Integrated Venturi air washing device

An air scrubbing and Venturi technology, which is applied to combined devices, climate change adaptation, climate sustainability, etc., can solve the problems of insufficient velocity gradient, device operation impact, complex structure, etc., and achieves increased adjustability, can be arranged, The effect of flexible arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

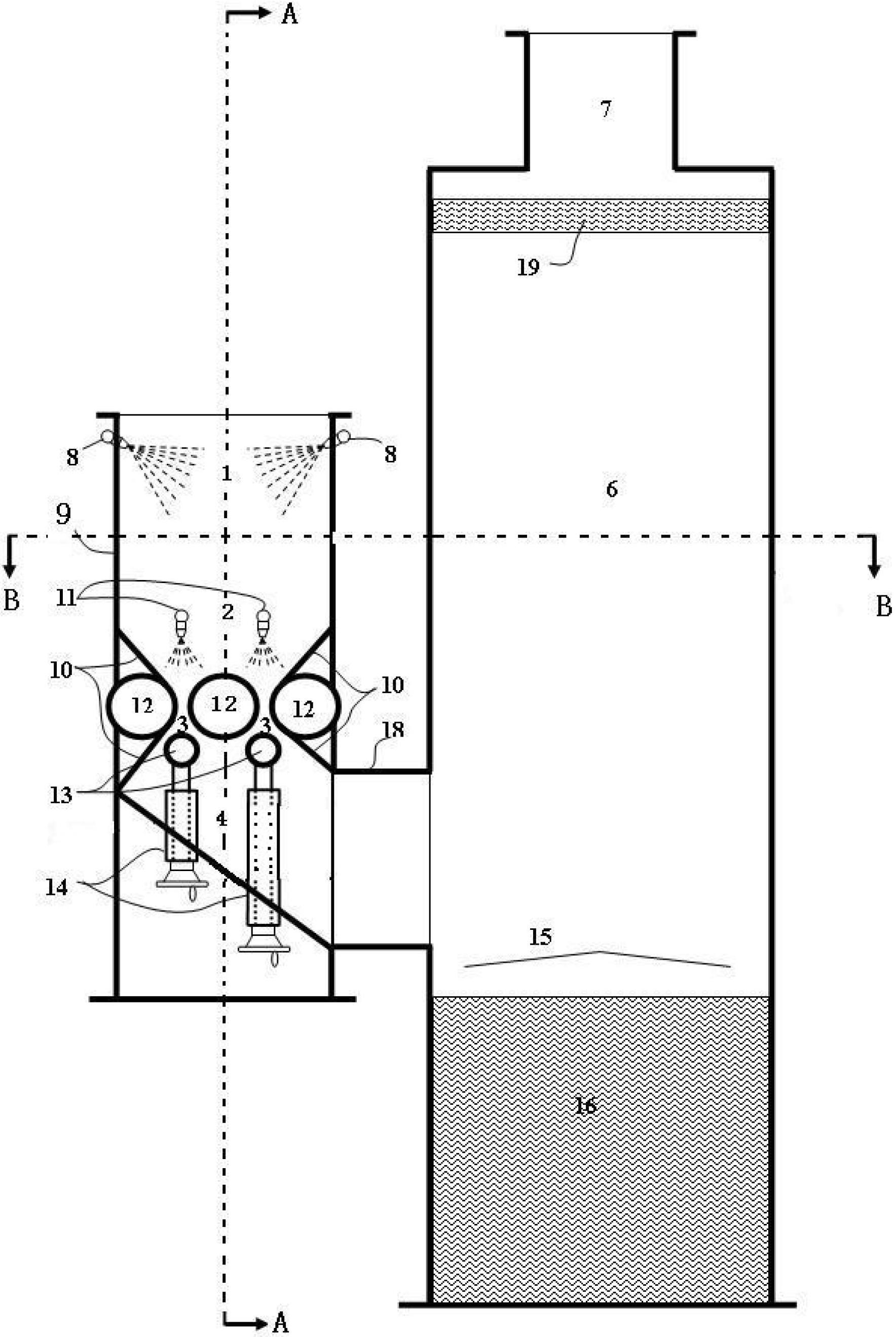

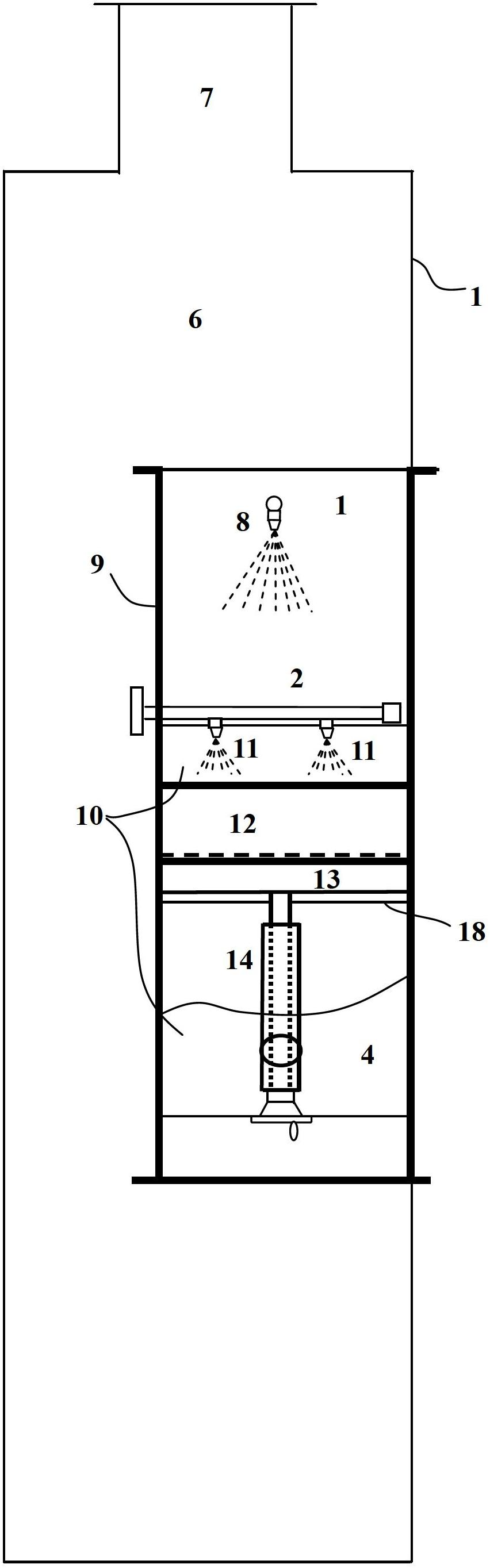

[0054] like Figure 1-3 The shown Venturi washing device, in the described device, the washing tower and the separation tower are placed side by side. The flue gas to be treated first enters the pretreatment area 1 at the top of the washing tower from the flue gas discharge pipe of the factory or workshop. The residence time of the flue gas in the pretreatment area 1 is generally less than 0.5 seconds. On the tower wall 9, it is sprayed into the pretreatment zone 1 at an angle of 60° with the airflow direction. The pre-washing liquid is used as the washing liquid, which is transported by the water pump from the sump 16 located at the lower part of the separation tower 6 to the pre-treatment nozzle 8. After the flue gas is pre-washed, the temperature drops to 80 °C and the relative humidity is 100%.

[0055] After the flue gas leaves the pretreatment area 1, it enters the washing liquid spraying area 2, where it is sprayed by the spraying liquid. The washing liquid nozzles 11...

Embodiment 2

[0062] The Venturi scrubber and the cyclone separation tower can be placed parallel to each other as described in the above embodiments, or they can be placed at a certain angle to each other. When placed at an angle of 90°, the separation tower can be placed vertically and the washing tower can be placed horizontally, or the washing tower can be placed vertically and the separation tower can be placed horizontally. When the separation tower is placed horizontally, it still needs to have a slope greater than one-thousandth in the horizontal direction, so that the separated washing liquid can flow into the sump along the wall. At this time, the sump can be set next to the main separation tower , and communicate with the bottom of the main separation tower with a pipeline.

