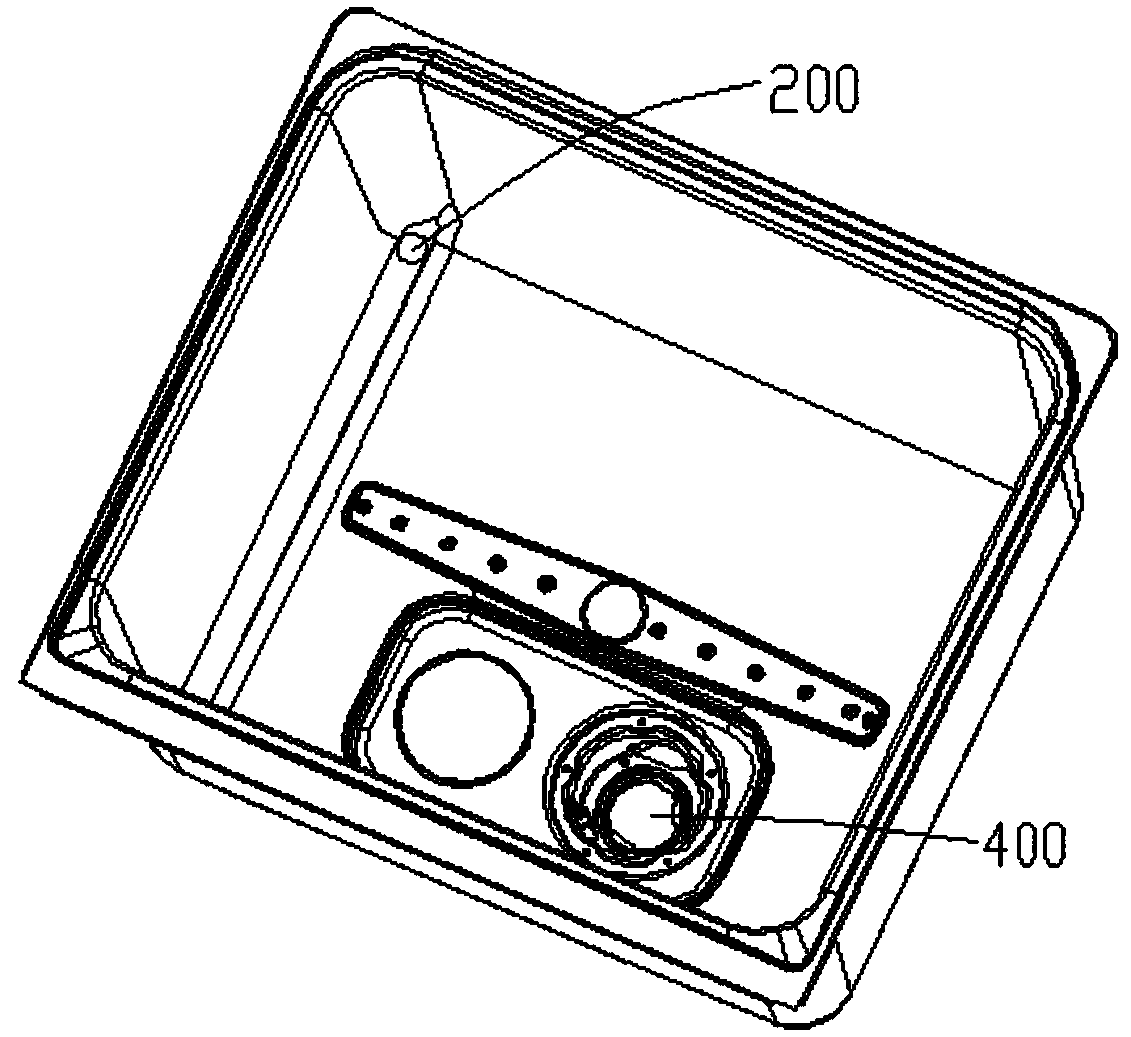

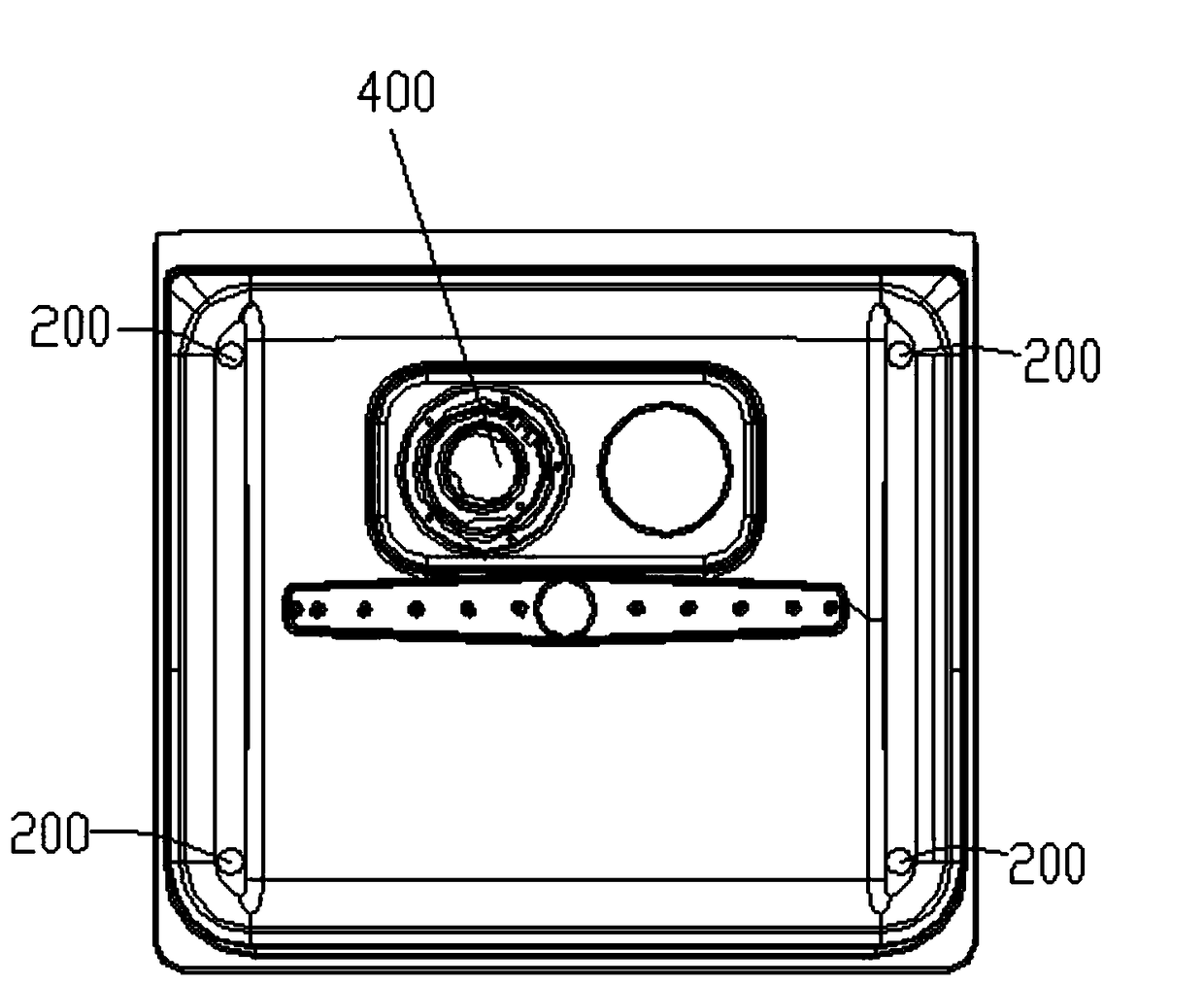

[0079] Embodiment two: if Figure 1 to Figure 5 As shown, this embodiment is an automatic washing control device for a dishwasher, including:

[0080] Weight detection module 200, for detecting the weight of tableware in the dishwasher;

[0081] The turbidity detection module 100 is used to detect the turbidity of the washing water in the dishwasher in the necessary washing stage to obtain the turbidity value;

[0082] The control module is used to determine whether the dishwasher enters the corresponding washing mode according to the detected tableware weight, determine whether to enter the optional washing stage according to the turbidity value, and adjust the running time of the mandatory washing stage and the optional washing stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com