Embodiment 3-6

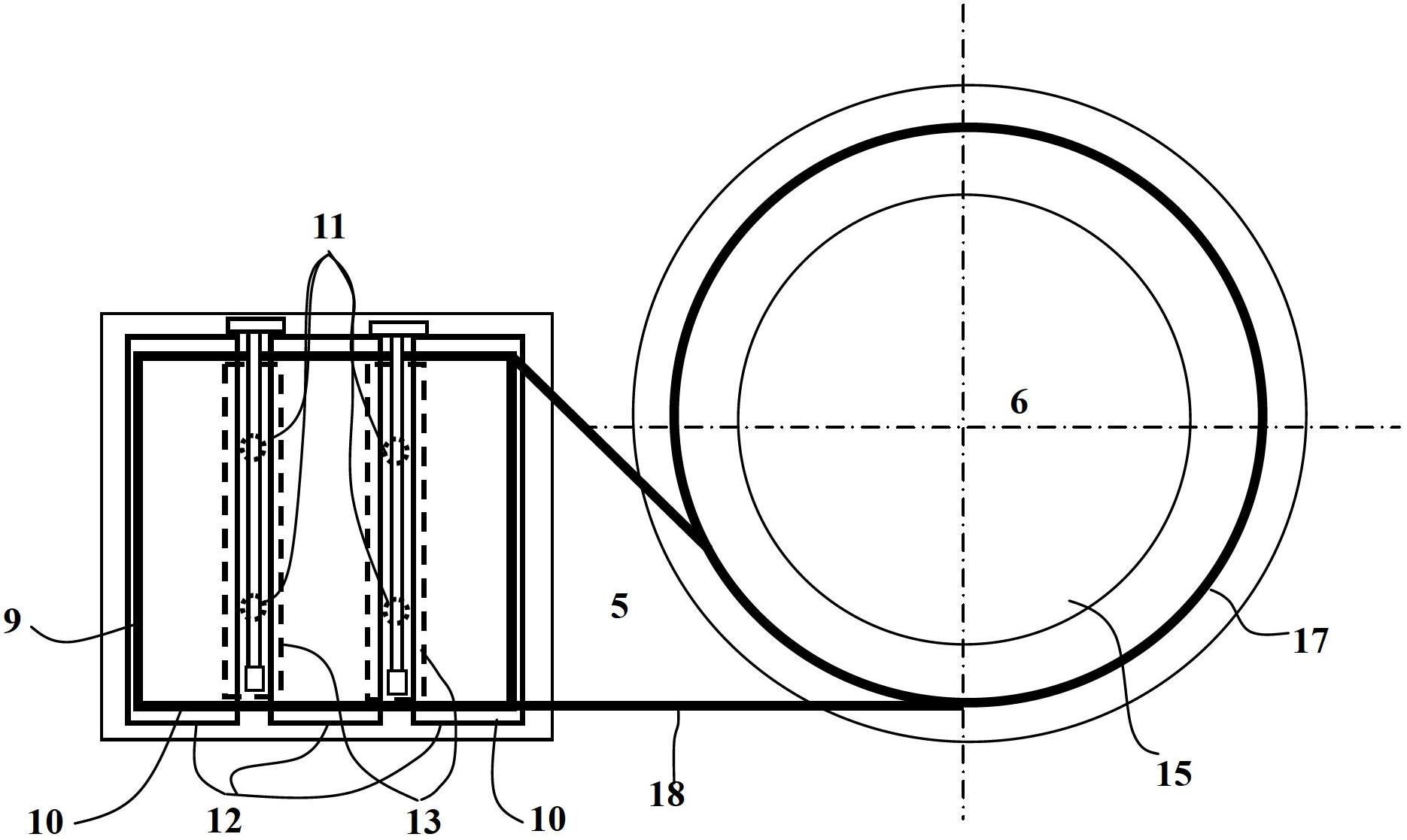

[0064] The design of the Venturi notch can choose different channel arrangements according to the actual situation. As shown in Figures 4-1, 4-2, 4-3 and 4-4, the cross section of the segmented columnar body 12 can take various shapes such as circle, ellipse, rhombus and water drop; The cross section is generally circular or elliptical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com